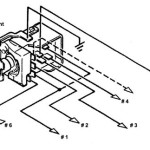

An exhaust fan wiring diagram provides a detailed plan for the electrical connections required to install and operate an exhaust fan. It ensures the fan is wired correctly, optimizing its functionality and preventing electrical hazards. For instance, in a bathroom, an exhaust fan wiring diagram guides the connection of the fan to the electrical circuit, including the power supply, switch, and ground wire.

Following the wiring diagram is crucial for several reasons. It ensures the fan operates safely by preventing electrical shocks or fires. Proper wiring ensures efficient fan performance, optimizing ventilation and reducing moisture buildup. Moreover, it aids in troubleshooting, making it easier to identify and resolve any electrical issues that may arise.

Historically, the development of exhaust fan wiring diagrams has paralleled advancements in electrical codes and safety standards. As building regulations evolved, so did the need for clear and standardized wiring diagrams to ensure compliance and protect against electrical hazards. This evolution has contributed to safer and more efficient ventilation practices.

An exhaust fan wiring diagram is a vital component of any ventilation system, providing a roadmap for the electrical connections necessary for safe and efficient operation. Understanding its key aspects is essential for proper installation, maintenance, and troubleshooting. These aspects encompass:

- Circuit Design: Determines the electrical circuit configuration, including wire gauge, circuit breaker size, and grounding requirements.

- Power Source: Specifies the electrical source (voltage, amperage) required to power the fan.

- Switch Wiring: Outlines the wiring connections between the fan and the switch that controls it.

- Grounding: Ensures proper grounding of the fan to prevent electrical shocks.

- Ductwork Connection: Indicates the electrical connections between the fan and the ductwork, ensuring proper ventilation.

- Timer or Humidity Sensor Integration: Details the wiring required for optional features such as timers or humidity sensors.

- Code Compliance: Adherence to electrical codes and safety standards, ensuring compliance with building regulations.

- Troubleshooting Guide: Provides a reference for identifying and resolving common electrical issues.

These aspects are interconnected, working together to ensure the safe and effective operation of an exhaust fan wiring diagram. Proper understanding and adherence to these aspects are crucial for optimal ventilation, electrical safety, and compliance with industry standards.

Circuit Design

Circuit design plays a critical role in an exhaust fan wiring diagram, as it ensures the electrical circuit is configured correctly for safe and efficient fan operation. The wire gauge, circuit breaker size, and grounding requirements are all determined based on the specific electrical characteristics of the fan and the intended application.

The wire gauge, which refers to the thickness of the electrical wire, must be appropriate for the amount of current the fan will draw. Using a wire gauge that is too thin can lead to overheating and potential fire hazards. The circuit breaker size should be selected to protect the circuit from overloads and short circuits. A circuit breaker that is too small may trip prematurely, while one that is too large may not provide adequate protection.

Proper grounding is also essential for electrical safety. Grounding provides a low-resistance path for electrical current to flow in the event of a fault, preventing dangerous voltage spikes and reducing the risk of electrical shocks. The grounding requirements for an exhaust fan wiring diagram will depend on the specific fan model and the electrical code regulations in the area where it is being installed.

Real-life examples of circuit design considerations in exhaust fan wiring diagrams include:

- Selecting a wire gauge that is appropriate for the fan’s amperage rating, ensuring safe current flow.

- Choosing a circuit breaker size that aligns with the fan’s maximum current draw, providing adequate protection against overloads.

- Implementing proper grounding techniques, such as connecting the fan’s grounding wire to a grounded electrical box or grounding rod, to ensure electrical safety.

Understanding the connection between circuit design and exhaust fan wiring diagrams is crucial for ensuring the safe and efficient operation of ventilation systems. Proper circuit design helps prevent electrical hazards, optimizes fan performance, and ensures compliance with electrical codes.

Power Source

The power source is a critical component of an exhaust fan wiring diagram, as it determines the electrical parameters necessary to power the fan and ensure its safe and efficient operation. The power source section of the diagram specifies the voltage and amperage requirements of the fan, which must be compatible with the available electrical supply.

A mismatch between the power source and the fan’s electrical requirements can lead to several issues. If the voltage is too low, the fan may not operate properly or may even burn out. Conversely, if the voltage is too high, it can damage the fan’s motor or other components. Similarly, if the amperage is too low, the fan may not be able to draw enough current to operate effectively. On the other hand, if the amperage is too high, it can overload the circuit and potentially cause a fire.

Real-life examples of power source considerations in exhaust fan wiring diagrams include:

- In a residential bathroom, the exhaust fan wiring diagram will typically specify a 120-volt, 15-amp circuit to power the fan.

