Wiring a lamp holder entails connecting electrical wires to a lamp holder, enabling the attachment of a light bulb and subsequent illumination. It serves as a vital component in electrical circuits, allowing the safe and efficient use of lighting fixtures.

The proper wiring of lamp holders ensures a reliable electrical connection, preventing potential hazards and ensuring the intended functionality of the lighting system. Benefits include enhanced safety, improved performance, and extended lifespan of the lamp holder.

A key historical development in this field was the invention of the screw-in lamp holder by Thomas Edison. This standardized design simplified lamp installation and revolutionized the way lighting was utilized.

This concise overview will delve into the essential aspects of wiring a lamp holder, its practical applications, and the impact of its evolution on modern lighting solutions.

Wiring a lamp holder encompasses a multitude of essential aspects that dictate its proper functioning and overall effectiveness as a component in electrical circuits. Understanding these aspects is paramount to ensuring safety, optimizing performance, and extending the lifespan of lighting systems.

- Electrical Safety: Wiring must adhere to electrical codes and standards to prevent accidents, fires, and electrical shocks.

- Proper Gauge Wire: Using the correct wire gauge ensures safe current flow and prevents overheating.

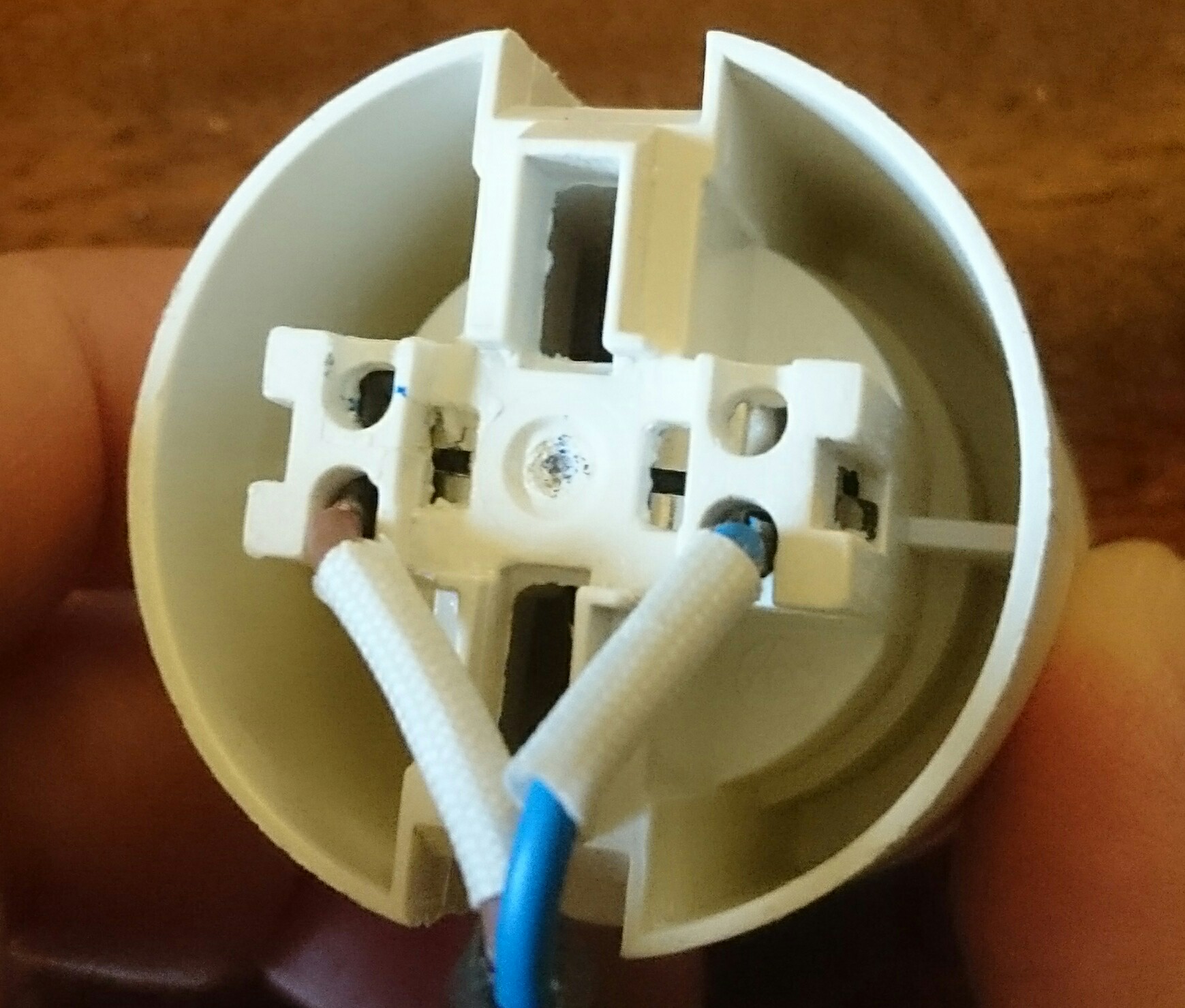

- Secure Connections: Tight and secure connections between wires and terminals are crucial for reliable electrical contact.

- Insulation: Proper insulation prevents electrical shorts and ensures safety during handling.

- Strain Relief: Strain relief mechanisms protect connections from stress and prevent accidental disconnections.

- Compatibility: The lamp holder must be compatible with the type of lamp being used, considering factors like wattage and base type.

- Environmental Factors: Considerations such as moisture, temperature, and vibration must be addressed to ensure reliable performance in various environments.

- Maintenance and Inspection: Regular maintenance and inspection are essential to identify and address any potential issues or deterioration over time.

These aspects are interconnected and equally important for ensuring the optimal performance of a wired lamp holder. Neglecting any of these aspects can compromise safety, functionality, and the longevity of the lighting system. Understanding and adhering to these guidelines are crucial for safe and effective electrical installations.

Electrical Safety

