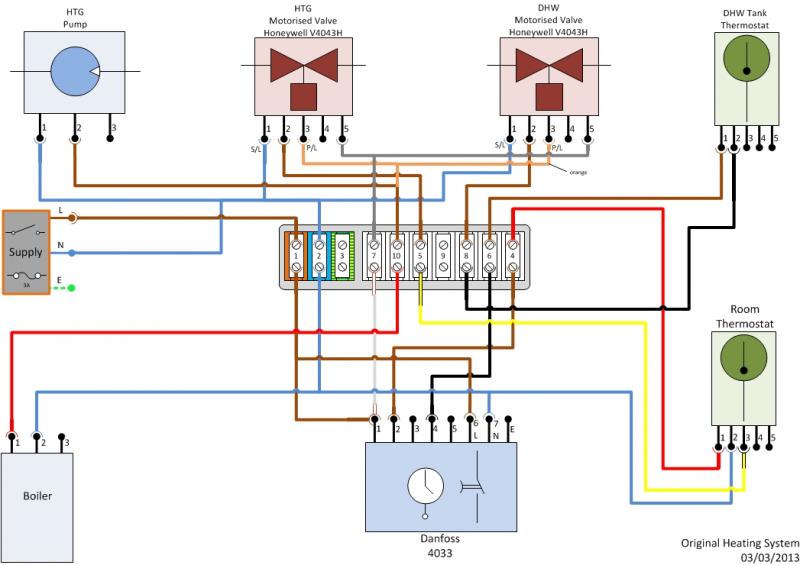

A Honeywell Zone Valve Wiring Schematic visually represents a sequence of electrical connections required to integrate a Honeywell Zone Valve into a heating or cooling system. It guides installers in wiring the valve to the zone control panel, boiler, and other components, ensuring proper operation and control of the heating or cooling zones.

The schematic’s significance lies in its ability to:

- Optimize system performance by ensuring accurate and efficient control of zone temperatures.

- Prevent wiring errors that could compromise system safety or damage equipment.

- Facilitate troubleshooting and maintenance.

A key historical development was the introduction of wireless zone valves, eliminating the need for complex wiring and enhancing flexibility in system design.

Understanding Honeywell Zone Valve Wiring Schematics is essential for HVAC professionals who install, maintain, and troubleshoot heating and cooling systems. This article will delve into the specific aspects of these schematics, providing detailed explanations, diagrams, and practical guidance for successful system integration.

Honeywell Zone Valve Wiring Schematics are essential for the installation, maintenance, and troubleshooting of heating and cooling systems. They provide a visual representation of the electrical connections required to integrate a Honeywell Zone Valve into a system, ensuring proper operation and control of the heating or cooling zones.

- Accuracy: Schematics ensure precise wiring connections, preventing errors that could compromise system performance or damage equipment.

- Efficiency: Accurate wiring optimizes system efficiency, ensuring that each zone receives the appropriate amount of heating or cooling.

- Safety: Schematics help prevent electrical hazards by guiding installers in connecting wires correctly and avoiding potential short circuits.

- Troubleshooting: Schematics serve as a valuable tool for troubleshooting system issues, allowing technicians to quickly identify and resolve wiring problems.

- Documentation: Schematics provide a permanent record of the wiring configuration, facilitating future maintenance and modifications.

- Customization: Schematics can be tailored to specific system requirements, ensuring compatibility with different types of boilers, zone control panels, and other components.

- Compatibility: Honeywell Zone Valve Wiring Schematics are designed to be compatible with a wide range of Honeywell products, ensuring seamless integration.

- Simplicity: Schematics are easy to understand and follow, even for technicians with limited experience.

- Availability: Schematics are readily available from Honeywell and its authorized distributors, ensuring accessibility for installers and homeowners.

- Cost-effectiveness: Schematics help prevent costly mistakes and downtime, saving time and resources during system installation and maintenance.

