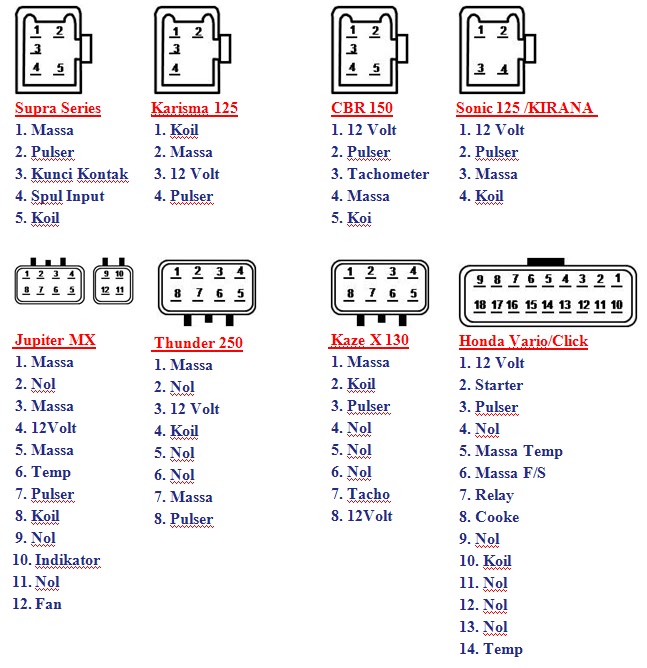

A 5 Pin CDI Wiring Diagram is a specific electrical schematic that illustrates the interconnected wiring of a 5-pin Capacitive Discharge Ignition (CDI) system, typically used in small engines like those found in lawnmowers, chainsaws, and motorcycles. It serves as a blueprint for the proper installation and maintenance of the CDI system.

Understanding this wiring diagram is crucial for efficient engine operation, troubleshooting, and repair. It provides a visual guide to connect the CDI unit, ignition coil, spark plug, and other electrical components correctly. Additionally, it ensures optimal timing of the ignition spark, which directly affects engine performance and emissions.

A significant historical development in CDI technology was the introduction of electronic circuitry in the 1970s. This advancement replaced the mechanical points and condensers with solid-state components, resulting in improved reliability, accurate timing, and reduced maintenance requirements.

The subsequent sections of this informative article will delve deeper into the components, functionality, and troubleshooting techniques of 5 Pin CDI Wiring Diagrams, providing valuable insights for technicians, hobbyists, and anyone interested in understanding small engine ignition systems.

The key aspects of a 5 Pin CDI Wiring Diagram are crucial for understanding its functionality and ensuring proper engine operation. These aspects encompass various dimensions related to the diagram’s purpose, components, and implications.

- Purpose: Blueprint for CDI system installation and maintenance.

- Components: CDI unit, ignition coil, spark plug, wiring.

- Function: Facilitates electrical connections and timing of ignition spark.

- Accuracy: Precise timing for optimal engine performance.

- Reliability: Ensures consistent engine operation.

- Troubleshooting: Guide for diagnosing and resolving ignition issues.

- Compatibility: Specific to 5-pin CDI systems.

- Complexity: Relatively simple diagram, easy to understand.

- Universality: Applicable to various small engines.

- Availability: Easily accessible online and in repair manuals.

These aspects are interconnected and contribute to the overall effectiveness of the 5 Pin CDI Wiring Diagram. Understanding these aspects enables technicians and enthusiasts to properly install, maintain, and troubleshoot CDI systems, ensuring optimal engine performance and longevity.

Purpose

Within the context of “5 Pin CDI Wiring Diagram,” the “Purpose: Blueprint for CDI system installation and maintenance” aspect holds paramount importance. This diagram serves as a crucial guide for technicians and enthusiasts alike, providing a clear roadmap for proper installation, maintenance, and troubleshooting of CDI systems in various small engines.

