Wiring 12V Batteries in Parallel is an electrical technique that combines multiple batteries with the same voltage (in this case, 12 volts) by connecting their positive terminals to each other and their negative terminals to each other. This configuration allows for an increase in the overall current capacity of the system while maintaining the same voltage.

The primary purpose of wiring batteries in parallel is to extend the run time of a device or system. By combining multiple batteries, you effectively increase the total amount of charge available, allowing the device or system to operate for a longer period of time. This technique is particularly useful in applications where reliable and extended power supply is crucial, such as medical equipment, emergency lighting, and off-grid power systems.

Wiring batteries in parallel offers several advantages. It allows for easy expansion of the power capacity by simply adding more batteries, without the need to modify the electrical system. Additionally, it provides redundancy, as the failure of one battery will not affect the operation of the remaining batteries in the system. Furthermore, it can improve the overall efficiency of the electrical system by reducing internal resistance.

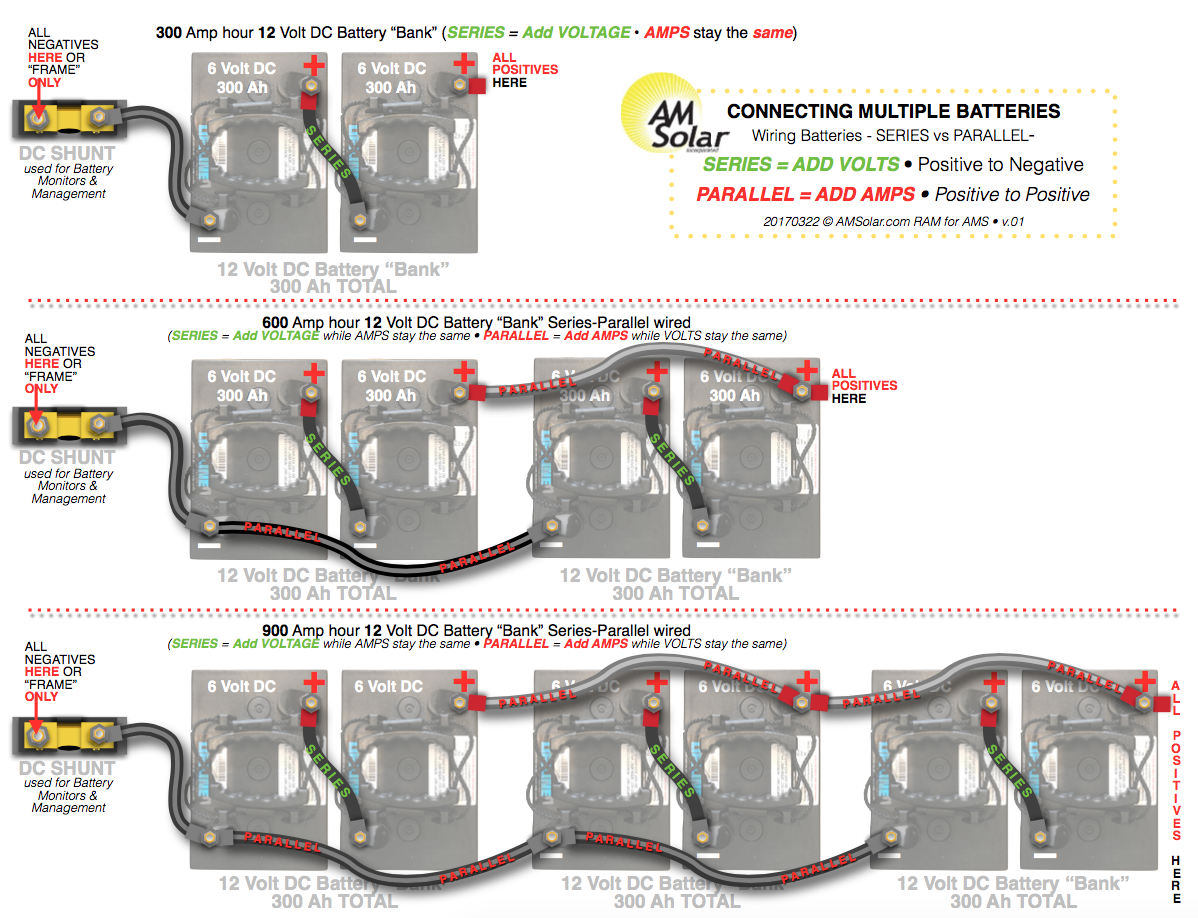

A notable historical development in the field of battery wiring is the invention of the battery pack. Battery packs are pre-assembled units that consist of multiple batteries wired in parallel or series (or a combination of both). They provide a convenient and standardized way to store and manage batteries, simplify installation, and ensure proper electrical connections.

