U Haul Trailer Wiring Harness Installation Cost refers to the expense associated with installing a wiring harness in a U-Haul trailer, which connects the trailer’s electrical system to the towing vehicle.

This installation is crucial for enabling functions such as brake lights, turn signals, and tail lights on the trailer, ensuring safe and compliant towing. The cost of this service varies depending on factors like the type of trailer, complexity of the wiring system, and labor rates in the specific location.

U Haul trailer wiring harness installation holds relevance in the realm of towing and transportation, providing a secure and reliable connection between the towing vehicle and the trailer, enhancing safety and compliance with regulations. Its historical development has contributed to the advancement of towing capabilities, making it an essential aspect of trailer operations.

Understanding the key aspects of “U-Haul Trailer Wiring Harness Installation Cost” is essential for comprehensive content creation. These aspects explore various dimensions, providing valuable insights into the topic.

- Cost Factors: Labor rates, trailer type, and wiring complexity influence the installation cost.

- Safety Implications: Proper wiring ensures functioning brake lights, turn signals, and taillights, enhancing safety.

- Legal Compliance: Meeting legal requirements for trailer lighting is crucial to avoid penalties.

- Electrical System Compatibility: Matching the wiring harness to the trailer’s electrical system is essential for proper functionality.

- DIY vs. Professional Installation: Assessing the complexity and potential cost savings can guide the decision.

- Type of Trailer: Different trailer types (e.g., enclosed, flatbed) may have specific wiring requirements.

- Towing Vehicle Compatibility: Ensuring compatibility between the towing vehicle and trailer’s electrical systems is crucial.

- Maintenance and Repair Costs: Regular maintenance and potential repair costs should be considered in the overall budget.

Exploring these key aspects provides a deeper understanding of the topic, encompassing cost factors, safety considerations, legal implications, and technical details. By considering these aspects, individuals can make informed decisions regarding U-Haul trailer wiring harness installation, ensuring a safe and compliant towing experience.

Cost Factors

The cost of installing a U-Haul trailer wiring harness is directly influenced by several key factors, namely labor rates, trailer type, and wiring complexity. These factors are interconnected and play a crucial role in determining the overall expense associated with the installation process.

Labor Rates: Labor rates vary based on the geographical location, the experience of the installer, and the complexity of the installation. Higher labor rates in certain regions or for specialized technicians can result in increased installation costs.

Trailer Type: Different types of trailers have varying electrical system requirements. Enclosed trailers, for instance, typically require more complex wiring than flatbed trailers, leading to higher installation costs.

Wiring Complexity: The complexity of the wiring system also affects the installation cost. Trailers with additional features, such as brake controllers or reverse lights, require more extensive wiring, increasing the time and effort needed for installation.

Understanding the relationship between these cost factors and the overall installation cost of a U-Haul trailer wiring harness is essential for budgeting purposes and decision-making. By considering these factors, individuals can make informed choices and allocate resources accordingly.

Safety Implications

Within the context of “U-Haul Trailer Wiring Harness Installation Cost,” the safety implications of proper wiring hold paramount importance. Ensuring that brake lights, turn signals, and taillights are functioning correctly is not merely a matter of convenience but a critical safety measure that can prevent accidents and protect lives.

- Preventing Rear-End Collisions: Properly functioning brake lights alert following vehicles of the trailer’s deceleration, providing ample time to react and avoid rear-end collisions.

- Indicating Turning Intentions: Turn signals convey the trailer’s intended direction, allowing other drivers to anticipate its movements and adjust accordingly, reducing the risk of side-impact collisions.

- Enhanced Visibility at Night: Taillights ensure that the trailer is visible to other vehicles, especially during nighttime or low-visibility conditions, preventing rear-end collisions and providing a clear indication of the trailer’s presence on the road.

- Legal Compliance: Meeting legal requirements for trailer lighting is not only a responsible action but also avoids potential fines and penalties, ensuring compliance with safety regulations.

The safety implications of proper trailer wiring extend beyond individual vehicles, contributing to the overall safety of the road environment. By ensuring that trailers are equipped with functioning lighting systems, we collectively reduce the likelihood of accidents, safeguard lives, and promote a culture of responsible driving.

