A Gm Upfitter Wiring Diagram presents a comprehensive schematic for electrical wiring and circuitry within a General Motors vehicle. These diagrams are crucial for aftermarket installers, upfitters, and technicians to understand the vehicle’s electrical architecture and seamlessly integrate additional components or equipment into the vehicle’s existing electrical system.

The wiring diagram provides a detailed roadmap of harnesses, fuse panels, connectors, and module locations, enabling installers to correctly tap into the vehicle’s power sources, lighting, and communication systems. By following the diagram, installers can ensure proper functionality of the newly added equipment, maintain electrical integrity, and minimize potential electrical faults.

Gm Upfitter Wiring Diagrams have revolutionized the aftermarket industry, allowing technicians and businesses to customize vehicles for specific purposes, including commercial, emergency, and recreational applications. These diagrams have empowered upfitters to seamlessly integrate advanced technologies, accessories, and vehicle conversions, ensuring the safety and reliability of modified vehicles.

Gm Upfitter Wiring Diagrams are indispensable tools for customizing General Motors vehicles, playing a pivotal role in ensuring the proper integration of aftermarket components and electrical systems. Understanding the key aspects of these wiring diagrams is crucial for upfitters, technicians, and anyone involved in vehicle modifications.

- Accuracy: Wiring diagrams provide precise and detailed information, ensuring that installers can accurately connect components and avoid electrical faults.

- Comprehensiveness: These diagrams offer a comprehensive overview of the vehicle’s electrical architecture, covering harnesses, fuse panels, connectors, and module locations.

- Compatibility: Gm Upfitter Wiring Diagrams are specifically designed for GM vehicles, ensuring compatibility with the vehicle’s existing electrical systems.

- Customization: Diagrams enable installers to tailor electrical systems to meet specific requirements, supporting the integration of specialized equipment and accessories.

- Electrical Safety: By following the diagrams, installers can maintain electrical integrity, minimize the risk of electrical fires, and protect sensitive vehicle components.

- Efficiency: Wiring diagrams streamline the installation process, reducing downtime and increasing efficiency for upfitters and technicians.

- Functionality: Diagrams ensure that newly installed equipment functions correctly, preventing electrical malfunctions and maintaining vehicle performance.

- Industry Standard: Gm Upfitter Wiring Diagrams adhere to industry standards, promoting consistency and facilitating collaboration among upfitters and manufacturers.

- Technical Support: Wiring diagrams provide a valuable reference for troubleshooting electrical issues and obtaining technical support from GM or authorized upfitters.

These key aspects collectively highlight the significance of Gm Upfitter Wiring Diagrams in the aftermarket industry, enabling safe, reliable, and efficient vehicle modifications. By understanding these aspects, upfitters can harness the full potential of these diagrams to customize vehicles for various applications, enhancing their functionality and meeting the evolving needs of the automotive industry.

Accuracy

The accuracy of Gm Upfitter Wiring Diagrams is paramount, providing precise and detailed information that guides installers in accurately connecting components and avoiding electrical faults. These diagrams serve as blueprints for electrical installations, ensuring the proper integration of aftermarket equipment into the vehicle’s existing electrical system.

Inaccurate wiring can lead to a range of issues, including:

Electrical shorts: Incorrect wire connections can create electrical shorts, causing damage to components, fires, or even electrical shocks. Malfunctioning components: Improper wiring can prevent components from functioning correctly, affecting vehicle performance and safety. Electrical fires: Faulty wiring can overheat and cause electrical fires, posing significant risks to the vehicle and its occupants.

Gm Upfitter Wiring Diagrams mitigate these risks by providing accurate and detailed information, enabling installers to confidently make proper connections. The diagrams clearly indicate wire colors, terminal locations, and connector types, ensuring that components are connected according to the manufacturer’s specifications.

For example, when installing a new lighting system, the wiring diagram provides precise instructions on which wires to connect to the vehicle’s power source, ground, and lighting controls. This level of accuracy ensures that the lighting system functions correctly, providing adequate illumination and maintaining electrical safety.

Overall, the accuracy of Gm Upfitter Wiring Diagrams is a critical component for ensuring the successful and safe integration of aftermarket components into GM vehicles. By providing precise and detailed information, these diagrams empower installers to make accurate connections, preventing electrical faults and maintaining vehicle performance and safety.

Comprehensiveness

The comprehensiveness of Gm Upfitter Wiring Diagrams is a cornerstone of their value, providing a holistic view of the vehicle’s electrical architecture. These diagrams meticulously document all the key components and their interconnections, empowering installers with a deep understanding of the vehicle’s electrical system.

