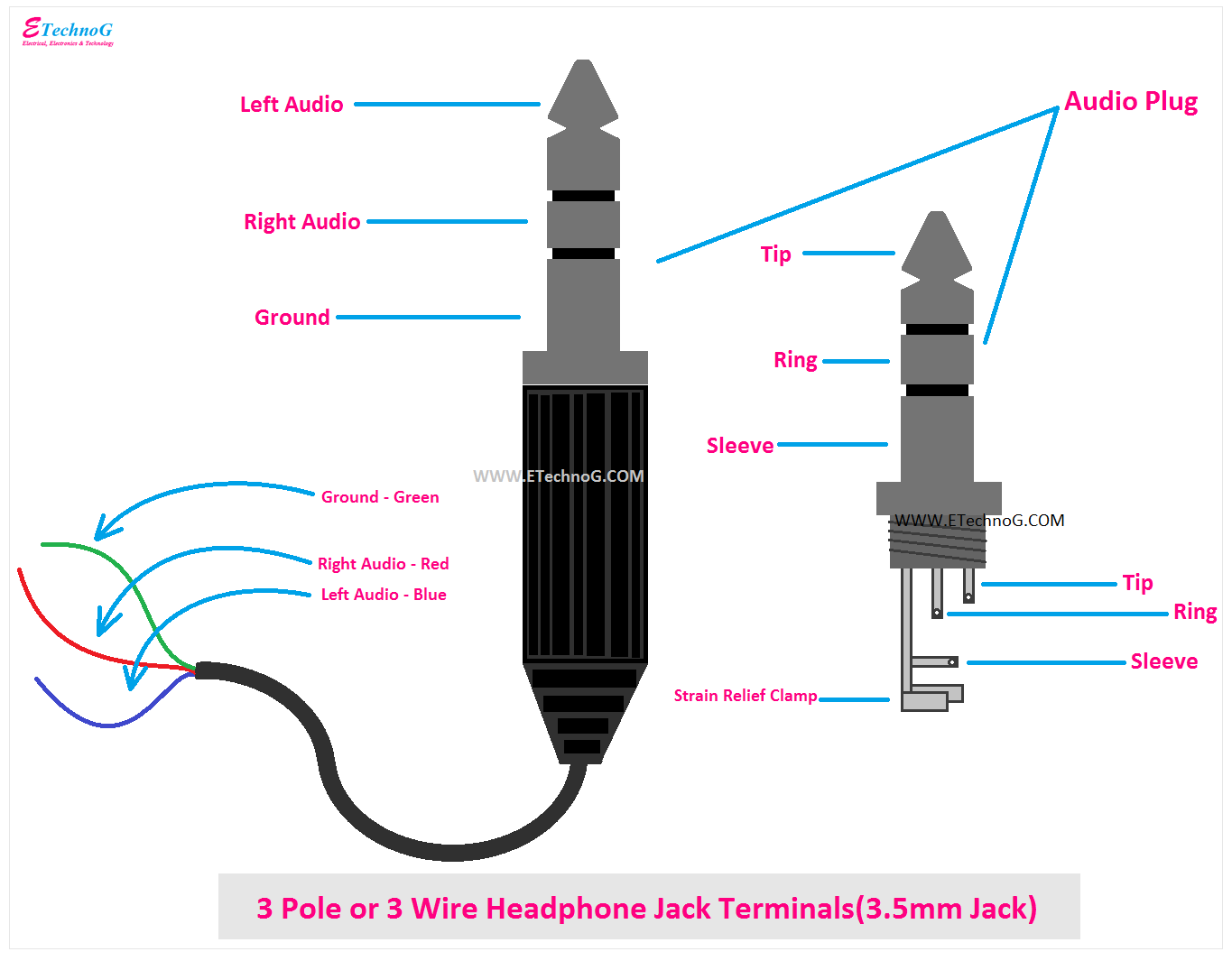

A “Headphones Wiring Color Code” provides standardized wiring guidelines for connecting audio jacks to headphone components. For instance, a common code designates the left channel as green, the right channel as red, and the ground as black or uninsulated.

This code ensures proper audio signal transmission, avoiding channel confusion and ensuring correct sound delivery. It facilitates efficient repairs, reduces manufacturing errors, and guarantees consistent audio performance.

The standardization of this color scheme dates back to 1979, when the Japanese Audio Society established a uniform wiring code for headphones. This code has since become widely adopted, creating a reliable framework for headphone manufacturing and maintenance.

Understanding the essential aspects of “Headphones Wiring Color Code” is crucial for various stakeholders, including manufacturers, repair technicians, and consumers. These aspects encompass technical specifications, industry standards, and practical applications.