By understanding and utilizing Honeywell Zone Valve Wiring Schematics, HVAC professionals can ensure the safe, efficient, and reliable operation of heating and cooling systems. These schematics are an indispensable tool for anyone involved in the installation, maintenance, or troubleshooting of these systems.

Accuracy

In the context of Honeywell Zone Valve Wiring Schematics, accuracy is paramount. Precise wiring connections are essential to ensure the proper operation and safety of heating and cooling systems. Any errors in wiring can lead to system malfunctions, reduced efficiency, or even equipment damage.

Honeywell Zone Valve Wiring Schematics play a critical role in achieving this accuracy. They provide detailed instructions on how to connect the zone valve to the zone control panel, boiler, and other components. By following these schematics carefully, installers can ensure that all connections are made correctly, eliminating the risk of errors.

For example, if a wire is connected to the wrong terminal on the zone valve, it could cause the valve to open or close at the wrong time, resulting in improper temperature control or even system failure. Similarly, if a wire is not properly secured, it could become loose and cause intermittent connection issues, leading to system malfunctions.

By providing clear and accurate wiring instructions, Honeywell Zone Valve Wiring Schematics help prevent these types of errors. They ensure that the system is wired correctly from the outset, minimizing the risk of problems down the road.

Moreover, these schematics serve as a valuable troubleshooting tool. If a system is not operating properly, technicians can refer to the schematic to identify potential wiring issues. This can save time and effort in diagnosing and resolving the problem.

In summary, accuracy is a critical aspect of Honeywell Zone Valve Wiring Schematics. By providing precise wiring instructions, these schematics help ensure the proper operation and safety of heating and cooling systems, preventing errors that could compromise system performance or damage equipment.

Efficiency

In the context of Honeywell Zone Valve Wiring Schematics, efficiency is of paramount importance. Accurate wiring ensures that the heating and cooling system operates at its optimal level, delivering the desired comfort levels while minimizing energy consumption.

- Precise Temperature Control: Accurate wiring enables precise temperature control in each zone. By ensuring that the zone valve receives the correct signals from the zone control panel, the valve can adjust the flow of hot or cold water to maintain the desired temperature, eliminating hot or cold spots.

- Balanced System Operation: Proper wiring ensures that all zones in the system operate in balance. This prevents some zones from receiving too much or too little heating or cooling, ensuring that the entire system operates efficiently and effectively.

- Reduced Energy Consumption: Optimized system efficiency directly translates to reduced energy consumption. Accurate wiring ensures that the system does not waste energy on over-heating or over-cooling, leading to lower utility bills and a smaller carbon footprint.

- Extended Equipment Life: Efficient system operation reduces wear and tear on system components, extending their lifespan. By preventing overheating or overcooling, accurate wiring helps protect the boiler, zone valves, and other components from premature failure.

In summary, accurate wiring plays a critical role in optimizing the efficiency of Honeywell Zone Valve-based heating and cooling systems. It ensures precise temperature control, balanced system operation, reduced energy consumption, and extended equipment life, delivering maximum comfort and efficiency for homeowners and businesses alike.

Safety

In the context of Honeywell Zone Valve Wiring Schematics, safety is paramount. Accurate wiring is essential to prevent electrical hazards and ensure the safe operation of heating and cooling systems. Honeywell Zone Valve Wiring Schematics play a critical role in this regard by providing clear and detailed instructions on how to connect the zone valve to the zone control panel, boiler, and other components.

- Electrical Shock Prevention: Schematics guide installers in connecting wires correctly, preventing loose or exposed wires that could pose an electrical shock hazard. Proper wire insulation and secure connections ensure that electricity flows safely through the system, minimizing the risk of electrical accidents.

- Short Circuit Protection: Schematics help installers avoid short circuits by ensuring that wires are connected to the correct terminals. Short circuits occur when electricity takes an unintended path, potentially leading to overheating, fires, or equipment damage. Schematics prevent this by providing clear instructions on which wires should be connected to each terminal.

- Equipment Protection: Accurate wiring protects system components from damage. For example, if a wire is connected to the wrong terminal on the zone valve, it could cause the valve to open or close at the wrong time, leading to overheating or freezing of the boiler or other components.

