A U-Haul Wiring Harness is a crucial electrical component designed specifically for U-Haul trailers. Its primary function is to establish a secure electrical connection between the towing vehicle and the trailer, ensuring the proper operation of essential lighting and safety features.

The wiring harness is a vital component, as it allows for the transmission of electrical signals for functions such as brake lights, turn signals, and hazard lights. Without a properly installed wiring harness, these essential safety features would be inoperable, posing a significant safety hazard while towing a trailer.

The development of standardized wiring harnesses for U-Haul trailers has played a key role in enhancing road safety and ensuring the reliability of these vehicles. The article delves into the historical context of U-Haul wiring harnesses, the benefits they offer, and the advancements that have been made over the years to improve their functionality and overall reliability.

Understanding the essential aspects of a U-Haul Wiring Harness is crucial for ensuring the safe and reliable operation of U-Haul trailers. These harnesses play a vital role in establishing a secure electrical connection between the towing vehicle and the trailer, allowing for the proper functioning of essential lighting and safety features.

- Compatibility: U-Haul wiring harnesses are designed to be compatible with specific U-Haul trailer models, ensuring a precise fit and optimal electrical connectivity.

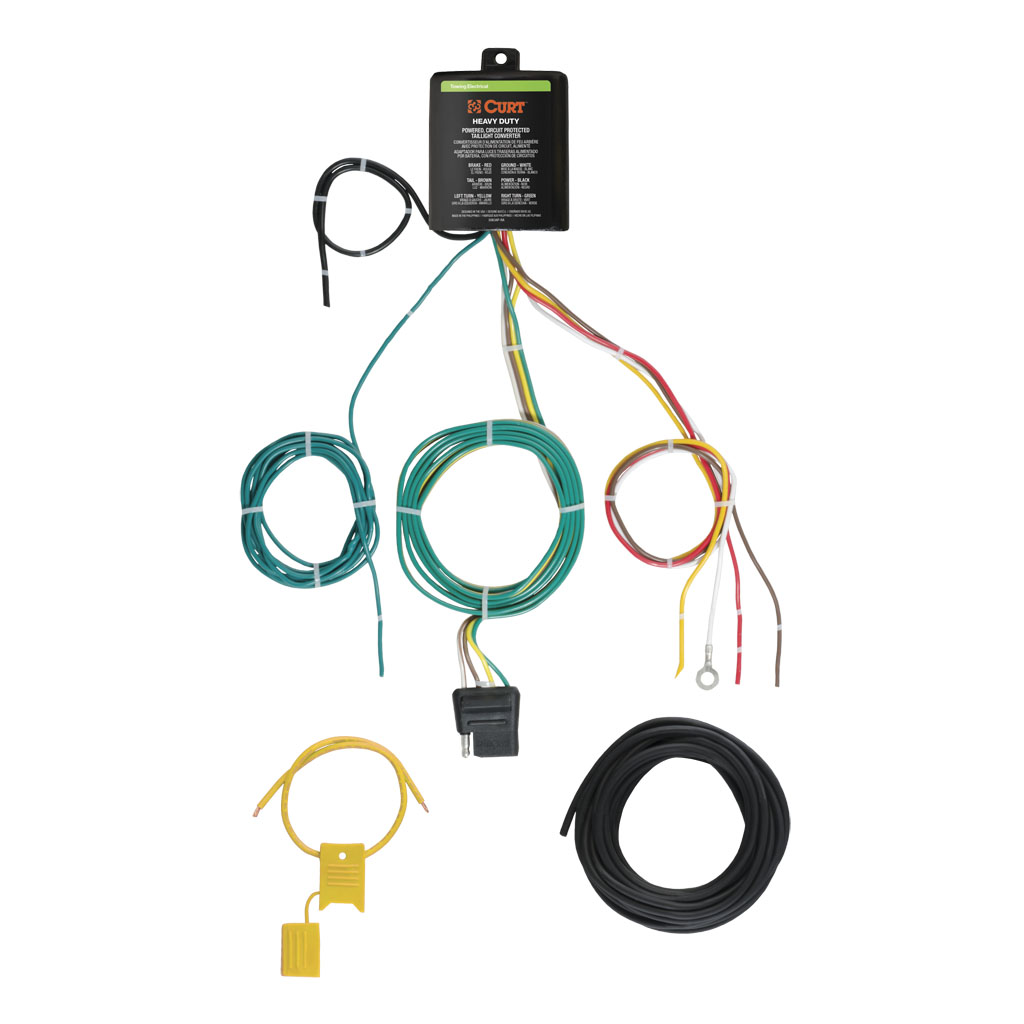

- Safety Features: These harnesses are equipped with essential safety features such as fused circuits, preventing electrical overload and potential fire hazards.

