A wiring toggle switch is a mechanical device that controls the flow of electricity in a circuit. It consists of a lever that is pivoted in the center and has two electrical contacts. When the lever is in one position, the contacts are connected, allowing current to flow through the circuit. When the lever is moved to the other position, the contacts are disconnected, interrupting the flow of current. A common example of a wiring toggle switch is a light switch, which allows users to turn a light on or off.

Wiring toggle switches are important because they provide a simple and convenient way to control the flow of electricity. They are also relatively inexpensive and easy to install. One key historical development in the field of wiring toggle switches was the invention of the spring-loaded toggle switch in the early 20th century. This type of switch is more reliable and durable than earlier designs, and it is still widely used today.

In this article, we will explore the different types of wiring toggle switches, their applications, and how to wire them correctly. We will also discuss the safety precautions that must be taken when working with electricity.

Wiring toggle switches are an essential component of electrical circuits, providing a simple and convenient way to control the flow of electricity. They come in a variety of types and sizes, and can be used in a wide range of applications. Understanding the key aspects of wiring toggle switches is crucial for proper selection, installation, and maintenance.

- Type: Single-pole, double-pole, three-way, four-way

- Size: Miniature, subminiature, standard

- Material: Plastic, metal

- Rating: Voltage, amperage, wattage

- Function: On/off, momentary contact, maintained contact

- Mechanism: Spring-loaded, gravity-operated

- Connection: Screw terminals, solder terminals, quick-connect terminals

- Mounting: Panel mount, chassis mount, surface mount

- Application: Lighting, appliances, motors, industrial controls

These key aspects of wiring toggle switches are interconnected and influence each other. For example, the type of switch will determine the size, rating, and function. The material will affect the durability and cost. The connection type will determine the ease of installation. The mounting style will determine the switch’s placement and accessibility. By understanding these key aspects, electrical professionals can select the right wiring toggle switch for their specific application, ensuring safe and reliable operation.

Type

The type of wiring toggle switch determines its function and application. Single-pole switches are the most common type and are used to control a single circuit, such as a light or fan. Double-pole switches are used to control two circuits simultaneously, such as a pair of lights or a motor. Three-way switches are used to control a circuit from two different locations, such as a light switch at the top and bottom of a staircase. Four-way switches are used to control a circuit from three or more locations, such as a light switch in a hallway that controls lights at both ends. Single and double pole switches have two terminals. Three-way switches have three, and four-way switches have four. Depending on the circuit configuration, the type of toggle switch used will determine the necessary wiring and connections.

Understanding the different types of wiring toggle switches is essential for proper selection and installation. For example, if you need to control a light from two locations, you will need to use a three-way switch. If you need to control a light from three or more locations, you will need to use a four-way switch. Using the correct type of switch will ensure that the circuit functions properly and safely.

Here are some real-life examples of how different types of wiring toggle switches are used:

- Single-pole switches are used to control lights, fans, and other small appliances.

- Double-pole switches are used to control larger appliances, such as motors and heaters.

- Three-way switches are used to control lights from multiple locations, such as at the top and bottom of a staircase.

- Four-way switches are used to control lights from three or more locations, such as in a hallway with lights at both ends.

By understanding the different types of wiring toggle switches and their applications, you can ensure that you are using the correct switch for the job. This will help to prevent electrical problems and ensure that your circuits function safely and reliably.

Size

The size of a wiring toggle switch is a critical component that affects its functionality and application. Miniature and subminiature toggle switches are smaller than standard toggle switches, making them ideal for use in tight spaces or on printed circuit boards (PCBs). Standard toggle switches are larger and more robust, making them suitable for use in industrial applications or where higher amperage is required.

The size of a wiring toggle switch also determines its current rating. Miniature toggle switches typically have a current rating of 1-3 amps, while subminiature toggle switches have a current rating of 0.5-1 amps. Standard toggle switches have a current rating of 5-15 amps or higher. It is important to select a toggle switch with a current rating that is appropriate for the application. Using a switch with too low of a current rating can lead to overheating and failure.

Real-life examples of the use of miniature, subminiature, and standard toggle switches include:

- Miniature toggle switches are used in electronic devices such as smartphones, laptops, and digital cameras.