Understanding the essential aspects of “Wiring 12v Batteries in Parallel” is crucial for effective and safe implementation of this technique. These aspects encompass various dimensions, ranging from the fundamental principles to practical considerations.

- Voltage: Wiring batteries in parallel maintains the same voltage as the individual batteries, typically 12 volts.

- Current Capacity: The total current capacity of the system increases with the number of batteries connected in parallel.

- Capacity: The overall capacity of the system remains the same, as the batteries are not connected in series.

- Internal Resistance: Parallel wiring reduces the overall internal resistance of the system, improving efficiency.

- Redundancy: If one battery fails, the remaining batteries continue to provide power, ensuring system reliability.

- Scalability: Adding or removing batteries is straightforward, allowing for easy expansion or reduction of power capacity.

- Wiring: Proper wiring is essential to ensure correct connections and prevent short circuits.

- Safety: Precautions must be taken to avoid electrical hazards, such as using insulated wires and avoiding overcharging.

- Applications: Parallel wiring is used in various applications, including automotive, marine, and renewable energy systems.

- Maintenance: Regular maintenance, such as cleaning terminals and monitoring battery health, is crucial for optimal performance.

These key aspects provide a comprehensive understanding of “Wiring 12v Batteries in Parallel,” enabling effective implementation and ensuring safe and reliable operation. They encompass the technical principles, practical considerations, and wider applications of this technique.

Voltage

When wiring batteries in parallel, the voltage remains the same as the voltage of the individual batteries. This is because the positive terminals of the batteries are connected together, and the negative terminals are connected together. This creates a single circuit, and the voltage across the circuit is the same as the voltage across each individual battery. For example, if you wire two 12-volt batteries in parallel, the voltage across the circuit will still be 12 volts.

Maintaining the same voltage is critical in “Wiring 12v Batteries In Parallel” because it ensures that the devices or systems being powered will receive the correct voltage. If the voltage is too high, it can damage the devices or systems. If the voltage is too low, the devices or systems may not function properly.

A real-life example of “Wiring 12v Batteries In Parallel” is in automotive applications. Car batteries are typically 12 volts, and they are often wired in parallel to increase the current capacity of the system. This allows the car to start and operate even if one of the batteries fails.

Understanding the relationship between voltage and parallel wiring is essential for designing and implementing electrical systems. By maintaining the same voltage, parallel wiring ensures that devices and systems receive the correct voltage for optimal performance and safety.

Current Capacity

In the context of “Wiring 12v Batteries In Parallel,” understanding current capacity is crucial as it determines the amount of electrical current that the system can deliver. By connecting batteries in parallel, the overall current capacity of the system increases, allowing it to power devices and systems with higher current demands.

- Increased Power Output: Connecting batteries in parallel effectively multiplies the current capacity, enabling the system to provide more power to the connected devices or systems. This is particularly useful in applications where high-power devices or multiple devices need to be powered simultaneously.

- Redundancy and Reliability: Parallel wiring introduces redundancy into the system. If one battery fails or becomes depleted, the remaining batteries continue to provide current, ensuring uninterrupted operation. This enhances the overall reliability of the power supply.

- Scalability: The modular nature of parallel wiring allows for easy scalability of the system. As power requirements increase, additional batteries can be added to the system to meet the demand, without the need for complex reconfigurations.

- Real-Life Example: A practical application of this principle can be seen in automotive electrical systems. Car batteries are wired in parallel to increase the current capacity, allowing the car to start and operate even if one battery fails.

In summary, “Current Capacity: The total current capacity of the system increases with the number of batteries connected in parallel” is a fundamental aspect of “Wiring 12v Batteries In Parallel.” It enables increased power output, redundancy, scalability, and reliability, making it a valuable technique for various applications where reliable and high-current power supply is required.

Capacity

In the context of “Wiring 12v Batteries In Parallel,” understanding the relationship between capacity and series/parallel configurations is critical for optimizing battery performance and system efficiency. When batteries are connected in parallel, their overall capacity remains unchanged, unlike when they are connected in series. This distinction has significant implications for system design and applications.

- Capacity and Runtime: The capacity of a battery determines the amount of charge it can store, which directly affects the runtime of the system. Wiring batteries in parallel does not increase the overall capacity. Instead, it allows the batteries to discharge simultaneously, providing a higher current capacity while maintaining the same overall runtime.

- Voltage vs. Current: Connecting batteries in parallel maintains the voltage while increasing the current capacity. This is in contrast to connecting batteries in series, which increases the voltage while maintaining the current capacity. The choice between parallel and series configuration depends on the specific requirements of the system.

- Real-Life Example: A practical application of parallel wiring to maintain the same capacity can be seen in electric vehicles. Multiple battery packs are often connected in parallel to provide a higher current capacity, enabling the vehicle to draw more power for acceleration and hill climbing while maintaining the same overall range.