- Durability: Constructed with high-quality materials, U-Haul wiring harnesses are built to withstand the rigors of towing and exposure to various weather conditions.

- Installation: Designed for ease of installation, these harnesses typically come with clear instructions and color-coded wires, simplifying the connection process.

- Customization: Some U-Haul wiring harnesses offer customization options, allowing users to add additional electrical components or accessories to their trailers.

- Compliance: U-Haul wiring harnesses adhere to industry standards and regulations, ensuring compliance with safety and electrical codes.

- Troubleshooting: These harnesses are designed to facilitate troubleshooting, with features such as accessible fuse panels and diagnostic connectors.

- Warranty: U-Haul wiring harnesses are typically backed by a warranty, providing peace of mind and ensuring the reliability of the product.

These essential aspects of U-Haul Wiring Harnesses underscore their importance in maintaining the safety, reliability, and functionality of U-Haul trailers. By considering these key aspects, users can make informed decisions when selecting and installing a wiring harness, ensuring the proper operation of their trailers and enhancing their overall towing experience.

Compatibility

In the context of “Uhaul Wiring Harness,” compatibility plays a pivotal role in ensuring the seamless integration and functionality of electrical systems between towing vehicles and U-Haul trailers. To achieve this, U-Haul wiring harnesses are meticulously engineered to match the specific electrical configurations of different U-Haul trailer models.