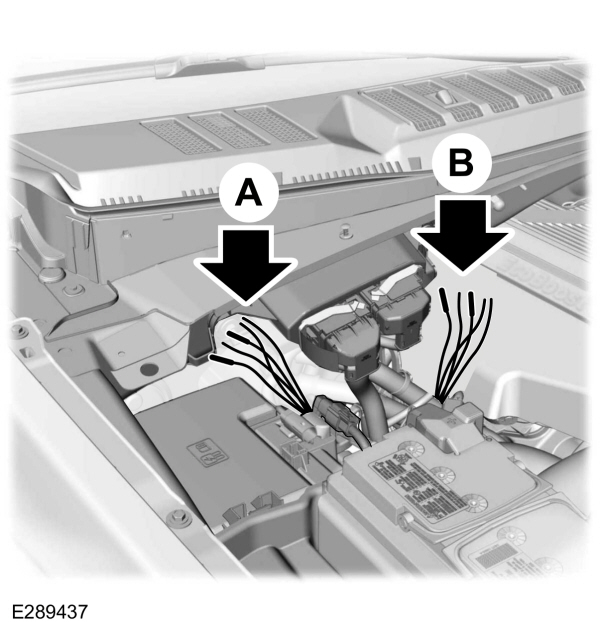

- Harnesses: Wiring diagrams provide detailed maps of the electrical harnesses that carry power and signals throughout the vehicle. This information is critical for installers to identify the correct harness for tapping into the vehicle’s electrical system and to ensure proper routing and protection of the wires.

- Fuse Panels: Fuse panels are crucial for protecting electrical circuits from overcurrent conditions. Wiring diagrams clearly indicate the location and amperage of each fuse, allowing installers to quickly identify and replace blown fuses, minimizing downtime and potential electrical hazards.

- Connectors: Gm Upfitter Wiring Diagrams provide detailed information on the types and locations of electrical connectors throughout the vehicle. This information is essential for installers to correctly mate connectors and ensure secure electrical connections, preventing intermittent faults and maintaining reliable operation.

- Module Locations: The diagrams also include the locations of various electronic modules within the vehicle. This information is crucial for installers to identify and access modules for programming, troubleshooting, or replacement, ensuring efficient and accurate electrical system modifications.

The comprehensiveness of Gm Upfitter Wiring Diagrams empowers installers with the knowledge and understanding to confidently make electrical modifications to GM vehicles. By providing a holistic view of the electrical architecture, these diagrams streamline the installation process, reduce downtime, and enhance the safety and reliability of upfitted vehicles.

Compatibility

Compatibility is a cornerstone of Gm Upfitter Wiring Diagrams, ensuring seamless integration of aftermarket components into GM vehicles’ electrical systems. These diagrams are meticulously tailored to the specific electrical architecture of each GM vehicle model, guaranteeing compatibility and preventing potential electrical conflicts or damage.

- Vehicle-Specific Design: Gm Upfitter Wiring Diagrams are created exclusively for GM vehicles, taking into account the unique electrical configurations and components of each model. This vehicle-specific design ensures that the diagrams accurately reflect the vehicle’s electrical system, enabling installers to confidently make modifications without compatibility concerns.

- OEM Standards Compliance: The diagrams adhere to GM’s original equipment manufacturer (OEM) standards, guaranteeing compatibility with the vehicle’s existing wiring and electrical components. By following these standards, installers can maintain the vehicle’s electrical integrity and avoid voiding warranties or compromising safety features.

- Tested and Verified: Gm Upfitter Wiring Diagrams undergo rigorous testing and verification processes to ensure their accuracy and reliability. This testing involves real-world installations and performance evaluations, guaranteeing that the diagrams provide accurate guidance for upfitters and technicians.

- Reduced Installation Time: The compatibility of Gm Upfitter Wiring Diagrams significantly reduces installation time by eliminating the need for guesswork or trial-and-error approaches. By providing precise and vehicle-specific instructions, the diagrams streamline the installation process, saving time and minimizing potential errors.

In summary, the compatibility of Gm Upfitter Wiring Diagrams is paramount for ensuring seamless integration of aftermarket components into GM vehicles. These diagrams are meticulously designed for each vehicle model, adhering to OEM standards and undergoing rigorous testing to guarantee accuracy and reliability. By leveraging these diagrams, upfitters and technicians can confidently modify GM vehicles’ electrical systems, reducing installation time and maintaining the vehicle’s electrical integrity.

Customization

Within the realm of Gm Upfitter Wiring Diagrams, customization stands as a cornerstone, empowering installers to tailor electrical systems to meet the unique demands of specialized equipment and accessories. These diagrams provide a roadmap for modifying and integrating additional components seamlessly, ensuring optimal functionality and maintaining electrical integrity.

