A Wiring Rule Bilge Pump is an electrical device in a boat designed to automatically pump water out of the bilge, the lowest area in the hull that collects water. It is connected to the boat’s electrical system and activates when the water level in the bilge rises to a predetermined height, typically through a float switch or water sensor. The pump draws power from the boat’s battery and expels the water overboard through a discharge hose.

Wiring Rule Bilge Pumps are integral to the safety of a boat by preventing the accumulation of water in the bilge, which can lead to instability, loss of buoyancy, and potential sinking. They provide peace of mind for boaters, especially in inclement weather or when operating in areas with a risk of flooding. The development of reliable and efficient Wiring Rule Bilge Pumps has been a significant advancement in marine safety, contributing to the prevention of accidents and loss of life.

This article will delve into the technical specifications, installation procedures, and maintenance practices associated with Wiring Rule Bilge Pumps, providing valuable information for boat owners, marine electricians, and anyone interested in the safety and reliability of boats.

Wiring Rule Bilge Pumps are crucial components of boat safety and reliability. Understanding their essential aspects is paramount for proper installation, maintenance, and operation.

- Function: Automatically pumps water out of the bilge, preventing accumulation and potential sinking.

- Activation: Triggered by a float switch or water sensor when water level rises.

- Power Source: Draws electrical power from the boat’s battery.

- Discharge: Expels water overboard through a discharge hose.

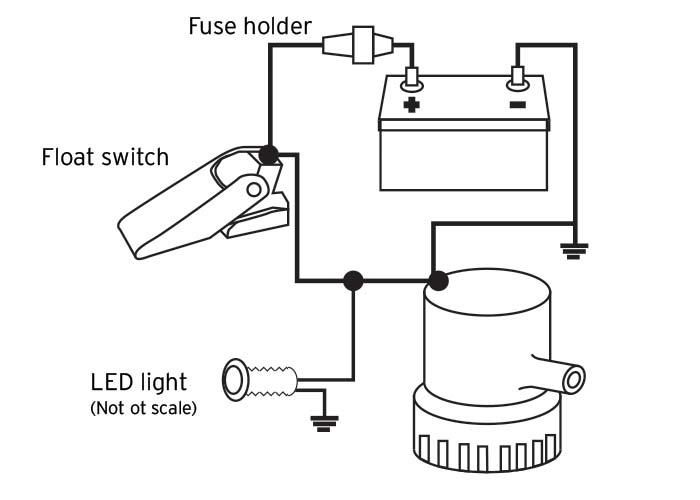

- Wiring: Must be installed according to electrical wiring rules for boats.

- Capacity: Measured in gallons per hour (GPH), determines the volume of water the pump can handle.

- Bilge Access: Requires proper mounting location in the bilge for effective water removal.

- Maintenance: Regular inspection, cleaning, and testing are essential for optimal performance.

These aspects are interconnected and contribute to the overall effectiveness of Wiring Rule Bilge Pumps. For example, proper wiring ensures the pump receives adequate power, while sufficient capacity ensures it can handle the volume of water in the bilge. Regular maintenance prevents failures and ensures the pump is ready for use when needed. Understanding these aspects empowers boat owners and marine professionals to make informed decisions about bilge pump selection, installation, and maintenance, ultimately enhancing boat safety and reliability.

Function

The function of a Wiring Rule Bilge Pump is inextricably linked to its ability to automatically pump water out of the bilge, preventing accumulation and potential sinking. This critical function is achieved through a combination of electrical and mechanical components that work together to safeguard the boat and its occupants.

When water accumulates in the bilge, either due to leaks, waves, or other factors, the Wiring Rule Bilge Pump’s float switch or water sensor detects the rising water level. This triggers the pump’s electrical system, which draws power from the boat’s battery and activates the pump motor. The pump motor then drives an impeller, which creates suction to draw water from the bilge and expel it overboard through a discharge hose.

The effectiveness of a Wiring Rule Bilge Pump in preventing bilge accumulation and potential sinking depends on several factors, including its capacity, installation location, and maintenance. Selecting a pump with sufficient capacity for the size of the boat and bilge is crucial to ensure it can handle the volume of water that may accumulate. Proper installation in the lowest point of the bilge ensures the pump can access and remove water effectively. Regular maintenance, including cleaning and testing, is essential to prevent failures and ensure the pump is always ready to perform its critical function.

In summary, the function of a Wiring Rule Bilge Pump automatically pumping water out of the bilge, preventing accumulation and potential sinking is a cornerstone of boat safety. Understanding this function and its connection to the pump’s electrical and mechanical components empowers boat owners and marine professionals to make informed decisions about bilge pump selection, installation, and maintenance, ultimately enhancing boat safety and reliability.