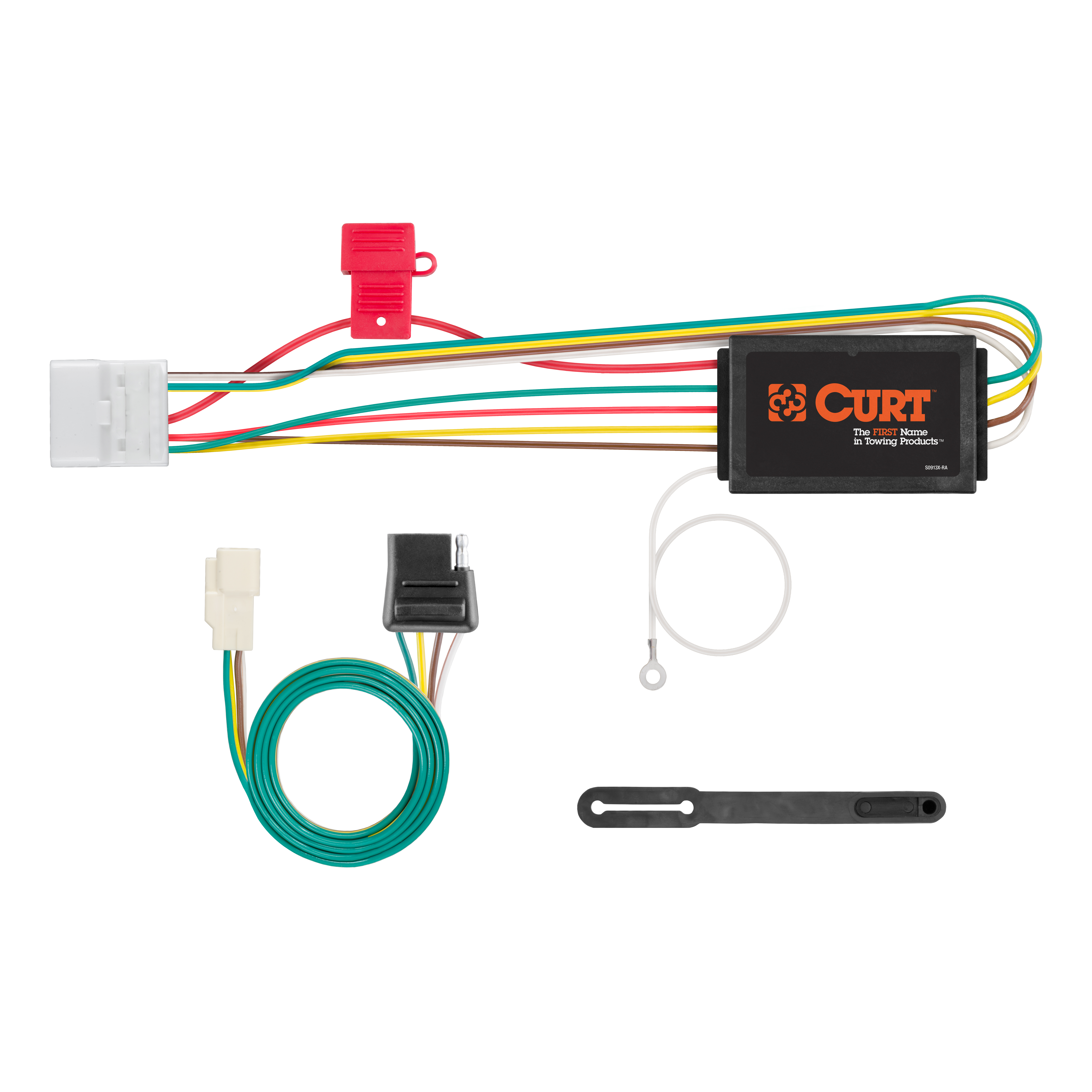

- Tailored Connectors: U-Haul wiring harnesses feature customized connectors that are designed to fit precisely into the corresponding sockets on the towing vehicle and the trailer. This precise fit prevents loose connections, ensuring a secure and reliable electrical connection.

- Model-Specific Wiring: Each U-Haul trailer model has unique electrical requirements. U-Haul wiring harnesses are tailored to meet these specific requirements, ensuring that the correct wires are connected to the appropriate components, such as lighting, brakes, and turn signals.

- Plug-and-Play Design: To simplify installation and minimize the risk of errors, U-Haul wiring harnesses are designed with a plug-and-play approach. The connectors are color-coded and keyed to prevent incorrect connections.

- Electrical Compatibility: U-Haul wiring harnesses are engineered to handle the electrical load and voltage requirements of specific U-Haul trailer models. This ensures that the electrical system operates within safe parameters, preventing damage to components or electrical fires.

By ensuring compatibility with specific U-Haul trailer models, U-Haul wiring harnesses guarantee a precise fit, optimal electrical connectivity, and hassle-free installation. This compatibility is essential for maintaining the safety, reliability, and functionality of U-Haul trailers, ensuring a smooth and efficient towing experience.

Safety Features

In the context of U-Haul Wiring Harnesses, safety features play a critical role in ensuring the safe and reliable operation of U-Haul trailers. These harnesses are equipped with essential safety features that protect against electrical hazards and potential fire risks, enhancing the safety of both the towing vehicle and the trailer.

- Fused Circuits: Electrical circuits within U-Haul wiring harnesses are protected by fuses. Fuses act as safety switches, designed to melt and break the circuit in the event of an electrical overload. This prevents excessive current flow, which can lead to overheating, damage to electrical components, or even electrical fires.

- Circuit Protection: Each circuit in a U-Haul wiring harness is protected by a specific fuse rating. The fuse rating is carefully chosen to provide adequate protection for the circuit, preventing damage to sensitive electrical components. This circuit protection ensures that individual components can fail without causing damage to the entire electrical system.

- Ground Fault Protection: Ground fault protection is incorporated into U-Haul wiring harnesses to prevent electrical shocks and potential electrocution hazards. Ground fault circuit interrupters (GFCIs) monitor electrical circuits and quickly shut off power in the event of a ground fault, preventing dangerous electrical currents from flowing through the system.

- Surge Protection: U-Haul wiring harnesses may include surge protection devices to safeguard against voltage spikes and electrical surges. These devices divert excess voltage away from sensitive electrical components, preventing damage and ensuring the reliable operation of the trailer’s electrical systems.

The integration of these safety features in U-Haul Wiring Harnesses underscores the importance of safety in the design and manufacturing of these critical components. By incorporating fused circuits, circuit protection, ground fault protection, and surge protection, U-Haul ensures the safe and reliable operation of its trailers, minimizing electrical hazards and potential fire risks.

Durability

In the context of “Uhaul Wiring Harness,” durability is of paramount importance, ensuring the reliable performance and longevity of these critical components. U-Haul wiring harnesses are meticulously crafted using high-quality materials and construction techniques to endure the demanding conditions associated with towing and exposure to diverse weather elements.

- Corrosion Resistance: U-Haul wiring harnesses employ corrosion-resistant materials, such as copper conductors and weatherproof connectors, to withstand exposure to moisture, road salts, and other corrosive elements. This resistance prevents rust and degradation, ensuring reliable electrical connections over an extended lifespan.

- Strain Relief: Wiring harnesses are subjected to stress and strain during towing. U-Haul wiring harnesses incorporate strain relief mechanisms, such as flexible conduits and reinforced connectors, to protect wires from excessive bending, pulling, and vibration. This reduces the risk of wire damage and ensures uninterrupted electrical performance.

