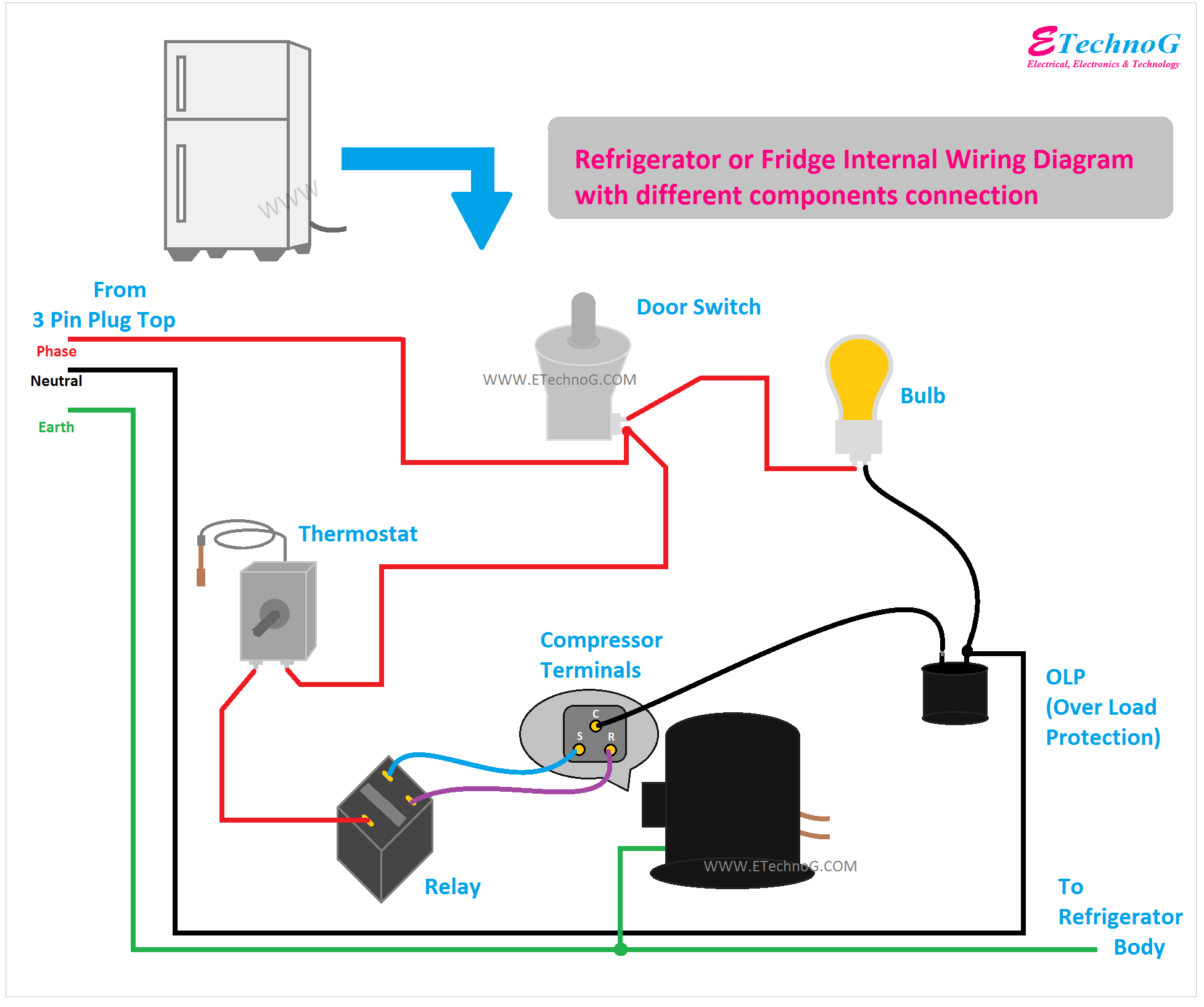

A refrigerator start relay wiring diagram illustrates the electrical connections between the relay, compressor, and other components responsible for starting the refrigerator’s cooling system. For instance, a typical wiring diagram may show the relay connected to the compressor’s start winding, run winding, and an overload protector.

Understanding this wiring diagram is crucial for troubleshooting and repairing refrigerator cooling issues. It provides a roadmap for identifying faulty connections, diagnosing relay problems, and ensuring proper wiring during repairs. Historically, the development of reliable start relays has significantly improved refrigerator performance and lifespan.

In the following sections, we will delve into the intricacies of refrigerator start relay wiring diagrams, exploring their components, functions, and practical applications.

