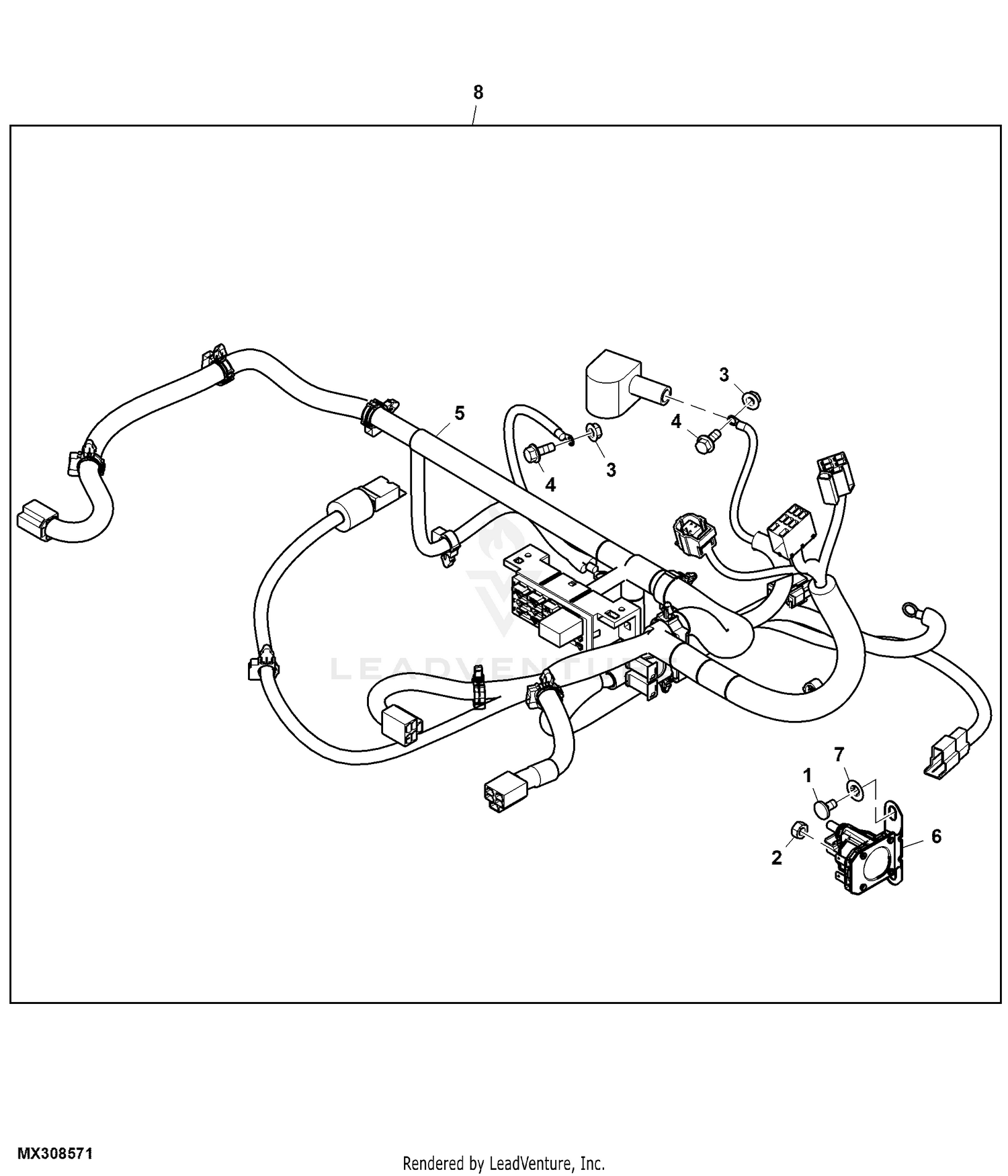

A John Deere Z425 Wiring Diagram is a detailed schematic that displays the electrical connections and components within the lawnmower’s electrical system. Its core function is to provide a visual representation of the electrical circuitry, enabling technicians and homeowners to troubleshoot issues, diagnose faults, and perform repairs or upgrades.

