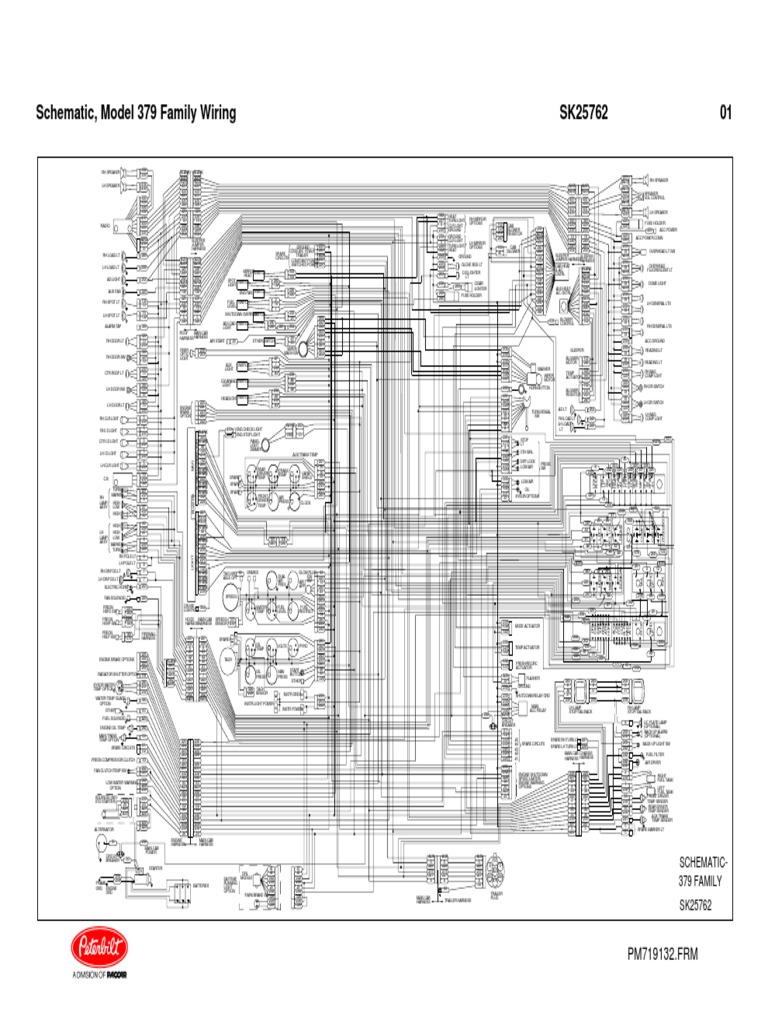

A Wiring Diagram for Peterbilt 379 is a technical document that visually illustrates the electrical connections and components within the vehicle. It serves as a detailed guide for troubleshooting, repairing, and modifying the electrical system.

Wiring diagrams play a vital role in maintaining and servicing heavy-duty vehicles such as Peterbilt 379s. By providing a comprehensive view of the electrical system, they enable technicians to quickly identify and resolve electrical faults, ensuring the vehicle’s optimal performance and safety. The benefits of wiring diagrams include enhanced troubleshooting efficiency, reduced downtime, and improved accuracy in electrical repairs.

Historically, wiring diagrams have evolved from physical blueprints to digital formats. This digitalization has greatly improved accessibility and ease of use, allowing technicians to access and update diagrams remotely.

Wiring diagrams are essential for understanding, troubleshooting, and repairing the electrical systems of Peterbilt 379 vehicles. These diagrams provide a visual representation of the electrical connections and components, making it easier to identify and resolve electrical faults.

- Accuracy: Wiring diagrams are highly accurate, providing a detailed and reliable representation of the electrical system.

- Comprehensiveness: They include all of the electrical components and connections in the vehicle, making them a valuable resource for troubleshooting.

- Ease of Use: Wiring diagrams are typically easy to read and understand, even for those who are not familiar with electrical systems.