A refrigerator start relay wiring diagram is a crucial component that ensures the proper functioning of a refrigerator’s cooling system. It provides a visual representation of the electrical connections between the relay, compressor, and other components involved in starting the cooling process. Understanding the various aspects of a refrigerator start relay wiring diagram is essential for effective troubleshooting, repair, and maintenance.

- Components: Relay, compressor, overload protector

- Connections: Start winding, run winding, power supply

- Function: Starts the compressor

- Troubleshooting: Identify faulty connections, diagnose relay problems

- Repair: Ensure proper wiring during repairs

- Maintenance: Preventative measures to avoid breakdowns

- Safety: Electrical hazards, proper handling

- Efficiency: Optimal performance, energy consumption

- Environmental impact: Refrigerant handling, disposal

These aspects are interconnected and play a vital role in the overall functionality of a refrigerator start relay wiring diagram. By understanding and considering these aspects, technicians and homeowners can ensure the reliable and efficient operation of their refrigerators.

Components

In the context of a refrigerator start relay wiring diagram, the components play crucial roles in ensuring the proper functioning of the cooling system. These components include the relay, compressor, and overload protector, each with its distinct purpose and characteristics.

-

Relay:

The relay is an electromagnetic switch that controls the flow of electricity to the compressor. When the thermostat signals a need for cooling, the relay closes, allowing current to flow to the compressor’s start winding.

-

Compressor:

The compressor is the heart of the refrigeration system, responsible for circulating the refrigerant and creating the cooling effect. The start winding and run winding within the compressor are energized by the relay to initiate and maintain compression.

-

Overload protector:

The overload protector is a safety device that safeguards the compressor from overheating or electrical overload. If excessive current is detected, the overload protector trips, cutting off power to the compressor and preventing damage.

Understanding the functions and interactions of these components is vital for troubleshooting and repairing refrigerator cooling issues. By accurately identifying and addressing component failures within the start relay wiring diagram, technicians can effectively restore the refrigerator’s cooling functionality and ensure optimal performance.

Connections

Within the context of a refrigerator start relay wiring diagram, the connections between the start winding, run winding, and power supply play a crucial role in initiating and maintaining the cooling process. These connections establish the electrical pathways that energize the compressor, enabling it to circulate the refrigerant and provide cooling. Understanding the relationship between these connections and the start relay wiring diagram is essential for effective troubleshooting and repair of refrigerator cooling systems.

The start winding is responsible for providing the initial torque needed to start the compressor motor. Once the motor reaches a certain speed, the run winding takes over to keep the compressor running continuously. The power supply provides the electrical energy to both the start and run windings. The start relay is responsible for connecting and disconnecting the start winding from the power supply, ensuring that the compressor starts and runs properly.

Real-life examples of these connections can be observed in any refrigerator’s start relay wiring diagram. Typically, the start winding is connected to one terminal of the start relay, while the run winding is connected to another terminal. The power supply is connected to the remaining terminals of the start relay, completing the electrical circuit. By understanding these connections, technicians can accurately identify and address any issues within the start relay wiring diagram, ensuring that the refrigerator’s cooling system operates efficiently and reliably.

In summary, the connections between the start winding, run winding, and power supply form the foundation of a refrigerator start relay wiring diagram. These connections enable the start relay to control the flow of electricity to the compressor, initiating and maintaining the cooling process. By comprehending these connections and their significance, technicians and homeowners can effectively troubleshoot, repair, and maintain their refrigerators, ensuring optimal cooling performance.

Function

The function of a refrigerator start relay wiring diagram revolves around starting the compressor, the central component responsible for driving the refrigeration cycle and providing cooling. The start relay, as depicted in the wiring diagram, orchestrates the electrical connections and sequence of events to initiate compressor operation.

When the thermostat detects a rise in temperature, it signals the start relay to energize the compressor’s start winding. This winding generates a strong initial torque, overcoming the inertia of the compressor and setting it in motion. Once the compressor reaches a stable operating speed, the start relay disconnects the start winding and connects the run winding, allowing the compressor to continue running smoothly.

Real-life examples of the “Function: Starts the compressor” are prevalent in any refrigerator’s start relay wiring diagram. Technicians rely on this diagram to trace the electrical pathways and connections that control the compressor’s operation. By understanding the sequence of events and the role of each component, they can effectively troubleshoot and repair any issues that may arise within the start relay circuit.

The practical applications of this understanding extend beyond troubleshooting and repairs. By comprehending the function of the start relay in initiating compressor operation, homeowners can gain insights into the overall functioning of their refrigerators. This knowledge empowers them to make informed decisions regarding maintenance and care, ensuring optimal cooling performance and longevity of the appliance.