Legal Compliance

Ensuring compliance with legal requirements for trailer lighting is a critical aspect of “U Haul Trailer Wiring Harness Installation Cost.” Overlooking this aspect can lead to costly penalties and compromise road safety.

- State and Federal Regulations: Trailer lighting systems must adhere to regulations set forth by individual states and federal agencies, such as the U.S. Department of Transportation (DOT). These regulations specify the minimum requirements for lighting devices, placement, and visibility.

- Enforcement and Penalties: Law enforcement officials are authorized to inspect trailers and issue citations for non-compliant lighting systems. Penalties may include fines, vehicle impoundment, and points added to the driver’s license.

- Insurance Implications: In the event of an accident involving a trailer with non-compliant lighting, insurance companies may dispute claims or reduce payouts, as the lack of proper lighting can be deemed contributory negligence.

- Safety and Liability: Properly functioning trailer lighting is essential for ensuring the safety of all road users. Negligence in maintaining compliant lighting can result in legal liability in the event of an accident.

Understanding the legal implications of trailer lighting compliance is paramount for avoiding penalties, ensuring road safety, and protecting oneself from legal repercussions. By adhering to legal requirements and investing in proper wiring harness installation, individuals can operate their trailers with peace of mind, knowing that they are fulfilling their legal obligations and contributing to a safer driving environment.