- Troubleshooting: Wiring diagrams are essential for troubleshooting electrical problems, as they allow technicians to quickly identify the source of the fault.

- Repair: Wiring diagrams provide step-by-step instructions for repairing electrical components, making it easier to fix problems.

- Modification: Wiring diagrams can be used to modify electrical systems, such as adding new components or changing the wiring configuration.

- Safety: Wiring diagrams help to ensure that electrical systems are safe and operate properly, reducing the risk of electrical fires or other hazards.

- Documentation: Wiring diagrams serve as a valuable documentation of the electrical system, making it easier to maintain and service the vehicle over time.

- Training: Wiring diagrams can be used to train technicians on how to troubleshoot and repair electrical systems.

- Customization: Wiring diagrams can be customized to meet the specific needs of a particular vehicle or application.

Overall, wiring diagrams are an essential tool for anyone who works on the electrical systems of Peterbilt 379 vehicles. They provide a wealth of information that can help to troubleshoot problems, make repairs, and modify the electrical system.

Accuracy

Accuracy is a critical aspect of wiring diagrams, as they serve as the foundation for troubleshooting, repair, and modification of electrical systems in Peterbilt 379 vehicles. The accuracy of wiring diagrams ensures that technicians can rely on them to make informed decisions and perform effective work.

- Component-Level Accuracy: Wiring diagrams accurately represent each electrical component, including its type, location, and connections. This level of detail is essential for troubleshooting and repairing specific electrical faults.

- System-Level Accuracy: Wiring diagrams also accurately depict the overall electrical system, showing how different components are interconnected and how they interact with each other. This comprehensive view is crucial for understanding the system’s behavior and identifying potential problems.

- Real-World Verification: Wiring diagrams are typically created based on actual measurements and testing, ensuring that they reflect the real-world configuration of the electrical system. This verification process minimizes the risk of errors and ensures that the diagrams are reliable.

- Regular Updates: Wiring diagrams are regularly updated to reflect changes in the electrical system, such as the addition of new components or modifications to existing ones. This ensures that technicians always have access to the most accurate and up-to-date information.

The accuracy of wiring diagrams is essential for the safe and efficient operation of Peterbilt 379 vehicles. By providing a detailed and reliable representation of the electrical system, wiring diagrams empower technicians to diagnose problems quickly and accurately, make informed repairs, and modify the system as needed, minimizing downtime and ensuring the vehicle’s optimal performance and safety.

Comprehensiveness

The comprehensiveness of wiring diagrams for Peterbilt 379 vehicles is a critical factor that contributes to their value as a troubleshooting resource. By including all of the electrical components and connections in the vehicle, these diagrams provide a complete picture of the electrical system, making it easier for technicians to identify and resolve electrical faults.

One of the key benefits of comprehensive wiring diagrams is that they allow technicians to quickly trace electrical circuits and identify the source of a problem. This is especially important in complex electrical systems, where multiple components and connections can be interconnected in various ways. By having a complete diagram of the system, technicians can systematically eliminate potential causes and narrow down the search for the fault.

For example, if a technician is troubleshooting a lighting issue on a Peterbilt 379, a comprehensive wiring diagram will show all of the electrical components and connections involved in the lighting system, including the light bulbs, switches, fuses, and wiring harnesses. This allows the technician to quickly identify which component or connection is causing the problem and make the necessary repairs.

In addition to troubleshooting, comprehensive wiring diagrams are also essential for planning and executing electrical modifications. By having a complete understanding of the existing electrical system, technicians can identify potential conflicts and ensure that any modifications are made safely and effectively.

Overall, the comprehensiveness of wiring diagrams for Peterbilt 379 vehicles is a critical factor that contributes to their value as a troubleshooting resource. By including all of the electrical components and connections in the vehicle, these diagrams provide a complete picture of the electrical system, making it easier for technicians to identify and resolve electrical faults.