In summary, the “Function: Starts the compressor” is a critical component of a refrigerator start relay wiring diagram, enabling the controlled and operation of the compressor. Understanding this function and its practical applications allows technicians and homeowners to effectively maintain and troubleshoot their refrigerators, ensuring reliable and efficient cooling performance.

Troubleshooting

Within the context of refrigerator maintenance and repair, the ability to identify faulty connections and diagnose relay problems is inextricably linked to the refrigerator start relay wiring diagram. This diagram serves as a roadmap, providing technicians with a visual representation of the electrical connections and components involved in starting the compressor.

Troubleshooting electrical faults within the start relay circuit requires a thorough understanding of the wiring diagram. By tracing the connections and identifying potential points of failure, technicians can pinpoint the exact location of the problem. This process involves examining wire connections for looseness or damage, testing relay contacts for proper operation, and measuring electrical resistance and continuity to ensure proper current flow.

Real-life examples of troubleshooting faulty connections and relay problems abound in refrigerator repair scenarios. A loose connection in the start winding circuit, for instance, can prevent the compressor from starting, leading to a lack of cooling. Similarly, a faulty relay may fail to energize the start winding, resulting in the same issue. By utilizing the start relay wiring diagram as a guide, technicians can systematically diagnose and resolve these problems, restoring the refrigerator’s cooling functionality.

The practical applications of this understanding extend beyond troubleshooting and repairs. Homeowners who possess a basic understanding of refrigerator start relay wiring diagrams can perform preventive maintenance tasks, such as checking and tightening electrical connections, to minimize the risk of future problems. This knowledge empowers them to make informed decisions regarding refrigerator care and maintenance, ensuring optimal cooling performance and extending the appliance’s lifespan.

In summary, the ability to identify faulty connections and diagnose relay problems is a critical component of refrigerator maintenance and repair. The refrigerator start relay wiring diagram provides an indispensable tool for technicians and homeowners alike, enabling them to troubleshoot electrical faults, perform preventive maintenance, and ensure the reliable operation of their refrigerators.

Repair

In the context of refrigerator start relay wiring diagrams, ensuring proper wiring during repairs is paramount to restoring the cooling system to optimal functionality. This involves meticulous attention to detail, accurate component identification, and a thorough understanding of the electrical connections outlined in the wiring diagram.

-

Verify Connections:

Confirming secure and correct connections between the start relay, compressor, overload protector, and power supply is crucial. Loose or faulty connections can hinder current flow, leading to relay malfunction or compressor failure.

-

Replace Components:

Identifying and replacing faulty components, such as a damaged relay or a blown fuse, is essential. Using genuine or compatible replacement parts ensures proper fit and electrical characteristics.

-

Follow Wiring Diagram:

Adhering strictly to the wiring diagram prevents incorrect connections and ensures the proper sequence of operation. Miswiring can cause short circuits, component damage, or even electrical hazards.

-

Test and Verify:

After completing repairs, perform thorough testing to verify the functionality of the start relay circuit. This includes checking for proper voltage and current flow, as well as ensuring the compressor starts and runs smoothly.

By meticulously following these steps, technicians and homeowners can ensure proper wiring during repairs, restoring the refrigerator’s cooling system to reliable and efficient operation. This not only extends the appliance’s lifespan but also ensures the safe and effective preservation of food items.

Maintenance

Within the context of “Refrigerator Start Relay Wiring Diagram”, “Maintenance: Preventative measures to avoid breakdowns” plays a crucial role in ensuring the longevity and reliability of the refrigerator’s cooling system. By implementing preventative maintenance practices, potential issues can be identified and addressed before they lead to costly repairs or premature equipment failure.

-

Regular Cleaning:

Accumulation of dust and debris on the start relay, compressor, and condenser coils can hinder heat dissipation and increase the risk of overheating. Regular cleaning helps maintain optimal operating temperatures and extends component life.

-

Connection Inspection:

Loose or corroded electrical connections can cause intermittent operation, reduced cooling efficiency, or even electrical hazards. Periodically inspecting and tightening connections ensures a secure and reliable electrical circuit.

-

Voltage Monitoring:

Voltage fluctuations or surges can damage the start relay and other electrical components. Using a voltage regulator or surge protector can safeguard the refrigerator from these harmful events.

-

Relay Testing:

Start relays can deteriorate over time, affecting their ability to energize the compressor. Periodic testing with a multimeter can identify weak relays before they cause compressor failure.

By incorporating these preventative maintenance measures into their refrigerator care routine, homeowners and technicians can proactively avoid breakdowns, minimize repair costs, and extend the lifespan of their refrigeration equipment. Regular maintenance not only ensures optimal cooling performance but also contributes to the overall safety and efficiency of the refrigerator.

