A U-Haul wiring harness is an electrical assembly that connects the vehicle’s electrical system to the trailer’s electrical system, enabling proper functioning of lights, brakes, and other electrical components.

This wiring harness is crucial for ensuring safe and legal operation of the trailer, as it allows for the transfer of electrical signals between the towing vehicle and the trailer. Its benefits include improved visibility for other motorists, enhanced safety through proper brake light operation, and compliance with legal requirements for trailer lighting. A key historical development in the area of U-Haul wiring harnesses is the introduction of standardized connectors to facilitate easier installation and compatibility between various vehicle and trailer models.

In exploring the subject of U-Haul wiring harnesses, we will delve deeper into their design, installation, maintenance, and the safety considerations associated with their use. By understanding these aspects, individuals can ensure proper functioning of their towing systems and contribute to overall road safety.

The U-Haul wiring harness, serving as a crucial component in the safe and efficient operation of towing systems, has several key aspects that warrant exploration. These aspects encompass various dimensions related to its design, installation, maintenance, and overall significance.

- Compatibility: Ensuring compatibility between the wiring harness and the specific vehicle and trailer models it is intended for.

- Electrical Safety: Adhering to electrical safety standards and regulations to prevent electrical hazards.

- Durability: Withstanding harsh weather conditions, road vibrations, and general wear and tear.

- Functionality: Enabling proper functioning of all electrical components connected to the trailer, including lights, brakes, and turn signals.

- Ease of Installation: Designed for straightforward installation, often involving plug-and-play connectors.

- Maintenance: Regular inspection and maintenance to ensure optimal performance and longevity.

- Legal Compliance: Meeting legal requirements for trailer lighting and signaling.

- Standardization: Utilizing standardized connectors and color-coding for ease of identification and compatibility.

- Troubleshooting: Understanding common troubleshooting techniques for electrical issues related to the wiring harness.

- Safety Implications: Recognizing the safety implications of a properly functioning wiring harness for both the towing vehicle and the trailer.

These key aspects collectively contribute to the effective and safe operation of U-Haul wiring harnesses. By considering these aspects, individuals can make informed decisions regarding the selection, installation, and maintenance of these wiring harnesses, thereby ensuring the proper functioning of their towing systems and promoting road safety.

Compatibility

Compatibility is a critical aspect of U-Haul wiring harnesses, as it ensures that the electrical system of the towing vehicle is properly connected to the electrical system of the trailer. This compatibility is achieved through the use of specific wiring harnesses designed for each make and model of vehicle and trailer. Without proper compatibility, the electrical components of the trailer, such as lights, brakes, and turn signals, may not function correctly, posing safety hazards and legal violations.

For example, a U-Haul wiring harness designed for a 2023 Ford F-150 pickup truck will not be compatible with a 2022 Chevrolet Silverado pickup truck. The electrical systems of these two vehicles are different, and the wiring harness must be matched to the specific vehicle to ensure proper functioning. Similarly, a wiring harness designed for a small utility trailer will not be compatible with a large cargo trailer, as the electrical requirements of these two trailers are different.

Understanding the importance of compatibility is essential for selecting and installing the correct U-Haul wiring harness for your specific towing needs. Using a compatible wiring harness helps prevent electrical problems, ensures the safety and functionality of your towing system, and allows you to comply with legal requirements for trailer lighting and signaling.

Electrical Safety

Ensuring electrical safety is paramount in the design and use of U-Haul wiring harnesses. Adhering to electrical safety standards and regulations helps prevent electrical hazards, such as short circuits, fires, and electrical shocks, which can cause damage to the towing vehicle, the trailer, and the electrical components themselves. By following established safety guidelines, manufacturers can design and produce wiring harnesses that meet or exceed industry standards for electrical safety.

