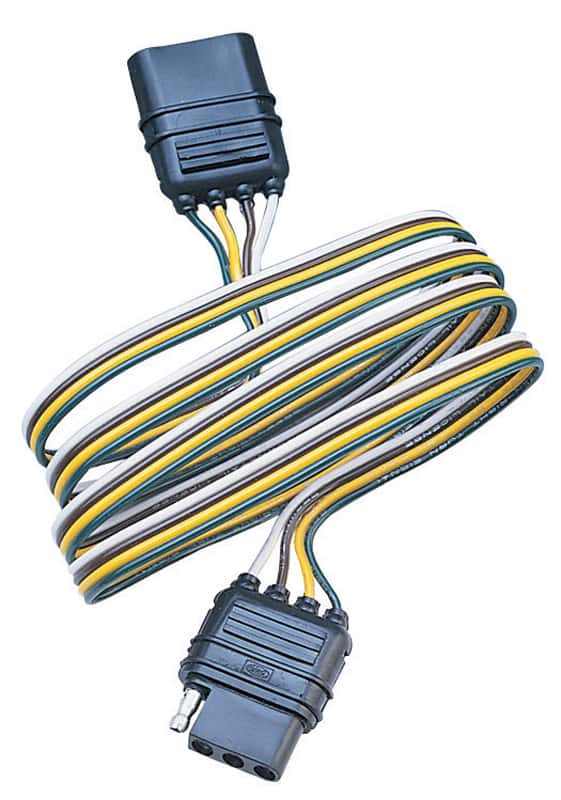

Flat Four Trailer Wiring is a trailer wiring configuration with four flat terminals that connect to a towing vehicle. It is used in various applications, such as connecting a trailer to a pickup truck for hauling or transporting equipment.

Flat Four Trailer Wiring offers the benefits of simplicity, affordability, and compatibility with older vehicles. Its historical development can be traced back to the standardized connector design introduced by the National Electrical Manufacturers Association (NEMA) in the 1960s.

This article delves into the technical aspects, safety considerations, and proper installation techniques for Flat Four Trailer Wiring. It provides a comprehensive guide for understanding the configuration, ensuring reliable connections, and maintaining the safety of both the towing vehicle and the trailer.

Understanding the essential aspects of Flat Four Trailer Wiring is crucial for ensuring proper functionality, safety, and compliance with industry standards. These key aspects encompass various dimensions, including:

- Connector Type

- Pin Configuration

- Wire Gauge

- Color Coding

- Grounding

- Testing

- Safety Precautions

- Troubleshooting

- Compatibility

- Legal Requirements

These aspects are interconnected and play a vital role in the overall effectiveness of Flat Four Trailer Wiring. Proper understanding of each aspect, from connector type to legal requirements, ensures reliable connections, prevents electrical hazards, and maintains the safety of both the towing vehicle and the trailer.

Connector Type

Connector type plays a crucial role in Flat Four Trailer Wiring, ensuring a secure and reliable connection between the towing vehicle and the trailer. It involves various components and considerations, encompassing:

-

Plug and Socket

The physical connectors that mate together, typically made of durable plastic or metal, ensuring proper alignment and electrical contact. -

Pin Configuration

The arrangement and number of pins within the connector, determining the specific functions and capabilities of the wiring. -

Housing

The protective casing that surrounds the connector, safeguarding it from external elements such as moisture, dirt, and mechanical damage. -

Locking Mechanism

A safety feature that prevents accidental disconnection, ensuring a secure connection during towing operations.

Understanding the different aspects of connector type empowers users to select the appropriate wiring configuration for their specific application, ensuring compatibility, reliability, and adherence to industry standards.

Pin Configuration

In the realm of Flat Four Trailer Wiring, pin configuration holds paramount importance, dictating the specific functions and capabilities of the wiring system. It involves the arrangement and number of pins within the connector, each pin designated for a specific electrical signal or function.

The pin configuration of Flat Four Trailer Wiring typically follows an industry-standardized layout, ensuring compatibility between different towing vehicles and trailers. Each pin is assigned a specific purpose, such as: – Ground – Left turn signal – Right turn signal – Brake lights

Understanding the pin configuration is essential for proper wiring and troubleshooting. Incorrect pin configuration can lead to malfunctioning lights, electrical shorts, and even safety hazards. By adhering to the standardized pin configuration, users can ensure reliable connections, prevent electrical issues, and maintain the safety of their towing system.

Wire Gauge

Wire gauge is a crucial aspect of Flat Four Trailer Wiring, influencing the electrical performance, safety, and overall functionality of the wiring system. It refers to the thickness or cross-sectional area of the electrical wires used in the wiring harness, which directly impacts the amount of current they can safely carry.

-

Conductor Size

The physical thickness of the wire, measured in American Wire Gauge (AWG), determines its current-carrying capacity. -

Voltage Drop

Thinner wires have higher resistance, leading to voltage drop over longer distances, potentially causing dim lights or electrical malfunctions. -

Amperage Rating

Each wire has a maximum amperage rating based on its gauge, which should not be exceeded to prevent overheating and electrical hazards. -

Insulation

The type and thickness of insulation around the wire affect its durability, resistance to environmental conditions, and overall safety.