Electrical System Compatibility

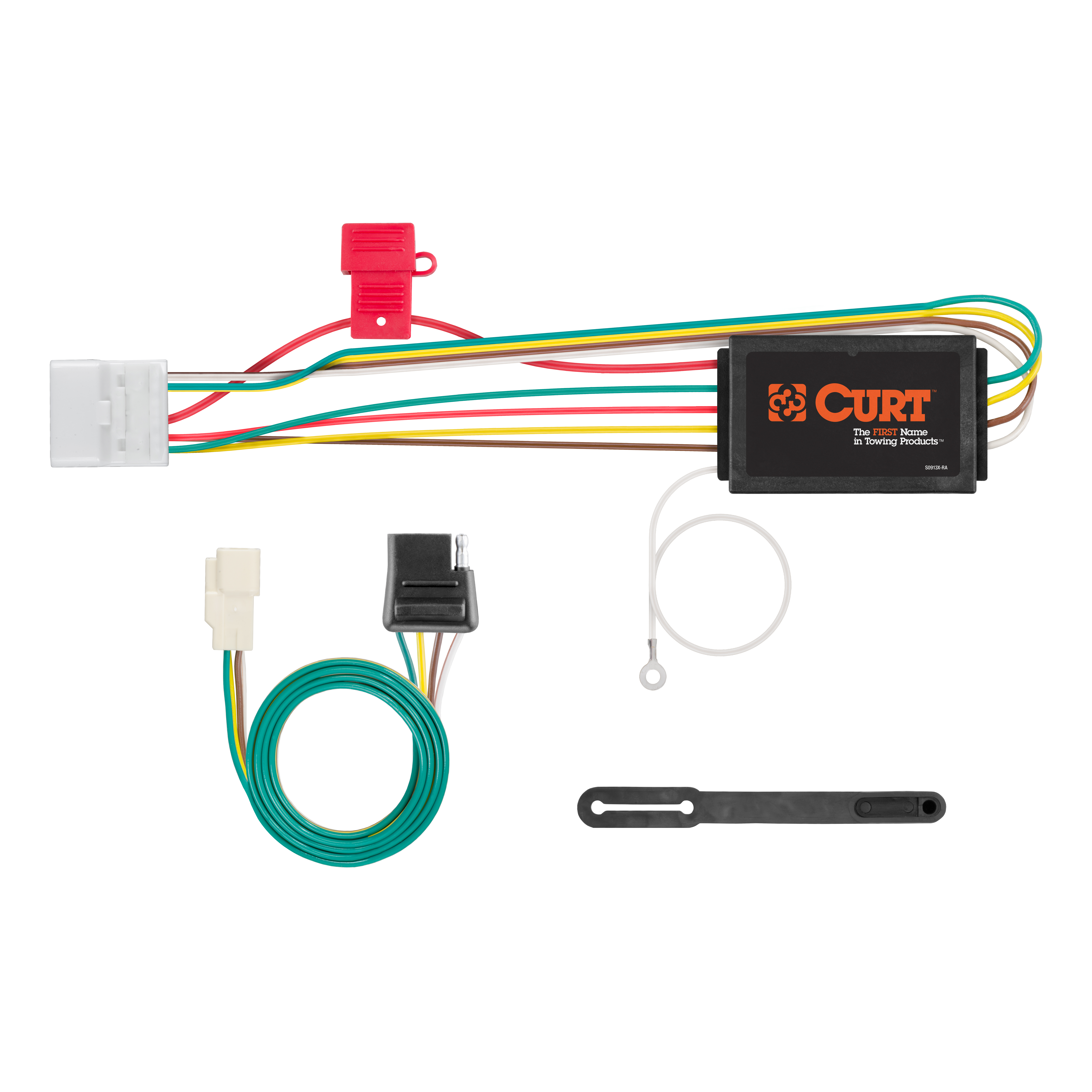

Within the context of “U Haul Trailer Wiring Harness Installation Cost,” electrical system compatibility plays a crucial role in ensuring the proper functioning of the trailer’s lighting system. Matching the wiring harness to the trailer’s electrical system is paramount, as any mismatch can lead to malfunctions, safety hazards, and additional costs.

Cause and Effect: An incompatible wiring harness can result in various issues, including:

- Malfunctioning Lights: Incorrectly matched wiring can cause lights to flicker, dim, or fail completely, compromising the trailer’s visibility and safety.

- Electrical Shorts: Mismatched wiring can create electrical shorts, leading to potential fire hazards and damage to the trailer’s electrical system.

- System Overloads: An incompatible wiring harness may not be able to handle the electrical load of the trailer, causing overloads and potential damage to electrical components.

Therefore, it is essential that the wiring harness is compatible with the trailer’s electrical system, ensuring proper functionality, safety, and cost-effective operation.

DIY vs. Professional Installation

When considering “U Haul Trailer Wiring Harness Installation Cost,” the decision between DIY installation and professional installation is crucial. This decision hinges on assessing the complexity of the installation and the potential cost savings associated with each option.

Complexity and Cost Savings: DIY installation may seem like a cost-effective option, but it can be more complex than anticipated, especially for individuals unfamiliar with electrical systems. Professional installation, while typically more expensive, ensures a proper and efficient installation, potentially saving costs in the long run by avoiding costly mistakes or the need for subsequent repairs.

Cause and Effect: Choosing the appropriate installation method directly impacts the overall cost. DIY installation can lead to incorrect wiring, electrical issues, or even safety hazards, resulting in additional expenses for repairs or replacements.

Real-Life Examples: Consider a scenario where a DIY installation leads to a faulty connection, causing a short circuit and damaging the trailer’s electrical system. This oversight could have been prevented with professional installation, ultimately saving the individual from additional repair costs.

Practical Applications: Understanding the connection between DIY vs. professional installation empowers individuals to make informed decisions. By carefully considering the complexity of the installation and the potential cost savings, they can choose the option that best suits their needs and budget.

Conclusion: The decision between DIY and professional installation for a U Haul trailer wiring harness installation is a critical one. Assessing the complexity and potential cost savings allows individuals to make informed choices, ensuring a safe and cost-effective installation that meets their specific requirements.

Type of Trailer

When considering “U Haul Trailer Wiring Harness Installation Cost,” the type of trailer plays a crucial role in determining the specific wiring requirements. Different trailer types have varying electrical needs, affecting the complexity and cost of installation.

- Enclosed Trailers: Enclosed trailers, often used for cargo transportation, require more extensive wiring due to their enclosed structure. Lighting systems, ventilation fans, and interior dome lights contribute to the overall electrical demand, necessitating a wiring harness that can accommodate these additional components.