- Standardization

- Manufacturing

- Repair

- Audio Quality

- Compatibility

- Troubleshooting

- Safety

- History

- Evolution

These aspects play interconnected roles in ensuring the proper functioning and overall effectiveness of headphones. Standardization facilitates consistent production and maintenance practices, while manufacturing processes rely on these codes for efficient assembly. Repair technicians utilize color codes for quick and accurate troubleshooting, enhancing audio quality and ensuring compatibility between different devices. Understanding the history and evolution of these codes provides insights into their development and adoption within the industry, highlighting their importance in the realm of audio technology.

Standardization

Within the context of “Headphones Wiring Color Code”, standardization plays a pivotal role in ensuring consistency and interoperability. It establishes uniform guidelines for the wiring of headphone components, enabling compatibility between different manufacturers and devices.

- Universal Compatibility: Standardization ensures that headphones can be seamlessly connected to audio jacks regardless of the brand or model, fostering universal compatibility and ease of use.

- Simplified Manufacturing: By adhering to standardized color codes, manufacturers can streamline production processes, reduce errors, and maintain high levels of quality control.

- Efficient Repairs: Technicians can quickly identify and repair faulty wires based on the standardized color scheme, minimizing downtime and enhancing the longevity of headphones.

- Enhanced Safety: Standardization promotes safety by ensuring proper insulation and polarity, preventing electrical hazards and protecting users from potential harm.

Overall, standardization in “Headphones Wiring Color Code” fosters a cohesive ecosystem where headphones and audio devices can interact seamlessly, providing users with a reliable and consistent audio experience.

Manufacturing

Within the context of “Headphones Wiring Color Code”, manufacturing plays a critical role in ensuring the consistent production of high-quality headphones. The standardized color code serves as a guiding framework for manufacturers, enabling them to adhere to established specifications and maintain optimal production efficiency.

The color code provides a universal language for headphone assembly, ensuring that components are correctly wired and connected. This reduces errors, streamlines production processes, and minimizes the risk of faulty products. Moreover, the standardized color scheme allows manufacturers to easily identify and replace damaged wires, enhancing the durability and longevity of headphones.

Real-life examples of manufacturing within “Headphones Wiring Color Code” can be observed in various production facilities worldwide. Manufacturers adhere to the color code to ensure that headphones meet industry standards and customer expectations. This standardized approach enables efficient mass production while maintaining consistent quality.

Understanding the connection between manufacturing and “Headphones Wiring Color Code” is crucial for several reasons. Firstly, it highlights the importance of standardized guidelines in ensuring product quality and manufacturing efficiency. Secondly, it showcases the practical applications of the color code in the production of headphones, demonstrating its impact on the overall performance and reliability of the final product.

Repair

Within the realm of “Headphones Wiring Color Code”, “Repair” emerges as a crucial aspect, enabling the restoration and maintenance of headphones to ensure optimal performance. The standardized color code serves as a guiding tool for repair technicians, providing vital information for accurate identification and resolution of wiring issues.

- Component Identification: The color code allows technicians to quickly locate and identify specific wires based on their function (e.g., left channel, right channel, ground), streamlining the repair process.

- Fault Diagnosis: The color code helps in determining the cause of wiring faults by enabling the isolation of problematic wires, facilitating efficient troubleshooting.

- Wire Replacement: When replacing damaged wires, the color code ensures the correct connection of new wires, preventing further issues and maintaining audio integrity.

- Compatibility Verification: In cases of headphone modifications or custom repairs, the color code assists in verifying the compatibility of replacement wires, ensuring proper functionality.

Understanding the interplay between “Repair” and “Headphones Wiring Color Code” underscores the practical significance of standardized wiring practices. The color code empowers repair technicians with the necessary knowledge to effectively diagnose and resolve wiring problems, extending the lifespan of headphones and ensuring continued audio enjoyment.

Audio Quality

Within the realm of “Headphones Wiring Color Code”, “Audio Quality” emerges as a paramount aspect, as it directly influences the overall listening experience and enjoyment of headphones. The standardized wiring color code plays a crucial role in ensuring optimal audio quality by guiding the proper connection and transmission of audio signals.

- Frequency Response: The color code ensures that each wire is correctly connected to its respective driver, maintaining the intended frequency response and delivering accurate sound reproduction.

- Channel Separation: By preventing the mixing of left and right channels, the color code preserves the stereo separation, resulting in a wider and more immersive soundstage.

- Noise Reduction: Proper wiring according to the color code minimizes electrical interference and noise, leading to a cleaner and more transparent audio experience.

- Durability: The standardized color scheme promotes the use of high-quality wires and insulation, enhancing the durability of headphones and ensuring consistent audio performance over an extended period.

