One-way light switch wiring is a simple electrical circuit that controls the flow of electricity to a single light fixture. It consists of a switch, a light fixture, and a power source. The switch acts as a gatekeeper, allowing electricity to flow to the light fixture when it is in the “on” position and blocking the flow of electricity when it is in the “off” position. A common example of this type of wiring is found in homes, where a single switch controls a light in a room.

The main benefit of one-way light switch wiring is its simplicity and ease of installation. It is also a cost-effective solution for controlling lighting in small areas. Additionally, this type of wiring has been around for over a century, making it a well-established and reliable method for controlling lighting.

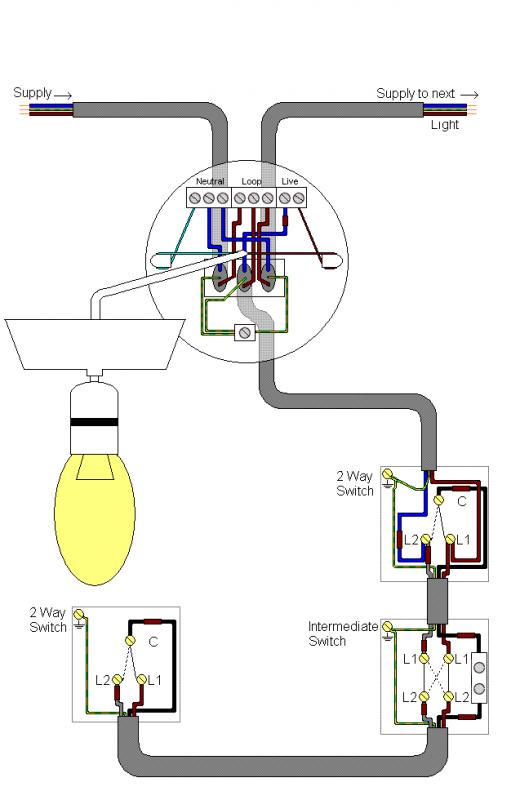

While one-way light switch wiring is simple and effective for many applications, it can be limited in situations where more complex light control is required. For instance, in a room with multiple light fixtures, multiple switches may be needed to control each fixture individually. In such cases, more advanced wiring methods, such as three-way or four-way switching, may be necessary.

One-way light switch wiring is a crucial aspect of electrical systems, particularly in residential and commercial buildings. Understanding its essential aspects is paramount for proper installation, maintenance, and troubleshooting. Here are eight key aspects to consider:

- Circuit design: One-way light switch wiring involves a simple circuit design, typically consisting of a power source, a switch, and a light fixture.

- Switch type: The switch used in one-way light switch wiring is a single-pole, single-throw (SPST) switch, which controls the flow of electricity to the light fixture.

- Wire gauge: The wire gauge used for one-way light switch wiring depends on the amperage of the circuit and the length of the wire run.

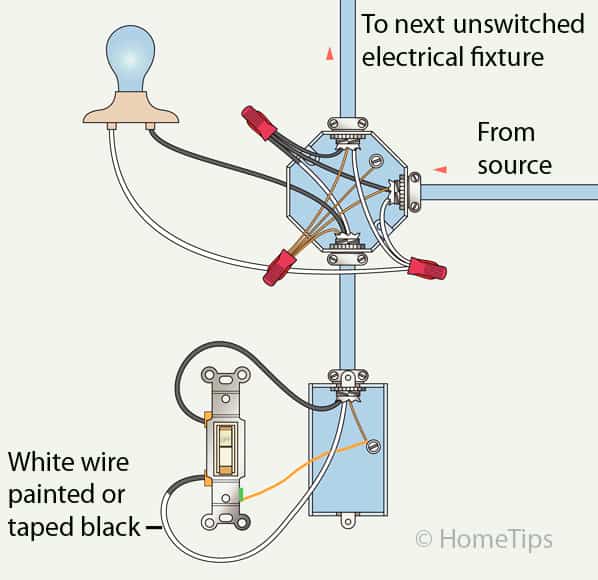

- Wiring method: One-way light switch wiring can be installed using various methods, including surface wiring, concealed wiring, or a combination of both.