- Flatbed Trailers: Flatbed trailers, commonly used for hauling vehicles or machinery, have simpler electrical requirements compared to enclosed trailers. Their primary lighting needs include brake lights, turn signals, and taillights, resulting in a less complex wiring harness installation.

- Utility Trailers: Utility trailers, designed for multipurpose use, fall somewhere in between enclosed and flatbed trailers in terms of wiring complexity. They may have additional features such as ramps, winches, or toolboxes, requiring a wiring harness that can support these accessories.

- Specialty Trailers: Specialty trailers, such as car haulers or livestock trailers, have unique wiring requirements tailored to their specific functions. Car haulers need wiring for loading lights and winches, while livestock trailers may require ventilation fans and heating systems, influencing the type and cost of the wiring harness.

Understanding the specific wiring requirements of different trailer types is essential for a successful and cost-effective installation. By matching the wiring harness to the trailer’s electrical needs, individuals can ensure proper functionality, safety, and compliance with regulations.

Towing Vehicle Compatibility

Within the context of “U Haul Trailer Wiring Harness Installation Cost,” towing vehicle compatibility plays a critical role, directly impacting the overall cost and effectiveness of the installation. Ensuring compatibility between the towing vehicle’s electrical system and the trailer’s electrical system is paramount for safe and reliable towing operations.

Cause and Effect: Incompatible electrical systems can lead to a range of issues, including:

- Electrical Malfunctions: Mismatched electrical systems can cause lights to malfunction, fuses to blow, or even damage sensitive electronic components.

- Safety Hazards: Inadequate or improper wiring can pose safety hazards, such as causing brake lights to fail or turn signals to malfunction, compromising the safety of both the towing vehicle and the trailer.

- Additional Costs: Addressing compatibility issues after installation can result in additional expenses for rewiring, purchasing adapters, or replacing damaged components.

Real-Life Examples: Consider a scenario where a trailer with an LED lighting system is connected to a towing vehicle with an incandescent lighting system. The different electrical requirements can lead to flickering lights, reduced brightness, or even electrical fires.

Practical Applications: Understanding the importance of towing vehicle compatibility empowers individuals to make informed decisions during the wiring harness installation process. By ensuring compatibility, they can avoid potential risks, ensure optimal performance, and minimize the overall cost of installation.

In summary, towing vehicle compatibility is a critical component of “U Haul Trailer Wiring Harness Installation Cost.” Neglecting compatibility can lead to electrical malfunctions, safety hazards, and additional expenses. By considering the electrical systems of both the towing vehicle and the trailer, individuals can ensure a successful and cost-effective installation.

Maintenance and Repair Costs

When considering “U Haul Trailer Wiring Harness Installation Cost,” it is crucial to factor in ongoing maintenance and potential repair costs associated with the wiring harness. Regular maintenance helps prevent premature failure and extends the lifespan of the installation, while budgeting for potential repairs ensures financial preparedness in the event of unforeseen circumstances.

Cause and Effect: Neglecting maintenance can lead to wiring deterioration, loose connections, and corrosion, increasing the likelihood of electrical issues and costly repairs. Regular maintenance, such as periodic inspections and cleaning, proactively addresses these issues, minimizing the risk of breakdowns and expensive fixes.

Real-Life Examples: For instance, failing to inspect wiring connections regularly can result in loose terminals or frayed wires, leading to intermittent lighting malfunctions or even electrical fires. Conversely, regular maintenance can identify and resolve these issues before they escalate into major problems.

Practical Applications: Understanding the relationship between maintenance and repair costs empowers individuals to make informed decisions about their trailer wiring harness. By incorporating maintenance into their budget, they can proactively prevent costly repairs, extend the lifespan of the installation, and ensure safe and reliable trailer operation.

In summary, “Maintenance and Repair Costs: Regular maintenance and potential repair costs should be considered in the overall budget” is an integral component of “U Haul Trailer Wiring Harness Installation Cost.” Regular maintenance helps minimize the likelihood of costly repairs, while budgeting for potential repairs provides financial security against unexpected expenses. By considering both aspects, individuals can ensure the long-term functionality and cost-effectiveness of their trailer wiring harness installation.

Related Posts