The interplay between “Audio Quality” and “Headphones Wiring Color Code” underscores the significance of standardized wiring practices. By adhering to the color code, manufacturers and repair technicians can guarantee the delivery of pristine audio quality, allowing users to fully appreciate the nuances and details of their favorite music, movies, and other audio content.

Compatibility

Within the realm of “Headphones Wiring Color Code”, “Compatibility” emerges as a critical aspect, ensuring seamless integration and interoperability between headphones and various devices. The standardized color code plays a pivotal role in maintaining compatibility throughout the audio signal chain, enabling users to enjoy a consistent and high-quality listening experience.

- Device Compatibility: The color code ensures compatibility with a wide range of audio devices, including smartphones, laptops, computers, amplifiers, and mixing consoles, allowing users to connect their headphones effortlessly.

- Replacement Parts: The standardized color scheme simplifies the replacement of damaged or worn-out headphone wires, ensuring compatibility with original or third-party parts, maintaining the integrity of the audio signal.

- Custom Modifications: For audio enthusiasts and professionals, the color code enables custom modifications and DIY projects, allowing them to tailor their headphones to specific preferences or requirements.

- Future-Proofing: Adherence to the color code ensures compatibility with future audio devices and technologies, safeguarding against obsolescence and extending the lifespan of headphones.

In conclusion, the “Headphones Wiring Color Code” serves as a cornerstone for compatibility, guaranteeing seamless connectivity, easy replacement of parts, support for modifications, and future-proofing. By adhering to the standardized color scheme, manufacturers, repair technicians, and users can ensure that headphones remain compatible with a wide range of devices and applications, delivering a consistently exceptional audio experience.

Troubleshooting

Within the context of “Headphones Wiring Color Code”, “Troubleshooting” emerges as a crucial aspect, empowering users and repair technicians to diagnose and resolve issues that may arise with headphone wiring. The standardized color code provides a systematic framework for identifying and addressing wiring problems, ensuring the optimal performance and longevity of headphones.

- Component Identification: The color code enables quick and accurate identification of individual wires based on their function (e.g., left channel, right channel, ground), simplifying the troubleshooting process.

- Fault Diagnosis: By examining the wiring and comparing it to the color code, potential faults can be pinpointed. For instance, a broken wire or incorrect connection can be easily identified.

- Repair Options: The color code guides repair decisions by providing insights into the type and location of the issue. This information helps determine whether a simple repair, such as re-soldering a loose connection, or a more complex intervention is required.

- Compatibility Verification: When replacing damaged wires, the color code ensures compatibility with the existing wiring scheme, preventing further issues and maintaining audio integrity.

In summary, “Troubleshooting” is an integral part of “Headphones Wiring Color Code”, providing a structured approach to identifying, diagnosing, and resolving wiring problems. By leveraging the standardized color scheme, users and repair technicians can effectively maintain and restore headphones, ensuring continued enjoyment of high-quality audio.

Safety

In the context of “Headphones Wiring Color Code”, “Safety” emerges as a paramount aspect, ensuring the well-being of users and preventing potential hazards associated with headphone usage. The standardized color code plays a crucial role in promoting safety by providing guidelines for proper wiring and handling, minimizing electrical risks and ensuring the durability of headphones.

-

Electrical Insulation

The color code specifies the use of insulated wires, preventing electrical shocks and short circuits. Proper insulation ensures that current flows safely through the wires, without posing a risk to the user.

-

Polarity Identification

The color code helps identify the polarity of wires, which is critical for maintaining proper audio signal transmission. Incorrect polarity can lead to distorted sound or damage to headphones.