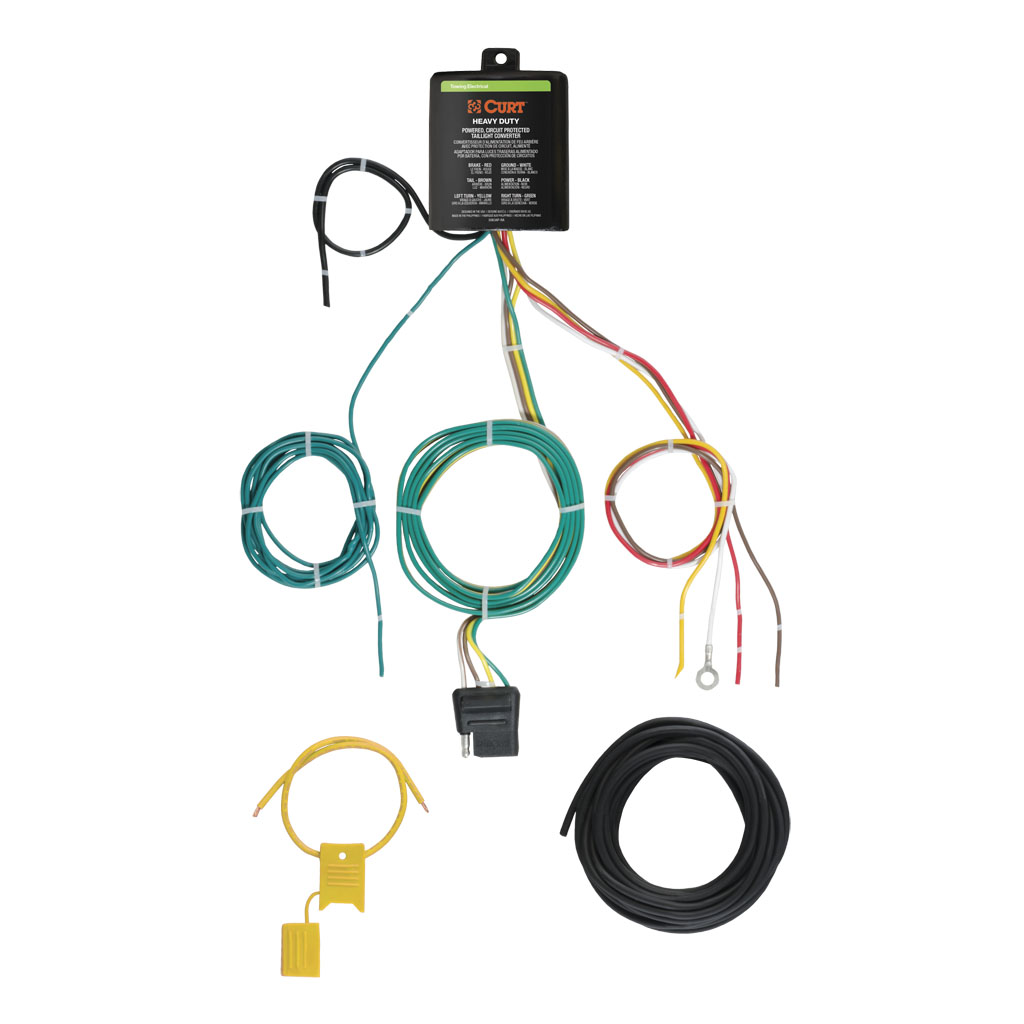

A critical component of electrical safety is proper insulation and protection of electrical wires and connections. U-Haul wiring harnesses are typically constructed with high-quality insulation materials that prevent current leakage and protect against electrical shocks. The use of color-coded wires also helps ensure proper identification and connection, reducing the risk of wiring errors.

Another important aspect of electrical safety is proper grounding. U-Haul wiring harnesses incorporate grounding wires that provide a path for electrical current to safely return to the vehicle’s chassis. This helps prevent electrical faults and ensures the proper functioning of electrical components.

By adhering to electrical safety standards and regulations, U-Haul wiring harnesses help ensure the safe and reliable operation of towing systems. Understanding the importance of electrical safety enables manufacturers to design and produce wiring harnesses that meet or exceed industry standards, and allows users to make informed decisions about the selection and installation of these harnesses, promoting overall safety on the road.

Durability

Durability is a critical aspect of U-Haul wiring harnesses, as these harnesses are subjected to harsh weather conditions, road vibrations, and general wear and tear. Ensuring durability is essential for maintaining reliable electrical connections and preventing malfunctions that could compromise the safety and functionality of the towing system.

- Weather Resistance: U-Haul wiring harnesses are designed to withstand extreme temperatures, moisture, and UV radiation. The insulation and protective materials used in the construction of the harness prevent damage from rain, snow, ice, and sunlight, ensuring reliable performance in all weather conditions.

- Vibration Resistance: Towing can subject the wiring harness to significant vibrations. U-Haul wiring harnesses are constructed with flexible materials and reinforced connections to withstand these vibrations without damage or loosening. This prevents electrical faults and ensures the continuity of electrical signals.

- Abrasion Resistance: The wiring harness may come into contact with rough surfaces or sharp objects during installation or use. U-Haul wiring harnesses utilize abrasion-resistant materials and protective sleeves to prevent damage to the wires and insulation, ensuring long-lasting performance.

