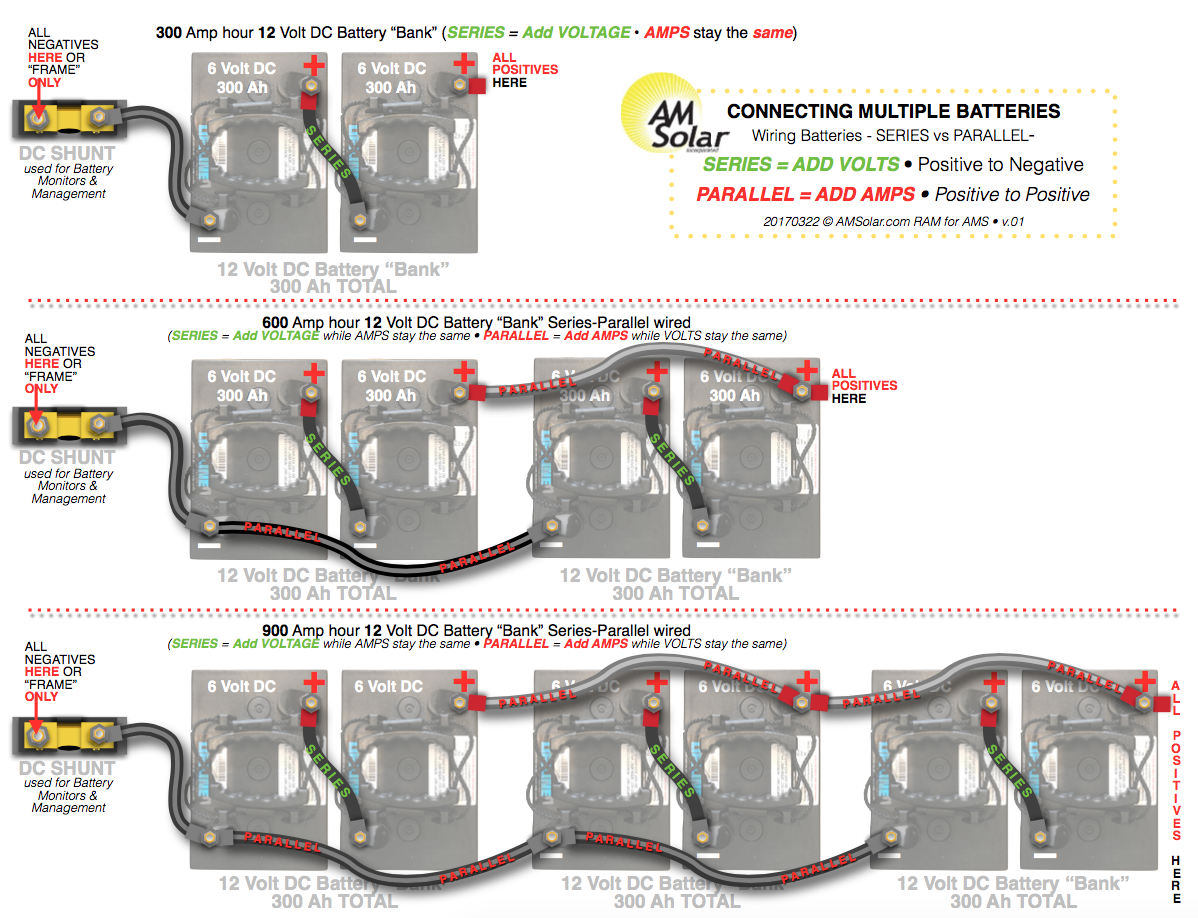

In the field of electricity, connecting batteries in series and parallel is a technique employed to combine their voltage or current capabilities. Wiring six 6-volt batteries in series involves connecting the positive terminal of one battery to the negative terminal of the next, forming a single string. This configuration multiplies the voltage while maintaining the same current capacity. Conversely, wiring the batteries in parallel involves connecting all the positive terminals together and all the negative terminals together, resulting in a higher current capacity at the same voltage.

