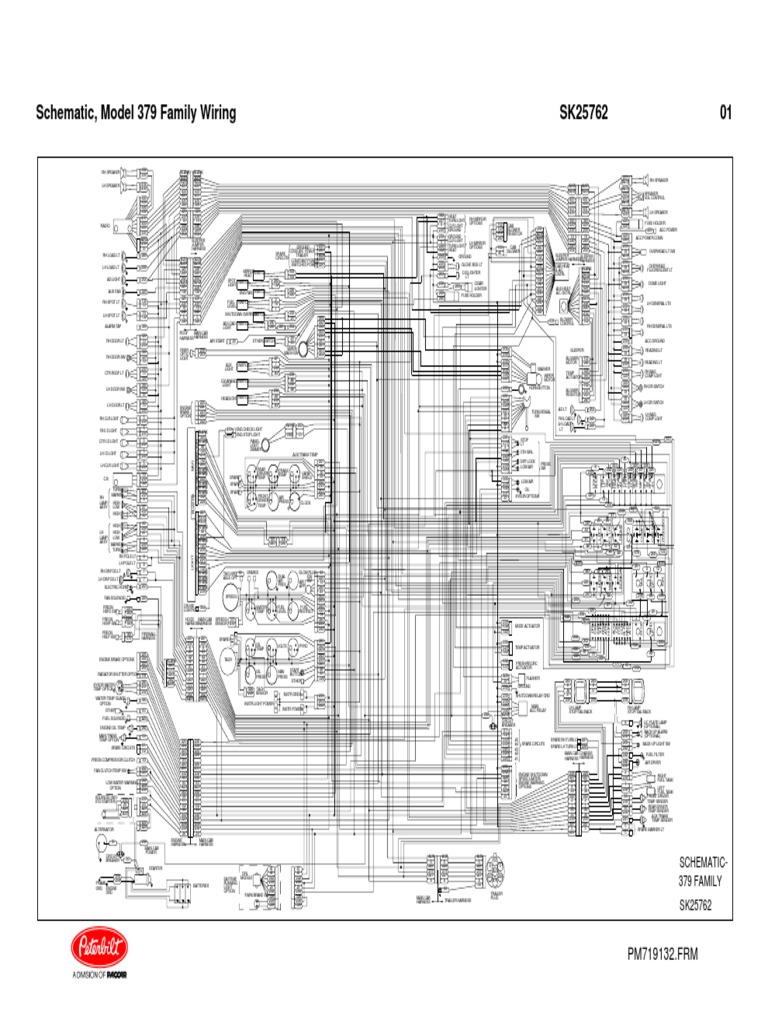

A Peterbilt 379 Wiring Schematic is a detailed diagram that outlines the electrical system of a Peterbilt 379 truck. It shows the location of all electrical components, as well as the wiring that connects them to each other. This information is essential for troubleshooting electrical problems and making repairs.

Some of the benefits of using a Peterbilt 379 Wiring Schematic include:

- Faster troubleshooting of electrical problems

- More accurate repairs

- Reduced downtime

A key historical development in the field of electrical schematics was the invention of the computer-aided design (CAD) software. This software allows engineers to create schematics that are more accurate and easier to read than hand-drawn schematics.

In this article, we will provide a detailed overview of the Peterbilt 379 Wiring Schematic. We will discuss the different components of the electrical system, as well as the wiring that connects them. We will also provide tips for troubleshooting electrical problems and making repairs.

The Peterbilt 379 Wiring Schematic is a crucial document for anyone who owns or operates a Peterbilt 379 truck. It provides a detailed overview of the truck’s electrical system, making it possible to troubleshoot problems and make repairs.

- Components: The schematic shows the location of all electrical components, including the battery, alternator, starter, and lights.

- Wiring: The schematic shows how all of the electrical components are wired together.

- Troubleshooting: The schematic can be used to troubleshoot electrical problems by identifying the circuit that is causing the problem.

- Repairs: The schematic can be used to make repairs by providing instructions on how to replace or repair electrical components.

- Maintenance: The schematic can be used to perform maintenance on the electrical system, such as checking connections and cleaning terminals.

- Modifications: The schematic can be used to make modifications to the electrical system, such as adding new lights or accessories.

- Safety: The schematic can be used to ensure that the electrical system is safe by identifying potential hazards and providing instructions on how to avoid them.

- Compliance: The schematic can be used to ensure that the electrical system complies with all applicable laws and regulations.

