A tail light wiring harness is an electrical assembly that connects the taillights of a vehicle to the vehicle’s electrical system. It provides power and ground connections, as well as turn signal and brake light signals. For example, a 2023 Toyota Camry has a tail light wiring harness that includes wires for the left and right taillights, as well as a license plate light.

Tail light wiring harnesses are essential for vehicle safety, as they ensure that the taillights are operational. They also provide convenience, as they eliminate the need for individual wires to be run from the taillights to the electrical system. A key historical development in tail light wiring harnesses was the introduction of multiplex wiring in the 1990s. Multiplex wiring uses a single wire to carry multiple signals, which reduces the number of wires needed in a harness and makes it easier to diagnose electrical problems.

In this article, we will discuss the different types of tail light wiring harnesses, their benefits, and how to install them. We will also provide troubleshooting tips for common problems with tail light wiring harnesses.

Tail light wiring harnesses are essential components of a vehicle’s electrical system, ensuring the proper functioning of taillights, brake lights, and turn signals. Understanding the key aspects of tail light wiring harnesses is crucial for ensuring vehicle safety and functionality.

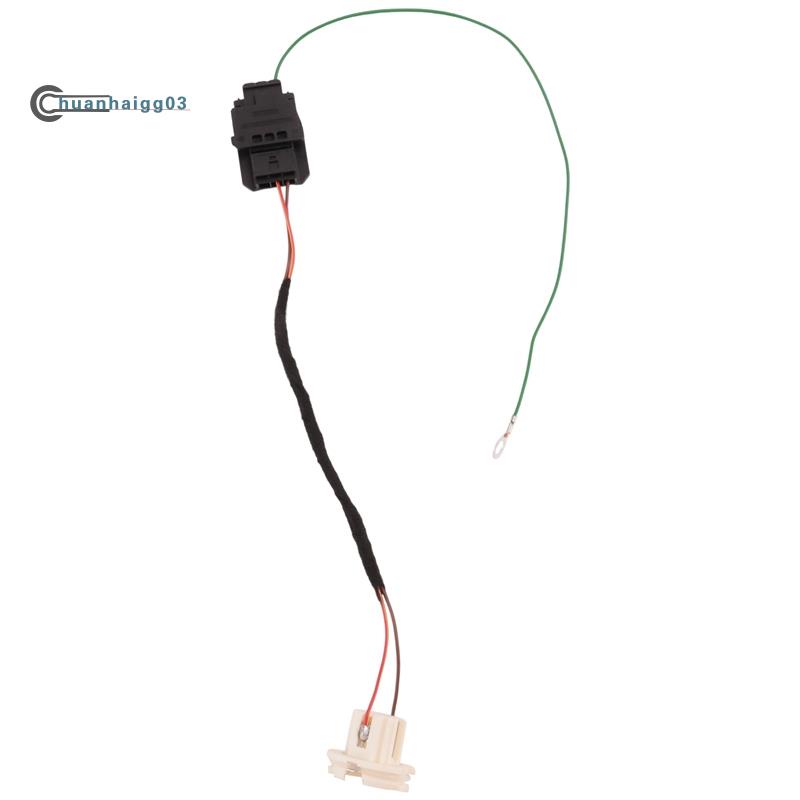

- Components: Wires, connectors, terminals, relays

- Function: Power and ground connections, signal transmission

- Types: OEM, aftermarket, custom

- Materials: Copper, aluminum, plastic

- Installation: Requires electrical knowledge and tools

- Safety: Proper installation and maintenance are essential

- Troubleshooting: Common problems include loose connections, damaged wires, and faulty relays

- Maintenance: Regular inspection and cleaning

- Customization: Aftermarket harnesses allow for modifications and upgrades

- Cost: Varies depending on type, quality, and installation

These key aspects provide a comprehensive understanding of tail light wiring harnesses. Proper selection, installation, and maintenance of tail light wiring harnesses are essential for ensuring the safety and reliability of a vehicle’s lighting system. Neglecting these aspects can lead to electrical problems, reduced visibility, and potential safety hazards.

Components

Wires, connectors, terminals, and relays are essential components of a tail light wiring harness. They work together to provide power and ground connections, as well as transmit turn signal and brake light signals. Without these components, the taillights would not be able to function properly.

Wires are the most basic component of a wiring harness. They are used to conduct electricity from one point to another. Connectors are used to join wires together, and terminals are used to connect wires to electrical components. Relays are used to switch electrical circuits on and off. In a tail light wiring harness, relays are used to turn the taillights on and off, as well as to flash the turn signals.