- Installation Guide: The diagram outlines the precise steps and connections required to correctly install a 5-pin CDI system. It ensures that all components, including the CDI unit, ignition coil, spark plug, and wiring, are interconnected in the proper sequence and orientation.

- Maintenance Schedule: The diagram provides insights into the maintenance requirements of the CDI system, highlighting the recommended intervals for inspections, cleaning, and replacement of components. This information is essential for ensuring optimal performance and longevity of the engine.

- Diagnostic Tool: In the event of engine issues or malfunctions, the wiring diagram serves as a valuable diagnostic tool. By tracing the electrical connections and testing the components according to the diagram, technicians can pinpoint the root cause of the problem, leading to efficient troubleshooting.

- Performance Optimization: Understanding the wiring diagram empowers users to fine-tune the CDI system for optimal engine performance. Adjustments to ignition timing and other parameters can be made based on the diagram, resulting in improved power output, fuel efficiency, and reduced emissions.

In summary, the “Purpose: Blueprint for CDI system installation and maintenance” aspect of “5 Pin CDI Wiring Diagram” is a comprehensive guide that facilitates proper installation, maintenance, troubleshooting, and performance optimization of CDI systems in small engines. It empowers technicians and enthusiasts with the knowledge and understanding necessary to ensure the reliable and efficient operation of their engines.

Components

Within the context of “5 Pin CDI Wiring Diagram,” the componentsCDI unit, ignition coil, spark plug, and wiringplay a critical role in the overall functionality of the system. These components are intricately interconnected, and their proper configuration and operation are essential for generating the necessary spark to ignite the air-fuel mixture in small engines.

The CDI unit serves as the central processing unit of the ignition system, receiving input signals from the engine’s crankshaft or camshaft sensors. Based on these signals, the CDI unit calculates the optimal timing for ignition and discharges high-voltage current to the ignition coil. The ignition coil then transforms this high-voltage current into an even higher voltage, which is delivered to the spark plug.

The spark plug is responsible for creating the spark that ignites the air-fuel mixture within the engine’s combustion chamber. The wiring, as the name suggests, provides the electrical connections between all these components, ensuring the proper flow of current and signals. Any fault or malfunction in any of these components can disrupt the ignition process, leading to engine performance issues or even complete failure.

Understanding the relationship between these components and the “5 Pin CDI Wiring Diagram” is crucial for several reasons.

- Troubleshooting: By comprehending how each component functions and interacts with the others, technicians can systematically troubleshoot ignition problems and identify the root cause of malfunctions.

- Performance Optimization: The wiring diagram allows for adjustments to ignition timing and other parameters, enabling users to optimize engine performance based on specific requirements or operating conditions.

- Safety: A thorough understanding of the wiring diagram ensures that the ignition system is installed and maintained correctly, minimizing the risk of electrical hazards or engine damage.

Overall, the “Components: CDI unit, ignition coil, spark plug, wiring” aspect of “5 Pin CDI Wiring Diagram” provides a comprehensive overview of the essential components involved in the ignition process of small engines. This understanding is vital for technicians, enthusiasts, and anyone seeking to maintain and troubleshoot these systems effectively.

Function

Within the context of “5 Pin CDI Wiring Diagram,” the primary function revolves around facilitating electrical connections and precisely timing the ignition spark in small engines. This intricate process involves a seamless interplay of various components working in unison, ensuring efficient combustion and optimal engine performance.

- Electrical Connections: The wiring diagram outlines the interconnected electrical pathways between the CDI unit, ignition coil, spark plug, and other electrical components. These connections enable the flow of current and signals, ensuring the proper functioning of the ignition system.

- CDI Unit: The CDI unit serves as the brain of the ignition system, receiving input signals from sensors and calculating the optimal timing for ignition. It then discharges high-voltage current to the ignition coil.

- Ignition Coil: The ignition coil amplifies the voltage received from the CDI unit, generating a high-voltage pulse that is directed towards the spark plug.