- Subminiature toggle switches are used in medical devices and other applications where space is limited.

- Standard toggle switches are used in industrial machinery, lighting fixtures, and other applications where higher amperage is required.

Understanding the relationship between the size and functionality of wiring toggle switches is essential for proper selection and use. By selecting the correct size switch for the application, electrical professionals can ensure that the circuit functions safely and reliably.

Material

The material of a wiring toggle switch is a critical component that affects its durability, cost, and performance. Plastic toggle switches are lightweight and inexpensive, making them ideal for general-purpose applications. Metal toggle switches are more durable and can withstand higher temperatures and currents, making them suitable for industrial and commercial applications.

The type of material used for a wiring toggle switch also affects its electrical properties. Plastic toggle switches have a higher resistance than metal toggle switches, which can lead to voltage drop and power loss in high-current applications. Metal toggle switches have a lower resistance and can handle higher currents without significant voltage drop or power loss.

Real-life examples of the use of plastic and metal toggle switches include:

- Plastic toggle switches are used in consumer electronics, appliances, and other general-purpose applications.

- Metal toggle switches are used in industrial machinery, automotive applications, and other applications where durability and high current handling are required.

Understanding the relationship between the material and functionality of wiring toggle switches is essential for proper selection and use. By selecting the correct material for the application, electrical professionals can ensure that the circuit functions safely and reliably.

Rating

The rating of a wiring toggle switch is a critical component that affects its functionality and performance. The rating includes the voltage, amperage, and wattage that the switch can handle. Voltage is the electrical potential difference between two points, amperage is the flow of electrical current, and wattage is the power consumed by the switch.

The voltage rating of a wiring toggle switch determines the maximum voltage that the switch can withstand without failing. The amperage rating determines the maximum current that the switch can handle without overheating. The wattage rating determines the maximum power that the switch can handle without burning out.

It is important to select a wiring toggle switch with a rating that is appropriate for the application. Using a switch with too low of a rating can lead to overheating, failure, or even fire. Using a switch with too high of a rating is unnecessary and can be more expensive.

Real-life examples of the importance of the rating of a wiring toggle switch include:

- A 120-volt toggle switch is used to control a light fixture. If the light fixture draws more than 120 volts, the switch will overheat and fail.

- A 15-amp toggle switch is used to control a motor. If the motor draws more than 15 amps, the switch will overheat and fail.

- A 1000-watt toggle switch is used to control a heater. If the heater draws more than 1000 watts, the switch will burn out.

Understanding the relationship between the rating and functionality of wiring toggle switches is essential for proper selection and use. By selecting the correct rating for the application, electrical professionals can ensure that the circuit functions safely and reliably.

Function

The function of a wiring toggle switch refers to its intended purpose and the type of electrical connection it provides. The three main functions are on/off, momentary contact, and maintained contact. On/off switches are the most common type and control the flow of electricity in a circuit by toggling between two positions: on and off. Momentary contact switches are designed to complete a circuit only when the switch is physically held in the on position. When the switch is released, the circuit opens. Maintained contact switches, also known as latching switches, are designed to maintain a circuit connection even after the switch is released from the on position.

The function of a wiring toggle switch is a critical component that determines its suitability for specific applications. On/off switches are ideal for controlling lights, appliances, and other devices that require simple on/off operation. Momentary contact switches are often used in applications where momentary control is desired, such as doorbells, push-buttons, and other signaling devices. Maintained contact switches are commonly used in applications where the circuit needs to remain closed even after the switch is released, such as in power tools, ignition systems, and other latching mechanisms.

Understanding the relationship between the function of a wiring toggle switch and its intended application is essential for proper selection and use. By choosing the correct switch for the job, electrical professionals can ensure that the circuit operates safely, efficiently, and as intended. Here are some real-life examples of how different switch functions are used:

- On/off switches are used to control lights, fans, and other appliances in homes, offices, and industrial settings.

- Momentary contact switches are used in doorbells, push-buttons, and other signaling devices.

- Maintained contact switches are used in power tools, ignition systems, and other latching mechanisms.

