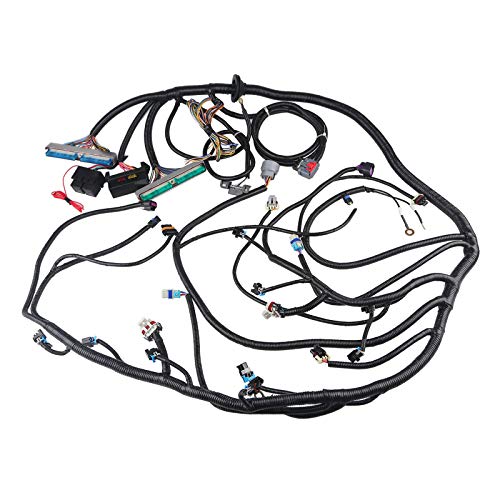

A wiring engine harness is a systematically assembled network of electrical wires, connectors, and terminals. It serves as the nerve center of a vehicle, routing electrical signals from a central power source to the various electrical components and devices.

This highly organized system ensures the smooth functioning of critical systems such as engine management, lighting, and entertainment, enabling seamless communication and control. Its relevance lies in its ability to securely carry electrical current, protect it from environmental hazards, and facilitate efficient repairs or replacements.

A notable historical development in wiring engine harnesses was the transition from single-wire to multiplexed harnesses. Multiplexed harnesses simplify the wiring architecture, reducing the number of wires and improving reliability and flexibility. This advancement has played a pivotal role in the evolution of automotive electronics and network systems, paving the way for more advanced vehicle designs and features.

Wiring Engine Harnesses are vital components in a vehicle’s electrical system, playing a critical role in the reliable and efficient distribution of electrical power. To delve into the intricacies of Wiring Engine Harnesses, it is essential to first identify the part of speech of this term.

- Wiring (noun): This refers to the network of electrical wires that make up the harness. These wires transmit electrical signals and power throughout the vehicle.

- Engine (noun): This specifies the primary purpose of the harness – to connect and provide power to the vehicle’s engine and its various components.

- Harness (noun): This represents the organized assembly of wires, connectors, and terminals, which are bundled together to protect them from damage and facilitate efficient installation and maintenance.

These key aspects highlight the interrelation between the wires, the engine, and the harness assembly. Each aspect plays a specific role in ensuring the proper functioning of the electrical system and the overall performance of the vehicle.

Wiring (noun)

Within the context of a Wiring Engine Harness, the wiring aspect encompasses the intricate network of electrical wires that serve as the backbone of the system. These wires are responsible for transmitting electrical signals and power throughout the vehicle, ensuring seamless communication and operation of various components.

- Types of Wires: Wiring harnesses utilize different types of wires, each designed for specific applications. These may include copper wires for their excellent conductivity, aluminum wires for their lightweight properties, and fiber optic cables for high-speed data transmission.

- Wire Insulation: The wires are covered with insulation to prevent electrical shorts and ensure safe operation. Insulation materials vary based on factors like temperature resistance, voltage rating, and flexibility.

- Wire Color Coding: To facilitate identification and maintenance, wires are often color-coded according to industry standards. This coding helps technicians quickly trace and troubleshoot electrical circuits.

- Wire Routing and Protection: Wires are strategically routed and protected within the harness to minimize damage from heat, vibration, and other environmental factors. This ensures the reliability and longevity of the electrical system.

In summary, the wiring component of a Wiring Engine Harness encompasses the selection, insulation, color-coding, and routing of electrical wires. These aspects work in unison to transmit electrical signals and power effectively, supporting the optimal performance of the vehicle’s electrical systems.

Engine (noun)

Within the context of a Wiring Engine Harness, the “Engine” aspect underscores the harness’s fundamental objective – to establish electrical connections and supply power to the vehicle’s engine and its associated components. This section delves into four specific facets of the “Engine” aspect, exploring their roles, real-life examples, and implications within the broader system.

-

Ignition System:

The Wiring Engine Harness provides electrical connections for the ignition system, which is responsible for initiating combustion within the engine. Key components include spark plugs, ignition coils, and wiring that transmit high-voltage signals.

-

Fuel Injection System:

Electrical signals from the Wiring Engine Harness control the fuel injection system, ensuring precise delivery of fuel into the engine’s cylinders. This system includes fuel injectors, fuel pumps, and sensors that monitor fuel pressure and flow rate.

-

Engine Sensors and Actuators:

The harness connects various sensors and actuators to the engine’s electronic control unit (ECU). These components provide real-time data on engine parameters such as temperature, speed, and oxygen levels, enabling the ECU to adjust engine performance accordingly.

-

Starter Motor:

The Wiring Engine Harness supplies power to the starter motor, which is responsible for cranking the engine and starting the combustion process. This connection ensures a reliable starting sequence and smooth engine operation.

In summary, the “Engine” aspect of a Wiring Engine Harness encompasses the electrical connections and power supply for critical engine components, including the ignition system, fuel injection system, sensors, actuators, and starter motor. These facets work in harmony to enable efficient engine operation, optimize performance, and ensure a seamless driving experience.

Harness (noun)

In the context of “Wiring Engine Harness,” the harness aspect plays a crucial role. It encompasses the organized assembly of wires, connectors, and terminals, bundled together to fulfill two primary purposes: protection and efficiency.

The harness provides protection against physical damage and environmental factors. Wires are bundled together and shielded within protective materials, such as insulation, conduit, or sheathing. This prevents damage from abrasion, moisture, heat, or chemicals, ensuring the integrity and reliability of electrical connections.

Moreover, the organized assembly enhances installation and maintenance efficiency. By bundling wires together, the harness simplifies the process of routing and securing them within the vehicle’s electrical system. This streamlined approach reduces labor time, minimizes the risk of errors, and facilitates future maintenance or modifications.

Real-life examples of “Harness (noun): This represents the organized assembly of wires, connectors, and terminals, which are bundled together to protect them from damage and facilitate efficient installation and maintenance.” within “Wiring Engine Harness” include:

- Wiring harnesses connecting the engine to the vehicle’s electrical system, providing power and control signals to various components.

- Harnesses for lighting systems, distributing power to headlights, taillights, and turn signals.

- Harnesses for infotainment systems, connecting audio, video, and navigation components.

Harness design and manufacturing techniques continue to evolve, incorporating advanced materials, automated assembly processes, and sophisticated testing methods to enhance performance and reliability. Understanding the critical role of the “Harness (noun): This represents the organized assembly of wires, connectors, and terminals, which are bundled together to protect them from damage and facilitate efficient installation and maintenance.” within “Wiring Engine Harness” is essential for designing, installing, and maintaining robust electrical systems in modern vehicles.

Related Posts