- Temperature Extremes: U-Haul wiring harnesses are designed to operate in extreme temperatures, from freezing cold to scorching heat. High-quality insulation and heat-resistant materials prevent damage to wires and ensure consistent electrical performance regardless of the ambient temperature.

- UV Protection: Exposure to sunlight can degrade wiring insulation over time. U-Haul wiring harnesses feature UV-resistant materials and coatings to protect against the harmful effects of ultraviolet radiation, ensuring long-lasting performance and preventing premature aging.

The emphasis on durability in U-Haul Wiring Harnesses underscores the commitment to providing reliable and long-lasting electrical connections for U-Haul trailers. By incorporating high-quality materials, employing robust construction techniques, and addressing potential failure points, U-Haul ensures that its wiring harnesses can withstand the rigors of towing and exposure to various weather conditions, contributing to the overall safety, performance, and longevity of U-Haul trailers.

Installation

In the context of U-Haul Wiring Harnesses, ease of installation is a critical aspect that enhances the overall usability and accessibility of these components. U-Haul wiring harnesses are meticulously designed with user-friendly features to simplify the installation process, making it accessible to individuals with varying levels of electrical expertise.

The inclusion of clear instructions plays a pivotal role in facilitating a smooth installation experience. These instructions provide step-by-step guidance, often accompanied by illustrations or diagrams, to help users navigate the installation process efficiently. The instructions typically cover aspects such as identifying the correct wires, connecting them to the appropriate terminals, and securing the harness securely.

Color-coded wires are another essential feature that contributes to the ease of installation. Each wire is assigned a specific color, corresponding to its function or purpose. This color-coding simplifies the identification of wires, preventing confusion and reducing the likelihood of incorrect connections. Additionally, color-coding aligns with industry standards, ensuring consistency and familiarity for users.

These user-centric design elements make U-Haul wiring harnesses more accessible and convenient to install, saving time and effort. By providing clear instructions and color-coded wires, U-Haul empowers users to confidently undertake the installation process, promoting self-reliance and reducing the need for professional assistance.

In practical applications, the ease of installation offered by U-Haul wiring harnesses translates to several benefits. Firstly, it allows users to install the wiring harness themselves, potentially saving on labor costs associated with hiring an electrician. Secondly, it minimizes downtime for trailers, as users can quickly and efficiently install the wiring harness, ensuring that their trailers are ready for use when needed. Thirdly, the user-friendly design promotes a sense of accomplishment and satisfaction, as users can successfully complete the installation task on their own.

In summary, the ease of installation feature of U-Haul Wiring Harnesses is a significant contributor to their overall value and usability. By incorporating clear instructions and color-coded wires, U-Haul simplifies the installation process, making it accessible to a wider range of users. This user-centric design not only enhances the installation experience but also promotes self-reliance and contributes to the efficient operation of U-Haul trailers.

Customization

The customization options provided by some U-Haul wiring harnesses play a crucial role in enhancing the functionality and versatility of U-Haul trailers. By allowing users to add additional electrical components or accessories, these harnesses empower users to tailor their trailers to meet their specific needs and requirements.

One of the key benefits of customizable wiring harnesses is the ability to integrate additional lighting systems. This can be particularly useful for users who frequently tow trailers in low-visibility conditions or need specialized lighting for specific tasks. By adding auxiliary lights, such as LED work lights or floodlights, users can improve visibility while reversing, loading or unloading cargo, or illuminating a campsite. The customization options provided by U-Haul wiring harnesses accommodate these additional lighting needs, enhancing safety and convenience during trailer operation.

Another practical application of customizable wiring harnesses lies in the integration of electrical accessories. This feature allows users to enhance the comfort and convenience of their trailers. For example, users can install electric brakes to improve braking performance, particularly when towing heavy loads. Additionally, the integration of a battery charger can be beneficial for users who plan to use their trailers for extended periods, ensuring that the trailer’s battery remains charged and ready for use.

In summary, the customization options offered by U-Haul wiring harnesses provide a valuable solution for users seeking to personalize and enhance the functionality of their trailers. By allowing the integration of additional electrical components and accessories, these harnesses empower users to address specific needs, improve safety, increase convenience, and adapt their trailers to a wider range of applications.

Compliance

In the context of “Uhaul Wiring Harness,” compliance plays a pivotal role in ensuring the safety and reliability of electrical systems in U-Haul trailers. U-Haul wiring harnesses are meticulously designed and manufactured to adhere to industry standards and regulations, guaranteeing conformance with established safety and electrical codes.