- Compliance with Electrical Codes: Schematics ensure that wiring complies with local electrical codes and regulations. These codes are in place to ensure the safety of electrical installations and prevent electrical hazards. By following the schematics, installers can be confident that their work meets these requirements.

Overall, Honeywell Zone Valve Wiring Schematics are essential for maintaining the safety of heating and cooling systems. They provide clear and comprehensive instructions that guide installers in connecting wires correctly, preventing electrical hazards, and ensuring the safe and efficient operation of the system.

Troubleshooting

In the context of Honeywell Zone Valve Wiring Schematics, troubleshooting is a critical component that enables technicians to identify and resolve system issues efficiently. Honeywell Zone Valve Wiring Schematics provide a comprehensive roadmap for the electrical connections within the heating and cooling system, making it easier for technicians to pinpoint the source of problems and implement effective solutions.

For instance, if a zone valve is not functioning correctly, the schematic can guide the technician in checking the wiring connections to ensure they are secure and free of any breaks or shorts. By following the schematic, the technician can quickly identify any discrepancies between the actual wiring and the intended configuration, allowing for prompt rectification.

Moreover, Honeywell Zone Valve Wiring Schematics empower technicians to troubleshoot more complex issues, such as intermittent problems or system-wide malfunctions. By analyzing the schematic, technicians can trace the flow of electricity throughout the system, identifying potential points of failure or areas where optimization can be applied.

The practical applications of understanding the connection between troubleshooting and Honeywell Zone Valve Wiring Schematics are evident in various scenarios. For example, in a commercial building with multiple HVAC zones, a technician can use the schematics to quickly identify the source of a temperature issue in a specific zone, minimizing downtime and ensuring occupant comfort.

In summary, the troubleshooting aspect of Honeywell Zone Valve Wiring Schematics is a critical component that empowers technicians with the knowledge and guidance to identify and resolve system issues efficiently. By providing a clear and detailed representation of the electrical connections, these schematics serve as an indispensable tool for maintaining the optimal performance and reliability of heating and cooling systems.

Documentation

Within the realm of Honeywell Zone Valve Wiring Schematics, documentation plays a vital role in ensuring the longevity and efficiency of heating and cooling systems. Schematics serve as indispensable tools that provide a permanent record of the wiring configuration, facilitating future maintenance and modifications.

- Historical Reference: Schematics act as a detailed historical record of the system’s wiring, allowing technicians to understand the original design intent and any subsequent modifications or repairs. This information is crucial for troubleshooting issues and ensuring the system operates as intended.

- Maintenance Planning: Schematics provide a roadmap for maintenance personnel, outlining the location and function of each component. This documentation enables technicians to perform routine maintenance tasks efficiently, reducing downtime and extending the system’s lifespan.

- Modification Flexibility: As buildings and their needs evolve, heating and cooling systems may require modifications or upgrades. Schematics provide a clear and concise reference point for planning and implementing these changes, ensuring the system remains compatible with the building’s updated requirements.

- Enhanced Troubleshooting: When troubleshooting system issues, schematics offer a valuable diagnostic tool. Technicians can quickly trace the flow of electricity and identify potential points of failure, enabling them to resolve problems faster and with greater accuracy.

In summary, Honeywell Zone Valve Wiring Schematics provide a permanent and indispensable record of the system’s wiring configuration, facilitating efficient maintenance, modifications, and troubleshooting. By documenting the system’s electrical connections, schematics empower technicians with the knowledge and tools necessary to ensure the heating and cooling system operates reliably and efficiently throughout its lifespan.

Customization

Within the context of Honeywell Zone Valve Wiring Schematics, customization is a critical aspect that enables the system to be tailored to specific project requirements and system configurations. This level of flexibility ensures compatibility with a wide range of boilers, zone control panels, and other components, providing versatility and adaptability in system design.

- Boiler Compatibility: Schematics can be customized to accommodate different types of boilers, including gas-fired, oil-fired, and electric boilers. By selecting the appropriate schematic for the specific boiler model, installers can ensure proper wiring and control integration.