When wiring a lamp holder, adhering to electrical codes and standards is paramount for ensuring the safety and reliability of the electrical system. Electrical codes and standards provide guidelines for the proper installation and use of electrical components, including lamp holders, to minimize the risk of electrical hazards.

Failure to comply with electrical codes and standards can lead to various adverse consequences:

- Electrical shocks: Improper wiring can create pathways for electrical current to flow unintentionally, posing a risk of electrical shocks to users.

- Fires: Overloaded circuits or loose connections can generate excessive heat, increasing the risk of electrical fires.

- Equipment damage: Incorrect wiring can damage the lamp holder, the lamp itself, or other electrical components.

By following electrical codes and standards, electricians and DIY enthusiasts can ensure that lamp holders are wired safely and correctly. This includes using the appropriate wire gauge, making secure connections, and providing proper insulation and strain relief. By adhering to these guidelines, individuals can help prevent electrical accidents, protect property, and ensure the longevity of their lighting systems.

Proper Gauge Wire

In the context of “Wiring A Lamp Holder”, selecting the correct wire gauge is crucial for ensuring the safe and efficient operation of the electrical system. The appropriate wire gauge allows for the safe passage of electrical current without overheating, a key factor in preventing electrical hazards and ensuring the longevity of the lighting system.

- Electrical Current Capacity: The wire gauge must be able to handle the amount of electrical current that will be flowing through the circuit. Using a wire gauge that is too small can lead to overheating and potential fire hazards.

- Voltage Drop: The wire gauge also affects the voltage drop over the length of the wire. A wire gauge that is too small can result in excessive voltage drop, leading to dimmer lighting or malfunctioning electrical devices.

- Heat Dissipation: The wire gauge influences the ability of the wire to dissipate heat. A wire gauge that is too small can overheat, potentially damaging the insulation and increasing the risk of electrical fires.

- Building Codes and Standards: Electrical codes and standards often specify the minimum wire gauge that can be used for different applications. These codes are in place to ensure the safety and reliability of electrical installations.

By understanding and adhering to the principles of proper wire gauge selection, individuals can ensure that their lamp holders are wired safely and effectively. This involves selecting a wire gauge that meets the electrical requirements of the circuit, considering factors such as current capacity, voltage drop, heat dissipation, and compliance with electrical codes and standards.