- In a commercial kitchen, the exhaust fan wiring diagram may specify a 240-volt, 30-amp circuit to power a larger, more powerful exhaust fan.

Understanding the connection between the power source and exhaust fan wiring diagrams is crucial for ensuring the safe and efficient operation of ventilation systems. Proper power source selection and wiring help prevent electrical hazards, optimize fan performance, and ensure compliance with electrical codes.

Switch Wiring

Switch wiring plays a crucial role within an exhaust fan wiring diagram, as it establishes the electrical pathway between the fan and the switch that controls its operation. This connection allows the user to manually turn the fan on and off as needed, providing convenient control over ventilation.

The switch wiring section of the diagram specifies the type of switch to be used (e.g., single-pole, double-pole), the number of wires required (typically two or three), and the specific terminals on the switch where the wires should be connected. Proper switch wiring ensures that the fan can be operated safely and efficiently.

Real-life examples of switch wiring in exhaust fan wiring diagrams include:

- In a bathroom exhaust fan wiring diagram, the switch wiring section will typically specify a single-pole switch that is connected to two wires: one wire from the power source and one wire to the fan.

- In a kitchen exhaust fan wiring diagram, the switch wiring section may specify a double-pole switch that is connected to three wires: one wire from the power source, one wire to the fan motor, and one wire to the fan light.

Understanding the connection between switch wiring and exhaust fan wiring diagrams is crucial for ensuring the safe and efficient operation of ventilation systems. Proper switch wiring helps prevent electrical hazards, optimizes fan performance, and ensures compliance with electrical codes. Moreover, it provides convenient control over ventilation, allowing users to adjust airflow as needed.

Grounding

Within the context of an exhaust fan wiring diagram, grounding plays a fundamental role in ensuring the safe and reliable operation of the fan, preventing electrical shocks and potential hazards. Grounding involves establishing a low-resistance path for electrical current to flow in the event of a fault or malfunction, effectively diverting any dangerous voltage away from the fan’s metal components and the user.

- Grounding Wire: The grounding wire, typically bare copper or green in color, serves as the primary conductor for electrical current in the grounding system. It is connected to the fan’s metal frame and extends to the electrical panel, providing a direct path for fault current to flow back to the ground.

- Grounding Electrode: The grounding electrode is a metal rod or plate buried underground and connected to the grounding wire. It provides a low-resistance connection to the earth, ensuring a stable and effective path for fault current to dissipate.

- Grounding Outlet: In modern electrical systems, grounding is achieved through a grounded outlet, which features a third prong that connects to the grounding wire. When the fan is plugged into a grounded outlet, it establishes a direct connection to the grounding system.

- Importance of Grounding: Proper grounding is crucial for preventing electrical shocks. If a fault occurs within the fan, such as a short circuit, the grounding system provides a safe path for the excessive current to flow, preventing it from passing through the fan’s metal components or the user’s body.

Understanding the importance of grounding and its implementation through the exhaust fan wiring diagram is essential for ensuring the safety and reliability of the ventilation system. By establishing a proper grounding system, electrical hazards are minimized, user safety is enhanced, and the overall integrity of the electrical installation is maintained.

Ductwork Connection

Within the context of an exhaust fan wiring diagram, ductwork connection plays a critical role in establishing the electrical pathways between the fan and the ductwork system, ensuring efficient and effective ventilation. This aspect of the wiring diagram outlines the precise electrical connections required to integrate the fan with the ductwork, enabling proper airflow and optimal performance of the ventilation system.

- Power Supply to Fan: The ductwork connection section of the wiring diagram specifies the electrical connections that provide power to the exhaust fan. This includes the connection of the fan motor to the power source, ensuring that the fan has the necessary electrical supply to operate.

- Control Wiring: In addition to the power supply, the wiring diagram outlines the control wiring connections between the fan and the ductwork system. This may involve connecting the fan to a switch or a thermostat, allowing for remote control and adjustment of the fan’s operation based on specific conditions or user preferences.

- Grounding: Proper grounding is essential for the safe and reliable operation of the exhaust fan and the ductwork system. The wiring diagram specifies the grounding connections that ensure a low-resistance path for electrical current to flow in the event of a fault, protecting against electrical shocks and potential hazards.

- Interconnection with Ductwork Components: The ductwork connection section of the wiring diagram may also include electrical connections to other components of the ductwork system, such as dampers or motorized vents. These connections enable coordinated operation and control of the entire ventilation system, optimizing airflow and ensuring efficient air exchange.

Understanding the electrical connections related to ductwork in an exhaust fan wiring diagram is crucial for ensuring the proper functioning of the ventilation system. By following the specified wiring instructions, electricians can establish secure and efficient electrical pathways between the fan and the ductwork, ensuring optimal ventilation performance, safety, and reliability.

