Honeywell Zone Valve Wiring is a system of wires and electrical components that allow multiple heating or cooling zones to be controlled independently within a single HVAC system. For instance, in a home with three bedrooms, each bedroom might have its own zone valve, allowing the occupants to adjust the temperature in their room without affecting the temperature in other rooms.

Zone valve wiring offers significant benefits, including improved energy efficiency, increased comfort, and reduced wear and tear on the HVAC system. Historically, zone valve wiring has evolved from simple on/off controls to sophisticated systems that can be integrated with smart home technology.

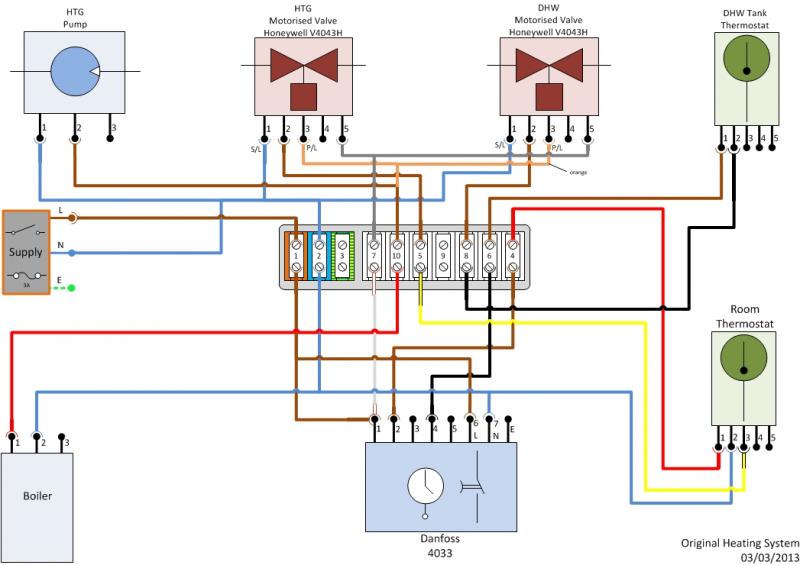

This article will delve into the technical aspects of Honeywell Zone Valve Wiring, including wiring diagrams, troubleshooting tips, and advanced features. We will also discuss the benefits and limitations of zone valve wiring and provide guidance on designing and installing a zone valve system.

Honeywell Zone Valve Wiring plays a crucial role in modern HVAC systems, offering numerous advantages. Understanding its essential aspects is key to effective design, installation, and maintenance.

- Components: Valves, actuators, controllers, wiring

- Function: Controls temperature in specific zones

- Benefits: Energy efficiency, comfort, reduced wear

- Types: On/off, modulating, smart

- Applications: Residential, commercial, industrial

- Installation: Requires skilled electrician

- Maintenance: Regular checks, occasional repairs

- Troubleshooting: Diagnose wiring faults, valve issues

- Integration: Compatible with smart thermostats, home automation

- Safety: Meets electrical and building codes

These aspects encompass the technical, practical, and functional elements of Honeywell Zone Valve Wiring. Understanding and considering them ensures optimal performance, energy savings, and occupant comfort. Proper installation, maintenance, and troubleshooting practices are essential to maximize the benefits and longevity of a zone valve system.

Components

In Honeywell Zone Valve Wiring, valves, actuators, controllers, and wiring are indispensable components that work together to regulate temperature in multiple zones. Valves control the flow of hot or cold water or refrigerant through the heating or cooling system. Actuators receive signals from controllers and use them to open or close the valves. Controllers, which can be manual or electronic, monitor the temperature in each zone and send signals to the actuators accordingly. Wiring connects all these components, allowing them to communicate and function as a unified system.