The diagram is crucial for understanding the electrical system’s functionality and ensuring the safe and efficient operation of the lawnmower. Its relevance extends to both professional mechanics and DIY enthusiasts who require a comprehensive understanding of the Z425’s electrical components and their interactions.

One key historical development in the evolution of wiring diagrams was the standardization of symbols and conventions, enabling universal interpretation and communication among technicians of different backgrounds. This standardization has greatly enhanced the accuracy and effectiveness of electrical system documentation.

Understanding the essential aspects of a John Deere Z425 Wiring Diagram is crucial for effectively troubleshooting, repairing, and maintaining the electrical system of the lawnmower. These key aspects encompass various dimensions related to the diagram’s structure, components, and functionality.

- Schematic Representation: The diagram provides a visual representation of the electrical circuitry, displaying the connections between components and the flow of electricity.

- Component Identification: It identifies and labels each electrical component, such as batteries, switches, relays, and motors, enabling easy recognition and location.

- Circuit Tracing: The diagram allows technicians to trace the path of electrical circuits, identifying potential breaks or faults.

- Troubleshooting Guide: It serves as a troubleshooting guide, providing information on common electrical problems and their potential causes.

- Repair Instructions: The diagram can guide repair procedures, indicating the correct replacement parts and wiring connections.

- Safety Precautions: It includes safety precautions and warnings related to handling electrical components and working on the lawnmower’s electrical system.

- Standardization: The diagram adheres to standardized symbols and conventions, ensuring universal understanding among technicians.

- Technical Accuracy: It provides accurate and detailed information about the electrical system, ensuring reliable troubleshooting and repairs.

- Accessibility: The diagram is readily available in the lawnmower’s technical manual or online, providing easy access for reference.

These key aspects collectively contribute to the effectiveness and usefulness of the John Deere Z425 Wiring Diagram, making it an essential tool for maintaining and repairing the lawnmower’s electrical system.

Schematic Representation

Within the context of the John Deere Z425 Wiring Diagram, schematic representation plays a pivotal role in conveying the intricate details of the lawnmower’s electrical system. It offers a graphical depiction of the electrical circuitry, capturing the interconnections between components and the flow of electricity throughout the system.

- Circuit Components: The diagram identifies and illustrates various electrical components, such as batteries, switches, relays, and motors, providing a clear understanding of their functions and interrelationships within the system.

- Wiring Connections: It meticulously portrays the wiring connections between components, detailing the paths of electrical current flow. This visual representation enables technicians to trace circuits, identify potential breaks or faults, and perform repairs or modifications.

- Circuit Analysis: The schematic representation allows for comprehensive circuit analysis, facilitating the identification of potential issues or inefficiencies. By studying the diagram, technicians can assess the flow of electricity, voltage distribution, and component interactions.

- Troubleshooting Guide: The diagram serves as a valuable troubleshooting guide, offering visual cues and insights into common electrical problems. Technicians can utilize the schematic to pinpoint potential fault locations, narrowing down the search and expediting the repair process.

In summary, the schematic representation aspect of the John Deere Z425 Wiring Diagram provides a comprehensive visual representation of the electrical circuitry, enabling technicians to understand the system’s functionality, diagnose issues, and perform repairs or upgrades efficiently and accurately.

Component Identification

Within the context of the John Deere Z425 Wiring Diagram, component identification plays a crucial role in understanding the electrical system’s functionality and facilitating efficient repairs or upgrades. The diagram meticulously identifies and labels each electrical component, including batteries, switches, relays, and motors, providing a clear visual representation of their locations and functions.

This component identification is a critical aspect of the wiring diagram as it enables technicians to:

- Rapidly Locate Components: The labeled components allow technicians to quickly identify and locate specific electrical components within the complex system, saving time and effort during troubleshooting or repairs.

- Understand System Functionality: By identifying each component’s function, the diagram helps technicians comprehend how the entire electrical system operates, enabling them to make informed decisions during repairs or modifications.