- Spark Plug: The spark plug utilizes the high-voltage pulse from the ignition coil to create an electrical spark across its electrodes, igniting the air-fuel mixture within the engine’s combustion chamber.

Understanding the “Function: Facilitates electrical connections and timing of ignition spark.” is crucial for several reasons. First, it provides a comprehensive overview of the ignition process in small engines, empowering users to grasp the fundamental principles of operation. Secondly, it aids in troubleshooting and diagnosing ignition-related issues by pinpointing potential faults in the electrical connections or timing mechanisms. Finally, it allows for performance optimization by enabling adjustments to ignition timing based on specific engine requirements.

Accuracy

In the context of “5 Pin CDI Wiring Diagram,” accuracy plays a pivotal role in ensuring optimal engine performance. The ignition timing, orchestrated by the CDI system, directly influences the efficiency of combustion, power output, fuel consumption, and emission levels of the engine. Precise timing is paramount for maximizing engine performance and minimizing detrimental effects.

When ignition occurs at the optimal moment, the air-fuel mixture within the combustion chamber is ignited, creating a controlled expansion of gases that drives the piston downward, generating power. Conversely, if the ignition timing is inaccurate, the combustion process is compromised, leading to reduced power, increased fuel consumption, and elevated emissions. This emphasizes the critical nature of accurate ignition timing for achieving optimal engine performance.

The “5 Pin CDI Wiring Diagram” provides a precise roadmap for establishing accurate ignition timing in small engines. It outlines the electrical connections and components responsible for generating and delivering the spark at the appropriate moment. By diligently following the diagram and ensuring proper installation and maintenance, technicians and enthusiasts can optimize ignition timing, resulting in improved engine performance, fuel efficiency, and reduced emissions.

In summary, the “5 Pin CDI Wiring Diagram” serves as an essential tool for achieving accurate ignition timing, which is a critical component of optimal engine performance. Understanding the relationship between accuracy and ignition timing empowers users to maintain and troubleshoot CDI systems effectively, maximizing the efficiency and longevity of their engines.

Reliability

Within the context of “5 Pin CDI Wiring Diagram,” reliability plays a pivotal role in ensuring consistent and dependable engine operation. The diagram provides a comprehensive blueprint for the electrical connections and timing mechanisms responsible for generating the ignition spark in small engines. By precisely outlining the interconnected components and their functions, the wiring diagram contributes directly to the overall reliability of the ignition system.

A reliable ignition system ensures that the spark plug consistently generates a high-voltage spark at the optimal moment, igniting the air-fuel mixture within the engine’s combustion chamber. This precise and consistent ignition timing is crucial for maintaining stable engine operation, preventing misfires and ensuring efficient combustion. A well-designed and accurately implemented “5 Pin CDI Wiring Diagram” forms the foundation for this reliability, minimizing the risk of electrical faults, timing errors, and premature component failures.

In practical terms, the reliability provided by a “5 Pin CDI Wiring Diagram” translates into several tangible benefits for engine users. Improved reliability means fewer engine stalls, smoother operation, increased fuel efficiency, and reduced emissions. Moreover, a reliable ignition system contributes to the overall longevity of the engine, reducing the likelihood of costly repairs and downtime.

Troubleshooting

Within the context of “5 Pin CDI Wiring Diagram,” the “Troubleshooting: Guide for diagnosing and resolving ignition issues” aspect plays a pivotal role in maintaining optimal engine performance and ensuring reliable operation. The wiring diagram provides a comprehensive roadmap for tracing electrical connections, identifying faulty components, and resolving ignition-related problems in small engines.

The “5 Pin CDI Wiring Diagram” serves as a critical foundation for effective troubleshooting by providing a clear understanding of the system’s components and their interrelationships. By meticulously following the diagram, technicians and enthusiasts can systematically test each component, isolate faults, and implement appropriate repair or replacement strategies.