- Versatile Installations: Upfitter Wiring Diagrams cater to a diverse range of upfitting needs, from commercial vehicle modifications to recreational equipment installations. They provide guidance on integrating various systems, including lighting, audio-visual equipment, and specialized machinery, into the vehicle’s electrical architecture.

- Real-Life Examples: Emergency vehicles, such as ambulances and fire trucks, heavily rely on customization to integrate specialized equipment like sirens, radios, and medical devices. Upfitter Wiring Diagrams guide installers in connecting these components to the vehicle’s power sources and control systems.

- Performance Optimization: Customization allows installers to fine-tune electrical systems for optimal performance. Diagrams provide insights into wire sizing, fuse selection, and circuit protection, ensuring efficient power distribution and preventing electrical overloads.

- Compliance and Safety: Adhering to Upfitter Wiring Diagrams is crucial for maintaining vehicle safety and compliance. These diagrams incorporate industry standards and manufacturer specifications, ensuring that electrical modifications meet regulatory requirements and minimize potential hazards.

Customization through Gm Upfitter Wiring Diagrams empowers installers with the flexibility to adapt electrical systems to specific requirements, unlocking a wide range of possibilities for vehicle modifications. These diagrams serve as a bridge between standard vehicle configurations and customized electrical solutions, enabling seamless integration of specialized equipment and accessories while maintaining safety and optimizing performance.

Electrical Safety

Electrical safety is paramount when modifying vehicle electrical systems. Gm Upfitter Wiring Diagrams play a pivotal role in ensuring electrical integrity, minimizing the risk of electrical fires, and protecting sensitive vehicle components. By adhering to these diagrams, installers can maintain optimal electrical functionality while safeguarding the vehicle and its occupants.

- Proper Wire Selection and Sizing: Wiring diagrams specify the correct wire gauge and type for each electrical circuit, ensuring adequate current-carrying capacity and minimizing the risk of overheating and electrical fires.

- Fuse and Circuit Protection: Diagrams indicate the appropriate fuse ratings and circuit protection devices, preventing excessive current flow and protecting sensitive electrical components from damage.

- Grounding and Bonding: Upfitter Wiring Diagrams provide clear instructions for grounding and bonding electrical components, ensuring proper electrical paths and minimizing the risk of electrical shocks or interference.

- Connector Compatibility and Protection: Diagrams specify the correct connectors and seals for electrical connections, preventing corrosion, moisture ingress, and loose connections that could lead to electrical faults.

By following Gm Upfitter Wiring Diagrams, installers can maintain electrical integrity, ensuring that the modified electrical system operates safely and reliably. These diagrams serve as a valuable tool for upfitters, technicians, and anyone involved in vehicle electrical modifications, empowering them to confidently integrate additional components and equipment while prioritizing electrical safety.

Efficiency

Within the realm of Gm Upfitter Wiring Diagrams, the aspect of efficiency holds significant importance. These diagrams serve as invaluable tools that streamline the installation process, minimizing downtime and enhancing efficiency for upfitters and technicians. This translates to reduced labor costs, faster vehicle modifications, and increased productivity, ultimately benefiting both businesses and end-users.

- Time-Saving Precision: Wiring diagrams eliminate guesswork and trial-and-error approaches, providing clear and concise instructions for electrical installations. This precision reduces the time spent on troubleshooting and ensures that components are connected correctly the first time, significantly reducing installation time.

- Reduced Downtime: By minimizing installation time, upfitter Wiring Diagrams directly contribute to reduced vehicle downtime. Vehicles are returned to service more quickly, maximizing their availability for revenue-generating activities or essential tasks.

- Enhanced Productivity: Streamlined installation processes allow upfitters and technicians to complete more installations within a given timeframe. This increased productivity translates to higher output, enabling businesses to take on more projects and grow their revenue.

- Cost Optimization: The efficiency gains provided by wiring diagrams lead to cost optimizations. Reduced labor hours and faster installations minimize overall project costs, making vehicle modifications more affordable for businesses and consumers alike.

In conclusion, the efficiency aspect of Gm Upfitter Wiring Diagrams is a key contributor to the success and widespread adoption of these diagrams within the vehicle upfitting industry. By reducing downtime, increasing productivity, and optimizing costs, these diagrams empower upfitters and technicians to deliver high-quality modifications with greater efficiency and cost-effectiveness.

Functionality

Within the realm of Gm Upfitter Wiring Diagrams, the aspect of functionality stands as a cornerstone, underscoring their critical role in ensuring the proper operation of newly installed equipment. These diagrams provide a comprehensive roadmap for electrical connections, enabling installers to integrate aftermarket components seamlessly, preventing electrical malfunctions, and maintaining optimal vehicle performance.