Ease of Use

In the context of “Wiring Diagram For Peterbilt 379”, “Ease of Use” refers to the user-friendliness and accessibility of wiring diagrams, making them valuable for individuals with varying levels of electrical expertise. This aspect is crucial for efficient troubleshooting, repair, and modification of electrical systems in Peterbilt 379 vehicles.

- Clarity and Simplicity: Wiring diagrams for Peterbilt 379 are designed with clarity and simplicity in mind. They use standardized symbols and color-coding to represent electrical components and connections, making it easy for users to identify and understand the system’s layout.

- Logical Organization: The diagrams are logically organized, with components and connections arranged in a way that follows the flow of electricity through the system. This logical organization makes it easier for users to trace circuits and identify potential problems.

- Multiple Views and Perspectives: Wiring diagrams for Peterbilt 379 often include multiple views and perspectives of the electrical system. This allows users to visualize the system from different angles and gain a comprehensive understanding of its operation.

- Availability of Supporting Materials: In addition to the diagrams themselves, manufacturers often provide supporting materials such as troubleshooting guides and technical documentation. These materials can further assist users in understanding and using the wiring diagrams effectively.

The “Ease of Use” of wiring diagrams for Peterbilt 379 is a key factor that contributes to their effectiveness as a troubleshooting and repair tool. By making the diagrams accessible to users with varying levels of electrical expertise, manufacturers empower individuals to maintain and repair their vehicles more efficiently, reducing downtime and ensuring the vehicle’s optimal performance and safety.

Troubleshooting

Within the context of “Wiring Diagram For Peterbilt 379”, the aspect of “Troubleshooting” highlights the critical role of wiring diagrams in diagnosing and resolving electrical problems in Peterbilt 379 vehicles. Wiring diagrams provide a visual representation of the electrical system, making it easier for technicians to trace circuits, identify faulty components, and determine the root cause of electrical malfunctions.

- Rapid Problem Identification: Wiring diagrams enable technicians to quickly pinpoint the source of electrical faults by providing a comprehensive view of the electrical system’s components and connections. This reduces troubleshooting time and minimizes vehicle downtime.

- Accurate Diagnosis: Wiring diagrams ensure accurate diagnosis of electrical problems by providing detailed information about each electrical component, its function, and its relationship with other components. This helps technicians identify the exact cause of the fault and implement targeted repairs.

- Real-Time Troubleshooting: Wiring diagrams can be used for real-time troubleshooting, allowing technicians to trace electrical circuits while the vehicle is in operation. This dynamic troubleshooting approach helps identify intermittent faults and complex electrical issues that may not be apparent during static testing.

- Reduced Repair Costs: By facilitating accurate and efficient troubleshooting, wiring diagrams contribute to reduced repair costs. Accurate fault identification minimizes unnecessary part replacements and labor costs, leading to cost savings for vehicle owners.

In summary, wiring diagrams are indispensable tools for troubleshooting electrical problems in Peterbilt 379 vehicles. They empower technicians to quickly identify the source of electrical faults, leading to accurate diagnosis, efficient repairs, and reduced vehicle downtime and repair costs.

Repair

Within the context of “Wiring Diagram For Peterbilt 379”, the aspect of “Repair” underscores the critical role of wiring diagrams in facilitating the repair and maintenance of electrical systems in Peterbilt 379 vehicles. These diagrams provide detailed instructions and visual guidance, empowering technicians to efficiently diagnose and resolve electrical issues, ensuring the vehicle’s optimal performance and safety.

- Precise Component Identification: Wiring diagrams enable technicians to accurately identify faulty electrical components by providing precise information about each component’s location, function, and interconnections. This facilitates targeted repairs and minimizes the risk of misdiagnosis.

- Step-by-Step Repair Instructions: Wiring diagrams offer comprehensive step-by-step instructions for repairing electrical components. These instructions guide technicians through the process of isolating the fault, replacing or repairing the faulty component, and reconnecting the system, reducing repair time and ensuring accuracy.

