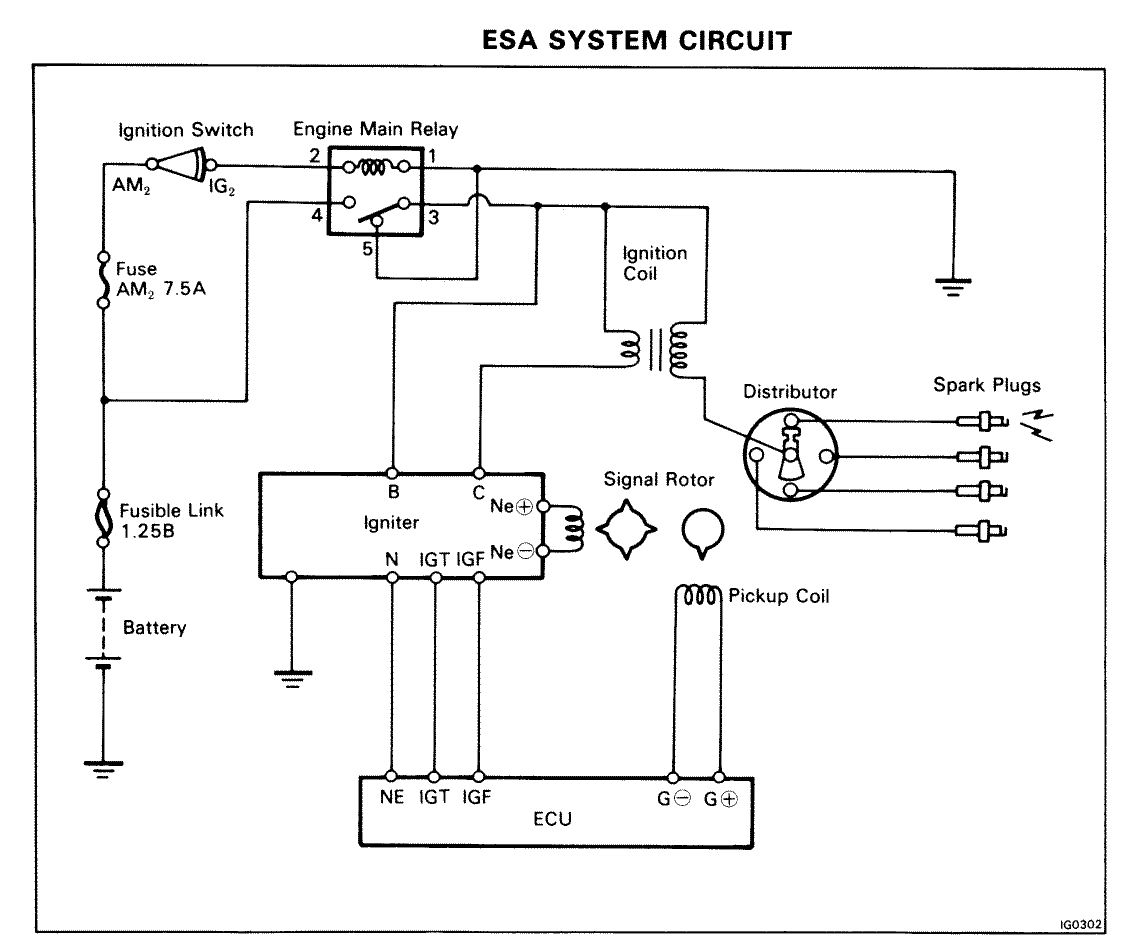

A Toyota Igniter Wiring Diagram is a schematic representation of the electrical connections within the ignition system of a Toyota vehicle. It provides a visual guide to the wiring, connectors, and components involved in starting the engine.

The igniter is a critical component of the ignition system, responsible for sending a high-voltage spark to the spark plugs to ignite the air-fuel mixture in the engine’s cylinders. The wiring diagram ensures that the igniter receives the appropriate electrical signals and power from the ignition control module, battery, and other components.