Understanding the relationship between “Capacity: The overall capacity of the system remains the same, as the batteries are not connected in series.” and “Wiring 12v Batteries In Parallel” is crucial for designing and implementing efficient electrical systems. By considering the capacity requirements and the desired voltage and current characteristics, engineers can optimize system performance and ensure reliable operation.

Internal Resistance

In the context of “Wiring 12v Batteries In Parallel,” understanding the concept of internal resistance and its reduction through parallel wiring is vital for optimizing system performance and efficiency. Internal resistance refers to the inherent resistance within a battery that opposes the flow of current. When batteries are connected in parallel, the overall internal resistance of the system is reduced, leading to several benefits.

- Reduced Voltage Drop: Internal resistance can cause a voltage drop in the system, especially under high current loads. By reducing the internal resistance, parallel wiring minimizes the voltage drop, ensuring that the connected devices receive the intended voltage.

- Increased Power Output: Lower internal resistance allows for better current flow, resulting in increased power output. This is particularly important for applications that require high power, such as electric vehicles or industrial equipment.

- Improved Efficiency: Reduced internal resistance translates into improved efficiency, as less energy is lost due to heat dissipation within the batteries. This leads to longer battery life and better overall system performance.

- Real-Life Application: In automotive applications, parallel wiring of batteries helps reduce the voltage drop during engine starting, ensuring reliable starting even in cold weather conditions or when the battery is partially discharged.

Comprehending the relationship between “Internal Resistance: Parallel wiring reduces the overall internal resistance of the system, improving efficiency.” and “Wiring 12v Batteries In Parallel” enables engineers to design and implement efficient electrical systems. By minimizing internal resistance, parallel wiring enhances power output, improves efficiency, and ensures reliable operation of connected devices.

Redundancy

In the context of “Wiring 12v Batteries In Parallel”, redundancy plays a crucial role in enhancing system reliability by mitigating the impact of individual battery failures. By connecting multiple batteries in parallel, the system can maintain power output even if one or more batteries fail.

- Multiple Power Sources: Parallel wiring provides multiple independent power sources within the system. If one battery fails, the remaining batteries can continue to supply power, ensuring uninterrupted operation.

- Increased Battery Life: Redundancy through parallel wiring extends the overall battery life of the system. When one battery degrades or fails, the other batteries can compensate, reducing the load on each individual battery and prolonging their lifespan.

- Real-Life Example: Uninterruptible Power Supplies (UPS): UPS systems utilize parallel-wired batteries to provide backup power in case of a power outage. If one battery fails, the remaining batteries ensure a seamless transition to backup power, protecting sensitive electronic equipment.

- Improved System Reliability: By incorporating redundancy, parallel wiring enhances the overall reliability of the system. It reduces the risk of system failure due to a single battery failure, ensuring critical systems remain operational.

In conclusion, redundancy is a key aspect of “Wiring 12v Batteries In Parallel” that contributes to system reliability and uninterrupted operation. By providing multiple power sources, increasing battery life, and enhancing overall system reliability, parallel wiring ensures that systems can continue to function even in the event of individual battery failures.

Scalability

In the context of “Wiring 12v Batteries In Parallel”, scalability plays a crucial role in adapting the system’s power capacity to varying demands. The ability to easily add or remove batteries enables flexible and efficient power management.

The straightforward process of adding or removing batteries is a key advantage of parallel wiring. By simply connecting additional batteries in parallel, the overall power capacity of the system can be increased to meet higher power demands. Conversely, removing batteries allows for a reduction in power capacity when necessary, optimizing the system for lower power requirements. This scalability feature provides system designers with the flexibility to tailor the power capacity to specific application needs.

A practical application of scalability in “Wiring 12v Batteries In Parallel” can be seen in electric vehicles. Electric vehicles often utilize multiple batteries connected in parallel to achieve the desired power capacity. As battery technology advances and energy demands change, the ability to easily add or remove batteries allows for upgrades or adjustments to the vehicle’s power system without major design overhauls.

Furthermore, scalability is crucial in renewable energy systems. In solar or wind power installations, the number of batteries required for energy storage can vary depending on the availability of renewable resources and power consumption patterns. By wiring batteries in parallel, the system can be easily expanded or reduced to match the fluctuating power generation and demand.

In summary, the scalability offered by “Wiring 12v Batteries In Parallel” is a key aspect that contributes to the flexibility and adaptability of power systems. The ability to easily add or remove batteries allows for tailored power capacity, efficient energy management, and the seamless integration of renewable energy sources.