Activation

In the context of Wiring Rule Bilge Pumps, the activation mechanism plays a pivotal role in ensuring the pump’s effectiveness in preventing bilge accumulation and potential sinking. The activation process, triggered by either a float switch or a water sensor when the water level rises, initiates a chain of events that leads to the automatic removal of water from the bilge.

The float switch, a mechanical device, is typically made of a buoyant material and is connected to the bilge pump’s electrical system. As the water level rises in the bilge, the float switch rises with it, triggering an electrical contact that activates the pump. Similarly, a water sensor, which uses electronic means to detect the presence of water, also initiates the pump’s activation when the water level reaches a predetermined height.

The activation mechanism is a critical component of a Wiring Rule Bilge Pump, as it ensures that the pump is activated only when necessary, preventing unnecessary operation and potential battery drain. Moreover, the activation mechanism’s sensitivity and reliability are crucial for timely water removal, especially in emergency situations where rapid bilge pumping is essential.

In real-life applications, the activation mechanism’s importance is evident in scenarios such as heavy rainfall, wave splash, or hull leaks. When water accumulates in the bilge, the activation mechanism triggers the bilge pump, which then expels the water overboard, preventing the bilge from overflowing and potentially compromising the boat’s stability and safety.

Understanding the connection between “Activation: Triggered by a float switch or water sensor when water level rises.” and “Wiring Rule Bilge Pump” is essential for boat owners and marine professionals alike. This understanding enables them to appreciate the critical role of the activation mechanism in ensuring the effectiveness of bilge pumps and, consequently, the safety and reliability of boats.

Power Source

In the realm of Wiring Rule Bilge Pumps, the power source plays a crucial role in ensuring the pump’s functionality and reliability. Drawing electrical power from the boat’s battery, Wiring Rule Bilge Pumps are equipped with specific components and considerations that contribute to their effectiveness in removing water from the bilge.

- Battery Capacity and Type: The capacity and type of battery used in the boat directly impact the power available to the bilge pump. Deep-cycle marine batteries are typically used, providing sustained power output over longer periods.

- Electrical Wiring and Connections: Proper electrical wiring and connections are essential for uninterrupted power supply to the bilge pump. Marine-grade wiring and waterproof connectors ensure reliability in harsh marine environments.

- Fuse or Circuit Breaker Protection: To prevent electrical overloads and potential fire hazards, Wiring Rule Bilge Pumps are typically protected by fuses or circuit breakers. These devices safeguard the electrical system and the bilge pump itself.

Understanding the power source aspect of Wiring Rule Bilge Pumps allows boat owners and marine professionals to make informed decisions about battery selection, electrical wiring, and maintenance practices. Regular battery maintenance, including cleaning terminals and checking water levels, is essential for ensuring the bilge pump has adequate power when needed. Additionally, periodic inspection of electrical connections and fuse/circuit breaker functionality helps prevent power-related failures and ensures the bilge pump’s reliability in emergency situations.

Discharge

Within the context of Wiring Rule Bilge Pumps, the discharge aspect is paramount to understanding the pump’s effectiveness in removing water from the bilge. To achieve this, Wiring Rule Bilge Pumps utilize a dedicated discharge system, comprising various components and considerations that facilitate the expulsion of water overboard.

- Discharge Hose: A crucial component of the discharge system, the discharge hose provides a dedicated pathway for water to be expelled overboard. Constructed from durable and flexible materials, the discharge hose must be properly sized and routed to ensure efficient water flow.

- Through-Hull Fitting: The through-hull fitting serves as the entry point for the discharge hose through the boat’s hull. It is designed to create a watertight seal, preventing water from leaking into the boat while allowing the discharge hose to pass through.

- Check Valve: To prevent backflow of water into the bilge, a check valve is installed within the discharge system. This valve allows water to flow out of the bilge but prevents water from flowing back in, ensuring the bilge remains dry.

- Discharge Location: The location of the discharge outlet is carefully considered to avoid recirculation of discharged water back into the bilge. Typically, the discharge outlet is positioned above the waterline to ensure effective expulsion of water overboard.

Understanding the discharge aspect of Wiring Rule Bilge Pumps enables boat owners and marine professionals to make informed decisions about discharge hose selection, routing, and maintenance practices. Regular inspection and maintenance of the discharge system, including cleaning the discharge hose and checking the functionality of the check valve, help ensure the bilge pump’s ability to effectively expel water overboard, maintaining the boat’s safety and reliability.

Wiring

In the realm of Wiring Rule Bilge Pumps, proper wiring is paramount for ensuring the pump’s functionality, safety, and reliability. Adhering to stringent electrical wiring rules for boats is crucial to prevent electrical hazards, ensure optimal pump performance, and maintain the integrity of the boat’s electrical system.

- Conduit and Protection: Electrical wiring for Wiring Rule Bilge Pumps must be enclosed in watertight conduit or protected by other approved means to prevent exposure to water and potential electrical shorts.