Understanding and utilizing a Toyota Igniter Wiring Diagram is essential for troubleshooting ignition problems, diagnosing electrical faults, and performing repairs or modifications to the ignition system. It serves as an invaluable resource for mechanics, technicians, and automotive enthusiasts who need to maintain and service Toyota vehicles.

The key aspects of a Toyota Igniter Wiring Diagram, a crucial component of the vehicle’s ignition system, encompass its:

- Schematic representation: A visual guide to the electrical connections within the ignition system.

- Connector identification: Clear labeling of connectors for easy identification during repairs or modifications.

- Component identification: Precise labeling of ignition system components, such as the igniter, ignition control module, and battery.

- Circuit tracing: Visual representation of the electrical circuits, allowing for efficient troubleshooting and fault diagnosis.

- Harness routing: Depiction of the routing of the wiring harness, ensuring proper installation and maintenance.

- Grounding points: Identification of grounding points for proper electrical connections.

- Color-coded wires: Color coding of wires for easy identification and tracing.

- Technical specifications: Provision of technical specifications for the igniter and related components.

- Compatibility information: Compatibility details for specific Toyota vehicle models and engine types.

These aspects play a vital role in understanding and troubleshooting the Toyota ignition system. The wiring diagram enables mechanics and technicians to diagnose electrical faults, repair or modify the ignition system, and ensure optimal engine performance.

Schematic representation

Within the context of a Toyota Igniter Wiring Diagram, the schematic representation serves as the cornerstone for understanding and troubleshooting the vehicle’s ignition system. It provides a visual depiction of the intricate network of electrical connections, enabling mechanics and technicians to trace circuits, identify components, and diagnose faults.

- Component identification: The schematic clearly labels and identifies each component within the ignition system, including the igniter, ignition coil, and ignition control module. This facilitates easy recognition and understanding of the system’s architecture.

- Circuit tracing: The diagram illustrates the flow of electrical current through the ignition system, allowing technicians to trace circuits and identify potential breaks or malfunctions. This aids in troubleshooting and repairing electrical faults.

- Connector identification: Connectors play a crucial role in the ignition system, and the schematic provides clear identification and labeling of each connector. This enables technicians to locate and disconnect connectors during maintenance or repairs, ensuring proper reassembly.

- Grounding points: Proper grounding is essential for the ignition system’s functionality. The schematic identifies grounding points, allowing technicians to verify proper grounding and resolve any issues that may arise.

In summary, the schematic representation within a Toyota Igniter Wiring Diagram is a powerful tool for visualizing and comprehending the electrical connections within the ignition system. It empowers mechanics and technicians with the knowledge to diagnose faults, perform repairs, and maintain the optimal performance of Toyota vehicles.

Connector identification

In the context of Toyota Igniter Wiring Diagrams, connector identification plays a pivotal role in ensuring the smooth and efficient maintenance, repair, and modification of the vehicle’s ignition system. Clear labeling of connectors provides a visual guide to the system’s architecture, enabling technicians to quickly identify and access specific components.

-

Standardized Color-coding:

Toyota Igniter Wiring Diagrams adhere to standardized color-coding conventions for connectors, making it easy to identify the purpose and function of each connector at a glance. This color-coding system aligns with industry standards, ensuring consistency and simplifying troubleshooting.

-

Connector Shape and Design:

Connectors in Toyota Igniter Wiring Diagrams are designed with unique shapes and configurations, preventing incorrect connections and ensuring a secure fit. This attention to detail minimizes the risk of electrical faults or damage during maintenance or repairs.

-

Connector Labeling:

Each connector in a Toyota Igniter Wiring Diagram is clearly labeled with its corresponding component or function. This labeling typically includes the component name, wire colors, and terminal numbers, providing technicians with precise information for accurate connections.