- Simplify Troubleshooting: Accurate component identification facilitates efficient troubleshooting by providing a visual reference for isolating potential issues and narrowing down the search for faults.

Real-life examples of component identification within the John Deere Z425 Wiring Diagram include:

- Battery Identification: The diagram clearly labels the battery, allowing technicians to quickly locate and inspect the power source of the electrical system.

- Switch Identification: Switches are labeled according to their functions, such as ignition switch or PTO switch, enabling technicians to easily identify and operate them.

- Relay Identification: Relays are labeled with their specific purposes, such as starter relay or fuel pump relay, providing technicians with a clear understanding of their roles in the system.

In summary, the component identification aspect of the John Deere Z425 Wiring Diagram is essential for efficient troubleshooting, repairs, and modifications of the electrical system. By providing a clear visual representation of each component’s location and function, the diagram empowers technicians to rapidly identify issues, understand system functionality, and make informed decisions during maintenance or repairs.

Circuit Tracing

Within the context of the John Deere Z425 Wiring Diagram, circuit tracing plays a critical role in troubleshooting electrical issues and ensuring the proper functioning of the lawnmower. The diagram serves as a roadmap, allowing technicians to visually trace the path of electrical circuits, identify potential breaks or faults, and pinpoint the root cause of electrical problems.

Circuit tracing is a fundamental aspect of electrical troubleshooting, as it enables technicians to:

- Locate Faults Rapidly: By tracing the electrical circuits, technicians can quickly identify the exact location of breaks or faults, expediting the repair process and minimizing downtime.

- Identify Intermittent Issues: Circuit tracing helps pinpoint intermittent electrical problems that may not be immediately apparent during initial inspections.

- Prevent Electrical Fires: By identifying and repairing circuit breaks or faults, technicians can prevent potential electrical fires, ensuring the safety of the lawnmower and its surroundings.

Real-life examples of circuit tracing within the John Deere Z425 Wiring Diagram include:

- Tracing a Faulty Starter Circuit: If the lawnmower fails to start, technicians can trace the starter circuit using the wiring diagram to identify any breaks or faults in the wiring, ignition switch, or starter solenoid.

- Identifying a Short Circuit: In the event of a short circuit, the wiring diagram allows technicians to trace the affected circuit and locate the point of failure, preventing further damage to the electrical system.

- Troubleshooting a Lighting Issue: If a headlight or taillight malfunctions, technicians can trace the lighting circuit using the diagram to identify any faults in the wiring, switches, or bulbs.

In summary, circuit tracing is a critical aspect of the John Deere Z425 Wiring Diagram, empowering technicians to troubleshoot electrical issues efficiently and accurately. By providing a visual representation of the electrical circuits, the diagram enables technicians to trace the flow of electricity, identify breaks or faults, and make informed decisions during repairs, ultimately ensuring the reliable operation of the lawnmower.

Troubleshooting Guide

Within the comprehensive framework of the John Deere Z425 Wiring Diagram, the troubleshooting guide emerges as a crucial component, offering invaluable assistance in diagnosing and resolving electrical issues that may arise in the lawnmower’s electrical system. This guide serves as a roadmap for technicians, providing a structured approach to problem identification and repair.

- Common Electrical Problems: The troubleshooting guide meticulously lists common electrical problems encountered in the Z425 lawnmower, including issues related to starting, charging, lighting, and instrumentation.

- Potential Causes: For each electrical problem, the guide outlines potential causes, ranging from faulty components to wiring issues and loose connections. This information empowers technicians to focus their troubleshooting efforts on the most likely causes.

- Diagnostic Steps: The guide provides step-by-step diagnostic procedures, guiding technicians through a series of tests and measurements to pinpoint the root cause of the electrical problem.

- Repair Recommendations: Once the cause of the electrical problem has been identified, the troubleshooting guide offers repair recommendations, including replacement of faulty components, repair of wiring, or adjustment of connections.

The troubleshooting guide is an indispensable tool for technicians, enabling them to efficiently and accurately diagnose and resolve electrical issues in the John Deere Z425 lawnmower. Its comprehensive coverage of common electrical problems, potential causes, diagnostic steps, and repair recommendations empowers technicians to maintain the electrical system in optimal condition, ensuring the reliable operation of the lawnmower.