- Corrosion Resistance: Exposure to moisture and road salts can lead to corrosion, which can degrade the electrical connections. U-Haul wiring harnesses are treated with anti-corrosion materials to protect the metal components and ensure reliable electrical conductivity over time.

By incorporating these durability features into their design, U-Haul wiring harnesses are able to withstand the rigors of towing, providing reliable and safe electrical connections between the towing vehicle and the trailer.

Functionality

Functionality is a critical aspect of U-Haul wiring harnesses, as they are designed to enable the proper functioning of all electrical components connected to the trailer, including lights, brakes, and turn signals. Without a properly functioning wiring harness, these essential electrical components would not be able to operate, leading to safety hazards and legal violations.

For example, if the wiring harness is not properly connected, the trailer’s lights may not work, making it difficult for other drivers to see the trailer at night or in low-visibility conditions. This could lead to accidents and serious injuries. Similarly, if the wiring harness is not properly connected, the trailer’s brakes may not work, which could cause the trailer to jackknife or lose control, resulting in a dangerous and potentially fatal situation.

Understanding the importance of functionality is essential for selecting and installing the correct U-Haul wiring harness for your specific towing needs. Using a properly functioning wiring harness helps ensure the safety and functionality of your towing system, and allows you to comply with legal requirements for trailer lighting and signaling.

By providing a reliable electrical connection between the towing vehicle and the trailer, U-Haul wiring harnesses ensure that all electrical components, including lights, brakes, and turn signals, function properly. This helps prevent accidents, protects lives, and promotes overall safety on the road.

Ease of Installation

Ease of installation is an important aspect of U-Haul wiring harnesses, as it enables users to quickly and easily connect the electrical system of their towing vehicle to the electrical system of their trailer. This straightforward installation process helps ensure that the trailer’s lights, brakes, and turn signals function properly, enhancing safety and compliance with legal requirements.

- Color-Coded Wires: U-Haul wiring harnesses often utilize color-coded wires to simplify the installation process. Each wire is assigned a specific color, which corresponds to a specific function (e.g., red for taillights, yellow for turn signals). This color-coding helps prevent wiring errors and ensures that the harness is connected correctly.