-

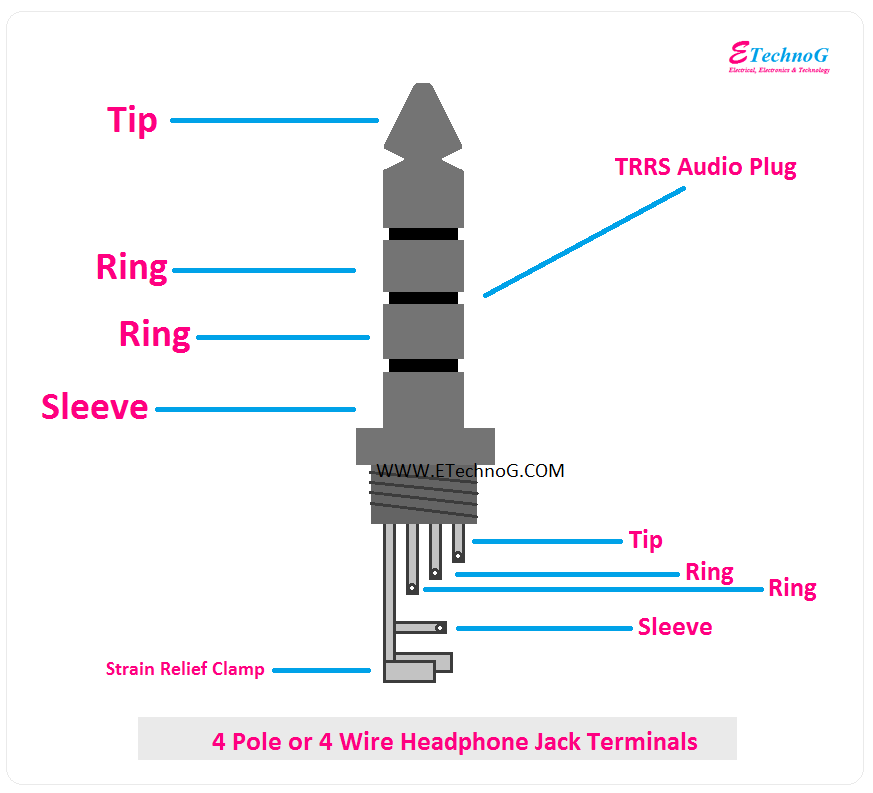

Strain Relief

The color code guides the placement of strain relief, which prevents excessive bending or pulling of wires at the connection points. This safeguards the integrity of the wires and extends the lifespan of headphones.

-

Durable Construction

The color code promotes the use of durable materials and construction techniques, ensuring that headphones can withstand regular use and handling without compromising safety.

In conclusion, “Safety” is an integral part of “Headphones Wiring Color Code”, encompassing various facets such as electrical insulation, polarity identification, strain relief, and durable construction. By adhering to the standardized color scheme, manufacturers and users can ensure the safe operation and longevity of headphones, minimizing potential hazards and enhancing the overall listening experience.

History

Within the context of “Headphones Wiring Color Code”, “History” plays a pivotal role in shaping the standardization and adoption of color codes for headphone wiring. The evolution of headphones and audio technology has been inextricably linked to the development and refinement of wiring color codes, leading to the establishment of industry-wide standards.

Early headphones, dating back to the late 19th century, were relatively simple devices with limited wiring requirements. As headphones became more sophisticated and widely adopted, the need for a standardized wiring scheme became apparent. In the 1970s, the Japanese Audio Society (JAS) took the initiative to develop a uniform color code for headphones, addressing the growing complexity and diversity of headphone designs.

The JAS color code quickly gained acceptance within the audio industry and became the de facto standard for headphone wiring. This standardization brought numerous benefits, including simplified manufacturing processes, improved compatibility between different headphone brands and devices, and easier troubleshooting and repair. Over time, the JAS color code has undergone revisions and refinements, but its fundamental principles have remained intact, ensuring continuity and consistency in headphone wiring practices.

Understanding the historical context of “Headphones Wiring Color Code” provides valuable insights into the evolution of audio technology and the importance of standardization. It demonstrates how historical developments have shaped current practices and highlights the practical significance of adhering to established color codes for ensuring compatibility, safety, and optimal audio performance.

Evolution

The evolution of “Headphones Wiring Color Code” has been driven by advancements in audio technology, manufacturing techniques, and user demands. Over time, the color code has undergone revisions and refinements, adapting to the changing landscape of the audio industry. This evolution has brought about several notable advancements.

-

Standardization

The establishment of a standardized color code has ensured consistency and interoperability among different headphone brands and models. This has simplified manufacturing processes, reduced errors, and made troubleshooting and repair easier.

-

Improved Compatibility

The standardized color code has facilitated the development of headphones that are compatible with a wide range of audio devices, including smartphones, laptops, computers, and amplifiers. This has enhanced the user experience and made it easier to enjoy high-quality audio from various sources.

-

Durability and Safety

The evolution of the color code has led to the adoption of more durable materials and construction techniques, improving the longevity and safety of headphones. The use of color-coded insulation and strain relief helps prevent electrical hazards and ensures reliable operation.

-

Custom Modifications

The standardized color code has empowered users and enthusiasts to make custom modifications to their headphones, tailoring them to their specific preferences. This has fostered a thriving community of DIY headphone enthusiasts and has contributed to the development of innovative and personalized audio solutions.

In summary, the evolution of “Headphones Wiring Color Code” has been marked by continuous improvements in standardization, compatibility, durability, safety, and user customization. These advancements have played a crucial role in the development and adoption of headphones as ubiquitous audio devices, enhancing the overall listening experience and meeting the evolving needs of users.

Related Posts