Real-life examples of troubleshooting scenarios within the context of “5 Pin CDI Wiring Diagram” include:

- Diagnosing a no-spark condition by tracing the electrical connections from the CDI unit to the spark plug, identifying loose connections or faulty components along the way.

- Resolving intermittent ignition problems by examining the wiring harness for breaks or damage, ensuring proper grounding, and testing the ignition coil and CDI unit for functionality.

- Optimizing ignition timing by adjusting the position of the pickup coil or CDI unit according to the specifications outlined in the wiring diagram, resulting in improved engine performance and fuel efficiency.

The practical applications of understanding the connection between “Troubleshooting: Guide for diagnosing and resolving ignition issues” and “5 Pin CDI Wiring Diagram” extend beyond resolving immediate problems. It empowers users to maintain and service their engines proactively, preventing costly breakdowns and extending the lifespan of their equipment. Moreover, a thorough understanding of the wiring diagram and troubleshooting techniques enables users to customize and modify ignition systems to meet specific performance requirements or adapt to different operating conditions.

In summary, the “Troubleshooting: Guide for diagnosing and resolving ignition issues” aspect of “5 Pin CDI Wiring Diagram” is an essential tool for maintaining optimal engine performance, ensuring, and maximizing the lifespan of small engines. By providing a comprehensive understanding of the electrical connections and components involved in the ignition system, the wiring diagram empowers users to diagnose and resolve ignition-related issues effectively, contributing to the overall reliability and efficiency of their engines.

Compatibility

Within the context of “5 Pin Cdi Wiring Diagram,” the aspect of “Compatibility: Specific to 5-pin CDI systems” highlights the unique characteristics and requirements of this particular ignition system. The “5 Pin Cdi Wiring Diagram” is designed to be compatible with specific components and configurations, ensuring optimal performance and functionality.

- CDI Unit: The wiring diagram is compatible with specific 5-pin CDI units, which are the central processing units of the ignition system, responsible for generating the high-voltage spark.

- Ignition Coil: The diagram outlines the connections to a compatible ignition coil, which amplifies the voltage generated by the CDI unit to create the spark.

- Spark Plug: The wiring diagram specifies the type of spark plug compatible with the system, ensuring proper fit, heat range, and electrical characteristics.

- Wiring Harness: The diagram provides a guide for connecting the CDI unit, ignition coil, and spark plug using a compatible wiring harness, which includes the necessary connectors and wire gauges.

Understanding the compatibility requirements of “5 Pin Cdi Wiring Diagram” is crucial for successful installation, maintenance, and troubleshooting of the ignition system. Using incompatible components can lead to improper operation, reduced performance, or even damage to the engine. The wiring diagram serves as a reference point for ensuring compatibility, guiding users in selecting the correct components and making the appropriate connections.

Complexity

The “Complexity: Relatively simple diagram, easy to understand.” aspect of “5 Pin Cdi Wiring Diagram” holds significant importance in the context of engine maintenance and repair. The simplicity and clarity of the wiring diagram make it accessible to a wide range of users, from novice enthusiasts to experienced technicians.

The “5 Pin Cdi Wiring Diagram” presents the electrical connections and components in a logical and straightforward manner, enabling users to easily trace the flow of current and signals throughout the ignition system. This simplicity stems from the use of standardized symbols, color-coded wires, and clear labeling, which facilitates the identification and understanding of each component’s function.

Real-life examples of the “Complexity: Relatively simple diagram, easy to understand.” aspect can be found in the widespread adoption of “5 Pin Cdi Wiring Diagram” across various industries and applications. From small engines used in lawnmowers and chainsaws to more complex systems in motorcycles and generators, the simplicity of the wiring diagram has contributed to its popularity and ease of use.

The practical applications of understanding the “Complexity: Relatively simple diagram, easy to understand.” aspect extend beyond basic troubleshooting and maintenance. It empowers users to customize and modify their ignition systems to meet specific performance requirements or adapt to different operating conditions. The simplicity of the wiring diagram allows users to make informed decisions about component upgrades or system modifications.