The proper selection and installation of these components is critical for the safe and reliable operation of a tail light wiring harness. If any of these components fail, the taillights may not function properly, which could lead to safety hazards. For example, if the wires in a tail light wiring harness are damaged, the taillights may not turn on, which could make it difficult for other drivers to see the vehicle at night.

Understanding the connection between the components of a tail light wiring harness is essential for anyone who works on vehicles. By understanding how these components work together, it is possible to troubleshoot and repair problems with tail light wiring harnesses quickly and efficiently.

Function

Within the context of a tail light wiring harness, “Function: Power and ground connections, signal transmission” encompasses the essential of supplying electrical power, establishing grounding pathways, and facilitating the transmission of signals that control the behavior of taillights. These functions are critical for ensuring the proper and reliable operation of a vehicle’s tail light assembly.

- Power Supply: Tail light wiring harnesses provide a conduit for electrical power to reach the taillights. This power is sourced from the vehicle’s battery and is essential for illuminating the taillights, enabling them to fulfill their primary function of providing visibility and signaling intentions to other road users.

- Grounding: Establishing proper grounding connections is equally important. The tail light wiring harness includes grounding wires that connect the taillights to the vehicle’s chassis or other grounding points. These connections provide a path for electrical current to complete its circuit, ensuring that the taillights function correctly and preventing electrical malfunctions.

- Turn Signal and Brake Light Signals: Tail light wiring harnesses also facilitate the transmission of signals that control the operation of turn signals and brake lights. These signals are generated by the vehicle’s turn signal switch and brake pedal, respectively. The wiring harness transmits these signals to the taillights, allowing them to flash when indicating turns or illuminate brightly when braking, thereby communicating the vehicle’s intentions to other drivers.

- License Plate Light: In many cases, tail light wiring harnesses also incorporate wires that provide power to the license plate light. This light illuminates the vehicle’s license plate, making it visible to law enforcement and other road users, especially during nighttime.

In summary, the “Function: Power and ground connections, signal transmission” of a tail light wiring harness encompasses the provision of electrical power, establishment of grounding pathways, and transmission of signals for turn signals, brake lights, and license plate illumination. These functions are crucial for ensuring the proper operation of a vehicle’s tail light assembly, enhancing visibility, and facilitating communication with other road users.

Types

Within the domain of tail light wiring harnesses, the distinction between OEM (Original Equipment Manufacturer), aftermarket, and custom harnesses offers a range of options catering to diverse needs and preferences. Understanding the characteristics and implications of each type is essential for making informed decisions when selecting and installing a tail light wiring harness.

-

OEM Harnesses:

OEM harnesses are designed and manufactured by the vehicle’s original manufacturer. They are specifically engineered to match the vehicle’s electrical system and taillight assembly, ensuring seamless integration and optimal performance. OEM harnesses are generally more expensive than aftermarket options but provide the highest level of compatibility and reliability.

-

Aftermarket Harnesses:

Aftermarket harnesses are manufactured by third-party companies and designed to be compatible with a range of vehicle models. They offer a wider selection of options and price points compared to OEM harnesses. While aftermarket harnesses may not always provide the same level of precision fit as OEM harnesses, they can be a cost-effective alternative for certain applications.

-

Custom Harnesses:

Custom harnesses are designed and built to meet specific requirements or preferences. They offer the highest level of customization, allowing for unique modifications or upgrades to the vehicle’s lighting system. Custom harnesses are typically more expensive and require professional installation, but they provide the most flexibility and control over the final outcome.

-

Implications:

The choice between OEM, aftermarket, and custom harnesses depends on several factors, including the vehicle model, desired features, budget, and skill level. OEM harnesses are the safest and most reliable option, while aftermarket harnesses offer a balance of affordability and customization. Custom harnesses provide the most flexibility but require specialized knowledge and expertise for proper installation.

Understanding the types of tail light wiring harnesses empowers enthusiasts and professionals alike to make informed decisions based on their specific requirements and preferences. Whether seeking a direct replacement, a cost-effective upgrade, or a fully customized solution, the availability of OEM, aftermarket, and custom harnesses ensures that there is an option to suit every need.

Materials

In the realm of “Tail Light Wiring Harness”, the choice of materials plays a pivotal role in ensuring reliability, durability, and optimal performance. Three primary materials copper, aluminum, and plastic serve distinct purposes, each contributing to the overall functionality and longevity of the wiring harness.

-

Conductors:

Copper and aluminum are the predominant materials used for conductors in tail light wiring harnesses. Copper offers superior conductivity, making it the preferred choice for transmitting electrical signals with minimal loss. Aluminum, while less conductive, is often utilized in larger gauge wires due to its lightweight and cost-effective nature.