Safety

In the context of “Refrigerator Start Relay Wiring Diagram,” “Safety: Electrical hazards, proper handling” plays a critical role in ensuring the safe and reliable operation of refrigeration equipment. Understanding and adhering to proper handling and safety guidelines are paramount to prevent electrical hazards, equipment damage, or personal injury.

The refrigerator start relay wiring diagram serves as a guide for technicians and homeowners to correctly connect and troubleshoot electrical components. Ignoring safety precautions can lead to severe consequences. For instance, mishandling electrical connections can result in short circuits, electrical fires, or damage to the compressor and other components. Improper grounding or faulty wiring can pose electrocution risks to individuals servicing or using the refrigerator.

Real-life examples of “Safety: Electrical hazards, proper handling” within “Refrigerator Start Relay Wiring Diagram” include proper insulation of electrical wires to prevent short circuits, secure connections to ensure reliable current flow, and the use of appropriate tools and protective gear during installation or repairs. By following the guidelines outlined in the wiring diagram and adhering to electrical safety codes, technicians and homeowners can minimize the risk of electrical hazards and ensure the safe and efficient operation of their refrigerators.

The practical applications of understanding the connection between “Safety: Electrical hazards, proper handling” and “Refrigerator Start Relay Wiring Diagram” extend beyond preventing accidents and equipment damage. It fosters a culture of safety awareness, promotes responsible maintenance practices, and contributes to the overall longevity and reliability of refrigeration equipment. By prioritizing safety, individuals can create a safer environment for themselves and others while ensuring that their refrigerators operate optimally and efficiently.

Efficiency

In the context of “Refrigerator Start Relay Wiring Diagram,” “Efficiency: Optimal performance, energy consumption” plays a crucial role in ensuring that refrigerators operate at their peak performance while minimizing energy usage. Understanding the various facets of efficiency and their implications can help technicians, homeowners, and manufacturers optimize refrigeration systems for maximum effectiveness and sustainability.

-

Correct Wiring and Connections:

Properly executed wiring and secure connections minimize electrical resistance and energy loss, ensuring that the compressor receives the necessary power to operate efficiently. Loose or faulty connections can lead to energy wastage and reduced cooling performance.

-

Relay and Compressor Condition:

A well-maintained start relay ensures that the compressor starts and operates smoothly, reducing energy consumption. A faulty relay or a worn-out compressor can draw excessive power, leading to higher energy bills and premature equipment failure.

-

Refrigerant Charge:

The correct amount of refrigerant charge is essential for optimal performance. Too little refrigerant can result in insufficient cooling, while an excess can overload the compressor and increase energy consumption.

-

Condenser Coil Maintenance:

Regular cleaning of the condenser coils helps dissipate heat effectively, reducing the workload on the compressor and minimizing energy usage. Dirty or clogged coils can hinder heat transfer, leading to increased energy consumption and reduced cooling capacity.

By addressing these aspects and ensuring efficient operation of the refrigerator start relay wiring diagram, technicians and homeowners can contribute to energy conservation, reduce operating costs, extend equipment lifespan, and minimize the environmental impact of refrigeration systems.

Environmental impact

Within the context of “Refrigerator Start Relay Wiring Diagram,” “Environmental impact: Refrigerant handling, disposal” emerges as a crucial aspect that underscores the importance of responsible practices in refrigeration systems. Improper handling and disposal of refrigerants can pose significant ecological concerns, and understanding these impacts is vital for technicians, homeowners, and manufacturers alike.

-

Refrigerant Properties and Regulations:

Refrigerants used in refrigeration systems, such as CFCs and HFCs, are potent greenhouse gases with high global warming potential. Improper release of these refrigerants into the atmosphere can contribute to climate change and ozone depletion, making their responsible handling and disposal essential.

-

Leak Detection and Prevention:

Refrigerant leaks can occur due to faulty wiring or damaged components, leading to refrigerant loss and potential environmental harm. Regular monitoring and timely repairs of any leaks are crucial to minimize refrigerant emissions and maintain system efficiency.

-

Proper Disposal Techniques:

Refrigerants cannot be disposed of like regular waste. Specialized techniques, such as recovery and recycling, are required to capture and reclaim refrigerants, preventing their release into the environment and ensuring proper disposal.

-

Technician Certification and Training:

Qualified technicians play a vital role in ensuring environmentally responsible handling of refrigerants. Certification and training programs equip them with the knowledge and skills to safely handle, recover, and dispose of refrigerants, minimizing environmental impact.

By understanding and adhering to proper refrigerant handling and disposal practices, individuals can contribute to mitigating the environmental impact of refrigeration systems, promoting sustainability, and protecting the planet for future generations.

Related Posts