A “Wiring 240v Plug” refers to the electrical wiring and components used to connect an appliance or device to a 240-volt power source. It typically involves connecting the appliance’s wires to a 240-volt outlet or circuit breaker panel, ensuring a secure and functional electrical connection.

Wiring a 240v plug is crucial for various applications, such as powering high-voltage appliances like clothes dryers, ovens, and air conditioners. It allows for efficient and safe operation of these appliances, delivering the necessary power to perform their functions effectively.

In the early days of electrical wiring, 240v plugs were not widely used due to safety concerns. However, with advancements in electrical safety standards and insulation materials, 240v plugs became more common, providing a reliable and convenient way to power heavy-duty appliances in homes and commercial establishments.

The essential aspects of “Wiring 240v Plug” hold immense significance in ensuring the safe and efficient operation of high-voltage appliances. These aspects encompass various dimensions, including electrical safety, wiring techniques, and regulatory compliance.

- Electrical Safety: Paramount importance in preventing electrical hazards, ensuring proper insulation, grounding, and circuit protection.

- Wiring Techniques: Skilled execution of wiring practices, adhering to electrical codes and standards, using appropriate materials and tools.

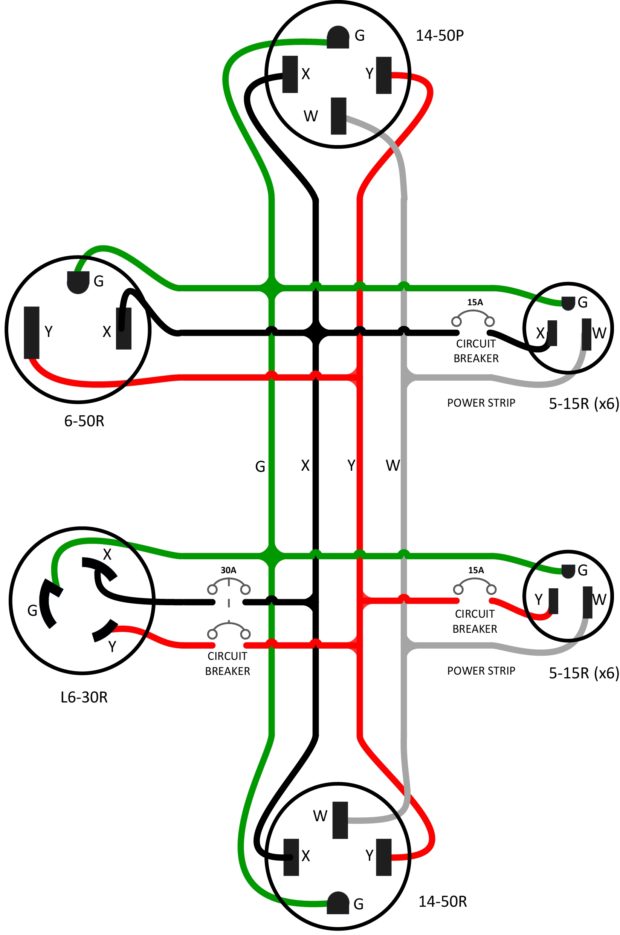

- Outlet Compatibility: Matching the plug type to the corresponding outlet configuration, ensuring a secure and functional connection.

- Circuit Breaker Protection: Installing appropriate circuit breakers to safeguard against overcurrent and short circuits, preventing damage to appliances and electrical systems.

- Gauge and Length: Selecting the correct wire gauge and length, considering the amperage and voltage requirements of the appliance.

- Insulation and Sheathing: Utilizing high-quality insulation and sheathing materials to prevent electrical shock and ensure durability.

- Grounding: Establishing a proper grounding system to provide a safe path for fault currents, protecting against electrical shocks.

- Polarity: Maintaining proper polarity in wiring connections, ensuring the correct flow of current and preventing malfunctions.

- Strain Relief: Incorporating strain relief devices to prevent excessive bending or pulling on the wire connections, ensuring longevity.

- Regulatory Compliance: Adhering to local electrical codes and regulations, ensuring compliance with safety standards and building requirements.

These aspects are interconnected and crucial for the proper functioning of 240v plugs. Understanding and adhering to these aspects empower individuals to safely and effectively wire 240v plugs, ensuring the reliable operation of high-voltage appliances.