- Safety considerations: Proper safety precautions must be taken during installation and maintenance, including using insulated wires and ensuring proper grounding.

- Code compliance: One-way light switch wiring must comply with local electrical codes and standards to ensure safety and functionality.

- Troubleshooting: Common troubleshooting issues with one-way light switch wiring include faulty switches, loose connections, and damaged wires.

- Maintenance: Regular maintenance, such as checking connections and cleaning switches, helps ensure the longevity and reliability of one-way light switch wiring.

These aspects are interconnected and play vital roles in the effective operation of one-way light switch wiring. Proper understanding and consideration of these aspects are essential for safe and efficient electrical systems.

Circuit design

In the context of one-way light switch wiring, circuit design plays a fundamental role in ensuring the proper functioning and safety of the electrical system. At its core, the circuit design involves three main components: a power source, a switch, and a light fixture. Understanding the specific roles and implications of each component is essential for a comprehensive understanding of one-way light switch wiring.

- Power source: The power source provides the electrical energy that flows through the circuit. In most residential and commercial buildings, the power source is the electrical panel, which distributes electricity throughout the building via various circuits.

- Switch: The switch acts as a gatekeeper, controlling the flow of electricity to the light fixture. When the switch is in the “on” position, it completes the circuit, allowing electricity to flow to the light fixture and illuminating it. Conversely, when the switch is in the “off” position, it breaks the circuit, interrupting the flow of electricity and turning off the light fixture.

- Light fixture: The light fixture is the device that produces light when electricity flows through it. Light fixtures come in various forms, such as ceiling lights, wall sconces, and floor lamps, and can accommodate different types of light sources, including incandescent bulbs, fluorescent tubes, and LED bulbs.

The simplicity of the circuit design in one-way light switch wiring is one of its key advantages. This simplicity makes it easy to install, maintain, and troubleshoot, even for those with limited electrical experience. Furthermore, the use of standard components, such as SPST switches and common wire gauges, ensures wide availability and affordability.

Switch type

In one-way light switch wiring, the switch plays a pivotal role in controlling the flow of electricity to the light fixture. The specific type of switch used in this wiring configuration is a single-pole, single-throw (SPST) switch. Understanding the characteristics and implications of SPST switches is essential for a comprehensive grasp of one-way light switch wiring.

- Single-pole: The term “single-pole” refers to the switch’s ability to control a single circuit, which in this case, is the flow of electricity to the light fixture. Unlike double-pole switches, which are used to control two separate circuits simultaneously, SPST switches are designed to manage a single electrical path.

- Single-throw: The “single-throw” aspect of the switch indicates that it has only two positions: “on” and “off”. When the switch is in the “on” position, it completes the circuit, allowing electricity to flow to the light fixture. Conversely, when the switch is in the “off” position, it breaks the circuit, interrupting the flow of electricity and turning off the light fixture.

- Real-life example: A common example of a SPST switch used in one-way light switch wiring is a standard wall switch found in residential and commercial buildings. These switches are typically mounted on walls and are used to control lighting in various rooms and spaces.

- Implications: The use of SPST switches in one-way light switch wiring has several implications. Firstly, it allows for simple and intuitive control of lighting, as the switch can be easily toggled between the “on” and “off” positions. Secondly, SPST switches are relatively inexpensive and widely available, making them a practical choice for various applications.

In summary, the switch type used in one-way light switch wiring is a single-pole, single-throw (SPST) switch. This type of switch is designed to control a single circuit and has two positions: “on” and “off”. SPST switches are commonly used in wall switches for controlling lighting in various settings. Understanding the characteristics and implications of SPST switches is essential for the proper installation, maintenance, and troubleshooting of one-way light switch wiring systems.