This technique holds significant relevance in various applications, such as powering electric vehicles, providing backup power systems, or creating specific voltage requirements for electronic devices. Its benefits include increased voltage or current, extended battery life, and the ability to customize power output to meet specific needs. Historically, this technique has been crucial in the development of electric vehicles, allowing for longer driving ranges and higher speeds.

Moving forward, this article will delve deeper into the specifics of wiring 6 6-volt batteries in series and parallel, exploring its technical aspects, optimal configurations, and practical applications. The discussion will provide a comprehensive understanding of this fundamental electrical practice.

Wiring 6 6-volt batteries in series and parallel is a crucial technique in electrical systems, offering versatility and customization of voltage and current output. Understanding the essential aspects of this technique is paramount for effective implementation and harnessing its full potential.

- Voltage Configuration: Wiring batteries in series increases the overall voltage while maintaining the same current capacity.

- Current Capacity: Connecting batteries in parallel increases the overall current capacity while maintaining the same voltage.

- Battery Life: By distributing the load across multiple batteries, wiring in series or parallel can extend battery life.

- Power Customization: This technique allows for tailoring the power output to specific requirements, such as higher voltage or current.

- Electrical Vehicles: Wiring batteries in series and parallel is essential for electric vehicles, enabling longer driving ranges and higher speeds.

- Backup Power Systems: This technique is valuable in backup power systems, providing extended runtime and redundancy.

- Battery Management Systems: Battery management systems play a crucial role in monitoring and controlling the charging and discharging process of batteries wired in series or parallel.

- Safety Considerations: Proper wiring techniques, including appropriate gauge wires and connectors, are vital for safety.

- Cost Optimization: Wiring batteries in series or parallel can be cost-effective compared to using a single high-voltage or high-current battery.

- Load Requirements: The load’s voltage and current requirements dictate the appropriate wiring configuration.

These essential aspects provide a comprehensive overview of wiring 6 6-volt batteries in series and parallel. By understanding and considering these factors, practitioners can optimize electrical systems, improve performance, and ensure safety.

Voltage Configuration

Wiring 6 6-volt batteries in series is a direct application of this voltage configuration principle. By connecting the batteries in a series, the overall voltage is increased to 36 volts (6 volts x 6 batteries) while maintaining the same current capacity as a single 6-volt battery. This configuration is commonly used in applications requiring higher voltage, such as electric vehicles, backup power systems, or industrial equipment.

A real-life example of this voltage configuration is in an electric vehicle. To achieve the necessary voltage for powering the electric motor, multiple batteries are wired in series. This allows the vehicle to operate at higher speeds and cover longer distances.

Understanding this voltage configuration is crucial for designing and maintaining electrical systems. By calculating the desired voltage and selecting the appropriate number of batteries, practitioners can achieve the required voltage output while ensuring the system operates within its current capacity limits.

In summary, the voltage configuration principle of wiring batteries in series to increase voltage while maintaining current capacity is a fundamental aspect of “Wiring 6 6 Volt Batteries In Series And Parallel.” It enables the customization of voltage output for various applications, ranging from portable devices to electric vehicles and backup power systems.

Current Capacity

Within the context of “Wiring 6 6 Volt Batteries In Series And Parallel”, understanding the concept of current capacity is crucial. Connecting batteries in parallel allows for increased current capacity, which plays a vital role in various applications. Here are four key facets of current capacity in relation to wiring 6 6-volt batteries in parallel:

- Load Requirements: The current capacity of the battery configuration must meet the demands of the load. Wiring batteries in parallel ensures that the combined current capacity can power the load effectively.

- Parallel Configuration: Connecting batteries in parallel involves joining the positive terminals together and the negative terminals together. This configuration allows the current to distribute across the batteries, increasing the overall current capacity.

- Real-Life Example: An electric drill is a practical example of using parallel configuration. Multiple batteries connected in parallel provide the necessary current capacity to power the drill’s high-torque motor.

- Battery Life: By distributing the load across multiple batteries in parallel, the overall battery life is extended compared to using a single battery with the same current capacity.