Understanding the relationship between these components is crucial for effective design, installation, and maintenance of Honeywell Zone Valve Wiring. Proper selection and configuration of valves, actuators, controllers, and wiring ensures optimal system performance, energy efficiency, and occupant comfort. For instance, choosing the right valve size and type is essential to handle the required flow rate and pressure. Similarly, selecting an appropriate controller with the desired features and compatibility is vital for precise temperature control and integration with other smart home devices.

In practice, Honeywell Zone Valve Wiring finds applications in various settings, including residential, commercial, and industrial buildings. In a residential home with multiple rooms, zone valve wiring allows each room to have its own thermostat, enabling occupants to adjust the temperature to their preference. In a commercial building with multiple zones, such as offices or retail spaces, zone valve wiring helps optimize energy usage by heating or cooling only the occupied zones. Industrial facilities often use zone valve wiring to control the temperature in different production areas or warehouses.

In summary, Honeywell Zone Valve Wiring relies on the seamless integration of valves, actuators, controllers, and wiring to deliver efficient and comfortable temperature control in multiple zones. Understanding the relationship between these components is key to maximizing system performance and achieving the desired outcomes. Whether in residential, commercial, or industrial applications, Honeywell Zone Valve Wiring offers a flexible and effective solution for managing temperature in modern buildings.

Function

Within the realm of Honeywell Zone Valve Wiring, its primary function stands out as controlling the temperature in specific zones. This capability empowers users to tailor the temperature of different areas within a building to their desired preferences, optimizing both comfort and energy efficiency.

- Zoning: Zone valve wiring divides an HVAC system into multiple zones, each with its own thermostat. This allows for independent temperature control in each zone, ensuring occupants can adjust the temperature to their comfort level.

- Energy Efficiency: By controlling the temperature in specific zones, zone valve wiring reduces energy consumption. When zones are unoccupied, the system can automatically adjust the temperature to a more energy-efficient setting, saving energy and lowering utility bills.

- Improved Comfort: Zone valve wiring enhances occupant comfort by allowing them to customize the temperature in their immediate surroundings. This is particularly beneficial in buildings with varying temperature needs, such as homes with multiple residents or commercial buildings with different departments.

- Enhanced Control: Zone valve wiring provides users with greater control over their HVAC system. They can easily adjust the temperature in each zone, set schedules, and monitor energy usage, leading to optimized performance and increased satisfaction.

In summary, Honeywell Zone Valve Wiring’s ability to control temperature in specific zones translates into tangible benefits such as enhanced comfort, reduced energy consumption, and improved control over the HVAC system. By effectively managing the temperature in different areas of a building, zone valve wiring contributes to a more comfortable, energy-efficient, and user-friendly indoor environment.

Benefits

Honeywell Zone Valve Wiring offers substantial benefits in terms of energy efficiency, comfort, and reduced wear and tear on HVAC systems. Its ability to control temperature in specific zones leads directly to these advantages.

Firstly, energy efficiency is enhanced by eliminating unnecessary heating or cooling in unoccupied zones. By adjusting the temperature in specific areas, zone valve wiring reduces energy consumption, resulting in lower utility bills and a smaller carbon footprint. For example, in a home with multiple bedrooms, zone valve wiring allows occupants to turn down the heat in unused bedrooms, saving energy and reducing overall heating costs. Another example is in commercial buildings, where zone valve wiring can be used to adjust the temperature in unoccupied offices or retail spaces, reducing energy waste during off-hours.

Secondly, zone valve wiring contributes to increased comfort by enabling occupants to customize the temperature in their immediate surroundings. This is particularly beneficial in buildings with varying temperature needs, such as homes with multiple residents or commercial buildings with different departments. For instance, in a home with a family member who prefers a warmer temperature, zone valve wiring allows them to adjust the temperature in their room without affecting other areas of the house. Similarly, in a commercial building with a server room that requires a cooler temperature, zone valve wiring ensures that the server room maintains an optimal temperature while other areas of the building can be adjusted to suit the comfort of occupants.