Wire gauge

In the context of one-way light switch wiring, the selection of the appropriate wire gauge is of paramount importance for ensuring the safety and reliability of the electrical system. The wire gauge refers to the thickness or cross-sectional area of the electrical wire, which directly influences its current-carrying capacity and resistance to voltage drop. Understanding the relationship between wire gauge, amperage, and wire run length is essential for proper installation and maintenance of one-way light switch wiring systems.

The amperage of a circuit refers to the amount of electrical current flowing through it. The higher the amperage, the greater the current flow and the thicker the wire gauge required to safely handle that current. Conversely, a lower amperage circuit can use a thinner wire gauge without exceeding the wire’s current-carrying capacity.

The length of the wire run also plays a significant role in determining the appropriate wire gauge. Longer wire runs introduce greater resistance to the flow of electricity, resulting in voltage drop. To compensate for this voltage drop and ensure adequate voltage at the light fixture, a thicker wire gauge is necessary for longer wire runs.

Real-life examples of wire gauge selection in one-way light switch wiring include:

- In a residential setting, a 14 AWG wire gauge is commonly used for lighting circuits with short to medium wire runs and amperage demands within the range of 15-20 amps.

- For longer wire runs or higher amperage circuits, such as those used in commercial or industrial applications, a thicker wire gauge, such as 12 AWG or 10 AWG, may be required.

Understanding the relationship between wire gauge, amperage, and wire run length is essential for ensuring the proper functioning and longevity of one-way light switch wiring systems. By carefully selecting the appropriate wire gauge, electrical professionals can minimize voltage drop, prevent overheating, and ensure the safe and efficient operation of lighting circuits.

Wiring method

The wiring method plays a crucial role in the installation and aesthetics of one-way light switch wiring. Surface wiring, as the name suggests, involves running the electrical wires along the surface of walls, ceilings, or other surfaces. This method is often used in older buildings, industrial settings, or when it is not feasible to conceal the wires within the walls or ceilings. Surface wiring is relatively easy to install and modify, making it a practical choice for temporary or exposed installations.

Concealed wiring, on the other hand, involves hiding the electrical wires within the walls, ceilings, or under the floorboards. This method provides a cleaner and more aesthetically pleasing appearance, as the wires are not visible. Concealed wiring is commonly used in newer buildings and renovations, where a more polished and integrated look is desired. However, installing concealed wiring requires more effort and expertise, as it involves cutting into walls or ceilings and ensuring proper insulation and protection of the wires.

In some cases, a combination of surface and concealed wiring may be used. For example, the main electrical wires may be concealed within the walls, while the final connection to the light fixture may be done using surface wiring. This approach allows for a balance between aesthetics and practicality.

The choice of wiring method depends on various factors, including the type of building, architectural constraints, desired aesthetics, and budget. Surface wiring is generally more cost-effective and easier to install, while concealed wiring provides a cleaner and more professional appearance. Understanding the different wiring methods and their implications is essential for making informed decisions during the design and installation of one-way light switch wiring systems.

Safety considerations

When working with electricity, safety should always be the top priority. This is especially true when installing or maintaining one-way light switch wiring, as improper handling can lead to electrical shocks, fires, or other hazards. There are several key safety considerations that must be taken into account to ensure a safe and reliable electrical system.

- Insulated wires: Electrical wires must always be properly insulated to prevent electrical shocks. Insulation is a non-conductive material that surrounds the wire and prevents the flow of electricity outside of the wire. When installing or repairing wires, it is important to ensure that the insulation is not damaged or frayed, as this can create a safety hazard.

- Proper grounding: Grounding is an essential safety feature that provides a path for electrical current to flow safely to the ground in the event of a fault. In one-way light switch wiring, the grounding wire is typically connected to the metal box that houses the switch. Proper grounding helps to protect against electrical shocks and prevents damage to equipment.

- Circuit breakers and fuses: Circuit breakers and fuses are devices that protect electrical circuits from overloads and short circuits. In the event of an electrical fault, a circuit breaker will trip or a fuse will blow, interrupting the flow of electricity to the circuit. This helps to prevent fires and other electrical hazards.