In summary, the “Complexity: Relatively simple diagram, easy to understand.” aspect of “5 Pin Cdi Wiring Diagram” is a key factor contributing to its widespread adoption and effectiveness. The simplicity of the diagram makes it accessible to users of varying skill levels, enabling them to troubleshoot, maintain, and modify their ignition systems with confidence.

Universality

Within the context of “5 Pin Cdi Wiring Diagram,” the aspect of “Universality: Applicable to various small engines” holds significant importance, as it highlights the broad applicability of the diagram across a range of engine types and applications.

- Engine Types: The “5 Pin Cdi Wiring Diagram” is compatible with a wide variety of small engines, including those found in lawnmowers, chainsaws, motorcycles, generators, and other equipment. This versatility stems from the standardized design and functionality of 5-pin CDI systems.

- Power Output: The wiring diagram can be applied to small engines with varying power outputs, from low-power engines used in handheld tools to higher-power engines found in larger equipment. The diagram provides the necessary guidance for adapting the ignition system to different power requirements.

- Operating Conditions: The “5 Pin Cdi Wiring Diagram” is designed to function effectively under diverse operating conditions, including extreme temperatures, vibration, and exposure to moisture. This ensures reliable ignition performance in various environments.

- Compatibility: The universality of the wiring diagram extends to its compatibility with different brands and models of small engines. By adhering to the standard 5-pin CDI configuration, the diagram can be easily adapted to most small engines, eliminating the need for custom wiring or modifications.

In summary, the “Universality: Applicable to various small engines” aspect of “5 Pin Cdi Wiring Diagram” underscores the broad applicability and adaptability of the diagram across a wide range of engine types, power outputs, operating conditions, and equipment brands. This versatility makes the “5 Pin Cdi Wiring Diagram” an invaluable tool for technicians, enthusiasts, and anyone involved in the maintenance and repair of small engines.

Availability

The aspect of “Availability: Easily accessible online and in repair manuals” holds significant importance in the context of “5 Pin Cdi Wiring Diagram.” This accessibility plays a pivotal role in enabling users to obtain, understand, and apply the wiring diagram for effective maintenance, troubleshooting, and repair of small engines.

The widespread availability of “5 Pin Cdi Wiring Diagram” online and in repair manuals ensures that users have convenient access to accurate and up-to-date information. This ready availability eliminates the need for users to rely solely on manufacturer-specific documentation or specialized knowledge, which may not always be readily available. The presence of the wiring diagram in multiple sources, both online and in print, increases its accessibility to a wider audience, including hobbyists, DIY enthusiasts, and professional technicians.

Real-life examples of the accessibility of “5 Pin Cdi Wiring Diagram” can be found in various online forums, technical websites, and dedicated repositories for small engine repair information. Additionally, many manufacturers provide the wiring diagram in their repair manuals, ensuring that users have access to the necessary information during maintenance or troubleshooting procedures.

The practical applications of understanding the connection between “Availability: Easily accessible online and in repair manuals” and “5 Pin Cdi Wiring Diagram” are numerous. Easy access to the wiring diagram empowers users to perform basic maintenance tasks, such as spark plug replacement and ignition timing adjustments, with confidence. It also enables them to diagnose and resolve common ignition-related issues without the need for professional assistance, saving both time and money.

In summary, the “Availability: Easily accessible online and in repair manuals” aspect of “5 Pin Cdi Wiring Diagram” is a critical factor contributing to the widespread use and effectiveness of the diagram. The ready availability of accurate and up-to-date information empowers users to maintain, troubleshoot, and repair small engines with greater confidence and efficiency.

![[DIAGRAM] 5 Pin Cdi Wiring Diagram Suzuki](https://i0.wp.com/www.suzukicentral.com/forums/attachments/electrical/8659d1331070377-03-04-cdi-pinout-2012-03-06-16.37.14.jpg?w=665&ssl=1)

Related Posts