- Training: The schematic can be used to train new technicians on the electrical system of the Peterbilt 379 truck.

- Documentation: The schematic can be used as documentation for the electrical system of the Peterbilt 379 truck.

These are just a few of the key aspects of the Peterbilt 379 Wiring Schematic. By understanding these aspects, you can use the schematic to troubleshoot problems, make repairs, and maintain the electrical system of your Peterbilt 379 truck.

Components

The Peterbilt 379 Wiring Schematic provides a detailed overview of the truck’s electrical system, including the location of all electrical components. This information is essential for troubleshooting problems and making repairs. The schematic shows the location of the battery, alternator, starter, lights, and other electrical components.

- Battery: The battery is the power source for the electrical system. It provides the electricity needed to start the engine and power the truck’s electrical components.

- Alternator: The alternator charges the battery and provides electricity to the truck’s electrical components when the engine is running.

- Starter: The starter is responsible for starting the engine. It draws electricity from the battery to turn over the engine.

- Lights: The truck’s lights are powered by the electrical system. They provide illumination for driving at night and in low-visibility conditions.

These are just a few of the many electrical components that are shown on the Peterbilt 379 Wiring Schematic. By understanding the location of these components, you can more easily troubleshoot problems and make repairs.

Wiring

The Peterbilt 379 Wiring Schematic is a detailed diagram that shows how all of the electrical components in the truck are wired together. This information is essential for troubleshooting electrical problems and making repairs. Without a wiring schematic, it would be very difficult to trace the wires and identify the source of a problem.

The wiring schematic is a critical component of the Peterbilt 379 Wiring Schematic because it provides a visual representation of the electrical system. This makes it possible to see how the different components are connected and how the system works as a whole. This information is essential for understanding the electrical system and making repairs.

Real-life examples of wiring schematics within the Peterbilt 379 Wiring Schematic include the diagrams for the lighting system, the starting system, and the charging system. These diagrams show how the different components in each system are wired together and how they work together to perform a specific function.

The practical applications of understanding the wiring schematic are numerous. For example, a mechanic can use the schematic to troubleshoot electrical problems, make repairs, and modify the electrical system. The schematic can also be used to train new technicians on the electrical system of the Peterbilt 379 truck.

In summary, the wiring schematic is a critical component of the Peterbilt 379 Wiring Schematic. It provides a visual representation of the electrical system, making it possible to troubleshoot problems, make repairs, and modify the system. Understanding the wiring schematic is essential for anyone who works on the electrical system of a Peterbilt 379 truck.

Troubleshooting

Troubleshooting electrical problems can be a daunting task, but it is made much easier with the help of a wiring schematic. The Peterbilt 379 Wiring Schematic is a detailed diagram that shows how all of the electrical components in the truck are wired together. This information is essential for identifying the circuit that is causing a problem and making repairs.

- Identifying Faulty Components: The schematic can be used to identify faulty components by tracing the circuit that is causing the problem. This can be done by using a multimeter to test the voltage and continuity of the circuit.

- Real-Life Examples: One example of how the schematic can be used to troubleshoot electrical problems is to identify a blown fuse. A blown fuse will cause the circuit to lose power, and the schematic can be used to trace the circuit to find the blown fuse.

- Implications for Repair: Troubleshooting electrical problems with the schematic can help to identify the root cause of the problem, which can lead to more efficient and effective repairs.

- Training and Documentation: The schematic can also be used to train new technicians on the electrical system of the Peterbilt 379 truck and serve as documentation for the electrical system.

In conclusion, the Peterbilt 379 Wiring Schematic is an essential tool for troubleshooting electrical problems. It can be used to identify faulty components, trace circuits, and make repairs. Understanding how to use the schematic is essential for anyone who works on the electrical system of a Peterbilt 379 truck.

Repairs

Within the comprehensive Peterbilt 379 Wiring Schematic, the aspect of Repairs holds immense significance. It empowers individuals to effectively address electrical issues, guided by precise instructions for replacing or repairing electrical components. This ability to perform repairs not only ensures the smooth functioning of the truck’s electrical system but also contributes to overall operational efficiency and cost savings.

- Component Identification: The schematic serves as a valuable tool for identifying malfunctioning components within the electrical system. By tracing circuits and analyzing voltage and continuity, technicians can pinpoint the exact component causing the problem, enabling targeted repairs.

- Replacement Instructions: The schematic provides detailed instructions on how to replace faulty electrical components. Step-by-step guidance ensures proper component removal, installation, and connection, minimizing the risk of further damage or incorrect assembly.