- Zone Control Panel Integration: Schematics can be adapted to work with various zone control panels, providing flexibility in system control. Whether using a basic thermostat or an advanced programmable controller, the schematic can be tailored to match the capabilities and features of the chosen panel.

- Component Compatibility: Schematics can be customized to incorporate additional components, such as pumps, valves, and sensors. This allows for the integration of specialized equipment or the expansion of the system to meet specific requirements, such as multi-zone heating or cooling.

- System Expansion: As system needs change or expand, schematics can be modified to accommodate additional zones or components. This scalability allows for future system growth without the need for major re-wiring or design changes.

The customization aspect of Honeywell Zone Valve Wiring Schematics empowers engineers, installers, and homeowners with the ability to design and implement heating and cooling systems that meet their unique requirements. By tailoring the schematics to the specific components and system configuration, they can ensure optimal performance, efficiency, and compatibility, delivering tailored comfort solutions for a wide range of applications.

Compatibility

Within the realm of Honeywell Zone Valve Wiring Schematics, compatibility plays a crucial role in ensuring the successful integration and operation of heating and cooling systems. Honeywell Zone Valve Wiring Schematics are meticulously designed to be compatible with a wide range of Honeywell products, providing seamless integration and maximizing system performance.

- Boiler Compatibility: Honeywell Zone Valve Wiring Schematics are compatible with various Honeywell boiler models, including gas-fired, oil-fired, and electric boilers. This compatibility allows for seamless integration between the zone valve and the boiler, ensuring proper control of heating or cooling throughout the system.

- Zone Control Panel Integration: Schematics are designed to work seamlessly with Honeywell zone control panels, providing flexible control options. Whether using a basic thermostat or an advanced programmable controller, the schematics ensure compatibility, allowing for efficient temperature management and system optimization.

- Accessory Compatibility: In addition to boilers and zone control panels, Honeywell Zone Valve Wiring Schematics enable the integration of additional Honeywell accessories, such as pumps, valves, and sensors. This compatibility expands system capabilities, allowing for the incorporation of specialized equipment or the expansion of the system to meet specific requirements.

- System Expansion: As system needs evolve, Honeywell Zone Valve Wiring Schematics provide the flexibility to accommodate system expansion. Whether adding additional zones or integrating new components, the schematics ensure compatibility, allowing for future system growth and adaptation to changing requirements.

The comprehensive compatibility of Honeywell Zone Valve Wiring Schematics empowers engineers, installers, and homeowners with the ability to design and implement heating and cooling systems that meet their unique requirements. By ensuring seamless integration with a wide range of Honeywell products, the schematics simplify system design, enhance performance, and provide a solid foundation for reliable and efficient operation.

Simplicity

Simplifying the design and comprehension of Honeywell Zone Valve Wiring Schematics is crucial for ensuring effective and efficient implementation of heating and cooling systems. These schematics serve as blueprints for connecting zone valves to boilers, zone control panels, and other system components. Their simplicity and ease of understanding empower technicians of varying experience levels to confidently install and maintain these systems.

The clarity of Honeywell Zone Valve Wiring Schematics stems from several factors:

- Standardized Symbols: Schematics utilize universally recognized symbols to represent system components, ensuring consistency and ease of interpretation across different projects and teams.

- Logical Flow: Schematics are structured in a logical manner, following the flow of electricity through the system. This intuitive organization makes it easy to trace connections and identify potential issues.

- Color-Coding: Color-coding is often employed to differentiate between different types of wires and components, further simplifying the identification and understanding of the system.

Real-life examples of the simplicity of Honeywell Zone Valve Wiring Schematics are abundant. In a residential setting, a homeowner with basic electrical knowledge can use the schematics to connect a new zone valve to their existing heating system, allowing them to control the temperature of a specific room or zone. In a commercial building, a maintenance technician can utilize the schematics to troubleshoot and repair a malfunctioning zone valve, ensuring optimal comfort levels for occupants.

