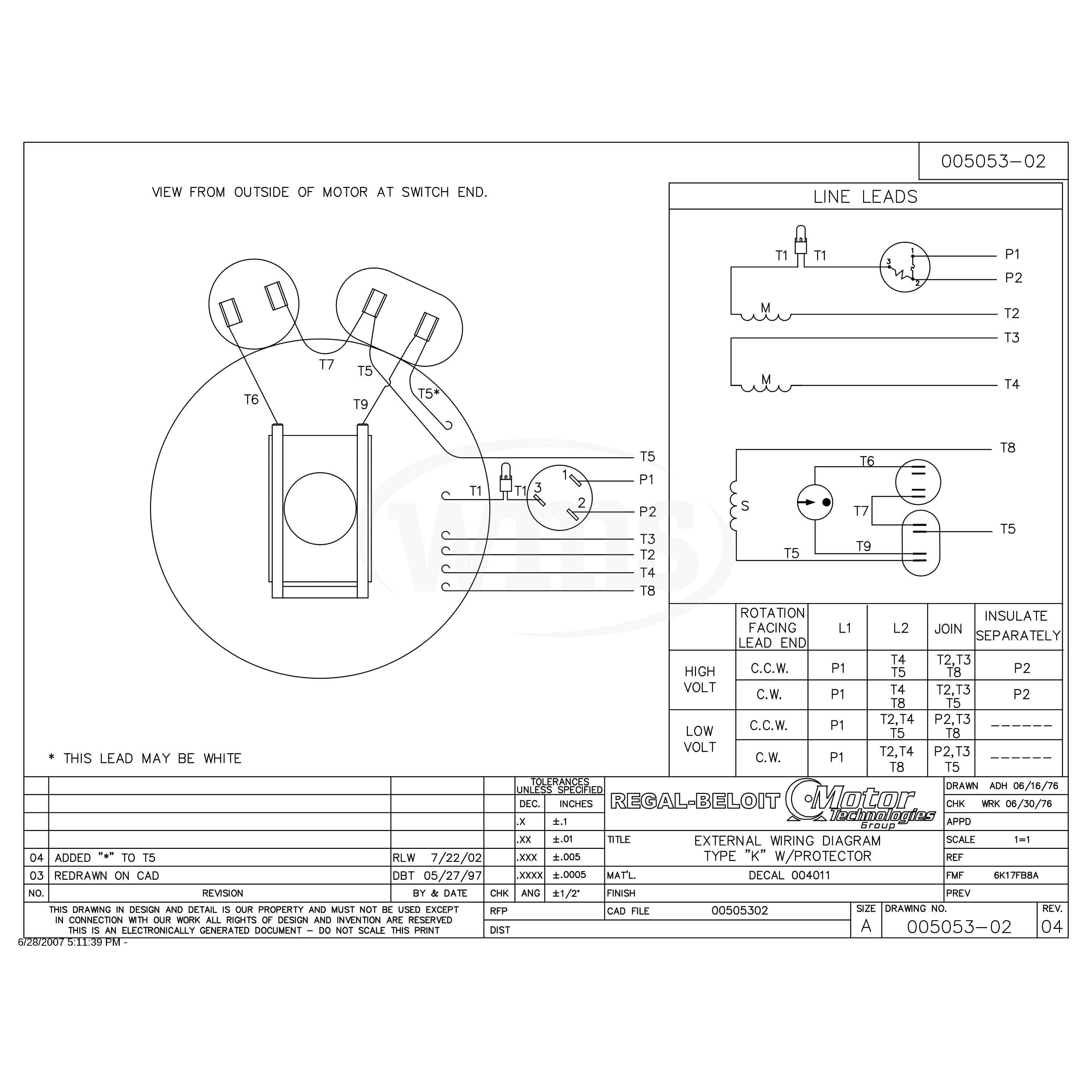

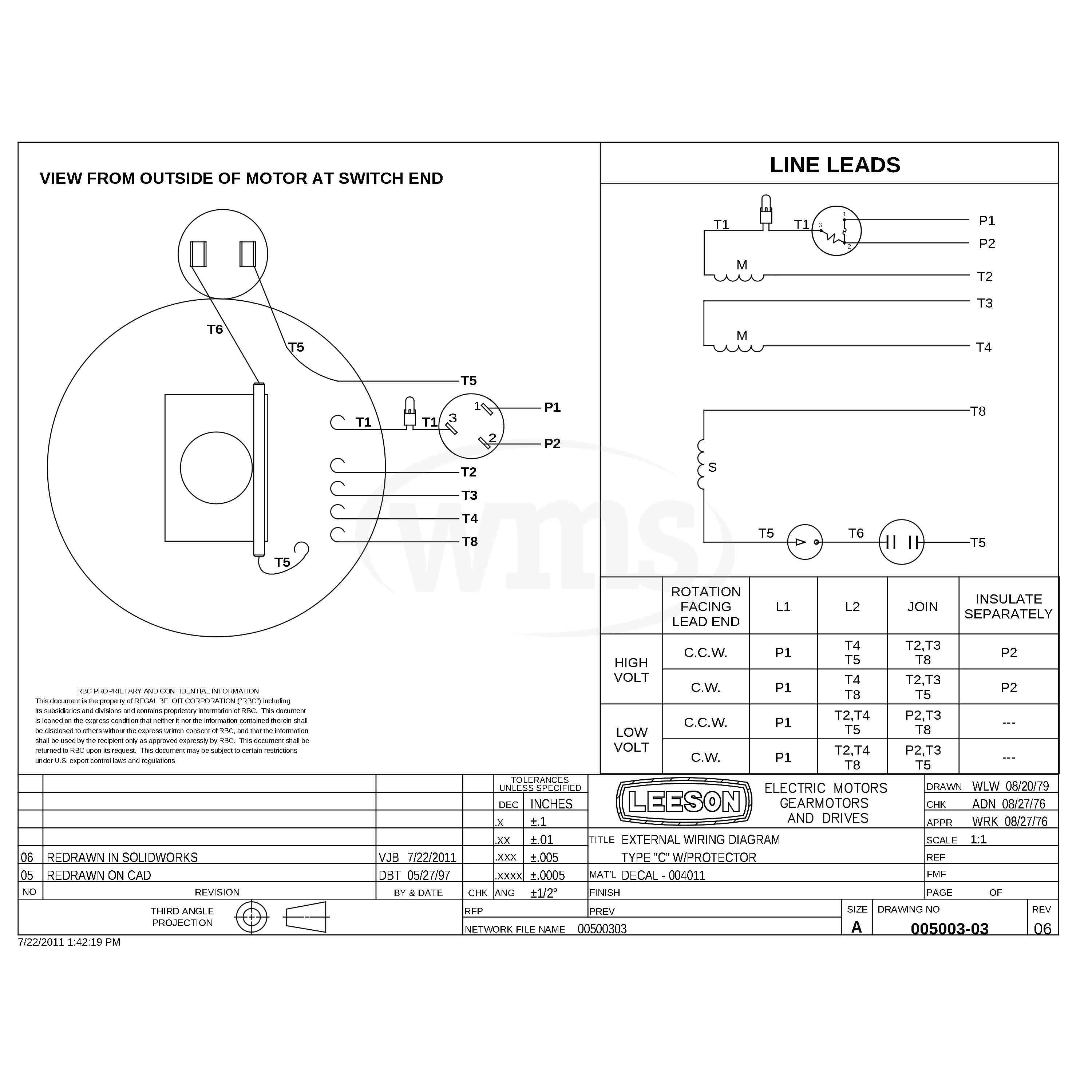

Leeson Electric Motors Wiring Diagrams are technical documents that provide detailed instructions on how to connect and wire Leeson electric motors for various applications. These diagrams serve as essential guides for electrical contractors, engineers, and technicians involved in the installation and maintenance of Leeson motors.