-

Detailed Schematics:

Toyota Igniter Wiring Diagrams provide detailed schematics that illustrate the precise location and orientation of connectors within the ignition system. This visual representation simplifies the identification and tracing of wires, making it easier to diagnose and resolve electrical issues.

Overall, clear labeling of connectors in Toyota Igniter Wiring Diagrams empowers technicians with the knowledge and tools necessary to perform repairs and modifications with precision and efficiency. The standardized color-coding, unique connector designs, and detailed labeling contribute to the overall reliability and serviceability of Toyota vehicles.

Component identification

Within the context of Toyota Igniter Wiring Diagrams, precise labeling of ignition system components plays a crucial role in enabling technicians to accurately identify and troubleshoot the system. This labeling provides a clear understanding of the function and location of each component, simplifying maintenance and repair procedures.

The Toyota Igniter Wiring Diagram serves as a comprehensive guide to the ignition system’s electrical connections, and the precise labeling of components is an integral part of this diagram. It allows technicians to trace circuits, identify faulty components, and perform repairs with greater efficiency and accuracy.

For instance, in a scenario where the vehicle experiences ignition problems, the wiring diagram provides a visual representation of the ignition system, including the igniter, ignition control module, and battery. The precise labeling of these components enables the technician to quickly identify the specific component causing the issue, reducing diagnostic time and ensuring a targeted repair.

Another practical application lies in the modification or upgrade of the ignition system. Whether it’s installing a performance ignition coil or replacing the battery, the wiring diagram’s clear component identification allows technicians to make informed decisions about the compatibility and integration of new components.

Overall, precise labeling of ignition system components within Toyota Igniter Wiring Diagrams is a critical aspect that enhances the usability and effectiveness of these diagrams. It empowers technicians with the knowledge and clarity necessary to diagnose, repair, and modify Toyota ignition systems efficiently and accurately.

Circuit tracing

Within the context of a Toyota Igniter Wiring Diagram, circuit tracing plays a vital role in enabling technicians to troubleshoot and diagnose electrical faults within the ignition system. The visual representation of electrical circuits provides a clear understanding of the signal flow and component interconnections, simplifying the process of identifying and resolving issues.

The Toyota Igniter Wiring Diagram is a comprehensive guide to the ignition system’s electrical connections, and circuit tracing is an integral part of this diagram. It allows technicians to follow the path of electrical current through the system, identifying potential breaks, shorts, or malfunctions. This visual representation simplifies the diagnostic process, reducing the time and effort required to pinpoint the root cause of an ignition problem.

For instance, in a scenario where a vehicle experiences intermittent ignition issues, the wiring diagram provides a visual representation of the ignition circuit. By tracing the circuit, the technician can identify loose connections, damaged wires, or faulty components that may be causing the problem. This targeted approach leads to more efficient and accurate repairs, minimizing downtime and ensuring optimal vehicle performance.

Another practical application lies in the modification or upgrade of the ignition system. Whether it’s installing a performance ignition coil or replacing aging wiring, the wiring diagram’s circuit tracing capability allows technicians to plan and execute modifications with precision. By understanding the signal flow and component interconnections, technicians can ensure proper integration of new components and maintain the integrity of the ignition system.

Overall, circuit tracing is a critical component of Toyota Igniter Wiring Diagrams, enabling technicians to efficiently troubleshoot and diagnose electrical faults within the ignition system. Its visual representation of electrical circuits provides a clear understanding of the system’s operation, leading to more targeted repairs and modifications, ultimately ensuring the reliability and performance of Toyota vehicles.

Harness routing

Harness routing, as depicted in a Toyota Igniter Wiring Diagram, plays a crucial role in ensuring the proper installation, maintenance, and functionality of the ignition system. The diagram provides a comprehensive visual representation of how the wiring harness is routed and connected throughout the engine compartment, offering valuable insights into its design and layout.