The practical significance of understanding Honeywell Zone Valve Wiring Schematics extends beyond ease of installation and maintenance. Accurate wiring is essential for ensuring the safety and efficiency of the system. Clear and concise schematics empower technicians to make confident connections, reducing the risk of electrical hazards or system failures.

In summary, the simplicity of Honeywell Zone Valve Wiring Schematics is a critical component, enabling technicians of all experience levels to effectively install, maintain, and troubleshoot heating and cooling systems. Their standardized symbols, logical flow, and color-coding enhance comprehension, simplifying complex electrical connections and ensuring the safety and efficiency of these systems.

Availability

The availability of Honeywell Zone Valve Wiring Schematics plays a pivotal role in the effective installation, maintenance, and troubleshooting of heating and cooling systems. Their accessibility through Honeywell and its authorized distributors ensures that these schematics are within reach for a wide range of users, including installers, homeowners, and technicians.

- Online Accessibility: Honeywell Zone Valve Wiring Schematics are readily available online through the Honeywell website and authorized distributor platforms. This digital access allows users to easily download and print the schematics, providing convenience and instant availability.

- Physical Distribution: In addition to online availability, Honeywell Zone Valve Wiring Schematics are distributed through a network of authorized distributors. These distributors maintain physical stock of the schematics, ensuring that they are readily accessible for purchase at local supply stores and hardware retailers.

- Technical Support: Honeywell and its authorized distributors provide technical support to assist users in understanding and utilizing the schematics. This support can be accessed through phone, email, or online chat, ensuring that installers and homeowners have access to expert guidance when needed.

- Community Resources: Online forums and discussion groups dedicated to Honeywell products and HVAC systems often share and discuss Honeywell Zone Valve Wiring Schematics. These communities provide additional support and knowledge-sharing opportunities for users.

The ready availability of Honeywell Zone Valve Wiring Schematics streamlines the installation, maintenance, and troubleshooting processes for heating and cooling systems. By providing easy access to these essential documents, Honeywell empowers users with the resources they need to ensure the optimal performance and reliability of their systems.

Cost-effectiveness

Within the realm of Honeywell Zone Valve Wiring Schematics, cost-effectiveness is a crucial factor that contributes to the overall success and efficiency of heating and cooling systems. These schematics play a vital role in minimizing expenses and maximizing system uptime, providing significant advantages for installers, homeowners, and businesses alike.

- Accurate Installations: Clear and precise schematics guide installers in making accurate connections, reducing the risk of errors that could lead to costly repairs or system failures. By eliminating the need for guesswork or trial-and-error approaches, schematics save time and resources during installation, minimizing disruption and ensuring the system operates as intended.

- Reduced Downtime: Properly wired systems based on accurate schematics experience fewer breakdowns and malfunctions, resulting in reduced downtime. This increased reliability translates into fewer service calls, lower repair costs, and enhanced occupant comfort. Businesses can avoid lost productivity, while homeowners enjoy uninterrupted heating or cooling, contributing to overall cost savings.

- Extended Equipment Life: Schematics help prevent electrical issues and ensure balanced system operation, reducing wear and tear on system components. By eliminating overloads or improper voltage conditions, schematics extend the lifespan of boilers, zone valves, and other system components, leading to lower replacement costs and long-term savings.

- Energy Efficiency: Accurate wiring based on schematics optimizes system performance, ensuring that each zone receives the correct amount of heating or cooling. This prevents energy waste due to over-heating or over-cooling, resulting in lower utility bills and a smaller carbon footprint. By promoting energy efficiency, schematics contribute to both financial savings and environmental sustainability.

In conclusion, the cost-effectiveness of Honeywell Zone Valve Wiring Schematics stems from their ability to prevent costly mistakes, reduce downtime, extend equipment life, and enhance energy efficiency. By providing clear and accurate guidance for system installation and maintenance, these schematics empower technicians to deliver reliable and efficient heating and cooling systems, ultimately saving time, resources, and money for end-users.

Related Posts