Secure Connections

In the realm of “Wiring A Lamp Holder”, establishing secure connections between wires and terminals is paramount for ensuring the safe and reliable operation of the electrical system. Loose or improperly secured connections can lead to a myriad of issues, ranging from flickering lights to electrical fires. A comprehensive understanding of the various facets of secure connections is essential for proper lamp holder wiring.

- Proper Crimping: Crimping is a technique used to create a secure connection between a wire and a terminal. Using the appropriate crimping tool and following the manufacturer’s guidelines ensures a strong and reliable connection that can withstand vibration and movement.

- Screw Terminals: Screw terminals provide a simple and effective method of securing wires to terminals. Tightening the screw creates a secure mechanical connection that prevents the wire from pulling out. However, overtightening can damage the terminal or the wire.

- Soldered Connections: Soldering involves melting solder onto the wire and terminal, creating a permanent and highly conductive connection. While strong and reliable, soldered connections require specialized equipment and expertise.

- Push-In Terminals: Push-in terminals allow for quick and easy wire insertion without the need for tools. However, they may not be as secure as other connection methods and can loosen over time.

Understanding and implementing these secure connection techniques are crucial for ensuring the proper functioning and longevity of lamp holders. Secure connections minimize electrical resistance, prevent overheating, and reduce the risk of electrical hazards. By adhering to these principles, individuals can ensure the safe and reliable operation of their lighting systems.

Insulation

In the context of “Wiring A Lamp Holder”, proper insulation plays a critical role in preventing electrical shorts and ensuring the safety of the electrical system. Electrical shorts occur when electrical current takes an unintended path, often due to exposed or damaged wires. Insulation acts as a protective layer around electrical wires, preventing them from coming into contact with each other or with other conductive surfaces.

Without proper insulation, electrical shorts can lead to a range of hazards, including:

- Electrical shocks

- Electrical fires

- Damage to electrical equipment

Using properly insulated wires and terminals is essential for safe lamp holder wiring. The insulation material should be rated for the voltage and temperature of the electrical circuit. It should also be resistant to wear, tear, and environmental factors such as moisture and chemicals.

In practical applications, proper insulation in lamp holder wiring can be seen in:

- The use of insulated wire nuts or electrical tape to cover exposed wire connections.

- The use of insulated terminals to connect wires to lamp holders.

- The use of insulated wire strippers to remove insulation from wires without damaging the conductors.

Understanding the importance of insulation in lamp holder wiring is crucial for ensuring the safe and reliable operation of lighting systems. Proper insulation prevents electrical shorts, reduces the risk of electrical hazards, and extends the lifespan of electrical components.

Strain Relief

In the context of “Wiring A Lamp Holder”, strain relief mechanisms play a critical role in ensuring the longevity and safety of electrical connections. Strain relief refers to the use of physical mechanisms to prevent excessive force or stress from being applied to wire connections, which can lead to damage or accidental disconnections.

Strain relief is particularly important in lamp holder wiring due to the potential for movement and vibration. Without proper strain relief, the wires connected to the lamp holder can become loose over time, leading to intermittent connections, flickering lights, or even electrical hazards.

In practical applications, strain relief in lamp holder wiring can be achieved through various methods, such as:

- Strain relief clamps: These clamps are attached to the lamp holder and provide a secure grip on the wires, preventing them from pulling out.

- Cable ties: Cable ties can be used to bundle wires together and secure them to the lamp holder, reducing strain on the individual wire connections.

- Electrical tape: Electrical tape can be wrapped around the wires and the lamp holder to provide additional support and prevent movement.

Understanding the importance of strain relief in lamp holder wiring is crucial for ensuring the safe and reliable operation of lighting systems. By implementing proper strain relief mechanisms, individuals can prevent accidental disconnections, extend the lifespan of electrical components, and minimize the risk of electrical hazards.

Compatibility

In the context of “Wiring A Lamp Holder”, compatibility between the lamp holder and the lamp is essential for proper functioning and safety.

The lamp holder must be compatible with the lamp’s wattage to ensure that the electrical circuit can safely handle the amount of power consumed by the lamp. Using a lamp holder with a lower wattage rating than the lamp can lead to overheating and potential fire hazards.