Thirdly, zone valve wiring reduces wear and tear on HVAC systems by minimizing the need for excessive temperature adjustments. When different zones have their own temperature control, the HVAC system does not have to work as hard to maintain a uniform temperature throughout the entire building. This reduces strain on the system’s components, leading to a longer lifespan and fewer costly repairs. For example, in a home with a traditional HVAC system, turning up the heat in one room often results in overheating in other rooms, causing the system to work harder and potentially leading to premature failure. With zone valve wiring, each room can be heated or cooled independently, reducing the on the HVAC system and extending its lifespan.

In summary, Honeywell Zone Valve Wiring offers significant advantages in terms of energy efficiency, comfort, and reduced wear and tear on HVAC systems. Its ability to control temperature in specific zones directly contributes to these benefits, making it a valuable solution for both residential and commercial buildings.

Types

Honeywell Zone Valve Wiring encompasses different types of valves, each designed for specific applications and offering varying levels of control and efficiency. The three primary types are on/off, modulating, and smart valves.

On/off valves are the simplest and most cost-effective type. They operate in a binary manner, fully opening or closing to allow or prevent the flow of water or refrigerant. While they provide basic zone control, they can result in temperature fluctuations and energy waste due to their limited ability to regulate flow.

Modulating valves offer greater precision and energy efficiency compared to on/off valves. They can partially open or close to modulate the flow of water or refrigerant, allowing for more precise temperature control and reduced energy consumption. Modulating valves are often used in applications where precise temperature control is critical, such as in data centers or laboratories.

Smart valves represent the latest advancement in zone valve technology. They incorporate electronic controls and sensors to provide intelligent temperature management. Smart valves can learn and adapt to occupant behavior, automatically adjusting the temperature based on preferences and schedules. Additionally, they can be integrated with smart home systems for remote control and monitoring.

The choice of valve type depends on the specific requirements of the application. For basic zone control in residential settings, on/off valves may be sufficient. In applications where precise temperature control and energy efficiency are critical, modulating valves are recommended. Smart valves offer the most advanced features and capabilities, making them ideal for sophisticated HVAC systems and smart homes.

Understanding the different types of valves is essential for designing and installing an effective Honeywell Zone Valve Wiring system. By selecting the appropriate valve type for each zone, building owners and occupants can optimize comfort, energy efficiency, and long-term system performance.

Applications

Honeywell Zone Valve Wiring finds versatile applications across residential, commercial, and industrial settings, addressing diverse temperature control needs and optimizing energy efficiency. Its adaptability stems from its ability to create independent temperature zones within a single HVAC system, offering tailored comfort and energy savings in various environments.

In residential homes, zone valve wiring allows for customized temperature control in different rooms or areas. For instance, bedrooms can be set to a warmer temperature, while living areas maintain a cooler setting. This personalized approach enhances comfort levels for occupants and reduces energy waste by heating or cooling only the occupied spaces.

Commercial buildings, such as offices and retail stores, benefit from zone valve wiring by enabling temperature regulation in separate zones. This is particularly useful in large buildings with varying occupancy patterns. For example, office spaces can be adjusted to a comfortable temperature during working hours, while unoccupied areas can be set to a more energy-efficient setting. Zone valve wiring also contributes to energy savings in commercial kitchens and server rooms, where specialized temperature requirements can be met independently.

Industrial facilities utilize zone valve wiring to maintain precise temperature control in different production areas or warehouses. This is crucial for industries such as manufacturing, pharmaceuticals, and food processing, where temperature variations can impact product quality and safety. By creating separate temperature zones, industrial facilities can optimize production processes and minimize energy consumption.

The connection between “Applications: Residential, commercial, industrial” and “Honeywell Zone Valve Wiring” is fundamentally driven by the need for efficient and customized temperature control. Zone valve wiring serves as a critical component in meeting these diverse requirements, offering flexibility, energy savings, and enhanced comfort. Understanding the practical applications of zone valve wiring in different settings empowers building owners, facility managers, and occupants to make informed decisions about their HVAC systems, leading to improved energy efficiency, occupant satisfaction, and overall cost savings.