Timer or Humidity Sensor Integration

Within the context of an exhaust fan wiring diagram, the integration of timers or humidity sensors adds an additional layer of functionality and automation to the ventilation system. These optional features enhance the convenience and efficiency of the exhaust fan, allowing for customized ventilation based on specific conditions or schedules.

Timers

Timer integration in an exhaust fan wiring diagram enables the setting of specific time intervals for the fan to operate. This feature is particularly useful in scenarios where regular ventilation is desired without manual intervention. For instance, in bathrooms, a timer can be set to automatically turn on the exhaust fan during and after showers, ensuring effective moisture removal and preventing mold growth.

Humidity Sensors

Humidity sensor integration in an exhaust fan wiring diagram allows the fan to respond to changes in humidity levels. The fan can be programmed to turn on or adjust its speed when the humidity exceeds a predefined threshold, ensuring optimal ventilation in humid environments. This feature is particularly beneficial in areas prone to moisture buildup, such as kitchens, laundry rooms, and indoor pools.

The wiring required for timer or humidity sensor integration in an exhaust fan wiring diagram typically involves additional connections to the fan’s control circuit. These connections may include power supply to the timer or sensor, wiring to the fan motor for speed control, and grounding for safety. Proper wiring ensures that these optional features function correctly and enhance the overall performance of the exhaust fan.

Understanding the integration of timers or humidity sensors in exhaust fan wiring diagrams is crucial for electricians and homeowners who seek to optimize ventilation systems. By incorporating these optional features, ventilation can be tailored to specific needs, improving indoor air quality, preventing moisture-related issues, and enhancing overall comfort levels.

Code Compliance

In the context of “Exhaust Fan Wiring Diagram”, code compliance plays a crucial role in ensuring the safety and efficacy of the ventilation system. Electrical codes and safety standards are established to minimize electrical hazards, prevent fires, and protect individuals from electrical shock. Adherence to these codes and standards is paramount for residential, commercial, and industrial buildings.

- National Electrical Code (NEC): The NEC serves as the benchmark for electrical wiring standards in the United States. It provides detailed guidelines for the installation, maintenance, and inspection of electrical systems, including exhaust fans and their wiring.

- Local Building Codes: Local building codes may impose additional requirements or amendments to the NEC. These codes address specific regional concerns, such as seismic activity or extreme weather conditions, and must be carefully followed during the installation process.

- Inspection and Permitting: In many jurisdictions, electrical installations, including exhaust fan wiring, require inspection and permitting by qualified electrical inspectors. Inspections ensure that the installation adheres to code requirements and promotes public safety.

- Consequences of Non-Compliance: Failure to comply with electrical codes and safety standards can have severe consequences. Improper wiring may lead to electrical fires, shock hazards, or even legal liabilities. Additionally, non-compliant installations may not receive necessary insurance coverage.

By adhering to electrical codes and safety standards, exhaust fan wiring diagrams ensure the proper installation and operation of ventilation systems. This not only safeguards occupants from electrical hazards but also contributes to the overall safety and reliability of the building’s electrical infrastructure.

Troubleshooting Guide

An exhaust fan wiring diagram often incorporates a troubleshooting guide to assist in identifying and resolving common electrical issues that may arise during installation, operation, or maintenance. This guide provides a systematic approach to diagnosing and addressing problems, minimizing downtime and ensuring the efficient functioning of the ventilation system.

The troubleshooting guide is a critical component of an exhaust fan wiring diagram as it empowers homeowners, electricians, and maintenance personnel to address minor electrical issues without the need for specialized expertise. By following the step-by-step instructions and utilizing the provided diagnostic charts, common problems can be quickly identified and resolved, preventing further complications or the need for costly repairs.

Real-life examples of troubleshooting guides within exhaust fan wiring diagrams include:

- Fuse or Circuit Breaker Tripping: The guide may provide instructions on how to locate and replace a blown fuse or tripped circuit breaker, restoring power to the exhaust fan.

- Fan Not Running: The guide may offer a checklist of potential causes, such as a faulty switch, a loose wire connection, or a malfunctioning motor, and provide steps to diagnose and resolve the issue.

- Excessive Noise or Vibration: The guide may suggest checking for loose mounting screws, unbalanced fan blades, or worn-out bearings, and provide instructions on how to address these problems.

Understanding the troubleshooting guide within an exhaust fan wiring diagram is essential for maintaining a well-functioning ventilation system. By having a reference to common electrical issues and their solutions readily available, homeowners can perform basic troubleshooting tasks, saving time and money. Electricians and maintenance personnel can also leverage the guide to quickly diagnose and resolve problems, ensuring the efficient operation of the ventilation system and preventing potential hazards.

Related Posts