- Real-Time Troubleshooting: Wiring diagrams can be used in conjunction with real-time troubleshooting techniques. By monitoring electrical signals and comparing them to the wiring diagram, technicians can pinpoint the exact location of a fault and make necessary repairs efficiently.

- Reduced Downtime: By providing clear repair instructions and facilitating accurate fault identification, wiring diagrams contribute to reduced vehicle downtime. Technicians can quickly resolve electrical issues, minimizing disruptions to vehicle operation and maximizing productivity.

In summary, wiring diagrams are invaluable resources for repairing electrical components in Peterbilt 379 vehicles. They provide precise component identification, step-by-step repair instructions, support for real-time troubleshooting, and ultimately contribute to reduced vehicle downtime, ensuring the efficient operation and safety of these vehicles.

Modification

Wiring diagrams play a crucial role in modifying the electrical systems of Peterbilt 379 vehicles. They provide a visual representation of the electrical architecture, enabling technicians and enthusiasts to make informed decisions about system modifications.

- Component Integration: Wiring diagrams facilitate the integration of new electrical components into the vehicle’s system. By providing a clear understanding of the existing electrical layout, technicians can determine the appropriate connection points and ensure compatibility with the new components.

- Circuit Alterations: Wiring diagrams allow for precise alterations to the electrical circuits, such as adding additional lighting systems, installing custom gauges, or reconfiguring the wiring for improved performance. These modifications can enhance the functionality and personalization of the vehicle.

- Accessory Installation: Wiring diagrams guide the installation of aftermarket accessories, such as audio systems, navigation devices, and towing packages. By following the diagram’s instructions, technicians can ensure proper integration with the vehicle’s electrical system, avoiding potential malfunctions or safety hazards.

- Troubleshooting Modifications: Wiring diagrams become indispensable when troubleshooting modifications made to the electrical system. By comparing the modified wiring to the original diagram, technicians can pinpoint any errors or inconsistencies that may have caused electrical issues.

In conclusion, wiring diagrams are essential tools for modifying electrical systems in Peterbilt 379 vehicles. They provide a comprehensive understanding of the electrical architecture, enabling technicians and enthusiasts to make informed decisions about system modifications, ensuring compatibility, functionality, and safety.

Safety

In the context of “Wiring Diagram For Peterbilt 379”, the aspect of “Safety” underscores the critical role that wiring diagrams play in maintaining the integrity and reliability of electrical systems, minimizing the potential for dangerous situations and ensuring the safety of both the vehicle and its occupants.

- Accurate Installations: Wiring diagrams provide clear and accurate instructions for installing and connecting electrical components, minimizing the risk of improper connections, shorts, or overloads that could lead to electrical fires or other hazards.

- Proper Circuit Protection: Wiring diagrams specify the appropriate fuses and circuit breakers for each electrical circuit, ensuring that overcurrents are safely interrupted before they can cause damage or pose a fire risk.

- Grounding and Bonding: Wiring diagrams ensure proper grounding and bonding of electrical components, providing a safe path for fault currents and preventing the accumulation of static electricity that could lead to sparks or fires.

- Regular Maintenance: Wiring diagrams facilitate regular maintenance and inspection of electrical systems, allowing technicians to identify potential problems early on and address them before they become safety hazards.

In summary, wiring diagrams are essential for ensuring the safety and reliability of electrical systems in Peterbilt 379 vehicles. By providing clear instructions for installation, circuit protection, grounding, and maintenance, wiring diagrams help to prevent electrical fires, reduce the risk of accidents, and ensure the safe operation of these heavy-duty vehicles.

Documentation

Within the context of “Wiring Diagram For Peterbilt 379”, the aspect of “Documentation” highlights the significance of wiring diagrams as a comprehensive record of the vehicle’s electrical system. These diagrams provide essential information for maintenance, troubleshooting, and repairs, ensuring the long-term reliability and safety of Peterbilt 379 vehicles.