Accurate harness routing is critical for several reasons. Firstly, it ensures that electrical signals are transmitted efficiently and reliably between the igniter and other components, such as the ignition control module, battery, and spark plugs. Proper routing minimizes the risk of interference, shorts, or damage to the wiring harness, which could lead to ignition problems or even more severe electrical issues.

Secondly, harness routing facilitates maintenance and repairs. By following the routing depicted in the diagram, technicians can easily locate and access connectors, wires, and other components within the ignition system. This simplifies troubleshooting procedures, allowing for quick and effective diagnosis and repair of any electrical faults or malfunctions.

Real-life examples of harness routing within a Toyota Igniter Wiring Diagram include the precise positioning of wires to avoid heat sources, such as exhaust manifolds or engine components. The diagram also indicates the use of protective sleeves or conduits to safeguard the wiring harness from abrasion, moisture, or other environmental factors that could compromise its integrity.

Understanding harness routing is essential for technicians performing maintenance or modifications on Toyota vehicles. By adhering to the routing specified in the diagram, they can ensure optimal performance, reliability, and longevity of the ignition system. Improper routing can lead to various issues, including electrical shorts, intermittent ignition, or even engine damage in severe cases.

In conclusion, harness routing, as depicted in a Toyota Igniter Wiring Diagram, is a critical component for ensuring proper installation, maintenance, and functionality of the ignition system. Understanding and following the specified routing guidelines are essential for technicians to troubleshoot, repair, or modify the system effectively, promoting the safe and reliable operation of Toyota vehicles.

Grounding points

Within the context of a Toyota Igniter Wiring Diagram, grounding points play a crucial role in ensuring the proper functionality and reliability of the ignition system. These points provide a common reference potential for electrical circuits, allowing current to flow safely and preventing electrical faults.

-

Chassis Grounding:

The chassis of the vehicle serves as a primary grounding point for the ignition system. The wiring diagram indicates the specific locations where the wiring harness connects to the chassis, ensuring proper grounding and minimizing electrical noise.

-

Engine Block Grounding:

The engine block is another critical grounding point for the ignition system. The diagram shows the connection points between the wiring harness and the engine block, ensuring a solid ground for the ignition coil and other components.

-

Dedicated Grounding Points:

In addition to chassis and engine block grounding, the wiring diagram may also specify dedicated grounding points located throughout the engine compartment. These points provide additional grounding for specific components, such as sensors or actuators, ensuring optimal performance and reducing the risk of electrical interference.

-

Grounding Wire Specifications:

The Toyota Igniter Wiring Diagram often includes specifications for the grounding wires, such as wire gauge and type. Proper selection and installation of grounding wires are crucial for ensuring a low-resistance path to ground and preventing voltage drop or ground loops.

Understanding and following the grounding point identification in a Toyota Igniter Wiring Diagram is essential for technicians performing maintenance or modifications on Toyota vehicles. Proper grounding ensures that electrical circuits function as intended, reduces the risk of electrical faults, and promotes the overall reliability and performance of the ignition system.

Color-coded wires

Within the context of a Toyota Igniter Wiring Diagram, color-coded wires play a crucial role in simplifying the identification and tracing of electrical circuits. This color coding standardizes the color assignment for specific functions, making it easier for technicians to navigate the complex wiring harness and locate the desired wires quickly and accurately.

-

Standardized Color Scheme:

Toyota Igniter Wiring Diagrams adhere to a standardized color scheme, ensuring consistency across different vehicle models and years. This standardization enables technicians to easily recognize the function of a wire based on its color, reducing the time and effort required for troubleshooting and repairs.

-

Functional Grouping:

Color coding facilitates the grouping of wires based on their function. For instance, all power wires may be colored red, while ground wires are typically black. This functional grouping simplifies circuit tracing, as technicians can quickly identify the wires associated with a particular component or circuit.

-

Circuit Identification:

Color coding aids in the identification of individual circuits within the ignition system. By following the color-coded wires, technicians can trace the path of electrical signals through various components, such as the igniter, ignition coil, and spark plugs. This enables them to isolate faults and make repairs more efficiently.