In summary, the function of a wiring toggle switch is a key factor in determining its suitability for specific applications. Understanding the differences between on/off, momentary contact, and maintained contact switches enables electrical professionals to select the right switch for the job, ensuring safe and reliable operation of electrical circuits.

Mechanism

Within the realm of wiring toggle switches, the mechanism employed to facilitate switching action plays a crucial role. Among the various mechanisms, spring-loaded and gravity-operated mechanisms stand out as two widely used and reliable options. This section delves into the specifics of these mechanisms, highlighting their components, principles of operation, and implications in the context of wiring toggle switches.

-

Spring-loaded Mechanism

In a spring-loaded mechanism, a spring is employed to provide the force necessary to return the toggle to its original position once it is released. This ensures a crisp and responsive switching action. Spring-loaded toggle switches are commonly used in applications where precise control and tactile feedback are desired, such as in electronic devices and musical instruments.

-

Gravity-operated Mechanism

In contrast to spring-loaded mechanisms, gravity-operated mechanisms utilize the force of gravity to return the toggle to its original position. These switches are often simpler in design and more cost-effective to manufacture. Gravity-operated toggle switches are commonly found in applications where precise switching action is not critical, such as in lighting fixtures and appliances.

-

Hybrid Mechanisms

Some toggle switches employ a hybrid mechanism that combines elements of both spring-loaded and gravity-operated mechanisms. This approach offers a balance between precise switching action and cost-effectiveness. Hybrid toggle switches are often used in industrial and commercial applications where reliability and durability are paramount.

-

Toggle Lever

The toggle lever is the primary component of a wiring toggle switch that is physically moved to control the flow of electricity. It is typically made of a durable material such as metal or plastic and is designed to withstand repeated switching actions.

The choice between spring-loaded, gravity-operated, and hybrid mechanisms depends on the specific application requirements. For applications demanding precise switching action and tactile feedback, spring-loaded mechanisms are preferred. For cost-sensitive applications where precise switching action is not critical, gravity-operated mechanisms offer a practical solution. Hybrid mechanisms provide a compromise between these two extremes, combining elements of both for a balanced approach.

Connection

In the realm of wiring toggle switches, the method of connecting electrical wires to the switch is a crucial aspect that influences the overall functionality, reliability, and safety of the electrical circuit. Screw terminals, solder terminals, and quick-connect terminals represent the three primary connection types commonly employed with wiring toggle switches. Each type possesses distinct characteristics, advantages, and considerations, and the choice among them hinges on factors such as the intended application, wire gauge, and desired level of security.

-

Screw Terminals

Screw terminals provide a simple and secure method of connecting wires to a wiring toggle switch. They consist of a metal screw that is tightened down onto the stripped end of the wire, creating a strong mechanical and electrical connection. Screw terminals are commonly found in applications where reliability and long-term stability are critical, such as industrial control systems and electrical panels. -

Solder Terminals

Solder terminals involve soldering the stripped end of the wire directly to the terminal on the wiring toggle switch. This method forms a permanent and highly conductive connection, making it ideal for applications demanding high reliability and minimal voltage drop. Solder terminals are often used in electronic circuits, audio equipment, and other sensitive applications where a secure and low-resistance connection is paramount. -

Quick-Connect Terminals

Quick-connect terminals, also known as push-in terminals, provide a fast and convenient way to connect wires to a wiring toggle switch. They feature a spring-loaded mechanism that allows the stripped end of the wire to be simply pushed into the terminal, forming a secure and reliable connection. Quick-connect terminals are commonly used in applications where speed and ease of installation are important, such as in residential wiring and lighting fixtures.

The choice of connection type for a wiring toggle switch depends on the specific application requirements and the desired level of reliability, security, and ease of installation. Screw terminals offer a robust and long-lasting connection, solder terminals provide a permanent and low-resistance connection, while quick-connect terminals offer a fast and convenient connection. By understanding the characteristics and implications of each connection type, electrical professionals can select the most appropriate option for their project, ensuring a safe and reliable electrical circuit.

Mounting

The mounting style of a wiring toggle switch plays a crucial role in determining its placement, accessibility, and overall functionality within an electrical system. Panel mount, chassis mount, and surface mount are the three primary mounting styles used for wiring toggle switches, each offering distinct advantages and considerations.