Leeson wiring diagrams are crucial for ensuring proper motor operation and safety. They specify the correct wiring configurations, including the connection of power supply, motor leads, control devices, and protective devices. By adhering to the diagrams, technicians can optimize motor performance, prevent electrical hazards, and extend the motor’s lifespan.

The development of Leeson wiring diagrams has paralleled the advancements in electric motor technology. As new motor designs and applications emerged, Leeson has continuously updated its diagrams to reflect the latest industry standards and safety regulations. The availability of comprehensive wiring diagrams contributes to the widespread adoption and reliability of Leeson electric motors in commercial, industrial, and residential settings.

Leeson Electric Motors Wiring Diagrams are indispensable for the proper installation and maintenance of Leeson electric motors. These diagrams provide detailed instructions on how to connect and wire the motors for various applications, ensuring optimal performance and safety. Understanding the key aspects of Leeson wiring diagrams is crucial for electrical professionals and anyone working with Leeson motors.

- Accuracy: Diagrams are meticulously designed by Leeson engineers, ensuring precise instructions for motor connections.

- Clarity: Diagrams use clear symbols and straightforward language, making them easy to interpret and follow.

- Comprehensiveness: Diagrams cover all aspects of motor wiring, from power supply to control devices and protective measures.

- Safety: Adhering to the diagrams promotes electrical safety by specifying proper grounding, insulation, and protection.

- Efficiency: Diagrams optimize motor performance by providing guidance on selecting the correct wire gauges and connection methods.

- Troubleshooting: Diagrams assist in diagnosing and resolving electrical issues, reducing downtime and maintenance costs.

- Compliance: Diagrams ensure compliance with electrical codes and standards, preventing safety hazards and legal liabilities.

- Customization: Diagrams can be modified to accommodate specific application requirements and motor configurations.

- Accessibility: Diagrams are readily available from Leeson and its distributors, ensuring easy access for electrical professionals.

- Technical Support: Leeson provides technical support to assist with understanding and applying the wiring diagrams.

These key aspects collectively contribute to the reliability, safety, and efficiency of Leeson electric motors. By thoroughly understanding and following the wiring diagrams, electrical professionals can ensure optimal motor performance, minimize downtime, and extend equipment lifespan.

Accuracy

Accuracy is a critical component of Leeson Electric Motors Wiring Diagrams. Meticulously designed by Leeson engineers, these diagrams provide precise instructions for motor connections, ensuring optimal performance, safety, and longevity. Without accurate diagrams, electrical professionals would face significant challenges in properly installing and maintaining Leeson motors.

Real-life examples of the importance of accuracy in Leeson wiring diagrams abound. Incorrect wiring can lead to motor damage, electrical hazards, and even personal injury. By providing clear and precise instructions, Leeson wiring diagrams help prevent these potential issues.

The practical applications of understanding the accuracy of Leeson wiring diagrams are numerous. Electrical contractors rely on these diagrams to ensure proper motor installation, minimizing downtime and maximizing efficiency. Engineers use the diagrams to design electrical systems that meet specific requirements and comply with safety regulations. Technicians utilize the diagrams for troubleshooting and maintenance, reducing repair time and costs.

In summary, the accuracy of Leeson Electric Motors Wiring Diagrams is essential for the safe, efficient, and reliable operation of Leeson motors. These diagrams are meticulously designed by Leeson engineers to provide precise instructions for motor connections, empowering electrical professionals to optimize motor performance and minimize risks.

Clarity

Clarity is of paramount importance in Leeson Electric Motors Wiring Diagrams. These diagrams utilize clear symbols and straightforward language, making them easily interpretable and actionable for electrical professionals. This clarity ensures accurate motor installation, efficient troubleshooting, and adherence to safety regulations.

- Standardized Symbols: Leeson wiring diagrams employ universally recognized electrical symbols, eliminating ambiguity and facilitating comprehension across different skill levels and language barriers.