-

Insulation:

Plastic materials, such as polyethylene and PVC, serve as insulation for the conductors. This insulation protects the conductors from short circuits and ensures safe operation by preventing current leakage. The type of plastic used determines factors such as flexibility, temperature resistance, and resistance to environmental factors.

-

Connectors:

Connectors, which facilitate the connection between different sections of the wiring harness, are often made of plastic or metal. Plastic connectors offer lightweight, cost-effective, and versatile solutions, while metal connectors provide enhanced durability and secure connections.

-

Sheathing:

To protect the entire wiring harness from physical damage, external sheathing is applied. Plastic materials, such as PVC and nylon, are commonly used for this purpose. The sheathing provides resistance to abrasion, moisture, and other environmental factors, ensuring the longevity of the wiring harness.

The careful selection and combination of these materials in the construction of a tail light wiring harness result in a robust and reliable component that ensures the proper functioning of the vehicle’s taillights. Understanding the materials used in “Tail Light Wiring Harness” empowers individuals to make informed decisions when selecting and maintaining this critical component of a vehicle’s electrical system.

Installation

The installation of a tail light wiring harness, while seemingly straightforward, demands a foundational understanding of electrical principles and the proper tools. This section delves into the intricacies of the installation process, highlighting crucial components, real-world examples, and the implications of proper installation.

-

Electrical Schematic Interpretation:

A comprehensive grasp of electrical schematics is essential for deciphering the wiring layout and identifying the correct connections. Misinterpretation can lead to incorrect installations, electrical malfunctions, or even safety hazards.

-

Wire Stripping and Crimping:

Meticulous wire stripping and crimping techniques ensure secure electrical connections. Improper stripping can result in exposed wires and potential short circuits, while inadequate crimping can lead to loose connections and intermittent failures.

-

Soldering and Heat Shrink:

Soldering and heat shrink tubing provide robust and reliable connections, preventing corrosion and ensuring long-term durability. Substandard soldering or improper heat shrink application can compromise the integrity of the harness, leading to potential electrical issues.

-

Grounding and Circuit Protection:

Establishing proper grounding and incorporating circuit protection devices, such as fuses or circuit breakers, are crucial for safety and functionality. Overlooked grounding can result in electrical malfunctions, while inadequate circuit protection can lead to catastrophic failures.

Understanding these facets of “Installation: Requires electrical knowledge and tools” emphasizes the significance of proper installation procedures when dealing with tail light wiring harnesses. By adhering to these principles and employing the appropriate tools, individuals can ensure the safe, reliable, and long-lasting operation of their vehicle’s tail light assembly.

Safety

When it comes to tail light wiring harnesses, safety should be the top priority. Proper installation and maintenance are crucial to ensure that your taillights are functioning correctly and providing adequate visibility for other drivers on the road. Neglecting these aspects can lead to serious consequences, including accidents and even fatalities.

One of the main reasons why proper installation is so important is that it ensures that the wiring harness is securely connected to the vehicle’s electrical system. A loose or improperly installed harness can cause intermittent electrical problems, which can lead to taillight failure at the most inopportune moments. Additionally, a poorly installed harness can create a fire hazard if it comes into contact with other electrical components.

Maintenance is equally important as it helps to prevent problems before they occur. Regular inspection of the wiring harness can help to identify any potential issues, such as loose connections, frayed wires, or corrosion. By addressing these issues early on, you can help to ensure that your taillights are always working properly.

In summary, safety should be the driving force behind all aspects of tail light wiring harness installation and maintenance. By taking the time to do it right, you can help to prevent accidents and keep yourself and others safe on the road.

Troubleshooting

Troubleshooting common problems with tail light wiring harnesses is essential for ensuring optimal functionality and safety. This involves identifying and resolving issues such as loose connections, damaged wires, and faulty relays, which can lead to taillight malfunctions and pose potential hazards on the road.

- Loose Connections: Poor electrical connections can cause intermittent taillight operation or complete failure. Inspect connectors for corrosion, dirt, or loose terminals, and ensure they are properly seated.

- Damaged Wires: Physical damage to wires, such as cuts or abrasions, can disrupt electrical flow. Examine the wiring harness for any visible damage and replace affected wires promptly.

- Faulty Relays: Relays act as switches that control the power supply to the taillights. A faulty relay can prevent the taillights from turning on or cause them to flicker erratically. Testing and replacing relays as needed is crucial.

- Grounding Issues: Proper grounding is vital for completing electrical circuits. Check for loose or corroded ground connections and ensure the wiring harness is securely attached to the vehicle’s chassis.