Gm Upfitter Wiring Diagrams serve as a vital guide for installers, providing precise instructions on how to connect electrical components to the vehicle’s existing electrical system. By following these diagrams meticulously, installers can ensure that each component receives the correct power, ground, and signal connections, minimizing the risk of electrical faults or malfunctions.

Real-life examples of the functionality aspect of Gm Upfitter Wiring Diagrams abound in the automotive upfitting industry. Consider the installation of a new lighting system in a commercial van. The wiring diagram provides detailed instructions on connecting the lights to the vehicle’s power source, ground, and lighting controls. By following these instructions precisely, the installer can ensure that the lighting system functions correctly, providing adequate illumination and maintaining electrical safety.

The practical significance of understanding the functionality aspect of Gm Upfitter Wiring Diagrams cannot be overstated. These diagrams empower installers with the knowledge and confidence to integrate aftermarket components into GM vehicles, ensuring that the newly installed equipment operates flawlessly and does not compromise the vehicle’s overall performance or safety.

In conclusion, the functionality aspect of Gm Upfitter Wiring Diagrams is paramount for the successful integration of aftermarket components into GM vehicles. These diagrams provide clear and concise instructions for electrical connections, minimizing the risk of electrical malfunctions and ensuring that newly installed equipment functions correctly, maximizing vehicle performance, and maintaining electrical integrity.

Industry Standard

Within the realm of “Gm Upfitter Wiring Diagram”, the aspect of “Industry Standard” holds significant importance. Gm Upfitter Wiring Diagrams adhere to established industry standards, fostering consistency and facilitating seamless collaboration among upfitters and manufacturers. This standardization plays a critical role in ensuring the reliability, safety, and compatibility of vehicle modifications.

- Uniformity and Compatibility: By adhering to industry standards, Gm Upfitter Wiring Diagrams promote uniformity in electrical system design and component compatibility. This ensures that components from different manufacturers can be integrated seamlessly, reducing the risk of mismatched connections and electrical faults.

- Simplified Installations: Standardized wiring diagrams simplify the installation process for upfitters. By following common conventions and symbols, technicians can quickly identify and connect components, minimizing installation time and reducing the potential for errors.

- Enhanced Safety: Industry standards incorporate safety considerations into wiring diagrams. Upfitters can be confident that the diagrams they follow have been designed with safety in mind, reducing the risk of electrical fires, shorts, and other hazards.

- Regulatory Compliance: Adhering to industry standards helps ensure that vehicle modifications comply with applicable regulations and safety codes. By following standardized wiring practices, upfitters can minimize the risk of legal issues or voiding vehicle warranties.

In conclusion, the “Industry Standard” aspect of Gm Upfitter Wiring Diagrams serves as a cornerstone for the successful and safe integration of aftermarket components into GM vehicles. By promoting consistency, facilitating collaboration, and adhering to safety guidelines, these diagrams empower upfitters and manufacturers to deliver high-quality vehicle modifications that meet industry best practices and regulatory requirements.

Technical Support

Within the context of Gm Upfitter Wiring Diagrams, the aspect of technical support plays a pivotal role in ensuring the successful installation and maintenance of aftermarket components in GM vehicles. These diagrams serve as invaluable references for troubleshooting electrical issues and obtaining expert assistance from GM or authorized upfitters, enabling installers to resolve complex problems efficiently and effectively.

The presence of detailed wiring diagrams empowers installers with the knowledge and confidence to diagnose and address electrical malfunctions. When an issue arises, the diagrams provide a clear roadmap of the electrical system, allowing installers to trace circuits, identify faulty components, and determine appropriate repair strategies. By following the diagrams meticulously, installers can minimize downtime, prevent further damage to the vehicle’s electrical system, and ensure the safe and reliable operation of installed equipment.

Moreover, Gm Upfitter Wiring Diagrams facilitate direct access to technical support from GM or authorized upfitters. These experts possess in-depth knowledge of GM electrical systems and can provide valuable assistance in resolving complex issues. By referencing the wiring diagrams, installers can clearly communicate the nature of the problem to technical support personnel, enabling them to provide accurate and timely solutions. This collaboration between installers and technical support ensures that electrical issues are resolved quickly and effectively, minimizing disruptions to vehicle operations.

In summary, the technical support aspect of Gm Upfitter Wiring Diagrams is a critical component that enhances the overall value and effectiveness of these diagrams. By providing a valuable reference for troubleshooting and facilitating access to expert assistance, these diagrams empower installers to confidently address electrical issues, ensuring the smooth functioning and reliability of upfitted vehicles.

Related Posts