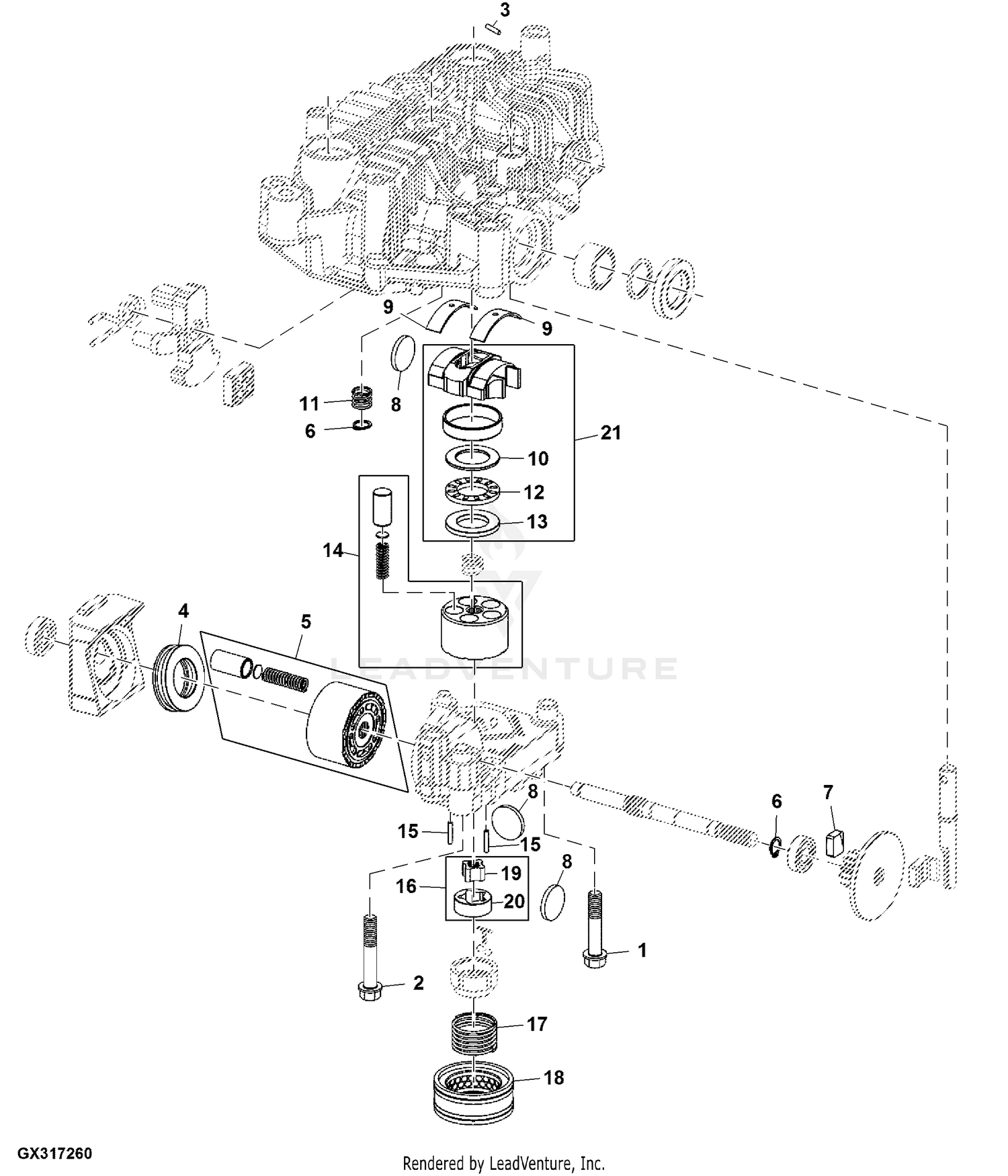

Repair Instructions

Within the context of the John Deere Z425 Wiring Diagram, repair instructions play a pivotal role in guiding technicians through the process of repairing electrical faults and restoring the proper functioning of the lawnmower’s electrical system. These instructions provide a step-by-step guide, detailing the necessary procedures for replacing faulty components, repairing wiring, and adjusting connections.