- Logical Flow: Diagrams are structured in a logical sequence, guiding users through the wiring process step-by-step. This logical flow minimizes confusion and reduces the risk of errors.

- Concise Language: Diagrams use concise and unambiguous language, avoiding technical jargon that could hinder understanding. This clarity enables quick interpretation and decision-making.

- Real-Life Examples: Diagrams often include real-life examples or application notes, providing practical context and illustrating the practical application of the wiring instructions.

The clarity of Leeson Electric Motors Wiring Diagrams empowers electrical professionals to confidently install, maintain, and troubleshoot Leeson motors. This clarity promotes safety, efficiency, and compliance, ensuring optimal motor performance and longevity.

Comprehensiveness

Comprehensiveness is a defining characteristic of Leeson Electric Motors Wiring Diagrams. These diagrams encompass every facet of motor wiring, from the initial power supply to intricate control devices and protective measures. This all-inclusive approach ensures that electrical professionals have the complete picture, empowering them to install, maintain, and troubleshoot Leeson motors efficiently and safely.

- Power Supply: Diagrams provide detailed instructions on connecting the motor to the power source, specifying voltage, amperage, and grounding requirements. This ensures proper power delivery and prevents electrical hazards.

- Control Devices: Diagrams include wiring instructions for various control devices, such as starters, contactors, and relays. These devices regulate motor operation, enabling precise control and protection.

- Protective Measures: Diagrams incorporate essential protective measures, including overcurrent protection, thermal protection, and grounding. These measures safeguard the motor from damage and enhance overall safety.

- Real-Life Examples: Diagrams often include real-life examples or application notes, demonstrating practical applications of the wiring instructions. These examples help clarify complex concepts and facilitate troubleshooting.

The comprehensiveness of Leeson Electric Motors Wiring Diagrams empowers electrical professionals to approach motor wiring projects with confidence. By providing a holistic view of all wiring aspects, these diagrams contribute to safe, efficient, and reliable motor operation.

Safety

Electrical safety is paramount in the installation and maintenance of Leeson Electric Motors. Leeson wiring diagrams play a crucial role in ensuring safety by providing detailed instructions on proper grounding, insulation, and protection measures. Adhering to these diagrams is essential for preventing electrical hazards, protecting equipment, and safeguarding personnel.

- Proper Grounding: Diagrams specify grounding requirements for the motor frame, conduit, and other components. Proper grounding provides a low-resistance path for fault currents, minimizing the risk of electric shock and equipment damage.

- Adequate Insulation: Diagrams indicate the correct insulation materials and techniques for motor leads, terminals, and other components. Adequate insulation prevents electrical leakage, reduces the risk of short circuits, and ensures safe operation.

- Overcurrent Protection: Diagrams include instructions on selecting and installing overcurrent protection devices, such as fuses or circuit breakers. These devices protect the motor from damage caused by excessive current flow, preventing overheating and potential fire hazards.

- Thermal Protection: Diagrams provide guidance on incorporating thermal protection devices, such as thermal switches or relays. These devices monitor motor temperature and shut off the motor in case of overheating, preventing motor burnout and other catastrophic failures.

By following the safety guidelines outlined in Leeson wiring diagrams, electrical professionals can ensure that Leeson motors are installed, maintained, and operated in a safe and reliable manner. Adhering to these diagrams minimizes electrical hazards, protects equipment investments, and promotes a safe working environment.

Efficiency

Within the context of “Leeson Electric Motors Wiring Diagrams”, the aspect of efficiency holds significant importance. These diagrams provide detailed guidance on selecting the correct wire gauges and connection methods, which directly influences the overall performance and efficiency of Leeson electric motors. By specifying the appropriate wire sizes and ensuring proper connections, the diagrams help optimize motor operation, reduce energy consumption, and extend motor lifespan.

Real-life examples illustrate the practical significance of this aspect. Motors wired according to Leeson diagrams exhibit improved efficiency, leading to reduced operating costs and increased productivity. In industrial settings, where motors account for a substantial portion of energy consumption, optimizing motor efficiency can result in significant savings and contribute to sustainability goals.