Wiring

In the context of “Wiring 12v Batteries In Parallel”, proper wiring practices are of paramount importance for maintaining safe and efficient operation of the system. Incorrect wiring can lead to a myriad of issues, including incorrect voltage distribution, power loss, and even hazardous short circuits. A comprehensive understanding of proper wiring techniques is crucial for ensuring the reliability and safety of the system.

- Correct Cable Selection: Choosing the proper cable size and type is essential to handle the current capacity required by the system. Undersized cables can overheat and become a fire hazard, while oversized cables are wasteful and can introduce unnecessary resistance.

- Secure Connections: All electrical connections should be mechanically secure and properly insulated to prevent loose connections, arcing, and potential short circuits. Loose connections can increase resistance, leading to power loss and overheating.

- Polarity and Color Coding: Batteries must be connected with the correct polarity (positive to positive, negative to negative) to ensure proper charging and discharge. Color coding of wires helps identify polarity and simplifies the wiring process.

- Avoiding Contact Between Terminals: Battery terminals should be insulated to prevent accidental contact between positive and negative terminals, which can cause a short circuit and potentially lead to a catastrophic event.

Adhering to these proper wiring practices ensures that the “Wiring 12v Batteries In Parallel” system operates as intended, providing reliable power while minimizing the risk of electrical hazards. By paying close attention to cable selection, secure connections, polarity, and terminal insulation, system designers and installers can create safe and efficient electrical systems.

Safety

When working with electrical systems, particularly when “Wiring 12v Batteries In Parallel,” safety should be paramount. Failing to adhere to proper safety precautions can result in electrical hazards, equipment damage, or even personal injury. Understanding and implementing the following safety measures are crucial to ensure a safe and successful installation:

- Insulated Wires: Using properly insulated wires is essential to prevent electrical shocks and short circuits. Insulation prevents current from flowing outside the intended path, protecting users from contact with live conductors.

- Proper Connections: All connections should be made securely using the appropriate connectors and tools. Loose or faulty connections can generate heat, increasing the risk of electrical fires.

- Overcharging Protection: Batteries should be protected from overcharging, which can lead to overheating, reduced battery life, and potential explosions. Proper charging systems should include overcharging protection circuits or devices.

- Ventilation: Batteries release hydrogen gas during charging, which is flammable and explosive. Ensure adequate ventilation in areas where batteries are being charged or stored to prevent the accumulation of hydrogen gas.

By implementing these safety precautions, individuals can mitigate electrical hazards and ensure the safe and reliable operation of “Wiring 12v Batteries In Parallel” systems. Remember, safety should always be the top priority when working with electrical systems, and any doubts or uncertainties should prompt consultation with qualified professionals.

Applications

Within the context of “Wiring 12v Batteries In Parallel”, understanding the diverse applications of parallel wiring is crucial. This technique finds widespread use in various industries, each with its unique requirements and benefits.

- Automotive Industry: In automotive applications, parallel wiring is commonly employed to increase the current capacity of vehicle batteries. By connecting multiple batteries in parallel, cars can meet the high power demands of starting the engine and operating electrical accessories, even if one battery fails.

- Marine Applications: In the marine industry, parallel wiring is utilized to power boats and other watercraft. Marine batteries are often connected in parallel to provide the necessary power for starting engines, operating navigation systems, and powering onboard appliances.

- Renewable Energy Systems: Parallel wiring plays a vital role in renewable energy systems, such as solar and wind power installations. Battery banks in these systems are often configured in parallel to increase the overall storage capacity and provide a reliable power source, even during periods of intermittent renewable energy generation.

In conclusion, the applications of parallel wiring extend beyond the automotive industry, reaching into marine and renewable energy sectors. Understanding these diverse applications highlights the versatility and importance of parallel wiring in providing reliable and efficient power solutions across various industries.

Maintenance

When wiring 12v batteries in parallel, regular maintenance is essential to ensure the continued optimal performance and longevity of the system. Neglecting maintenance can lead to decreased efficiency, reduced battery life, and potential safety hazards.

Regular maintenance includes tasks such as cleaning battery terminals to remove corrosion, checking connections for tightness, and monitoring battery health through voltage and capacity testing. By proactively addressing these maintenance needs, any potential issues can be identified and resolved before they become significant problems.

In real-life applications, regular maintenance is critical to avoid costly repairs or replacements. For instance, in automotive applications, neglecting battery maintenance can lead to starting problems, reduced fuel efficiency, and even electrical system failures. In renewable energy systems, proper maintenance of parallel-wired batteries ensures reliable power supply and extends the lifespan of the batteries.

Understanding the connection between maintenance and optimal performance is essential for harnessing the full potential of parallel-wired battery systems. By implementing regular maintenance practices, individuals can proactively address any issues, ensuring the system operates safely and efficiently over its intended lifespan.

Related Posts