Understanding wire gauge is essential for selecting the appropriate wiring harness for the specific application. Proper wire gauge ensures reliable electrical connections, prevents voltage drop and overheating, and maintains the safety and functionality of the Flat Four Trailer Wiring system.

Color Coding

Within the realm of Flat Four Trailer Wiring, color coding plays a vital role in ensuring proper wiring, efficient troubleshooting, and overall safety. It involves the use of standardized color-coded wires to differentiate their functions and facilitate quick identification during installation and maintenance.

-

Wire Identification

Each wire in the Flat Four Trailer Wiring harness is assigned a specific color code, making it easy to identify its purpose and connect it to the correct terminal on both the towing vehicle and the trailer. -

Industry Standards

The color coding follows industry-established standards, ensuring consistency across different manufacturers and models, allowing technicians to work on various trailer wiring systems with familiarity. -

Simplified Troubleshooting

Color coding simplifies troubleshooting by providing visual cues to trace wires, locate faults, and resolve electrical issues more quickly and accurately. -

Safety Enhancement

Proper color coding reduces the risk of miswiring, which can lead to electrical shorts, malfunctions, and even safety hazards, ensuring the safe operation of the trailer wiring system.

Understanding and adhering to the color coding standards for Flat Four Trailer Wiring is essential for ensuring reliable connections, preventing electrical problems, and maintaining the safety and functionality of the towing system. By following these color codes, users can confidently install, maintain, and troubleshoot their trailer wiring, promoting safe and efficient towing operations.

Grounding

Grounding, a fundamental aspect of Flat Four Trailer Wiring, plays a critical role in ensuring electrical safety, preventing malfunctions, and maintaining the proper functioning of the wiring system. It involves establishing a conductive path for electrical current to flow back to its source, typically the negative terminal of the vehicle’s battery.

-

Electrical Path

Grounding provides a complete circuit for electrical current to flow, enabling the proper operation of lights, signals, and other electrical components in the trailer.

-

Safety Mechanism

Grounding acts as a safety measure by diverting excess or stray electrical current away from sensitive components and preventing electrical shocks.

-

Voltage Stability

Proper grounding ensures stable voltage levels throughout the trailer wiring system, preventing voltage fluctuations that can affect the performance of electrical devices.

-

Corrosion Prevention

Grounding helps prevent corrosion by providing a path of least resistance for electrical current, reducing the likelihood of current flowing through other components and causing corrosion.

Understanding and ensuring proper grounding in Flat Four Trailer Wiring is essential for maintaining a reliable, safe, and efficient electrical system. Neglecting grounding can lead to various electrical issues, safety hazards, and diminished performance of the trailer’s electrical components.

Testing

Testing is a crucial aspect of Flat Four Trailer Wiring, ensuring the proper functionality, safety, and reliability of the electrical connection between the towing vehicle and the trailer. It involves a series of checks and measurements to verify the integrity of the wiring system and identify any potential issues before they become major problems.

-

Continuity Testing

Involves using a multimeter to check for a complete electrical path between different points in the wiring harness, ensuring proper signal transmission and power flow.

-

Grounding Verification

Tests the connection between the trailer’s frame and the towing vehicle’s ground, ensuring a proper grounding path for electrical current to flow safely.

-

Lights Functionality Check

Involves activating the various lights on the trailer, such as brake lights, turn signals, and running lights, to verify their proper operation and ensure they are visible to other drivers.

-

Circuit Overload Protection Test

Utilizes a circuit tester to check for any overloads or shorts in the wiring system, preventing potential electrical fires or damage to the wiring harness.

By conducting thorough testing, users can proactively identify and address any issues with Flat Four Trailer Wiring, ensuring the safe and reliable operation of their towing system. Regular testing can also help prevent costly repairs, breakdowns, and accidents, promoting the longevity and safety of both the towing vehicle and the trailer.

Safety Precautions

In the realm of Flat Four Trailer Wiring, safety precautions are paramount to ensuring the well-being of individuals and the integrity of equipment. These precautions encompass various aspects, ranging from proper handling and installation to regular maintenance and troubleshooting.

-

Wiring Inspection

Regularly inspecting the wiring harness for any signs of damage, wear, or corrosion is essential to prevent electrical hazards and ensure reliable performance.

-

Proper Grounding

Ensuring a proper grounding path for the trailer’s electrical system is crucial for safety, preventing electrical shocks and potential fires.

-

Circuit Protection

Utilizing fuses or circuit breakers in the wiring system safeguards against overloads and short circuits, preventing damage to the wiring harness and electrical components.

-

Tow Vehicle Compatibility

Matching the trailer’s wiring system to the capabilities of the towing vehicle ensures proper electrical compatibility, preventing overloading or damage to the vehicle’s electrical system.

Adhering to these safety precautions not only protects the electrical system and the longevity of the trailer wiring but also contributes to the overall safety of the towing operation. By implementing these measures, users can minimize the risks associated with electrical faults, accidents, and potential harm to themselves and others.