- Regulatory Compliance: U-Haul wiring harnesses meet the requirements of relevant regulatory bodies, such as the National Electrical Code (NEC) and the Department of Transportation (DOT). This compliance ensures that the wiring harnesses are installed and operated in a manner that minimizes electrical hazards and complies with established safety guidelines.

- Industry Standards: U-Haul wiring harnesses conform to industry standards, such as those set by the National Electrical Manufacturers Association (NEMA) and the Society of Automotive Engineers (SAE). Adhering to these standards ensures that the wiring harnesses are compatible with other electrical components and systems, promoting safe and reliable operation.

- Quality Control: U-Haul wiring harnesses undergo rigorous quality control processes to ensure that they meet the highest standards of safety and performance. These processes involve testing and inspections at various stages of production, verifying that the harnesses comply with specifications and perform as intended.

- Labeling and Documentation: U-Haul wiring harnesses are clearly labeled and accompanied by detailed documentation. This information helps ensure proper installation, maintenance, and troubleshooting, reducing the risk of errors and potential safety hazards.

By adhering to industry standards and regulations, U-Haul wiring harnesses provide peace of mind to users, knowing that their trailers are equipped with safe and compliant electrical systems. This compliance contributes to the overall reliability and longevity of U-Haul trailers, ensuring that they operate safely and efficiently on the road.

Troubleshooting

Within the realm of “Uhaul Wiring Harness,” the aspect of troubleshooting plays a pivotal role in ensuring the reliable operation and maintenance of U-Haul trailers. By incorporating features that facilitate troubleshooting, U-Haul wiring harnesses empower users to identify and resolve electrical issues efficiently, minimizing downtime and enhancing overall safety.

- Accessible Fuse Panels: U-Haul wiring harnesses feature readily accessible fuse panels, allowing users to quickly inspect and replace blown fuses. This ease of access simplifies troubleshooting, as users can swiftly locate and address fuse-related electrical faults without extensive disassembly or complex diagnostic procedures.

- Diagnostic Connectors: Some U-Haul wiring harnesses incorporate diagnostic connectors that enable the use of specialized diagnostic tools. These tools can be connected to the harness, providing valuable insights into the electrical system’s performance and identifying potential issues. By leveraging diagnostic connectors, users can pinpoint electrical problems with greater accuracy and efficiency.

- Color-Coded Wiring: U-Haul wiring harnesses often employ color-coded wires, making it easier to trace circuits and identify connections. This color-coding simplifies troubleshooting by providing visual cues that help users navigate the electrical system and locate specific wires or components.

- Detailed Documentation: U-Haul wiring harnesses come with comprehensive documentation, including wiring diagrams and instructions. These documents provide valuable guidance during troubleshooting, enabling users to understand the system’s configuration and locate potential problem areas.

In summary, the troubleshooting features incorporated into U-Haul wiring harnesses empower users to diagnose and resolve electrical issues with greater ease and efficiency. By providing accessible fuse panels, diagnostic connectors, color-coded wiring, and detailed documentation, U-Haul enhances the maintainability and reliability of its trailers, ensuring minimal downtime and optimal performance.

Warranty

Within the context of “Uhaul Wiring Harness,” warranty plays a pivotal role in establishing trust, ensuring product reliability, and enhancing customer satisfaction. U-Haul wiring harnesses are typically backed by a comprehensive warranty, offering several key benefits to users.

- Coverage: U-Haul wiring harnesses are covered under warranty against defects in materials and workmanship for a specified period, typically ranging from one to three years. This coverage provides peace of mind to users, knowing that they are protected against unexpected failures or malfunctions.

- Parts Replacement: In the event of a covered warranty claim, U-Haul will typically replace the defective wiring harness or its components free of charge. This ensures that the trailer’s electrical system is restored to proper working condition, minimizing downtime and maintaining the trailer’s reliability.

- Labor Costs: Some U-Haul wiring harness warranties may include coverage for labor costs associated with the replacement of the defective harness. This coverage can significantly reduce the financial burden on users, particularly if the replacement process is complex or time-consuming.

- Enhanced Reliability: The warranty offered by U-Haul serves as a testament to the high quality and reliability of its wiring harnesses. By providing a warranty, U-Haul demonstrates its confidence in the durability and performance of its products.

The warranty provided by U-Haul for its wiring harnesses offers numerous benefits to users. It provides peace of mind, ensures product reliability, and minimizes the financial impact of potential electrical issues. By backing its wiring harnesses with a comprehensive warranty, U-Haul demonstrates its commitment to customer satisfaction and reinforces the trust that users have in its products.

Related Posts