By addressing these common troubleshooting aspects, tail light wiring harness issues can be effectively resolved, ensuring reliable taillight operation and enhancing overall vehicle safety. Regular inspection and maintenance of the wiring harness can help prevent these problems from occurring in the first place, promoting peace of mind and safe driving experiences.

Maintenance

Regular inspection and cleaning play a critical role in ensuring the longevity and optimal performance of tail light wiring harnesses. Neglecting these maintenance tasks can lead to various problems, including:

- Corrosion: Moisture and dirt can accumulate on the wiring harness over time, leading to corrosion. Corrosion can damage the wires and connectors, causing electrical problems and taillight malfunction.

- Loose connections: Vibration and movement can cause the connections in the wiring harness to become loose. Loose connections can lead to intermittent electrical problems and taillight failure.

- Damaged wires: Physical damage to the wires in the wiring harness can occur due to abrasion, pinching, or rodent chewing. Damaged wires can cause electrical shorts and taillight failure.

Regular inspection and cleaning can help to prevent these problems by identifying and addressing potential issues early on. Inspection involves visually examining the wiring harness for any signs of damage or corrosion. Cleaning involves removing dirt and debris from the wiring harness using a mild cleaner and a soft brush.

In summary, regular inspection and cleaning are essential components of tail light wiring harness maintenance. By performing these tasks regularly, you can help to ensure that your taillights are always functioning properly and that your vehicle is safe to operate.

Customization

The advent of aftermarket tail light wiring harnesses has revolutionized the automotive industry, empowering enthusiasts and professionals alike to customize and upgrade their vehicles’ lighting systems. Aftermarket harnesses provide a range of options beyond the limitations of factory-installed harnesses, enabling modifications that enhance aesthetics, functionality, and personal style.

One of the primary reasons for the growing popularity of aftermarket tail light wiring harnesses is their adaptability to various vehicle models and lighting configurations. Unlike OEM harnesses, which are designed specifically for a particular make and model, aftermarket harnesses offer a wider range of compatibility, allowing for greater flexibility in customization. This flexibility empowers individuals to create unique and personalized lighting setups, tailored to their specific preferences and vehicle modifications.

Real-life examples of aftermarket tail light wiring harness customization include:

- Upgrading to LED taillights for improved visibility and a modern aesthetic

- Installing custom taillight assemblies with unique designs and patterns

- Adding additional taillights or auxiliary lighting for increased safety and visibility

These modifications not only enhance the vehicle’s appearance but also improve its functionality and safety on the road.

Understanding the connection between “Customization: Aftermarket harnesses allow for modifications and upgrades” and “Tail Light Wiring Harness” is crucial for anyone seeking to modify their vehicle’s lighting system. Aftermarket harnesses provide a platform for creativity and innovation, allowing individuals to express their personal style while enhancing the vehicle’s overall aesthetics and functionality. Whether it’s upgrading to LED taillights, installing custom taillight assemblies, or adding auxiliary lighting, aftermarket tail light wiring harnesses empower enthusiasts to transform their vehicles into truly unique and personalized creations.

Cost

The cost of a tail light wiring harness can vary significantly depending on several factors, including the type of harness, its quality, and the complexity of the installation. Understanding the relationship between these factors and the cost of a tail light wiring harness is essential for making informed decisions when purchasing and installing this critical component.

The type of tail light wiring harness is one of the primary determinants of its cost. OEM (Original Equipment Manufacturer) harnesses are typically the most expensive option, as they are designed and manufactured specifically for a particular make and model of vehicle. Aftermarket harnesses, on the other hand, are designed to be compatible with a wider range of vehicles and are generally more affordable than OEM harnesses. However, aftermarket harnesses may not always provide the same level of fit and finish as OEM harnesses.

The quality of a tail light wiring harness is another important factor that can affect its cost. Harnesses made from high-quality materials and components are more likely to be durable and reliable, and they may also come with longer warranties. However, high-quality harnesses tend to be more expensive than lower-quality harnesses.

Finally, the complexity of the installation can also affect the cost of a tail light wiring harness. Harnesses that require extensive modification or customization may be more expensive to install than harnesses that are designed for a direct fit. It is important to factor in the cost of installation when budgeting for a new tail light wiring harness.

Understanding the connection between “Cost: Varies depending on type, quality, and installation” and “Tail Light Wiring Harness” is essential for making informed decisions when purchasing and installing this critical component. By considering the factors discussed above, individuals can choose the right harness for their needs and budget, ensuring that their taillights are functioning properly and safely.

Related Posts