Installation

When it comes to Honeywell Zone Valve Wiring, the necessity of skilled electrician involvement is a crucial aspect that warrants careful consideration. Zone valve wiring comprises intricate electrical components and connections that demand expertise and precision to ensure proper functionality and safety within an HVAC system. Without the requisite knowledge and experience, improper installation can lead to a range of issues that compromise the system’s performance, efficiency, and safety.

The role of skilled electricians in Honeywell Zone Valve Wiring extends beyond basic wiring. They possess the expertise to assess the specific requirements of the HVAC system, taking into account factors such as the number of zones, valve types, and electrical load. Based on this assessment, they design and implement a customized wiring plan that meets the unique needs of the system. Moreover, skilled electricians are well-versed in electrical codes and safety regulations, ensuring that the installation complies with industry standards.

Real-life examples underscore the importance of skilled electrician involvement in Honeywell Zone Valve Wiring. DIY enthusiasts or unqualified individuals attempting to install zone valve wiring often encounter challenges that can have detrimental consequences. Incorrect wiring can result in electrical hazards, such as short circuits or overheating, which pose risks to both the system and occupants. Additionally, improper installation can lead to inefficient system operation, reduced energy efficiency, and premature component failure.

To ensure a safe, efficient, and long-lasting Honeywell Zone Valve Wiring system, entrusting its installation to a skilled electrician is paramount. Their expertise and adherence to industry best practices guarantee that the system meets the highest standards of performance and safety.

Maintenance

Within the realm of Honeywell Zone Valve Wiring, maintenance plays a pivotal role in ensuring optimal performance and longevity of the system. Regular checks and occasional repairs are indispensable aspects of maintenance, contributing to the overall reliability and efficiency of the HVAC system.

- Valve Inspections: Regular inspection of zone valves is crucial to ensure proper operation. This involves checking for leaks, corrosion, and any signs of wear. Early detection of valve issues can prevent more severe problems and costly repairs.

- Actuator Maintenance: Actuators, responsible for opening and closing valves, require periodic maintenance to ensure smooth operation. Lubrication, cleaning, and testing of actuators help prevent sticking or premature failure, ensuring reliable valve control.

- Wiring Integrity: The intricate wiring network of a Honeywell Zone Valve Wiring system necessitates regular checks for loose connections, damaged wires, and potential electrical hazards. Proactive inspection and maintenance of wiring prevents system malfunctions and ensures safe operation.

- Controller Checks: The controller, the “brain” of the zone valve wiring system, requires periodic checks to ensure accurate temperature readings and proper communication with other components. Regular calibration and software updates keep the controller functioning optimally.

By adhering to a comprehensive maintenance schedule that incorporates these facets, building owners and occupants can maximize the performance and lifespan of their Honeywell Zone Valve Wiring system. Regular checks and prompt repairs not only enhance comfort and energy efficiency but also contribute to the overall safety and reliability of the HVAC system, ensuring a comfortable and efficient indoor environment.

Troubleshooting

Within the realm of Honeywell Zone Valve Wiring, troubleshooting plays a critical role in maintaining optimal performance and ensuring system longevity. Diagnosing wiring faults and valve issues forms a key aspect of troubleshooting, empowering technicians and homeowners to identify and resolve problems efficiently.

- Wiring Continuity Checks: Ensuring proper electrical connections is paramount. Continuity checks using a multimeter help identify loose wires, damaged insulation, or faulty connections that can disrupt valve operation.

- Valve Resistance Measurement: Measuring the electrical resistance of valves can indicate their functionality. Deviations from expected resistance values may point to internal valve issues, such as coil failures or mechanical problems.

- Actuator Operation Tests: Testing actuator operation involves manually activating the valve and observing its response. Sluggish or erratic movement may indicate actuator malfunction, requiring further investigation or replacement.