- Repair Procedures: In cases where components can be repaired rather than replaced, the schematic offers valuable insights into the necessary repair procedures. This information empowers technicians to restore the functionality of electrical components, extending their lifespan and reducing replacement costs.

- Safety Considerations: The schematic emphasizes safety precautions and proper handling techniques when working with electrical components. By adhering to these guidelines, technicians can minimize the risk of electrical hazards, ensuring a safe working environment.

In conclusion, the “Repairs: The schematic can be used to make repairs by providing instructions on how to replace or repair electrical components” aspect of the Peterbilt 379 Wiring Schematic underscores the significance of electrical system maintenance and repair. By leveraging the schematic’s detailed instructions, technicians can effectively troubleshoot electrical problems, replace or repair faulty components, and maintain the optimal functioning of the truck’s electrical system, ultimately contributing to the efficiency, safety, and longevity of the vehicle.

Maintenance

Maintenance is a critical aspect of ensuring the proper functioning and longevity of the electrical system in a Peterbilt 379 truck. Regular maintenance tasks, such as checking connections and cleaning terminals, can help prevent electrical problems, improve performance, and extend the lifespan of electrical components.

The Peterbilt 379 Wiring Schematic plays a vital role in performing maintenance on the electrical system. The schematic provides a detailed diagram of the electrical system, including the location of all electrical components, wires, and terminals. This information is essential for technicians to identify and access the specific components that require maintenance.

Real-life examples of maintenance tasks that can be performed using the schematic include:

- Checking the tightness of electrical connections to ensure proper conductivity and prevent loose connections that can cause electrical problems.

- Cleaning terminals to remove corrosion and dirt buildup, which can reduce electrical flow and lead to malfunctions.

- Inspecting wires for damage or wear, such as cuts or fraying, which can compromise electrical safety and functionality.

By utilizing the Peterbilt 379 Wiring Schematic for maintenance purposes, technicians can ensure that the electrical system is operating at its optimal level. Regular maintenance helps prevent costly repairs, reduces downtime, and contributes to the overall safety and reliability of the truck.

Modifications

Within the multifaceted realm of the Peterbilt 379 Wiring Schematic, the aspect of Modifications holds significant importance, empowering users to tailor the electrical system to their specific needs and preferences. This ability to make modifications underscores the versatility of the schematic and its adaptability to various scenarios.

- Adding Accessories: The schematic enables the seamless integration of new electrical accessories, such as additional lighting systems, electronic devices, or specialized equipment, enhancing the functionality of the truck for specific applications.

- Upgrading Components: In cases where existing electrical components require upgrades, the schematic provides guidance on selecting suitable replacements, ensuring compatibility and optimizing system performance.

- Customizing Lighting: Modifications to the electrical system allow for customization of the truck’s lighting system, including the addition of auxiliary lights, fog lights, or decorative lighting, enhancing visibility and aesthetics.

- Electrical Troubleshooting: The schematic can serve as a valuable tool for troubleshooting electrical issues that arise from modifications, facilitating the identification and resolution of problems.

The ability to make modifications using the Peterbilt 379 Wiring Schematic empowers users to adapt the electrical system to their unique requirements, ensuring optimal performance, safety, and personalization of the truck. Whether it involves enhancing functionality, upgrading components, customizing lighting, or troubleshooting electrical issues, the schematic provides a comprehensive framework for successful modifications.

Safety

Within the comprehensive Peterbilt 379 Wiring Schematic, the aspect of Safety plays a critical role in safeguarding the electrical system and the overall well-being of the truck and its occupants. The schematic empowers users to identify potential hazards, mitigate risks, and ensure the safe operation of the electrical system.

- Hazard Identification: The schematic provides detailed information on the electrical system, enabling users to identify potential hazards such as overloaded circuits, loose connections, or damaged wires. This knowledge empowers them to proactively address these hazards and prevent electrical failures.

- Grounding and Bonding: The schematic emphasizes the importance of proper grounding and bonding, ensuring that electrical components are correctly connected to the chassis and that stray currents are safely discharged. This reduces the risk of electrical shocks, fires, and other safety concerns.

- Fuse and Circuit Breaker Protection: The schematic illustrates the location and function of fuses and circuit breakers within the electrical system. These protective devices play a crucial role in preventing electrical overloads and short circuits, safeguarding the electrical system and the truck from potential damage.