Panel mount toggle switches are designed to be mounted directly onto a panel or enclosure, providing a secure and flush installation. This mounting style is commonly used in industrial control systems, electrical panels, and other applications where a clean and professional appearance is desired. Chassis mount toggle switches, on the other hand, are designed to be mounted onto a chassis or sub-panel, allowing for easy access and replacement. This mounting style is often used in electronic equipment, telecommunications systems, and other applications where frequent maintenance or upgrades may be necessary.

Surface mount toggle switches are designed to be mounted directly onto a surface, such as a wall, ceiling, or tabletop. This mounting style is commonly used in residential and commercial lighting fixtures, appliances, and other applications where ease of installation and accessibility are important. The choice of mounting style for a wiring toggle switch depends on the specific application requirements, the desired level of security and accessibility, and the overall design and layout of the electrical system.

Understanding the relationship between mounting style and wiring toggle switches is essential for proper selection, installation, and maintenance. By choosing the most appropriate mounting style for the intended application, electrical professionals can ensure that the toggle switch is securely mounted, easily accessible, and able to perform its intended function effectively and reliably.

Application

Wiring toggle switches find extensive application in controlling various electrical devices and systems, ranging from lighting and appliances to motors and industrial controls. Understanding the diverse applications of wiring toggle switches is crucial for electrical professionals and homeowners alike, as it enables informed decision-making and ensures proper selection and installation of these essential components. This detailed exploration delves into four key application areas, highlighting their specific roles, real-life examples, and implications in the context of wiring toggle switches.

-

Lighting Control

Wiring toggle switches are commonly used to control lighting fixtures, both in residential and commercial settings. They provide a simple and convenient way to turn lights on or off, and can be easily integrated into various lighting control systems, such as dimmers and smart home automation. -

Appliance Control

Appliances like fans, heaters, and kitchen equipment often incorporate wiring toggle switches for user control. These switches allow users to conveniently operate appliances, adjust settings, and turn them on or off as needed. -

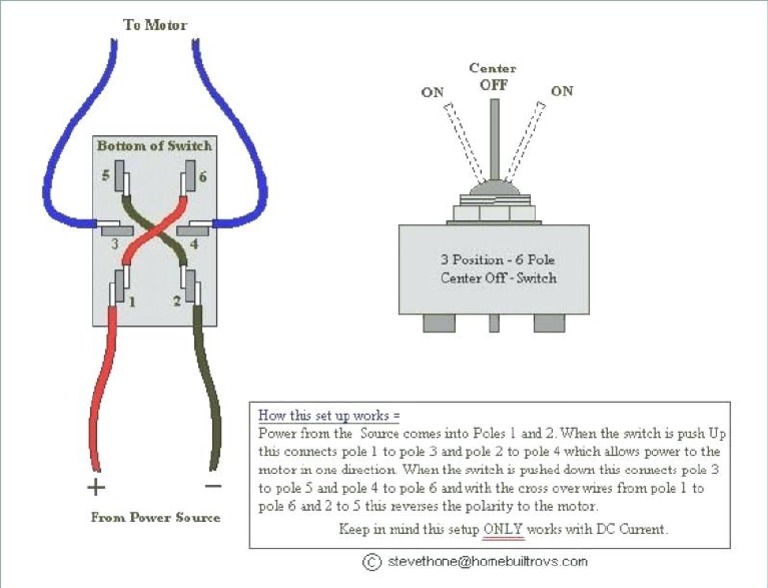

Motor Control

Wiring toggle switches are employed in motor control circuits to start, stop, and reverse the direction of motors. They provide a reliable and efficient means of controlling motors used in industrial machinery, pumps, and other applications. -

Industrial Controls

In industrial settings, wiring toggle switches are widely used in control panels and automation systems. They serve as critical components for controlling various processes, such as conveyor belts, assembly lines, and manufacturing equipment.

The diverse applications of wiring toggle switches underscore their versatility and importance in the electrical industry. By understanding the specific roles and implications of these switches in different application areas, electrical professionals can effectively design, install, and maintain electrical systems that meet the functional and safety requirements of various settings, from homes and offices to industrial facilities and manufacturing plants.

Related Posts