The repair instructions are closely intertwined with the John Deere Z425 Wiring Diagram, as they rely on the diagram’s visual representation of the electrical system to guide the repair process. The diagram serves as a reference point, enabling technicians to identify the location of faulty components, trace electrical circuits, and understand the interconnections between different components.

Real-life examples of repair instructions within the John Deere Z425 Wiring Diagram include:

- Replacing a Faulty Starter Solenoid: The wiring diagram guides the technician in locating the starter solenoid, identifying the correct replacement part, and providing the necessary steps for its replacement.

- Repairing a Broken Wire: The diagram helps the technician trace the affected circuit, identify the location of the break, and provides instructions on how to repair or replace the damaged wire.

- Adjusting Electrical Connections: The wiring diagram assists the technician in identifying loose or corroded connections, and provides instructions on how to properly clean and tighten them, ensuring optimal electrical flow.

The practical significance of understanding the connection between repair instructions and the John Deere Z425 Wiring Diagram lies in the ability to perform accurate and efficient repairs on the lawnmower’s electrical system. By following the step-by-step instructions and utilizing the diagram as a visual guide, technicians can effectively troubleshoot electrical faults, replace faulty components, and restore the electrical system to its optimal operating condition, ensuring the reliable operation of the lawnmower.

In summary, the repair instructions within the John Deere Z425 Wiring Diagram are essential for guiding technicians through the repair process, providing detailed procedures for replacing faulty components, repairing wiring, and adjusting connections. This understanding empowers technicians to accurately diagnose and resolve electrical issues, ensuring the proper functioning of the lawnmower’s electrical system.

Safety Precautions

Within the context of the John Deere Z425 Wiring Diagram, safety precautions play a paramount role in ensuring the well-being of technicians and preventing potential hazards while working on the lawnmower’s electrical system. These precautions and warnings provide essential guidance on the safe handling of electrical components, highlighting potential risks and outlining measures to mitigate them.

The inclusion of safety precautions in the John Deere Z425 Wiring Diagram is not merely an afterthought; it is a critical component that underscores the importance of safety in electrical work. By adhering to these precautions, technicians can minimize the risk of electrical shocks, fires, or other accidents, ensuring a safe working environment.

Real-life examples of safety precautions within the John Deere Z425 Wiring Diagram include:

- Proper Insulation: The diagram emphasizes the importance of using properly insulated tools and equipment to prevent electrical shocks.

- Lockout/Tagout Procedures: The diagram outlines lockout/tagout procedures to ensure that electrical power is isolated before working on the system.

- Grounding: The diagram provides instructions on grounding electrical components to prevent the buildup of static electricity.

- Protective Gear: The diagram recommends wearing appropriate protective gear, such as gloves and safety glasses, to minimize the risk of injury.

Understanding the connection between safety precautions and the John Deere Z425 Wiring Diagram is crucial for technicians working on the lawnmower’s electrical system. By following the outlined safety precautions, technicians can effectively reduce the risk of accidents, ensuring their safety and the safe operation of the lawnmower.

In summary, the inclusion of safety precautions in the John Deere Z425 Wiring Diagram is a testament to the importance of safety in electrical work. By adhering to these precautions, technicians can minimize the risk of electrical hazards, ensuring a safe working environment and the proper functioning of the lawnmower’s electrical system.

Standardization

Within the context of the John Deere Z425 Wiring Diagram, standardization emerges as a critical component, ensuring universal understanding among technicians and facilitating effective communication and collaboration in electrical system maintenance and repairs.

Standardization in the diagram is achieved through the adherence to universally recognized symbols and conventions, providing a common language for electrical schematics. This standardization transcends language barriers and cultural differences, enabling technicians from diverse backgrounds to interpret and utilize the diagram effectively.

