A Wiring Harness 1966 Mustang is an assembly of electrical wires, terminals, and connectors that transmit electrical power and signals throughout various systems in the vehicle, such as lighting, ignition, and fuel injection. It ensures the proper functioning of essential electrical components and accessories.

The Wiring Harness 1966 Mustang plays a critical role in the operation of the vehicle. It provides a structured and organized way to route and connect electrical wires, enhancing reliability and simplifying maintenance. By eliminating the need for individual wire connections, it reduces the risk of electrical faults and short circuits.

This historical development marked a significant advancement in automotive electrical systems, enabling the integration of complex electrical components and providing a standardized approach to wiring for future vehicle models.

The Wiring Harness 1966 Mustang, a crucial component of the vehicle’s electrical system, warrants a thorough examination of its essential aspects. These aspects encompass the design, function, materials, installation, maintenance, and historical significance, among others, each contributing to the overall performance and reliability of the wiring harness.

- Design: The design of the wiring harness determines the layout, routing, and connections of the electrical wires, ensuring optimal performance and ease of maintenance.

- Function: The primary function of the wiring harness is to transmit electrical power and signals throughout the vehicle’s systems, enabling the operation of essential components and accessories.

- Materials: The selection of materials for the wiring harness, including the conductors, insulation, and connectors, influences its durability, resistance to environmental factors, and overall reliability.

- Installation: Proper installation of the wiring harness is critical to ensure secure connections, prevent damage, and maintain the integrity of the electrical system.

- Maintenance: Regular maintenance and inspection of the wiring harness help identify and address any potential issues, ensuring continued reliability and preventing electrical faults.

- Historical Significance: The Wiring Harness 1966 Mustang represents an important development in automotive electrical systems, enabling the integration of complex electrical components and providing a standardized approach to wiring for future vehicle models.

- Customization: The wiring harness can be customized to accommodate specific electrical requirements, modifications, or the installation of aftermarket components.

- Safety: A well-maintained wiring harness plays a vital role in ensuring the electrical safety of the vehicle, preventing short circuits, electrical fires, and other hazards.

- Diagnostics: The wiring harness provides a systematic approach to troubleshooting electrical issues, simplifying the identification and repair of faults.

- Cost: The cost of the wiring harness, including materials, labor, and installation, is an important consideration in vehicle maintenance and restoration projects.

These key aspects collectively contribute to the significance of the Wiring Harness 1966 Mustang, underscoring its role in the vehicle’s electrical system and its impact on overall performance, safety, and historical relevance.