Electrical Safety

Electrical safety is paramount when it comes to wiring 240v plugs, as high-voltage appliances pose significant electrical hazards. This aspect involves a combination of measures to prevent electrical shocks, fires, and other accidents, ensuring the safety of individuals and the proper functioning of electrical systems.

- Insulation: Non-conductive materials encasing electrical wires and components to prevent current leakage and electrical shocks.

- Grounding: A path for electrical current to flow safely into the ground, protecting against electrical shocks in case of insulation failure.

- Circuit Protection: Devices like fuses and circuit breakers that automatically interrupt the flow of current in case of overloads or short circuits, preventing damage to appliances and electrical systems.

- Proper Wiring Techniques: Adhering to electrical codes and standards, using appropriate wiring materials, and ensuring secure connections to prevent loose connections, arcing, and electrical fires.

These facets of electrical safety are interconnected and crucial for the safe operation of 240v plugs. Understanding and implementing these measures empower individuals to mitigate electrical hazards, ensuring a safe and reliable electrical environment.

Wiring Techniques

In the realm of “Wiring 240v Plug”, wiring techniques play a pivotal role in ensuring the safe and efficient operation of high-voltage appliances. Skilled execution of wiring practices, adherence to electrical codes and standards, and the use of appropriate materials and tools form the cornerstone of effective and reliable wiring.

-

Electrical Code Compliance:

Adhering to established electrical codes and standards is paramount. These codes provide guidelines for safe wiring practices, ensuring compliance with industry best practices and local regulations. -

Proper Wire Selection:

Selecting the correct wire gauge and type is crucial. The wire’s thickness (gauge) must be appropriate for the current carrying capacity of the circuit, while the type of insulation should the application. -

Secure Connections:

Establishing secure and reliable electrical connections is essential. This involves using appropriate connectors, ensuring proper torque on terminals, and avoiding loose or damaged connections. -

Grounding and Polarity:

Proper grounding and polarity are essential for safety and functionality. Grounding provides a path for fault currents, while correct polarity ensures the proper flow of current in the circuit.

These facets of wiring techniques are interconnected and indispensable for the successful “Wiring 240v Plug”. Understanding and implementing these techniques empower individuals to create safe and reliable electrical connections, ensuring the proper and efficient operation of high-voltage appliances.

Outlet Compatibility

In the context of “Wiring 240v Plug”, outlet compatibility plays a vital role in ensuring the safe and efficient operation of high-voltage appliances. It involves matching the specific plug type of the appliance to the corresponding outlet configuration, guaranteeing a secure and functional electrical connection.

- Plug Types: There are various plug types designed for different current and voltage ratings, each with a unique configuration of prongs or pins. Matching the plug type to the corresponding outlet ensures compatibility and prevents incorrect or loose connections.

- Voltage and Amperage: Outlets are rated for specific voltage and amperage levels. Using an outlet compatible with the appliance’s voltage and amperage requirements ensures proper power delivery and prevents overloading or damage to the appliance.

- Polarity: In some cases, outlets may have polarized slots or prongs. Matching the polarized plug to the corresponding outlet ensures correct polarity, which is crucial for the proper functioning of certain appliances.

- Grounding: Grounding is an essential safety feature that provides a path for fault currents. Outlets with grounding terminals must be used with appliances that have grounded plugs to ensure proper grounding and protection against electrical shocks.

Ensuring outlet compatibility is a crucial aspect of “Wiring 240v Plug” as it directly impacts the safety and functionality of high-voltage appliances. By matching the plug type to the corresponding outlet configuration, individuals can create secure and reliable electrical connections, ensuring the proper and efficient operation of these appliances.

Circuit Breaker Protection

Circuit breaker protection plays a crucial role in the safe and efficient operation of “Wiring 240v Plug” systems. Circuit breakers act as safety switches, safeguarding against overcurrent and short circuits, effectively preventing damage to high-voltage appliances and electrical systems.

When excessive current flows through an electrical circuit, either due to an overload or a fault, the circuit breaker trips, interrupting the flow of electricity. This prompt response prevents overheating, electrical fires, and damage to appliances and wiring.