Real-life examples of standardization within the John Deere Z425 Wiring Diagram include:

- Symbol Consistency: The diagram consistently employs standardized symbols to represent electrical components, such as batteries, switches, and motors, ensuring immediate recognition and understanding.

- Color Coding: Wires are color-coded according to industry standards, providing visual cues for tracing circuits and identifying their functions.

- Terminal Designations: Standardized terminal designations are used to identify connection points, simplifying the process of wiring and troubleshooting.

The practical significance of understanding the connection between standardization and the John Deere Z425 Wiring Diagram lies in its impact on the efficiency and accuracy of electrical system maintenance. By adhering to standardized symbols and conventions, the diagram promotes clarity and reduces the risk of misinterpretations. This standardization empowers technicians to quickly and accurately diagnose electrical issues, perform repairs, and maintain the lawnmower’s electrical system to optimal standards.

Moreover, standardization fosters collaboration and knowledge sharing among technicians. The use of a common language for electrical schematics enables technicians to easily exchange information, work together on complex repairs, and contribute to a collective body of knowledge. This collaborative environment ultimately benefits the end-user, ensuring the reliable and efficient operation of the John Deere Z425 lawnmower.

Technical Accuracy

Within the context of “John Deere Z425 Wiring Diagram,” technical accuracy reigns supreme, serving as the cornerstone for ensuring reliable troubleshooting and repairs. The diagram’s meticulous attention to detail and precise representation of the electrical system empower technicians with the confidence to diagnose issues accurately and perform repairs with assurance.

- Comprehensive Component Representation: The diagram encompasses all electrical components within the Z425 lawnmower, from the battery to the ignition system, ensuring a thorough understanding of the system’s architecture.

- Precise Circuit Mapping: Each electrical circuit is meticulously mapped, revealing the intricate connections between components and providing a clear roadmap for troubleshooting.

- Up-to-Date Information: The diagram reflects the latest design revisions and engineering updates, ensuring that technicians have access to the most current and accurate information.

- Rigorous Testing and Validation: The diagram undergoes rigorous testing and validation processes to guarantee its accuracy and reliability, ensuring that technicians can trust the information it provides.

The implications of technical accuracy in the “John Deere Z425 Wiring Diagram” are far-reaching. Accurate component representation enables technicians to quickly identify faulty parts, while precise circuit mapping facilitates efficient tracing of electrical issues. Up-to-date information ensures that technicians are working with the latest system specifications, and rigorous testing and validation provide peace of mind that the diagram is a trustworthy guide. Ultimately, technical accuracy empowers technicians to perform repairs with confidence, knowing that they have the most accurate and reliable information at their fingertips.

Accessibility

Within the context of “John Deere Z425 Wiring Diagram,” the aspect of accessibility plays a crucial role in ensuring that technicians and users have convenient and timely access to the necessary information for maintenance and repairs. The diagram’s ready availability in the lawnmower’s technical manual or online empowers individuals to troubleshoot issues, locate replacement parts, and perform repairs with ease.

- Technical Manual Inclusion: The diagram is incorporated into the lawnmower’s technical manual, providing a comprehensive resource for maintenance and repair information. This integration ensures that technicians have instant access to the diagram while working on the lawnmower.

- Online Availability: In addition to the technical manual, the diagram is readily available online through John Deere’s official website or other reputable sources. This online accessibility allows for quick reference and retrieval of the diagram from anywhere with an internet connection.

- Digital Convenience: The digital format of the diagram enables technicians to easily view, print, or share the diagram with colleagues or customers. This flexibility enhances collaboration and facilitates remote troubleshooting.

- Time-Saving Resource: The easy accessibility of the diagram saves technicians and users valuable time by eliminating the need for extensive searching or manual tracing of electrical circuits. Quick access to the diagram allows for prompt identification of issues and efficient repairs.

In summary, the accessibility of the “John Deere Z425 Wiring Diagram” through its inclusion in the technical manual and online availability provides unparalleled convenience and ease of use. This accessibility empowers technicians and users to efficiently troubleshoot, repair, and maintain the lawnmower’s electrical system, maximizing its performance and longevity.

Related Posts