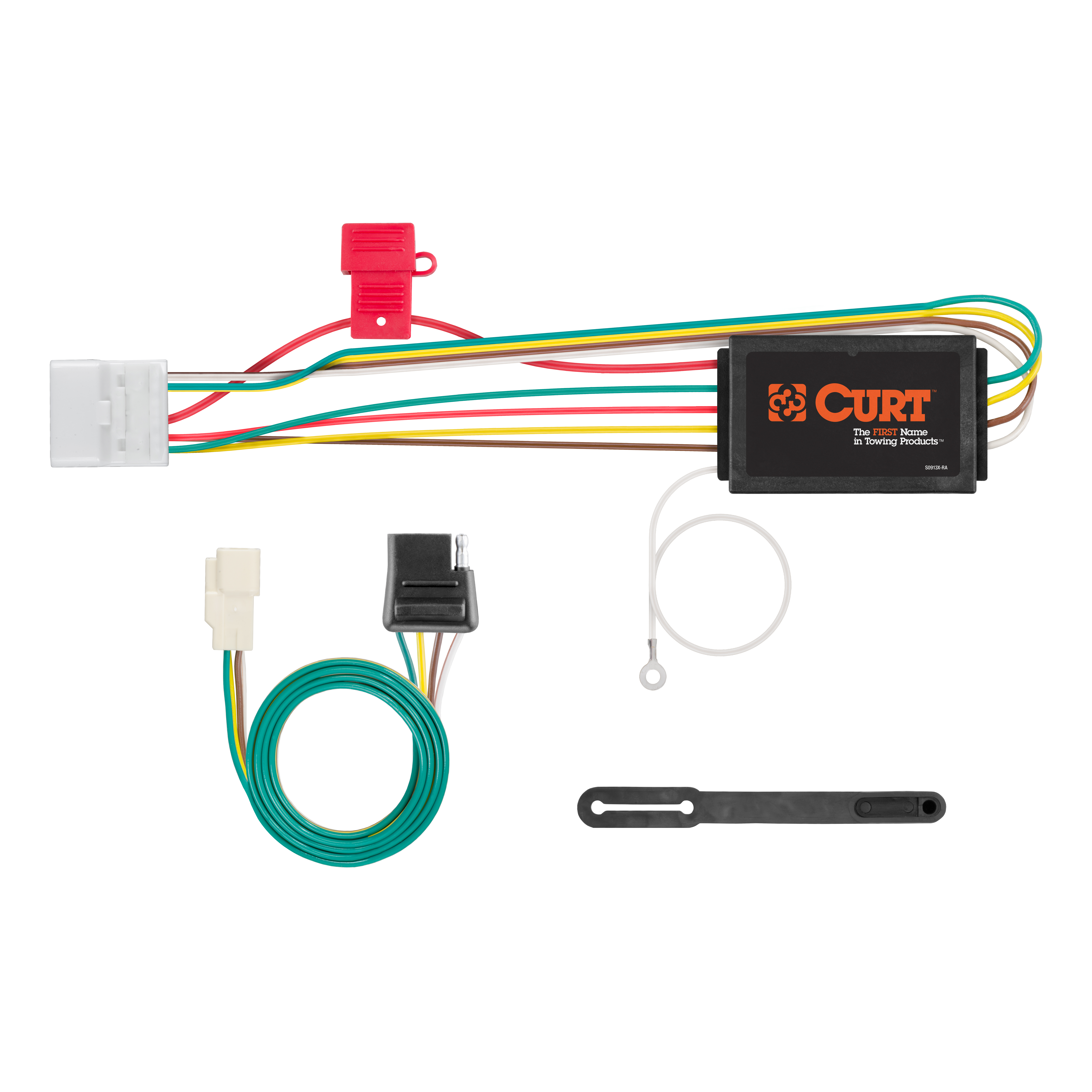

- Plug-and-Play Connectors: Plug-and-play connectors are commonly used in U-Haul wiring harnesses. These connectors allow for a quick and easy connection between the wiring harness and the trailer’s electrical system. Simply plug the connectors together, and the electrical connection is established.

- Detailed Instructions: U-Haul wiring harnesses typically come with detailed instructions that guide the user through the installation process. These instructions provide step-by-step guidance, making it easy for even novice users to install the harness correctly.

- Customer Support: U-Haul offers customer support to assist users with any questions or difficulties they may encounter during the installation process. This support can be accessed through phone, email, or online chat.

The ease of installation provided by U-Haul wiring harnesses is a significant benefit, as it allows users to quickly and easily connect their towing vehicles to their trailers. This straightforward installation process helps ensure that the trailer’s electrical components function properly, enhancing safety and compliance with legal requirements.

Maintenance

Maintaining your U-Haul wiring harness is crucial for ensuring its optimal performance and longevity. By regularly inspecting and maintaining the wiring harness, you can prevent potential issues, extend its lifespan, and ensure the safe and reliable operation of your towing system. Here are a few key aspects of maintenance to consider:

- Visual Inspection: Regularly inspect the wiring harness for any visible damage, such as cuts, abrasions, or loose connections. Pay attention to areas where the harness is exposed to friction or movement, as these are more prone to wear and tear.

- Electrical Testing: Periodically test the electrical continuity of the wiring harness using a multimeter or other electrical testing equipment. This will help identify any potential breaks or shorts in the wiring, ensuring that the electrical signals are transmitted properly.

- Connector Cleaning: Over time, dirt, grime, and moisture can accumulate on the electrical connectors, leading to corrosion and poor electrical contact. Regularly clean the connectors using a contact cleaner or electrical lubricant to maintain proper conductivity.

- Replacement of Worn Components: If any components of the wiring harness become damaged or worn beyond repair, it is essential to replace them promptly. This includes replacing any faulty wires, connectors, or other electrical components.

Regular maintenance of your U-Haul wiring harness is essential for ensuring the safety and reliability of your towing system. By following these simple maintenance tips, you can extend the lifespan of the wiring harness, prevent costly repairs, and ensure that your trailer’s electrical components function properly at all times.

Legal Compliance

When using a U-Haul wiring harness, it is crucial to ensure that the trailer’s lighting and signaling systems comply with all applicable legal requirements. This not only enhances the safety of your towing setup but also helps you avoid potential legal consequences and fines. Here are some key aspects to consider:

- Proper Lighting: The trailer must be equipped with functioning taillights, brake lights, turn signals, and side marker lights. These lights should meet specific visibility and color requirements as mandated by law.

- Reflective Markings: The trailer should have reflective markings or tape applied to its sides and rear to increase visibility, especially at night. These markings help other drivers see the trailer in low-light conditions.

- License Plate Lighting: The trailer’s license plate must be illuminated by a dedicated light to ensure that it is clearly visible to other motorists.