Understanding the relationship between efficiency and wiring practices empowers electrical professionals to make informed decisions during motor installation and maintenance. By adhering to the guidelines provided in Leeson wiring diagrams, they can ensure that motors operate at their optimal efficiency, delivering maximum performance while minimizing energy consumption.

Troubleshooting

Within the realm of “Leeson Electric Motors Wiring Diagrams”, troubleshooting plays a pivotal role in maintaining optimal motor performance, minimizing downtime, and reducing maintenance costs. Leeson wiring diagrams provide invaluable assistance in diagnosing and resolving electrical issues, empowering electrical professionals to identify and rectify faults efficiently.

- Precise Fault Identification: Diagrams enable technicians to pinpoint the exact location and nature of electrical faults, reducing diagnostic time and guesswork. This precision facilitates targeted repairs, minimizing downtime and preventing unnecessary component replacements.

- Step-by-Step Troubleshooting: Diagrams provide a step-by-step guide to troubleshooting procedures, guiding technicians through a logical sequence of tests and inspections. This structured approach minimizes the risk of overlooking potential issues and ensures comprehensive fault resolution.

- Real-Life Examples: Diagrams often include real-life examples or case studies of common electrical faults and their solutions. These examples provide practical insights and help technicians relate theoretical knowledge to actual troubleshooting scenarios.

- Reduced Maintenance Costs: Accurate and efficient troubleshooting leads to timely repairs, preventing minor issues from escalating into major failures. This proactive approach minimizes the need for extensive maintenance or costly replacements, reducing overall maintenance costs.

In conclusion, the troubleshooting capabilities provided by Leeson Electric Motors Wiring Diagrams empower electrical professionals to diagnose and resolve electrical issues swiftly and effectively. By leveraging these diagrams, technicians can minimize downtime, optimize motor performance, and reduce maintenance costs, ensuring the smooth and reliable operation of Leeson electric motors.

Compliance

Within the context of Leeson Electric Motors Wiring Diagrams, compliance with electrical codes and standards is of paramount importance for ensuring the safety and reliability of electrical installations.

Cause and Effect:Leeson wiring diagrams serve as a critical component in achieving compliance. By providing detailed instructions that adhere to established electrical codes and standards, these diagrams guide electrical professionals in the proper installation, maintenance, and troubleshooting of Leeson electric motors. This adherence minimizes the risk of electrical hazards, such as short circuits, ground faults, and electric shock, which could result in injury, property damage, or legal liabilities.

Real-Life Examples:In industrial settings, electrical inspectors often require proof of compliance with electrical codes and standards before approving the operation of electrical equipment. Leeson wiring diagrams provide this proof by demonstrating that the installation and wiring of Leeson motors have been conducted according to accepted industry practices.

Practical Applications:The practical significance of understanding the connection between compliance and Leeson wiring diagrams lies in the ability to ensure safe and efficient operation of electrical systems. By adhering to the guidelines provided in these diagrams, electrical professionals can minimize the risk of electrical accidents, protect equipment investments, and maintain compliance with regulatory requirements.

Summary:In conclusion, compliance with electrical codes and standards is a critical aspect of Leeson Electric Motors Wiring Diagrams. These diagrams empower electrical professionals to install, maintain, and troubleshoot Leeson motors in a manner that meets safety regulations and industry best practices. Understanding this connection is essential for ensuring the safe, reliable, and compliant operation of electrical systems.

Customization

Within the realm of Leeson Electric Motors Wiring Diagrams, customization plays a pivotal role in ensuring optimal motor performance and versatility. Leeson wiring diagrams are designed to be adaptable, allowing electrical professionals to tailor them to meet the unique requirements of specific applications and motor configurations.

- Component Selection: Leeson wiring diagrams provide guidance on selecting the appropriate components for a given application, including contactors, starters, and protective devices. This flexibility enables electrical professionals to optimize motor performance and protection based on specific operating conditions and load requirements.