Design

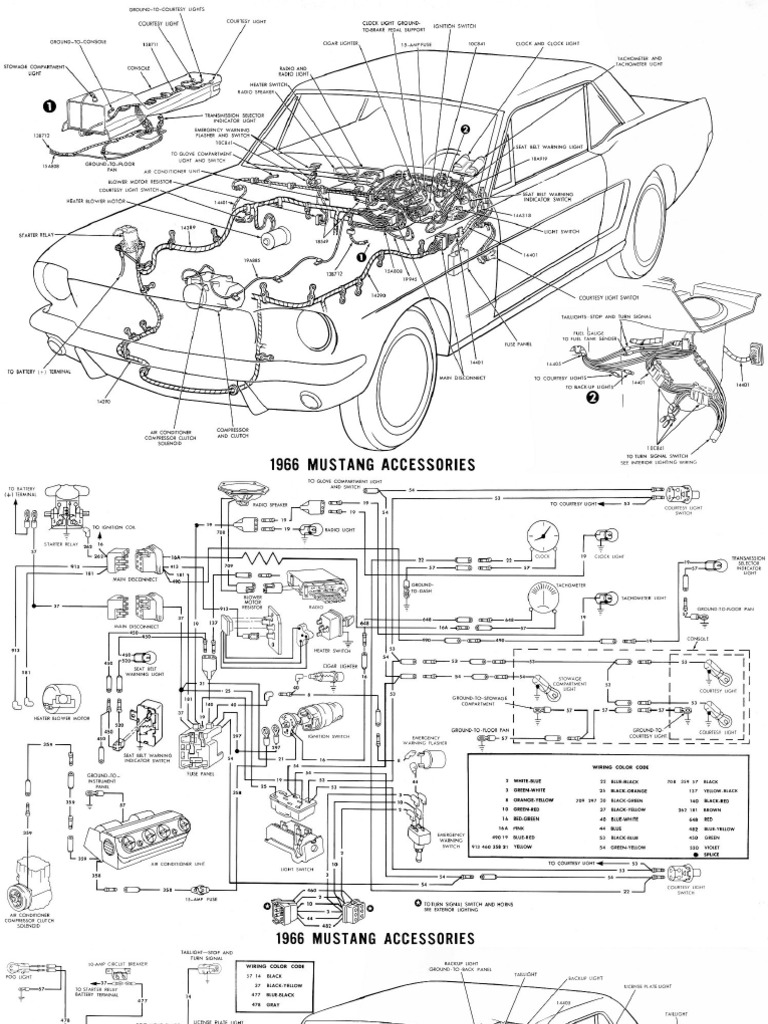

The design of the Wiring Harness 1966 Mustang plays a critical role in determining the vehicle’s overall electrical performance and reliability. The layout, routing, and connections of the electrical wires are carefully planned to ensure efficient power distribution, minimize voltage drop, and facilitate troubleshooting and maintenance. Each component of the wiring harness, including the wires, connectors, and terminals, is meticulously selected and assembled to meet the specific electrical requirements of the vehicle’s systems.

For instance, the use of color-coded wires and standardized connectors in the Wiring Harness 1966 Mustang simplifies the identification and tracing of electrical circuits, reducing the time and effort required for repairs and modifications. Additionally, the harness is designed to withstand the harsh operating conditions found in automotive applications, including exposure to heat, moisture, and vibration, ensuring long-term reliability.

Understanding the design principles and considerations of the Wiring Harness 1966 Mustang enables technicians and enthusiasts to effectively diagnose and address electrical issues, customize the vehicle’s electrical system, and maintain the integrity and performance of the wiring harness over the vehicle’s lifetime.

Function

The Wiring Harness 1966 Mustang serves as the backbone of the vehicle’s electrical system, facilitating the distribution of electrical power and signals to various components and accessories, ensuring their proper operation. This intricate network of wires, connectors, and terminals plays a crucial role in the functionality, performance, and safety of the vehicle.

- Power Distribution: The wiring harness ensures that electrical power is efficiently distributed from the battery to various electrical components, including lights, ignition systems, and fuel injectors. This uninterrupted flow of power enables the smooth functioning of these components, ensuring optimal vehicle performance.

- Signal Transmission: Beyond power distribution, the wiring harness also transmits electrical signals between different components. These signals allow for communication and coordination between various systems, such as the engine control module, sensors, and actuators. This efficient signal transmission ensures proper engine operation, optimal fuel efficiency, and enhanced safety features.

- Circuit Protection: The wiring harness incorporates protective measures such as fuses and circuit breakers to safeguard electrical components from excessive current or short circuits. These protective devices prevent damage to sensitive components and minimize the risk of electrical fires, enhancing the overall reliability and safety of the vehicle’s electrical system.

- Customization and Modifications: The wiring harness provides a structured framework for electrical modifications and customizations. It allows for the integration of additional components, such as aftermarket accessories or performance upgrades, while maintaining the integrity and functionality of the original electrical system. This adaptability enables enthusiasts and professionals to tailor the vehicle’s electrical system to their specific needs and preferences.

In summary, the function of the Wiring Harness 1966 Mustang extends beyond mere wire connections. It serves as a critical component responsible for the distribution of electrical power, transmission of signals, protection against electrical faults, and adaptability to modifications. Understanding the function and its multifaceted aspects is essential for maintaining the reliability, performance, and safety of the vehicle’s electrical system.

Materials

The selection of materials for the Wiring Harness 1966 Mustang is critical to its durability, resistance to environmental factors, and overall reliability. The conductors, insulation, and connectors are carefully chosen to withstand the harsh operating conditions found in automotive applications, including exposure to heat, moisture, vibration, and chemicals. These materials must also meet the electrical requirements of the vehicle’s systems, ensuring efficient power distribution and signal transmission.

For example, the conductors used in the Wiring Harness 1966 Mustang are typically made of copper, which offers excellent electrical conductivity and durability. The insulation is made of materials such as PVC or polyethylene, which provide protection against electrical shorts and environmental factors. The connectors are made of brass or other corrosion-resistant materials to ensure reliable electrical connections.