In “Wiring 240v Plug” applications, circuit breaker protection is particularly important due to the high power consumption of these appliances. Overloading a circuit with excessive current draw can lead to overheating, insulation damage, and potential fire hazards.

For instance, an air conditioner connected to a 240v outlet draws a significant amount of current during operation. Without proper circuit breaker protection, an overload or short circuit could cause the wiring to overheat, potentially leading to an electrical fire.

Therefore, installing appropriate circuit breakers with the correct amperage rating is crucial for “Wiring 240v Plug” systems, ensuring the safe operation of high-voltage appliances and protecting against electrical hazards.

Gauge and Length

In the context of “Wiring 240v Plug”, selecting the correct wire gauge and length is crucial for ensuring safe and efficient operation of high-voltage appliances. This involves choosing wires with the appropriate thickness (gauge) and length to handle the electrical current and voltage demands of the appliance.

- Wire Gauge: The wire gauge, measured in American Wire Gauge (AWG), determines the thickness of the wire. Thicker wires (lower AWG number) can carry more current without overheating. For 240v applications, thicker gauge wires are typically used to minimize voltage drop and ensure adequate current flow.

- Wire Length: The length of the wire also affects voltage drop. Longer wires have higher resistance, resulting in a greater voltage drop. When wiring 240v plugs, shorter wires are preferred to minimize voltage loss and maintain optimal appliance performance.

- Amperage and Voltage Requirements: The amperage and voltage requirements of the appliance determine the minimum wire gauge and length that can be used. Electrical codes and manufacturers’ specifications provide guidelines on the appropriate wire size and length for different appliances and circuit configurations.

- Voltage Drop: Voltage drop is the reduction in voltage that occurs when current flows through a conductor, such as a wire. Excessive voltage drop can lead to inefficient appliance operation or even damage. When wiring 240v plugs, selecting the correct wire gauge and length helps minimize voltage drop and ensure the appliance receives the necessary voltage to operate properly.

Understanding and implementing the principles of “Gauge and Length: Selecting the correct wire gauge and length, considering the amperage and voltage requirements of the appliance.” are essential for safe and effective “Wiring 240v Plug” installations. By selecting the appropriate wire gauge and length, individuals can ensure that high-voltage appliances receive the necessary power while minimizing voltage drop and preventing electrical hazards.

Insulation and Sheathing

In the realm of “Wiring 240v Plug”, insulation and sheathing play a paramount role in safeguarding against electrical hazards and ensuring long-lasting performance. High-quality insulation and sheathing materials serve as protective barriers, preventing current leakage, electrical shocks, and damage to electrical components.

-

Electrical Insulation:

Electrical insulation is a non-conductive material that surrounds electrical wires and components, preventing the flow of current outside the intended path. It safeguards against electrical shocks and short circuits, ensuring the safe operation of appliances and protecting individuals from electrical hazards. -

Wire Sheathing:

Wire sheathing is the outer protective layer that encloses electrical wires. Made from durable materials like PVC or rubber, it insulates and protects the wires from environmental factors such as moisture, abrasion, and heat. Robust wire sheathing ensures the longevity and reliability of electrical connections. -

Heat Resistance:

Insulation and sheathing materials must withstand high temperatures generated by electrical current flow. Heat-resistant insulation and sheathing prevent melting, degradation, and potential fire hazards, ensuring the safe operation of high-voltage appliances. -

Durability and Longevity:

Durable insulation and sheathing materials resist wear and tear, ensuring long-lasting performance. They protect against cracking, abrasion, and environmental factors, preventing damage to electrical wires and connections, and extending the lifespan of the electrical system.

By utilizing high-quality insulation and sheathing materials, individuals can create safe and reliable “Wiring 240v Plug” connections, minimizing electrical hazards and ensuring the efficient and durable operation of high-voltage appliances. These protective layers play a crucial role in safeguarding electrical systems, preventing accidents, and ensuring peace of mind.

Grounding

In the context of “Wiring 240v Plug,” grounding plays a pivotal role in ensuring electrical safety and preventing potentially lethal shocks. Grounding involves creating a low-resistance path for electrical current to flow safely into the earth, diverting it away from unintended paths like the human body.