Additionally, the lamp holder must be compatible with the lamp’s base type. Different types of lamps, such as incandescent, fluorescent, and LED, have different base types that are designed to fit specific lamp holders. Using a lamp holder that is not compatible with the lamp’s base type can result in a poor connection, flickering, or even damage to the lamp or the lamp holder.

Real-life examples of compatibility issues in lamp holder wiring include:

- Using a standard lamp holder with a high-wattage bulb, which can lead to overheating and potential fire hazards.

- Using a GU10 lamp holder with an E27 base bulb, which will result in a poor connection and flickering.

Understanding the importance of compatibility in lamp holder wiring is crucial for ensuring the safe and reliable operation of lighting systems.

By selecting a lamp holder that is compatible with the type of lamp being used, individuals can prevent electrical hazards, extend the lifespan of electrical components, and ensure optimal lighting performance.

Environmental Factors

In the context of “Wiring A Lamp Holder,” environmental factors play a critical role in ensuring the reliable performance and longevity of the electrical system. Factors such as moisture, temperature, and vibration can significantly impact the integrity of electrical connections and the overall safety of the lighting system.

Moisture can lead to corrosion of electrical contacts and terminals, increasing resistance and potentially leading to overheating, electrical shorts, or even fires. High temperatures can also degrade insulation materials, reducing their effectiveness and increasing the risk of electrical hazards. Vibration, caused by factors such as machinery or external forces, can loosen connections and lead to intermittent operation or complete failure of the lamp holder.

Real-life examples of the impact of environmental factors on lamp holder wiring include:

- Moisture: Installing a lamp holder in a bathroom or other humid environment without proper moisture protection can lead to corrosion and electrical hazards.

- Temperature: Using a lamp holder in an outdoor setting without considering the temperature range can result in insulation degradation and potential electrical failures.

- Vibration: Installing a lamp holder in a vibrating environment, such as near heavy machinery, can cause connections to loosen and lead to intermittent lighting or electrical faults.

Understanding the importance of environmental factors in lamp holder wiring allows individuals to take appropriate measures to mitigate these risks. This may involve using weatherproof lamp holders in outdoor or humid environments, selecting high-temperature rated components for high-heat applications, and employing vibration-resistant mounting techniques in areas prone to vibration.

By considering environmental factors and implementing appropriate (countermeasures), individuals can ensure the safe and reliable operation of lamp holders in various environments, extending their lifespan and minimizing the risk of electrical hazards.

Maintenance and Inspection

In the context of “Wiring A Lamp Holder,” regular maintenance and inspection play a crucial role in ensuring the ongoing safety, reliability, and optimal performance of the electrical system. Maintenance and inspection involve examining electrical connections, components, and the overall condition of the lamp holder to identify and address any potential issues or signs of deterioration that may arise over time.

Electrical connections can loosen due to factors such as vibration or thermal expansion and contraction. Regular inspection allows for the early detection of loose connections, enabling prompt tightening or repair, thus preventing potential electrical hazards such as arcing, overheating, or even fires.

Furthermore, components within the lamp holder, such as terminals and insulation materials, can degrade over time due to factors such as exposure to heat, moisture, or electrical stress. Regular inspection helps identify any signs of damage or deterioration, allowing for timely replacement or repair before they lead to electrical failures or safety concerns.

Real-life examples of the importance of maintenance and inspection in “Wiring A Lamp Holder” include:

- Loose Connections: A loose connection in the lamp holder can cause flickering lights, intermittent operation, or complete failure of the lamp. Regular inspection and tightening of connections can prevent these issues and ensure reliable electrical contact.

- Damaged Insulation: Deteriorated insulation can expose live wires, increasing the risk of electrical shocks or short circuits. Inspection can identify damaged insulation, allowing for prompt replacement and restoration of electrical safety.

Understanding the importance of maintenance and inspection in “Wiring A Lamp Holder” empowers individuals to proactively address potential issues, minimizing the risk of electrical hazards, extending the lifespan of electrical components, and ensuring the continued safe and reliable operation of their lighting systems.

Related Posts