These facets highlight the significance of current capacity in “Wiring 6 6 Volt Batteries In Series And Parallel”. By understanding and considering these aspects, practitioners can optimize electrical systems, improve performance, and ensure the system operates within its intended parameters.

Battery Life

In the context of “Wiring 6 6 Volt Batteries In Series And Parallel”, understanding the impact on battery life is crucial. Distributing the load across multiple batteries can significantly extend battery life, making this technique valuable in various applications. Here is a detailed exploration of this aspect:

- Reduced Individual Battery Load: Wiring batteries in series or parallel distributes the load across multiple batteries, reducing the stress on each individual battery. This reduces the rate of depletion and extends the lifespan of each battery.

- Real-Life Example: Electric Vehicles: In electric vehicles, multiple batteries are wired in series or parallel to meet the high power demands. This configuration extends the overall battery life, allowing for longer driving ranges on a single charge.

- Battery Management Systems: Battery management systems play a vital role in monitoring and controlling the charging and discharging of batteries wired in series or parallel. By optimizing the charging and discharging cycles, these systems further enhance battery life.

- Cost Savings: Extending battery life through wiring in series or parallel reduces the frequency of battery replacements, leading to cost savings over the long term.

These facets underscore the importance of battery life extension in “Wiring 6 6 Volt Batteries In Series And Parallel.” By distributing the load across multiple batteries, practitioners can enhance the durability and performance of their electrical systems.

Power Customization

Within the context of “Wiring 6 6 Volt Batteries In Series And Parallel”, power customization is a crucial aspect that enables the tailoring of power output to meet specific requirements. This technique empowers practitioners to design electrical systems that precisely match their voltage and current needs, leading to optimized performance and efficiency.

- Voltage Customization: Wiring batteries in series allows for increased voltage output, which is essential for applications such as electric vehicles, power tools, and industrial equipment.

- Current Customization: Connecting batteries in parallel increases the current capacity, which is crucial for powering high-current devices like audio amplifiers, welding equipment, and portable electronics.

- Real-World Example: Electric Vehicles: In electric vehicles, battery packs are configured using a combination of series and parallel connections to achieve the desired voltage and current output, enabling efficient and powerful operation.

- Cost Optimization: Power customization through wiring batteries in series or parallel allows for cost-effective solutions compared to using a single high-voltage or high-current battery.

In conclusion, the power customization aspect of “Wiring 6 6 Volt Batteries In Series And Parallel” provides immense flexibility and control over the electrical system’s power output. By understanding the principles of series and parallel connections, practitioners can tailor the voltage and current to match the specific requirements of their applications, resulting in optimized performance, efficiency, and cost-effectiveness.

Electrical Vehicles

Within the realm of “Wiring 6 6 Volt Batteries In Series And Parallel”, the aspect of electric vehicles holds significant importance. Wiring batteries in series and parallel is a fundamental technique employed in electric vehicles, empowering them with extended driving ranges and enhanced speeds. This section delves into the intricacies of this aspect, exploring its components, real-life examples, and implications.

- Battery Configuration: Electric vehicles utilize multiple batteries wired in series and parallel to achieve the required voltage and current output. This configuration optimizes the power delivery to the electric motor, enabling efficient performance and extended driving ranges.

- Voltage Optimization: Wiring batteries in series increases the overall voltage, allowing electric vehicles to reach higher speeds. This is particularly crucial for highway driving and uphill climbs, where higher torque is required.

- Current Capacity: Connecting batteries in parallel enhances the current capacity, providing the necessary power to accelerate quickly and handle heavy loads. This is essential for electric vehicles that require high bursts of power, such as during overtaking or merging into traffic.

- Range Optimization: By distributing the load across multiple batteries, wiring in series and parallel extends the driving range of electric vehicles. This is a critical factor in reducing range anxiety and increasing the practicality of electric vehicles for long-distance travel.

In conclusion, the aspect of “Electrical Vehicles: Wiring batteries in series and parallel is essential for electric vehicles, enabling longer driving ranges and higher speeds.” underscores the crucial role of this technique in the design and operation of electric vehicles. By understanding and applying the principles of series and parallel connections, engineers and manufacturers can optimize the performance, efficiency, and driving experience of electric vehicles.