The use of high-quality materials in the Wiring Harness 1966 Mustang contributes to the vehicle’s overall performance, safety, and longevity. By understanding the importance of materials selection in wiring harness design, technicians and enthusiasts can make informed decisions when maintaining or modifying their vehicles’ electrical systems.

Installation

The proper installation of the Wiring Harness 1966 Mustang is paramount to the vehicle’s electrical system’s performance, reliability, and safety. A well-installed wiring harness ensures secure connections, prevents damage to the wires and components, and maintains the integrity of the electrical system. Conversely, improper installation can lead to loose connections, electrical shorts, and even electrical fires.

For example, if the wiring harness is not properly secured, it could vibrate or move during vehicle operation, leading to loose connections and potential electrical problems. Additionally, if the wires are not routed correctly, they could come into contact with sharp edges or hot surfaces, causing damage to the insulation and creating a risk of electrical shorts or fires.

Understanding the importance of proper installation enables technicians and enthusiasts to take the necessary precautions and follow best practices when working on the vehicle’s electrical system. This includes using the correct tools, following the manufacturer’s instructions, and ensuring that all connections are secure and protected.

By recognizing the critical role of proper installation, individuals can contribute to the longevity, safety, and optimal performance of the Wiring Harness 1966 Mustang, as well as the overall electrical system of the vehicle.

Maintenance

Maintenance of the Wiring Harness 1966 Mustang goes hand-in-hand with preserving the vehicle’s electrical integrity, reliability, and safety. Regular maintenance and inspection enable early detection of potential problems, allowing proactive measures to be taken, thus avoiding electrical faults and ensuring continued reliability of the vehicle’s electrical system.

- Visual Inspection: Regular visual inspections of the wiring harness, including its insulation, connectors, and terminals, can reveal signs of damage, wear, or corrosion. This allows for timely repair or replacement of affected components, preventing electrical malfunctions and ensuring optimal performance.

- Electrical Testing: Using a multimeter or other diagnostic tools, technicians can conduct electrical tests to measure voltage, current, and resistance within the wiring harness. This helps identify weak connections, shorts, or other electrical issues that may not be readily apparent during visual inspection.

- Cleaning and Protection: Dirt, moisture, and other contaminants can accumulate on the wiring harness over time, leading to corrosion or electrical problems. Regular cleaning and application of protective coatings can prevent these issues, maintaining the integrity of the wiring harness and extending its lifespan.

By implementing a comprehensive maintenance plan that incorporates regular inspections, electrical testing, and cleaning, owners and enthusiasts can proactively address potential issues with the Wiring Harness 1966 Mustang, ensuring its continued reliability, preventing electrical faults, and preserving the overall electrical performance of their classic vehicle.

Historical Significance

The Wiring Harness 1966 Mustang played a pivotal role in the evolution of automotive electrical systems. Its introduction marked a significant departure from the traditional point-to-point wiring methods, introducing a more structured and organized approach to electrical system design.

Prior to the Wiring Harness 1966 Mustang, automotive electrical systems were often a haphazard collection of wires and components, making troubleshooting and repairs time-consuming and challenging. The Wiring Harness 1966 Mustang, with its standardized wiring and color-coded connectors, simplified the process of tracing electrical circuits, reducing the likelihood of errors and improving overall system reliability.

Furthermore, the Wiring Harness 1966 Mustang enabled the integration of more complex electrical components, such as fuel injection and electronic ignition systems. These advancements in electrical technology enhanced vehicle performance, fuel efficiency, and emissions control.

The impact of the Wiring Harness 1966 Mustang extended beyond the Mustang model. Its standardized approach to wiring became the blueprint for future vehicle electrical systems, laying the foundation for the increasingly complex and sophisticated electrical architectures found in modern vehicles.

In summary, the Wiring Harness 1966 Mustang represents a critical milestone in the evolution of automotive electrical systems. Its introduction brought about increased reliability, simplified troubleshooting, and enabled the integration of advanced electrical components, shaping the direction of future vehicle designs.

Customization

The Wiring Harness 1966 Mustang provides a flexible foundation for electrical modifications and customization, enabling enthusiasts and professionals to tailor the vehicle’s electrical system to their specific needs and preferences. This customization capability extends to various aspects of the wiring harness, including the addition of new components, integration of aftermarket accessories, and modifications to accommodate unique electrical requirements.