When a fault occurs in an electrical system, such as a short circuit or insulation failure, a large amount of current can flow through unintended paths, potentially causing severe shocks or electrocution. A proper grounding system provides a safe and controlled path for this fault current to flow, effectively preventing it from passing through individuals or causing damage to equipment.

Real-life examples of grounding in “Wiring 240v Plug” applications include connecting the grounding wire of an appliance to a grounded outlet or installing a grounding rod into the earth. These measures ensure that any fault current is directed into the grounding system and safely dissipated into the ground.

The practical significance of understanding grounding in “Wiring 240v Plug” lies in its ability to prevent electrical accidents and protect human life. By establishing a proper grounding system, individuals can minimize the risk of electrical shocks, fires, and other hazards associated with high-voltage appliances.

Polarity

In the context of “Wiring 240v Plug,” understanding polarity is crucial for ensuring the safe and proper functioning of high-voltage appliances. Polarity refers to the correct orientation of electrical connections, ensuring that current flows in the intended direction, preventing malfunctions and potential hazards.

When wiring a 240v plug, it is essential to maintain proper polarity by connecting the live wire to the terminal designated as “L” and the neutral wire to the terminal designated as “N”. Reversing this polarity can lead to incorrect operation of the appliance, damage to its internal components, or even electrical shocks.

For instance, in a 240v clothes dryer, improper polarity can cause the motor to rotate in the wrong direction, potentially damaging the appliance. Similarly, in a 240v oven, reversed polarity can disrupt the heating elements, leading to uneven cooking or even electrical fires.

Ensuring proper polarity in “Wiring 240v Plug” applications is a critical safety measure. By adhering to the correct polarity, individuals can minimize the risk of electrical accidents, protect their appliances from damage, and ensure their efficient and reliable operation.

Strain Relief

Within the context of “Wiring 240v Plug,” strain relief plays a pivotal role in ensuring the long-lasting performance and safety of electrical connections. Strain relief devices are crucial components that prevent excessive bending or pulling on wire connections, safeguarding against potential damage and electrical hazards.

- Anchor Points: Strain relief devices often incorporate anchor points that provide a secure hold on the wire, preventing it from being accidentally pulled out or strained during handling or movement.

- Flexible Boots: Flexible boots made of rubber or plastic are commonly used as strain relief devices. They provide a flexible covering around the wire entry point, absorbing stress and preventing sharp bends that could damage the wires.

- Cable Ties: Cable ties, while not specifically designed for strain relief, can be used to bundle and support wires, reducing the likelihood of excessive bending or pulling on individual connections.

- Conduit Fittings: In industrial or commercial settings, conduit fittings such as locknuts and bushings are used to secure and protect wires as they enter or exit enclosures. These fittings provide strain relief by preventing excessive movement or bending at the connection points.

Understanding and implementing proper strain relief techniques is crucial for ensuring the longevity and reliability of “Wiring 240v Plug” connections. By incorporating strain relief devices, individuals can minimize the risk of wire damage, loose connections, and potential electrical hazards, ensuring the safe and efficient operation of high-voltage appliances.

Regulatory Compliance

In the domain of “Wiring 240v Plug,” regulatory compliance holds paramount importance. Adhering to local electrical codes and regulations is not merely a legal obligation but a cornerstone of ensuring the safety and integrity of electrical installations.

Electrical codes and regulations are meticulously crafted by experts to establish minimum safety standards for electrical systems. These standards govern various aspects, including wiring methods, component specifications, and installation practices. By adhering to these codes and regulations, electricians can minimize the risk of electrical fires, shocks, and other hazards.

For instance, the National Electrical Code (NEC) in the United States provides comprehensive guidelines for electrical installations. Complying with the NEC helps ensure that 240v plugs are wired correctly, with appropriate wire gauges, overcurrent protection, and proper grounding. This compliance safeguards against potential electrical faults and accidents.

Furthermore, building requirements often mandate compliance with specific electrical codes. This is especially crucial in commercial and industrial settings, where electrical systems are more complex and the consequences of non-compliance can be severe.

Understanding and implementing regulatory compliance in “Wiring 240v Plug” applications is a critical component of ensuring electrical safety. It empowers individuals to create safe and reliable electrical connections, minimizing risks and protecting against potential hazards.

Related Posts