- Wiring and Connections: The wiring harness used to connect the trailer’s lighting system to the towing vehicle must be in good condition, with no loose connections or exposed wires. Faulty wiring can lead to electrical issues and lighting malfunctions.

By ensuring legal compliance with trailer lighting and signaling, U-Haul wiring harnesses contribute to the safe and responsible operation of towing systems. They help prevent accidents, protect drivers and other road users, and demonstrate adherence to established safety regulations.

Standardization

In the realm of U-Haul wiring harnesses, standardization plays a critical role in ensuring the efficient and reliable operation of towing systems. Standardization refers to the utilization of established and widely accepted connectors and color-coding schemes, which brings numerous benefits to the design, installation, and maintenance of U-Haul wiring harnesses.

Standardized connectors, such as the 7-pin or 4-pin flat connectors, facilitate a universal connection between the towing vehicle and the trailer. This uniformity eliminates the need for custom wiring or adapters, simplifying installation and reducing the risk of incorrect connections. Color-coding further enhances ease of identification and compatibility. Each wire within the harness is assigned a specific color, corresponding to its designated function (e.g., red for taillights, yellow for turn signals). This color-coding aligns with industry standards, enabling technicians and users to quickly identify and connect the wires correctly, minimizing the potential for errors.

The practical applications of standardization in U-Haul wiring harnesses are extensive. Standardized connectors allow for seamless interchangeability of trailers with different towing vehicles, ensuring compatibility across various makes and models. This flexibility is particularly advantageous in rental situations, where customers may use different vehicles to tow U-Haul trailers. Color-coding simplifies the troubleshooting process, as technicians can easily trace and identify specific wires based on their assigned colors. This expedited troubleshooting reduces downtime and ensures the prompt restoration of proper electrical functionality.

In summary, standardization in U-Haul wiring harnesses, through the use of standardized connectors and color-coding, promotes ease of identification, compatibility, and efficient troubleshooting. It contributes to the overall safety and reliability of towing systems, minimizing the risk of electrical failures and ensuring the proper functioning of trailer lights, brakes, and other electrical components.

Troubleshooting

Troubleshooting electrical issues related to the wiring harness is a critical aspect of maintaining the proper functioning of U-Haul trailers. By understanding common troubleshooting techniques, individuals can effectively diagnose and resolve electrical problems, ensuring the safety and reliability of their towing systems.

- Visual Inspection: A thorough visual inspection of the wiring harness is the first step in troubleshooting. Look for any visible damage, such as cuts, abrasions, or loose connections. Check the connectors for corrosion or debris that may hinder electrical contact.

- Electrical Testing: Using a multimeter or other electrical testing equipment, test the continuity of the wiring harness. This involves checking for breaks or shorts in the wires, ensuring that the electrical signals are transmitted properly.

- Component Replacement: If a specific component of the wiring harness, such as a fuse or relay, fails, it may need to be replaced. Always use high-quality replacement parts that meet the specifications of the original component.

- Professional Assistance: In some cases, electrical issues may be complex and require the assistance of a qualified electrician or mechanic. They have the expertise and equipment to diagnose and repair more intricate electrical problems.

Understanding common troubleshooting techniques empowers individuals to maintain their U-Haul wiring harnesses and resolve electrical issues promptly. By following these steps, they can ensure the proper functioning of trailer lights, brakes, and other electrical components, contributing to the overall safety and reliability of their towing systems.

Safety Implications

A properly functioning wiring harness is a critical component of any U-Haul trailer, as it ensures the safe and reliable operation of the trailer’s electrical system. Without a properly functioning wiring harness, the trailer’s lights, brakes, and other electrical components may not work properly, which can lead to serious safety hazards.

For example, if the trailer’s lights are not working properly, it may be difficult for other drivers to see the trailer at night or in low-visibility conditions. This could lead to a collision between the trailer and another vehicle. Similarly, if the trailer’s brakes are not working properly, the trailer may not be able to stop quickly enough in the event of an emergency, which could lead to a serious accident.

In addition to these specific safety hazards, a properly functioning wiring harness also helps to prevent electrical fires. Electrical fires can occur if the wiring harness is damaged or if there is a short circuit in the electrical system. These fires can cause extensive damage to the trailer and the towing vehicle, and they can also be a danger to people and property.

By understanding the safety implications of a properly functioning wiring harness, you can take steps to ensure that your trailer is safe to tow. This includes having the wiring harness inspected regularly by a qualified technician and replacing any damaged or worn components.

Related Posts