-

Simplified Repairs:

Color-coded wires simplify repairs by allowing technicians to quickly identify the correct wires to connect or replace. This reduces the risk of errors and ensures that the ignition system is reassembled correctly, minimizing downtime and maximizing vehicle performance.

In conclusion, color-coded wires in a Toyota Igniter Wiring Diagram are a valuable tool for technicians, enabling them to easily identify, trace, and repair electrical circuits within the ignition system. The standardized color scheme, functional grouping, circuit identification, and simplified repair procedures contribute to the overall efficiency, accuracy, and reliability of Toyota ignition systems.

Technical specifications

Technical specifications play a crucial role within the context of Toyota Igniter Wiring Diagrams. These specifications provide detailed information about the igniter and related components, enabling technicians to understand their functionality, performance parameters, and installation requirements.

-

Component Specifications:

Wiring diagrams include technical specifications for the igniter, such as its operating voltage, current draw, and resistance. These specifications ensure that the igniter is compatible with the vehicle’s electrical system and delivers the necessary spark energy to ignite the air-fuel mixture.

-

Ignition Coil Specifications:

The ignition coil’s specifications, including its primary and secondary resistance, inductance, and turns ratio, are provided in the wiring diagram. These specifications determine the coil’s ability to generate the high voltage required for spark generation.

-

Spark Plug Specifications:

Spark plug specifications, such as their thread size, reach, and heat range, are included in the wiring diagram. These specifications ensure that the spark plugs are properly installed and provide optimal ignition for the engine.

-

Wire Harness Specifications:

The wiring diagram provides specifications for the wire harness, including wire gauge, insulation type, and routing. These specifications ensure that the wire harness can handle the electrical current and withstand the operating conditions within the engine compartment.

By providing technical specifications for the igniter and related components, Toyota Igniter Wiring Diagrams empower technicians with the knowledge necessary to troubleshoot, repair, and modify the ignition system effectively. These specifications ensure that the components are properly matched, installed, and operating within their specified parameters, contributing to the overall reliability and performance of Toyota vehicles.

Compatibility information

Within the context of Toyota Igniter Wiring Diagrams, compatibility information plays a critical role in ensuring the correct installation and operation of the ignition system. By providing compatibility details for specific Toyota vehicle models and engine types, wiring diagrams empower technicians and enthusiasts to select the appropriate components and ensure that the ignition system is properly configured for optimal performance.

-

Vehicle Model Compatibility:

Toyota Igniter Wiring Diagrams specify the specific vehicle models that the diagram is applicable to. This information is crucial to ensure that the wiring diagram matches the electrical system and configuration of the vehicle being serviced or modified.

-

Engine Type Compatibility:

Different engine types, such as inline-four, V6, or V8, have unique ignition requirements. Wiring diagrams provide compatibility information for specific engine types, ensuring that the igniter and related components are compatible with the engine’s firing order, compression ratio, and other characteristics.

-

Ignition System Variations:

Toyota vehicles may be equipped with different ignition system variations, such as distributor-based or coil-on-plug systems. Wiring diagrams provide compatibility information for the specific ignition system configuration, ensuring that the igniter and related components are compatible with the vehicle’s design.

-

Performance Modifications:

For enthusiasts seeking to modify or upgrade their Toyota’s ignition system, wiring diagrams provide compatibility information for performance-oriented components. This information helps in selecting the appropriate igniter and related components that are compatible with aftermarket upgrades, such as high-performance ignition coils or spark plugs.

By carefully considering the compatibility information provided in Toyota Igniter Wiring Diagrams, technicians and enthusiasts can ensure that the ignition system is properly configured for the specific vehicle model, engine type, and any performance modifications. This attention to compatibility ensures optimal ignition performance, reliability, and longevity of the Toyota vehicle.

Related Posts