Backup Power Systems

Within the context of “Wiring 6 6 Volt Batteries In Series And Parallel”, the application of this technique in backup power systems holds significant importance. Backup power systems rely on stored energy to provide power during outages or emergencies. Wiring batteries in series and parallel is a crucial aspect that contributes to the effectiveness and reliability of these systems.

By connecting multiple batteries in series, the overall voltage is increased, allowing backup power systems to supply the necessary voltage for critical equipment. This is particularly important in areas where power outages are frequent or prolonged. Additionally, wiring batteries in parallel increases the current capacity, ensuring that the system can deliver sufficient power to operate essential devices and appliances.

A real-life example of this technique in action is in hospitals and data centers. These facilities require uninterrupted power supply to maintain critical operations. Backup power systems utilizing batteries wired in series and parallel provide extended runtime, ensuring that essential equipment continues to function during power failures. The redundancy offered by multiple batteries also enhances reliability, minimizing the risk of system failure.

Understanding the connection between “Backup Power Systems: This technique is valuable in backup power systems, providing extended runtime and redundancy.” and “Wiring 6 6 Volt Batteries In Series And Parallel” empowers practitioners to design and implement effective backup power solutions. By carefully considering the voltage and current requirements of the critical load, as well as the desired runtime and redundancy levels, engineers can optimize the configuration of batteries in series and parallel to meet specific needs.

In conclusion, the technique of wiring 6 6 volt batteries in series and parallel plays a vital role in backup power systems, providing extended runtime and redundancy. This understanding is crucial for ensuring the reliability and effectiveness of backup power solutions, particularly in critical applications such as healthcare and data management.

Battery Management Systems

Within the context of “Wiring 6 6 Volt Batteries In Series And Parallel”, understanding the connection to battery management systems is critical. These systems play a central role in ensuring the safe, efficient, and reliable operation of batteries wired in series or parallel.

Battery management systems monitor and control the charging and discharging process of batteries to prevent overcharging, over-discharging, and other hazardous conditions. They also balance the individual cells within a battery pack, ensuring that each cell receives the appropriate amount of charge and discharge current. This helps to extend battery life and improve overall performance.

For example, in electric vehicles that utilize multiple batteries wired in series and parallel, battery management systems are essential for maintaining optimal battery performance. They prevent over-discharging, which can damage the batteries and reduce their lifespan. Additionally, they ensure that the batteries are charged evenly, maximizing the vehicle’s range and efficiency.

Understanding the relationship between “Battery Management Systems: Battery management systems play a crucial role in monitoring and controlling the charging and discharging process of batteries wired in series or parallel.” and “Wiring 6 6 Volt Batteries In Series And Parallel” enables practitioners to design and implement robust and reliable battery systems. By integrating effective battery management systems, they can extend battery life, improve performance, and enhance safety.

In summary, battery management systems are critical components in applications involving batteries wired in series or parallel. They ensure safe and efficient operation, monitor and control the charging and discharging process, balance individual cells, and extend battery life. Understanding this connection is vital for optimizing the performance and reliability of battery-powered systems.

Safety Considerations

In the context of “Wiring 6 6 Volt Batteries In Series And Parallel,” safety considerations are paramount. Proper wiring techniques, appropriate gauge wires, and suitable connectors are essential to prevent electrical hazards and ensure the safe operation of battery systems. This section explores the critical connection between safety considerations and wiring 6 6 volt batteries in series and parallel.

When batteries are wired together, it is crucial to use wires with an appropriate gauge that can handle the current flow without overheating. Oversized wires reduce the risk of resistance and potential fire hazards. Similarly, using proper connectors ensures secure connections, preventing arcing and short circuits.

For instance, in electric vehicles that utilize multiple batteries wired in series and parallel, safety considerations are of utmost importance. Improper wiring or the use of inadequate gauge wires can lead to overheating, electrical fires, and even explosions. Battery management systems typically incorporate safety features to monitor and protect the batteries, but proper wiring remains a critical component of overall safety.