- Proper installation and maintenance: One-way light switch wiring should always be installed and maintained by a qualified electrician. Improper installation or maintenance can create safety hazards, such as loose connections or overloaded circuits. Regular inspections and maintenance can help to identify and correct potential problems before they become serious.

By following these safety considerations, you can help to ensure that your one-way light switch wiring is installed and maintained safely and reliably. Remember, electrical work can be dangerous, so it is important to always take the necessary precautions to protect yourself and your property.

Code compliance

Code compliance is a critical aspect of one-way light switch wiring, ensuring the safety and reliability of electrical systems. Local electrical codes and standards establish specific requirements for the installation and maintenance of electrical wiring, including one-way light switch wiring. Adhering to these codes is essential to minimize electrical hazards and ensure the proper functioning of lighting systems.

- Electrical safety: Electrical codes prioritize safety by mandating the use of appropriate materials, wiring methods, and installation practices. These regulations help to prevent electrical shocks, fires, and other hazards that can arise from faulty wiring.

- Component specifications: Codes and standards specify the types and ratings of electrical components that can be used in one-way light switch wiring. This includes the type of wire, wire gauge, switch type, and other components. Using non-compliant components can compromise the safety and functionality of the wiring system.

- Inspection and approval: In many jurisdictions, electrical installations, including one-way light switch wiring, must be inspected and approved by a qualified electrician or electrical inspector. This inspection process ensures that the wiring meets code requirements and is safe for use.

- Insurance implications: Homeowners’ and business insurance policies may require electrical systems to be compliant with local codes and standards. Failing to comply with these codes can void insurance coverage in the event of an electrical accident.

Code compliance is not merely a legal obligation but a fundamental aspect of responsible electrical practices. By adhering to local electrical codes and standards, electricians and homeowners can ensure the safety and reliability of one-way light switch wiring systems, protecting people and property from electrical hazards.

Troubleshooting

Troubleshooting is a critical aspect of one-way light switch wiring, as it enables the identification and resolution of common issues that can affect the functionality and safety of the wiring system.

Faulty switches, loose connections, and damaged wires are some of the most prevalent problems encountered in one-way light switch wiring. These issues can manifest in various ways, such as flickering lights, intermittent operation, or complete failure of the lighting system.

Identifying the root cause of these issues is essential for effective troubleshooting. Faulty switches may need to be replaced, while loose connections can be tightened or secured. Damaged wires, on the other hand, may require repair or replacement to ensure proper electrical flow and prevent safety hazards.

Understanding the relationship between troubleshooting and one-way light switch wiring is crucial for homeowners and electricians alike. By promptly addressing troubleshooting issues, it is possible to maintain the reliability and safety of the electrical system, preventing further damage or potential accidents.

Maintenance

Maintenance is an essential aspect of one-way light switch wiring, contributing significantly to its longevity and reliability. By regularly checking connections and cleaning switches, potential issues can be identified and addressed before they lead to more serious problems.

- Checking Connections: Loose connections are a common cause of electrical problems, including flickering lights and intermittent operation. Regularly checking and tightening connections, especially at terminals and wire nuts, ensures a secure and reliable electrical flow.

- Cleaning Switches: Over time, switches can accumulate dust and debris, which can interfere with their proper operation. Cleaning switches with a soft brush or cloth helps remove contaminants and ensures smooth switching action.

- Inspecting Wires: Regular inspection of wires can help identify any signs of damage or wear. Damaged wires can create safety hazards and should be repaired or replaced promptly to prevent electrical faults.

- Lubrication: In some cases, lubricating switch mechanisms with a light lubricant can improve their operation and reduce wear and tear.

By incorporating these maintenance practices into a regular routine, homeowners and electricians can proactively maintain the health of their one-way light switch wiring systems. This not only extends the lifespan of the wiring but also helps prevent electrical issues and ensures the continued safe and reliable operation of lighting systems.

Related Posts