- Historical Record: Wiring diagrams serve as a historical record of the electrical system’s design and modifications over time. By documenting changes and updates, they provide valuable insights for technicians and owners who need to understand the system’s evolution.

- Maintenance Planning: Wiring diagrams are crucial for planning and scheduling maintenance tasks. They help technicians identify components that require regular inspection, cleaning, or replacement, minimizing the risk of electrical failures.

- Troubleshooting Guide: In the event of electrical problems, wiring diagrams serve as an invaluable troubleshooting guide. Technicians can use them to trace circuits, identify potential faults, and determine the most efficient repair strategy.

- Repair Accuracy: Wiring diagrams ensure accurate repairs by providing detailed instructions for component replacement and wiring reconnections. This reduces the risk of errors and ensures that the electrical system is restored to its original functionality.

In conclusion, wiring diagrams are an indispensable form of documentation for Peterbilt 379 vehicles. They provide a comprehensive record of the electrical system’s design, facilitate maintenance planning, guide troubleshooting efforts, and ensure accurate repairs. By serving as a valuable reference throughout the vehicle’s lifespan, wiring diagrams contribute to the safe and reliable operation of Peterbilt 379 vehicles.

Training

Wiring diagrams play a critical role in training technicians to troubleshoot and repair electrical systems in Peterbilt 379 vehicles. They provide a visual representation of the electrical system’s components and connections, making it easier for technicians to understand how the system works and how to identify and fix problems.

One of the main benefits of using wiring diagrams for training is that they allow technicians to see the entire electrical system at once. This helps them to understand the relationships between different components and how they work together. Wiring diagrams also show the location of fuses, relays, and other important components, which can be helpful for troubleshooting problems.

In addition to providing a visual representation of the electrical system, wiring diagrams also contain important information about the system’s operation. This information can be used by technicians to diagnose problems and determine the best course of action for repair.

For example, a wiring diagram can show the technician the amperage rating of a particular fuse or the voltage drop across a specific component. This information can help the technician to determine if the fuse is blown or if the component is faulty.

Wiring diagrams are an essential tool for training technicians to troubleshoot and repair electrical systems in Peterbilt 379 vehicles. They provide a visual representation of the system’s components and connections, as well as important information about the system’s operation. This information can help technicians to quickly and accurately diagnose and repair electrical problems.

Customization

In the context of “Wiring Diagram For Peterbilt 379”, the aspect of “Customization” highlights the adaptability and flexibility of wiring diagrams to meet the unique requirements of specific vehicles or applications. This customization capability allows technicians and enthusiasts to tailor the electrical system to their specific needs, ensuring optimal performance and functionality.

A critical reason for customizing wiring diagrams is to accommodate modifications and upgrades to the electrical system. As vehicles undergo modifications, such as the installation of additional lighting systems, audio equipment, or specialized equipment, the original wiring diagram may not suffice. Customization allows technicians to incorporate these changes into the diagram, ensuring that the electrical system remains organized, efficient, and safe.

For example, in a Peterbilt 379 used for long-haul trucking, the owner may choose to install additional lighting systems for enhanced visibility during night driving. By customizing the wiring diagram, the technician can integrate the new lighting system into the existing electrical architecture, ensuring proper power distribution and circuit protection.

Another practical application of customization is in the creation of custom vehicle configurations. Specialty vehicles, such as those used for emergency response or construction, often require unique electrical configurations to accommodate specialized equipment and accessories. By customizing the wiring diagram, technicians can design and implement an electrical system that meets the specific demands of these applications.

The ability to customize wiring diagrams empowers technicians and enthusiasts to unleash their creativity and ingenuity in tailoring electrical systems to their specific needs. This customization capability is a key aspect of “Wiring Diagram For Peterbilt 379”, allowing for the creation of unique and optimized electrical configurations that meet the demands of various applications.

Related Posts