- Real-Life Examples: In industrial settings, Leeson motors are often used in variable speed applications or harsh environments. Customization of the wiring diagrams allows electrical professionals to incorporate additional control devices or protective measures to ensure reliable operation under demanding conditions.

- Motor Modifications: Leeson wiring diagrams can be modified to accommodate custom motor configurations, such as dual-voltage motors or motors with special windings. This customization ensures that the wiring diagram accurately reflects the specific motor’s electrical characteristics and operating requirements.

- Compliance and Safety: Customization of Leeson wiring diagrams must adhere to electrical codes and safety standards. Electrical professionals must have a thorough understanding of the applicable codes and regulations to ensure that modified diagrams maintain compliance and prioritize safety.

In conclusion, the customization aspect of Leeson Electric Motors Wiring Diagrams empowers electrical professionals to adapt and modify these diagrams to suit specific application requirements and motor configurations. This flexibility enables the optimization of motor performance, ensures compatibility with unique operating conditions, and maintains compliance with electrical codes and safety standards.

Accessibility

Within the context of Leeson Electric Motors Wiring Diagrams, accessibility holds paramount importance, as it ensures that electrical professionals have convenient and timely access to these essential documents.

- Online Availability: Leeson Electric Motors Wiring Diagrams are readily accessible online through Leeson’s website and authorized distributor platforms. This online availability allows electrical professionals to download and print diagrams anytime, anywhere, eliminating the need for physical storage or retrieval.

- Physical Distribution: In addition to online access, Leeson wiring diagrams are also distributed through a network of authorized distributors. This physical distribution ensures that electrical professionals can obtain hard copies of diagrams conveniently, even in remote areas with limited internet connectivity.

- Multiple Formats: Leeson Electric Motors Wiring Diagrams are available in various formats, including PDF, AutoCAD, and hard copy. This diversity of formats allows electrical professionals to choose the format that best suits their needs and preferences, enhancing accessibility and ease of use.

- Technical Support: Leeson provides comprehensive technical support to assist electrical professionals in understanding and applying the wiring diagrams. This support includes access to online resources, documentation, and direct communication with Leeson’s technical experts, ensuring that electrical professionals have the necessary guidance to use the diagrams effectively.

The accessibility of Leeson Electric Motors Wiring Diagrams empowers electrical professionals with the information they need to install, maintain, and troubleshoot Leeson motors efficiently and safely. By providing convenient and timely access to these diagrams, Leeson ensures that electrical professionals can perform their jobs with confidence and competence.

Technical Support

The technical support provided by Leeson is an integral component of Leeson Electric Motors Wiring Diagrams, forming a synergistic relationship that empowers electrical professionals to navigate the intricacies of motor wiring and ensure optimal performance.

This technical support manifests in various forms, including access to online resources, comprehensive documentation, and direct communication with Leeson’s technical experts. Through these channels, electrical professionals can obtain expert guidance on interpreting and applying the wiring diagrams to specific motor configurations and application requirements.

Real-life examples abound, showcasing the practical significance of Leeson’s technical support. In complex industrial settings, where motors are often subjected to demanding operating conditions, electrical professionals rely on Leeson’s technical experts to provide tailored advice on customizing wiring diagrams to meet specific needs. This support ensures that motors operate at peak efficiency, minimizing downtime and maximizing productivity.

The practical applications of understanding the connection between Leeson Electric Motors Wiring Diagrams and the technical support provided by Leeson extend far beyond troubleshooting and maintenance. By leveraging this support, electrical professionals gain a deeper comprehension of motor wiring principles and best practices, enabling them to design and implement electrical systems with enhanced safety, reliability, and efficiency.

In summary, the technical support provided by Leeson is not merely an add-on but an essential element of Leeson Electric Motors Wiring Diagrams. This support empowers electrical professionals to confidently navigate the complexities of motor wiring, ensuring optimal performance, minimizing downtime, and maximizing the lifespan of Leeson electric motors.

Related Posts