- Component Addition: The wiring harness can be modified to incorporate additional electrical components, such as upgraded headlights, fog lights, or performance ignition systems. This allows enthusiasts to enhance the vehicle’s functionality, safety, or performance.

- Aftermarket Integration: The wiring harness can be adapted to seamlessly integrate aftermarket accessories, such as audio systems, GPS devices, or remote starters. This enables the addition of modern conveniences and technologies to the classic Mustang.

- Electrical Modifications: The wiring harness can be modified to accommodate electrical system upgrades, such as converting to electronic fuel injection or installing a performance ignition system. These modifications can improve engine performance, fuel efficiency, or overall driving experience.

- Unique Electrical Requirements: The wiring harness can be customized to meet the unique electrical requirements of custom builds or specialty applications. This flexibility allows enthusiasts to create one-of-a-kind vehicles with tailored electrical systems.

The ability to customize the Wiring Harness 1966 Mustang empowers owners and enthusiasts to personalize their vehicles, enhance their functionality, and adapt them to specific performance or aesthetic goals. This customization capability contributes to the enduring popularity of the Mustang as a platform for both classic car restoration and modern performance modifications.

Safety

The Wiring Harness 1966 Mustang is critical to the electrical safety of the vehicle. A well-maintained wiring harness ensures that electrical power is distributed properly throughout the vehicle’s systems, preventing short circuits and electrical fires. Poor maintenance, aging, or damage to the wiring harness can compromise its integrity, increasing the risk of electrical hazards.

For instance, frayed or damaged wires can create electrical shorts, causing sparks or overheating that could lead to a fire. Loose or corroded connections can result in poor electrical contact, generating excessive heat and potentially sparking. A properly maintained wiring harness, with secure connections, intact insulation, and components, minimizes these risks and ensures the safe operation of the vehicle’s electrical systems.

Understanding the importance of wiring harness maintenance empowers owners and enthusiasts to take proactive measures, such as regular inspections, cleaning, and repairs, to prevent electrical hazards and ensure the continued safety of their vehicles.

Diagnostics

The Wiring Harness 1966 Mustang incorporates a systematic diagnostic approach that simplifies troubleshooting electrical issues, enabling efficient identification and repair of faults. The structured design of the wiring harness, with standardized color-coding and organized routing, provides a logical framework for tracing electrical circuits and isolating problems.

For instance, if a particular electrical component malfunctions, technicians can use the wiring harness as a roadmap to trace the circuit, identify potential breaks or shorts, and pinpoint the exact location of the fault. This systematic approach minimizes guesswork, reduces diagnostic time, and allows for targeted repairs, enhancing the overall reliability and performance of the vehicle’s electrical system.

Understanding the diagnostic capabilities of the Wiring Harness 1966 Mustang empowers owners and enthusiasts to perform basic electrical troubleshooting, identify common issues, and make informed decisions regarding repairs. This knowledge contributes to the preservation and maintenance of the vehicle’s electrical integrity, ensuring a safe and trouble-free driving experience.

Cost

When evaluating the Wiring Harness 1966 Mustang, cost is a crucial factor that encompasses materials, labor, and installation. Understanding the cost implications of each aspect enables informed decision-making for vehicle maintenance and restoration projects.

- Materials: The cost of materials for the wiring harness includes the wires, connectors, terminals, and insulation. The quality and type of materials used can impact the overall cost, with higher-quality materials typically resulting in a higher price.

- Labor: Labor costs associated with the wiring harness involve the time and effort required for installation. The complexity of the wiring harness and the skill level of the technician can influence the labor costs.

- Installation: The installation process includes preparing the vehicle, routing the wiring harness, and connecting the components. The cost of installation can vary depending on the complexity of the vehicle and the availability of specialized tools or equipment.

- Customization: Customizing the wiring harness to accommodate specific modifications or performance upgrades can incur additional costs. This may involve adding or modifying circuits, integrating aftermarket components, or reconfiguring the harness to suit unique requirements.

Considering these cost factors is essential for budgeting and planning vehicle maintenance and restoration projects. Balancing the cost with the desired outcome and the value of the vehicle can help individuals make informed decisions and achieve their restoration or performance goals.

Related Posts