Troubleshooting

Troubleshooting is a fundamental aspect of Flat Four Trailer Wiring, as it empowers users to identify and resolve electrical issues, ensuring the reliable operation and safety of their towing system. Electrical faults within the wiring harness can manifest in various ways, ranging from non-functioning lights to complete electrical failure.

Understanding the principles and techniques of electrical troubleshooting enables individuals to systematically diagnose and rectify these issues. By utilizing tools such as multimeters and circuit testers, they can trace electrical signals, identify faulty components, and repair or replace damaged wires or connectors. Proactive troubleshooting can prevent minor electrical problems from escalating into more severe issues, reducing the likelihood of breakdowns, accidents, and costly repairs.

Real-life examples of troubleshooting in Flat Four Trailer Wiring include:

- Dim or Non-Functioning Lights: Troubleshooting involves checking for loose connections, damaged wires, or faulty bulbs, ensuring proper electrical contact and resolving any underlying issues.

- Electrical Shorts: Identifying and repairing electrical shorts is crucial to prevent overheating, electrical fires, and damage to the wiring harness. Troubleshooting involves isolating the affected circuit, testing for continuity, and replacing any damaged components.

- Grounding Problems: Establishing a proper grounding path is essential for electrical safety. Troubleshooting involves checking the connection between the trailer’s frame and the towing vehicle’s ground, ensuring a complete circuit for electrical current to flow safely.

By understanding the principles and techniques of troubleshooting, individuals can effectively maintain and repair their Flat Four Trailer Wiring, ensuring the safety and reliability of their towing system. This practical knowledge empowers them to identify and resolve electrical issues promptly, preventing more significant problems and enhancing the overall towing experience.

Compatibility

Within the realm of Flat Four Trailer Wiring, compatibility plays a pivotal role in ensuring seamless and reliable electrical connectivity between towing vehicles and trailers. It encompasses the ability of the trailer’s wiring system to match and interact effectively with the electrical system of the towing vehicle. Achieving compatibility is crucial for the proper functioning of various electrical components, including lights, signals, and brakes.

Compatibility in Flat Four Trailer Wiring is primarily determined by the adherence to standardized wiring configurations and protocols. Trailer manufacturers and vehicle manufacturers follow established industry guidelines to ensure that the pin configuration, wire gauge, and color coding of the Flat Four connectors align precisely. By maintaining compatibility, users can avoid electrical mismatches and ensure that signals are transmitted and received correctly between the towing vehicle and the trailer.

Real-life examples of compatibility in Flat Four Trailer Wiring include:

- Matching the 4-pin flat connector on a trailer to the corresponding 4-pin receptacle on a towing vehicle.

- Ensuring that the wire gauge of the trailer’s wiring harness is compatible with the amperage requirements of the towing vehicle’s electrical system.

- Following the standardized color coding scheme to correctly connect the wires for ground, left turn signal, right turn signal, and brake lights.

Understanding the importance of compatibility in Flat Four Trailer Wiring enables users to make informed decisions when selecting and installing wiring harnesses. It empowers them to identify and resolve compatibility issues, preventing electrical malfunctions, safety hazards, and costly repairs. By adhering to compatibility guidelines, individuals can ensure that their towing systems operate seamlessly, delivering a safe and enjoyable towing experience.

Legal Requirements

Within the realm of Flat Four Trailer Wiring, legal requirements are a crucial aspect governing the safe and compliant operation of trailers. These regulations vary depending on geographical locations and jurisdictions, but they generally aim to ensure the proper functioning of electrical systems, adherence to safety standards, and compliance with industry best practices.

-

Electrical Safety Standards

Legal requirements often mandate adherence to established electrical safety standards, such as those set forth by the National Electrical Manufacturers Association (NEMA) or the Society of Automotive Engineers (SAE). These standards provide guidelines for wire gauge, insulation, and connector specifications to ensure the safe and reliable transmission of electrical signals.

-

Lighting and Signaling Regulations

Many jurisdictions have specific regulations governing the use of lighting and signaling devices on trailers. These regulations may specify the required number, placement, and visibility of lights, as well as the color and flashing patterns of turn signals and brake lights, ensuring that trailers are clearly visible to other motorists.

-

Periodic Inspections

Some jurisdictions require periodic inspections of trailer wiring systems to ensure their continued compliance with legal requirements. These inspections may be conducted by certified technicians or law enforcement officials and can help identify any potential safety hazards or electrical issues.

-

Enforcement and Penalties

Violations of legal requirements related to Flat Four Trailer Wiring can result in fines, penalties, or even legal action. Law enforcement officials may issue citations for non-compliant wiring systems, and insurance companies may deny coverage for accidents caused by electrical malfunctions.

Understanding and adhering to legal requirements for Flat Four Trailer Wiring is not only a matter of compliance but also a fundamental aspect of safety and responsibility. By ensuring that their trailer wiring systems meet the necessary standards and regulations, individuals can contribute to the safe and efficient operation of trailers, reducing the risk of accidents, legal issues, and costly repairs.

Related Posts