- Wire Gauge and Length: The gauge and length of the electrical wires used must meet specific requirements to ensure adequate current carrying capacity and minimize voltage drop, ensuring the bilge pump receives sufficient power to operate effectively.

- Fuses and Circuit Breakers: Wiring Rule Bilge Pumps must be protected by appropriately sized fuses or circuit breakers to prevent electrical overloads and potential fire hazards.

- Grounding: Proper grounding of the bilge pump and its electrical system is essential to provide a safe path for electrical current and prevent the accumulation of static electricity, which could lead to electrical shocks or fires.

By adhering to these electrical wiring rules, boat owners and marine professionals can ensure that Wiring Rule Bilge Pumps are installed and operated safely and effectively, contributing to the overall safety and reliability of the boat.

Capacity

Within the context of Wiring Rule Bilge Pumps, capacity plays a pivotal role in ensuring the pump’s ability to effectively remove water from the bilge and maintain the safety of the boat. Measured in gallons per hour (GPH), capacity determines the volume of water the pump can handle, directly impacting its suitability for different boat sizes and bilge water accumulation rates.

- Pump Sizing: Selecting a bilge pump with sufficient capacity is crucial to ensure it can handle the potential volume of water that may accumulate in the bilge. Factors to consider include the size of the boat, the bilge’s volume, and the expected water ingress rate.

- Real-Life Examples: For small boats, a bilge pump with a capacity of 500-1000 GPH may be adequate, while larger boats may require a pump with a capacity of 2000 GPH or more.

- Implications for Safety: An undersized bilge pump may not be able to keep up with water accumulation, potentially leading to flooding and compromising the boat’s stability and safety.

- Redundancy and Backup: In critical applications, such as larger boats or those operating in challenging conditions, it is advisable to install multiple bilge pumps with varying capacities to provide redundancy and backup in case of pump failure.

Understanding the concept of capacity and its implications for Wiring Rule Bilge Pumps is essential for boat owners and marine professionals to make informed decisions about pump selection and installation. Proper sizing and consideration of capacity help ensure that the bilge pump is equipped to effectively handle the potential volume of water, contributing to the overall safety and reliability of the boat.

Bilge Access

In the realm of Wiring Rule Bilge Pumps, bilge access plays a critical role in ensuring the pump’s effectiveness in removing water from the bilge and maintaining the boat’s safety and reliability. Proper mounting location in the bilge is paramount to allow the pump to access and remove water efficiently, preventing bilge accumulation and potential sinking. Understanding the various facets of bilge access is essential for optimal pump performance and overall boat safety.

- Pump Placement: The pump should be mounted at the lowest point in the bilge, ensuring it can access and remove water effectively from all areas of the bilge.

- Suction Strainer: A suction strainer should be installed at the pump’s inlet to prevent debris from clogging the pump and impairing its performance.

- Bilge Shape and Obstructions: The shape of the bilge and the presence of obstacles, such as ribs, frames, or fuel tanks, should be considered when determining the optimal mounting location for the bilge pump.

- Maintenance and Accessibility: The pump should be mounted in a location that allows for easy access for maintenance and inspection, including cleaning the suction strainer and checking the pump’s functionality.

By understanding and considering these facets of bilge access, boat owners and marine professionals can ensure that Wiring Rule Bilge Pumps are properly mounted and positioned to effectively remove water from the bilge, contributing to the overall safety and reliability of the boat.

Maintenance

In the realm of Wiring Rule Bilge Pumps, maintenance plays a pivotal role in ensuring the pump’s reliability and effectiveness in removing water from the bilge. Regular inspection, cleaning, and testing are essential for optimal performance, preventing unexpected failures and maintaining the boat’s safety and seaworthiness.

- Regular Inspection: Periodic visual inspections of the bilge pump and its components, including the wiring, connections, and discharge hose, help identify potential issues early on. This allows for timely repairs or replacements, preventing minor problems from escalating into major failures.

- Thorough Cleaning: Debris, dirt, and corrosion can accumulate over time, impairing the pump’s performance. Regular cleaning, using appropriate solvents and techniques, removes these contaminants, ensuring the pump’s moving parts operate smoothly and efficiently.

- Functional Testing: Periodic testing of the bilge pump is crucial to verify its functionality and response time. This involves simulating bilge water accumulation and observing the pump’s activation, water discharge, and automatic shut-off. Testing helps identify any potential issues, such as faulty switches, weak motors, or blockages, allowing for prompt corrective actions.

- Battery and Electrical System Check: The bilge pump’s performance is directly linked to the boat’s battery and electrical system. Regular checks of the battery’s voltage and capacity, as well as the electrical connections and wiring, ensure the pump has adequate power to operate effectively.

By adhering to a regular maintenance schedule, boat owners and marine professionals can proactively address potential issues, extend the life of their Wiring Rule Bilge Pumps, and ensure the bilge remains dry and the boat safe in all conditions.

Related Posts