- Maintenance and Inspection: The schematic serves as a guide for regular maintenance and inspection of the electrical system. By following the schematic, users can identify areas that require attention, such as loose terminals, aging wires, or worn-out components. Timely maintenance helps prevent electrical problems and ensures the continued safe operation of the truck.

By utilizing the Peterbilt 379 Wiring Schematic, users can gain a thorough understanding of the electrical system, identify potential hazards, and implement appropriate safety measures. This proactive approach to electrical safety contributes to the reliable and safe operation of the truck, protecting both the vehicle and its occupants.

Compliance

The Peterbilt 379 Wiring Schematic is a critical tool for ensuring that the electrical system of a Peterbilt 379 truck complies with all applicable laws and regulations. This is important for a number of reasons. First, it helps to ensure the safety of the truck and its occupants. Electrical systems that are not compliant with applicable laws and regulations can pose a fire hazard or other safety risks. Second, it helps to protect the environment. Electrical systems that are not compliant with applicable laws and regulations can emit harmful pollutants.

The Peterbilt 379 Wiring Schematic provides detailed instructions on how to wire the electrical system of a Peterbilt 379 truck in a way that complies with all applicable laws and regulations. This information is essential for anyone who is working on the electrical system of a Peterbilt 379 truck, including mechanics, electricians, and do-it-yourselfers. By following the instructions in the schematic, you can help to ensure that the electrical system of your truck is safe and compliant with all applicable laws and regulations.

There are a number of real-life examples of how the Peterbilt 379 Wiring Schematic can be used to ensure compliance with applicable laws and regulations. For example, the schematic can be used to ensure that the electrical system of a truck is compliant with the Federal Motor Vehicle Safety Standards (FMVSS). The FMVSS are a set of safety standards that are issued by the National Highway Traffic Safety Administration (NHTSA). These standards cover a wide range of topics, including the design and installation of electrical systems. By following the instructions in the Peterbilt 379 Wiring Schematic, you can help to ensure that the electrical system of your truck meets all of the applicable FMVSS.

Training

The Peterbilt 379 Wiring Schematic serves as an invaluable resource for training new technicians, enabling them to gain a comprehensive understanding of the electrical system of the Peterbilt 379 truck. This training aspect plays a vital role in ensuring the proficiency and safety of technicians working on these vehicles.

- Component Identification: The schematic provides a detailed visual representation of the electrical system, allowing trainees to identify and locate individual components, such as batteries, alternators, and wiring harnesses.

- Circuit Analysis: Using the schematic, trainers can guide trainees in analyzing electrical circuits, explaining the flow of electricity and the functions of various components within each circuit.

- Troubleshooting Techniques: The schematic serves as a valuable tool for teaching troubleshooting techniques. Trainees can learn how to identify potential electrical problems and systematically isolate the root cause, enhancing their diagnostic skills.

- Safe Work Practices: The schematic emphasizes the importance of following safe work practices when working with electrical systems, including proper grounding, lockout/tagout procedures, and the use of personal protective equipment.

In addition to these facets, the schematic also provides a common platform for experienced technicians to share their knowledge and expertise with trainees, fostering a collaborative learning environment. The training aspect of the Peterbilt 379 Wiring Schematic is essential for developing a skilled and competent workforce capable of maintaining and repairing the electrical systems of these heavy-duty trucks.

Documentation

Within the comprehensive domain of the Peterbilt 379 Wiring Schematic, the aspect of Documentation stands out as a crucial element, providing a detailed historical record of the electrical system for future reference and analysis.

- Parts Catalog: The schematic serves as a comprehensive catalog of all electrical components within the Peterbilt 379 truck, enabling technicians and engineers to quickly identify and locate specific parts.

- Maintenance History: The schematic facilitates the recording of maintenance and repair work performed on the electrical system, providing a valuable timeline of servicing activities for troubleshooting and future reference.

- Modification Tracking: Any modifications or upgrades made to the electrical system can be documented on the schematic, ensuring an accurate representation of the current system configuration.

- Compliance Verification: The schematic can be used to verify compliance with electrical safety regulations and industry standards, acting as a reference point for auditors and inspectors.

In conclusion, the Documentation aspect of the Peterbilt 379 Wiring Schematic is a critical tool for maintaining an accurate and comprehensive record of the electrical system. It provides a valuable resource for troubleshooting, maintenance, modifications, and compliance verification, ensuring the safety, reliability, and longevity of the Peterbilt 379 truck.

Related Posts