- Controller Communication Verification: The controller serves as the central hub, communicating with valves and actuators. Verifying communication ensures proper signal transmission and reception, ruling out controller-related issues.

Effectively troubleshooting wiring faults and valve issues in Honeywell Zone Valve Wiring requires a methodical approach, combining electrical testing techniques with an understanding of system components and their interactions. By isolating and resolving these issues promptly, building owners and occupants can restore optimal system operation, enhance comfort levels, and extend the lifespan of their HVAC system.

Integration

In the realm of Honeywell Zone Valve Wiring, integration with smart thermostats and home automation systems opens up a world of possibilities for enhanced comfort, energy efficiency, and remote control. By seamlessly connecting zone valve wiring to these advanced technologies, homeowners and building managers can unlock a range of benefits that elevate the user experience and optimize HVAC system performance.

- Remote Control and Monitoring: Integration with smart thermostats allows users to remotely control and monitor the temperature of each zone from anywhere using a smartphone app. This provides unparalleled convenience and enables adjustments to be made on the go, ensuring maximum comfort and energy savings.

- Scheduling and Automation: Smart thermostats offer advanced scheduling features that can automatically adjust temperatures based on daily routines and preferences. Integration with home automation systems takes this a step further, allowing users to create custom scenes that trigger specific temperature settings based on events such as waking up, leaving home, or going to bed.

- Energy Optimization: Integration with smart thermostats enables real-time energy monitoring, providing users with detailed insights into their energy consumption. This information can be used to identify areas for improvement and make informed decisions to reduce energy usage and lower utility bills.

- Voice Control and Smart Assistants: Smart thermostats and home automation systems often support voice control through popular virtual assistants like Amazon Alexa and Google Assistant. This hands-free convenience allows users to adjust temperatures, check the weather, and control other smart home devices simply by speaking.

The integration of Honeywell Zone Valve Wiring with smart thermostats and home automation systems represents a significant advancement in HVAC control and energy management. By embracing these technologies, homeowners and building managers can transform their HVAC systems into intelligent and responsive networks that deliver unparalleled comfort, convenience, and efficiency.

Safety

Within the realm of Honeywell Zone Valve Wiring, adherence to electrical and building codes stands as a critical cornerstone, ensuring the safety and reliability of the system. These codes, established by regulatory bodies and industry experts, provide a comprehensive framework for electrical installations, dictating standards for wiring, component selection, and system design. By adhering to these codes, Honeywell Zone Valve Wiring not only meets regulatory requirements but also minimizes electrical hazards, prevents fires, and ensures the overall integrity of the HVAC system.

Real-life examples underscore the importance of safety in Honeywell Zone Valve Wiring. Electrical fires caused by faulty wiring or improper installation pose significant risks to property and human life. By complying with electrical codes, such as the National Electrical Code (NEC), Honeywell Zone Valve Wiring ensures that electrical components are properly sized, protected, and installed, minimizing the likelihood of electrical faults and potential hazards.

The practical significance of understanding the connection between safety and Honeywell Zone Valve Wiring extends beyond regulatory compliance. It empowers homeowners, building managers, and HVAC professionals to make informed decisions regarding system design, installation, and maintenance. By prioritizing safety, they can create and maintain HVAC systems that operate reliably and efficiently, providing peace of mind and protecting against costly repairs or system failures. Moreover, adherence to safety codes contributes to insurance coverage and protects against potential legal liabilities.

In summary, the connection between “Safety: Meets electrical and building codes” and “Honeywell Zone Valve Wiring” is paramount. By adhering to established codes and standards, Honeywell Zone Valve Wiring ensures the safety and reliability of HVAC systems, minimizes electrical hazards, and safeguards against potential risks. Understanding this connection empowers individuals to make informed decisions and create safe and efficient HVAC systems that enhance comfort, energy efficiency, and peace of mind.

Related Posts