Understanding the connection between “Safety Considerations: Proper wiring techniques, including appropriate gauge wires and connectors, are vital for safety.” and “Wiring 6 6 Volt Batteries In Series And Parallel” empowers practitioners to design and implement safe and reliable battery systems. By adhering to safety guidelines, using appropriate materials, and thoroughly testing the system, practitioners can minimize risks and ensure the safe operation of battery-powered applications.

In summary, safety considerations are an integral part of “Wiring 6 6 Volt Batteries In Series And Parallel.” Proper wiring techniques, appropriate gauge wires, and suitable connectors are essential to prevent electrical hazards, ensure safe operation, and maintain the integrity of battery systems in various applications, including electric vehicles, backup power systems, and portable devices.

Cost Optimization

In the context of “Wiring 6 6 Volt Batteries In Series And Parallel,” cost optimization is a critical consideration. Wiring batteries in series or parallel can lead to significant cost savings compared to using a single high-voltage or high-current battery. This is especially relevant for applications requiring specific voltage or current requirements.

Consider an electric vehicle that requires a high-voltage battery pack. Using multiple 6-volt batteries wired in series to achieve the desired voltage is often more cost-effective than purchasing a single high-voltage battery. Additionally, wiring batteries in parallel to increase current capacity can be more economical than purchasing a single high-current battery.

Furthermore, using multiple smaller batteries provides flexibility and redundancy. If one battery fails, the system can continue operating with the remaining batteries, reducing downtime and maintenance costs. This is particularly advantageous in critical applications such as backup power systems or medical equipment.

Understanding the cost optimization potential of “Wiring batteries in series or parallel” empowers practitioners to design and implement cost-effective battery systems that meet specific performance requirements. By carefully evaluating the voltage and current needs of the application, as well as considering the cost and availability of batteries, practitioners can optimize the configuration and minimize overall system costs.

In summary, the connection between “Cost Optimization: Wiring batteries in series or parallel can be cost-effective compared to using a single high-voltage or high-current battery.” and “Wiring 6 6 Volt Batteries In Series And Parallel” highlights the importance of considering cost-effectiveness in battery system design. By leveraging the principles of series and parallel connections, practitioners can achieve the desired voltage and current requirements while minimizing costs, enhancing the practicality and affordability of battery-powered applications.

Load Requirements

In the realm of “Wiring 6 6 Volt Batteries In Series And Parallel,” understanding the significance of load requirements is crucial. The load’s voltage and current demands directly influence the optimal wiring configuration, ensuring compatibility and efficient operation. This aspect plays a pivotal role in designing and implementing reliable battery systems that meet specific application needs.

- Voltage Compatibility: The load’s voltage requirement must align with the total voltage provided by the battery configuration. Wiring batteries in series increases the voltage, while parallel wiring maintains the voltage. Selecting the appropriate configuration ensures the load receives the necessary voltage to function correctly.

- Current Capacity: The load’s current draw should not exceed the current capacity of the battery configuration. Wiring batteries in parallel increases the current capacity, allowing the load to draw more current without depleting the batteries prematurely. Matching the current capacity to the load’s demand ensures stable operation.

- Power Consumption: The load’s power consumption determines the overall power output required from the battery configuration. By considering the load’s voltage and current requirements, practitioners can calculate the necessary power output and configure the batteries accordingly. This optimization ensures efficient energy utilization and extends battery life.

- Real-Life Example: Electric Vehicles: In electric vehicles, the load comprises electric motors, controllers, and other components. Understanding the voltage and current requirements of these components is essential in designing the battery pack. Wiring batteries in series and parallel allows for customization of the battery configuration to meet the specific voltage and current demands of the electric vehicle.

In summary, the load’s voltage and current requirements dictate the appropriate wiring configuration for “Wiring 6 6 Volt Batteries In Series And Parallel.” By carefully considering these requirements, practitioners can design and implement battery systems that are compatible with the load, provide reliable power, and optimize energy efficiency. This understanding is pivotal in various applications, from portable electronics to electric vehicles and backup power systems.

Related Posts