Barrel connector wiring entails connecting wires to a barrel connector, a cylindrical electrical component that joins two or more wires. It involves stripping the wire ends, inserting them into the connector, and securing them with screws or by crimping.

This wiring technique is crucial for establishing secure and reliable electrical connections. It finds widespread application in electronics, particularly in power distribution systems, lighting fixtures, and audio-visual equipment. The benefits of using barrel connectors include ease of assembly, cost-effectiveness, and adaptability to various wire sizes.

A notable historical development in barrel connector wiring was the invention of the screw-type barrel connector in the 1950s. This innovation simplified the connection process, eliminating the need for soldering and reducing assembly time.

As we explore further in this article, we will delve into the intricacies of barrel connector wiring, including its advantages, limitations, and specialized applications. We will also examine the safety considerations and proper installation techniques associated with this versatile wiring method.

The essential aspects of “Barrel Connector Wiring” encompass a diverse range of considerations, each shaping the practical application and overall effectiveness of this wiring technique.

- Connector type: Screw-type, crimp-type, push-in, etc.

- Wire size compatibility: AWG range and maximum current capacity

- Insulation material: PVC, nylon, etc.

- Voltage and current ratings: Determines the power handling capability

- Environmental protection: Waterproof, dustproof, etc.

- Polarity: Important for DC connections to ensure proper circuit operation

- Durability: Resistance to vibration, corrosion, and mechanical stress

- Safety certifications: UL, CE, RoHS, etc.

- Cost-effectiveness: Balancing quality and affordability

- Ease of installation: Time and effort required for assembly and maintenance

These aspects are interconnected and influence the overall performance and suitability of barrel connector wiring for specific applications. For instance, the connector type impacts the ease of installation and durability, while the insulation material affects the environmental protection and voltage rating. Understanding these aspects is crucial for selecting the appropriate barrel connectors and ensuring reliable and efficient electrical connections.

Connector type

Within the realm of “Barrel Connector Wiring”, the choice of connector type holds significant importance, as it directly affects the installation process, durability, and overall performance of the electrical connection. Various types of connectors exist, each with its unique characteristics and applications.

- Screw-type connectors: These connectors utilize screws to secure the wires in place. They offer a robust and reliable connection, making them suitable for high-power applications. However, they require tools for installation and may be more time-consuming to assemble compared to other types.

- Crimp-type connectors: Crimp-type connectors employ a crimping tool to create a permanent connection between the wire and the connector. They provide a secure and efficient means of connecting wires, making them popular in mass production settings. However, the crimping process requires specialized tools and can be irreversible.

- Push-in connectors: As the name suggests, push-in connectors allow for wires to be simply pushed into the connector without the need for tools. They offer a quick and convenient method of making connections, but may not be as robust as screw-type or crimp-type connectors.

- Spring-clamp connectors: Spring-clamp connectors utilize a spring-loaded mechanism to hold the wires in place. They provide a secure connection without the need for tools or crimping. Spring-clamp connectors are commonly used in quick-disconnect applications and for connecting multiple wires together.

The choice of connector type ultimately depends on the specific requirements of the application, considering factors such as the wire size, current capacity, environmental conditions, and desired level of durability. Understanding the characteristics and limitations of each connector type is essential for selecting the most appropriate solution for a given barrel connector wiring application.

Wire size compatibility

In the realm of “Barrel Connector Wiring”, understanding the relationship between “Wire size compatibility: AWG range and maximum current capacity” is paramount. The AWG (American Wire Gauge) range specifies the diameter of a wire, while the maximum current capacity indicates the amount of electrical current it can safely carry. This relationship is critical because using a wire with an insufficient current capacity for the application can lead to overheating, damage to the wire and connectors, and potential fire hazards.

For instance, in a high-power application requiring a current of 10 amps, utilizing a wire with an AWG range of 22 or smaller would be inappropriate. A wire with an AWG range of 18 or larger would be necessary to safely handle the current without overheating. Conversely, using an excessively large wire, such as AWG 10 for a low-power application, would be inefficient and unnecessarily costly.

Selecting the appropriate wire size for “Barrel Connector Wiring” involves considering both the AWG range and the maximum current capacity. This ensures that the electrical connection is safe, reliable, and meets the specific requirements of the application. By adhering to the recommended AWG range and maximum current capacity guidelines, electrical professionals can prevent potential hazards and ensure the longevity of their wiring systems.

Insulation material

Within the realm of “Barrel Connector Wiring”, the choice of insulation material is a crucial aspect that influences the safety, durability, and overall performance of the electrical connection. Insulation material forms a protective layer around the conductive wires, preventing short circuits, preventing current leakage, and safeguarding against electrical hazards.

- Material composition: Insulation materials for barrel connectors primarily include PVC (Polyvinyl Chloride), nylon, and other polymers. Each material possesses distinct properties that cater to specific application requirements.

- Electrical properties: The insulation material’s dielectric strength, which measures its ability to withstand voltage without breakdown, is a critical factor. It ensures that the insulation can effectively prevent electrical arcing and maintain the integrity of the connection.

- Environmental resilience: Insulation materials are often subjected to various environmental conditions, such as moisture, extreme temperatures, and UV radiation. Choosing an insulation material with appropriate resistance to these factors is essential to ensure long-term reliability.

- Flexibility and formability: In applications where flexibility is required, such as in cable assemblies or tight spaces, insulation materials with good flexibility and formability are preferred. They allow for easy routing and bending of wires without compromising the insulation’s integrity.

Understanding the characteristics and limitations of different insulation materials is paramount for selecting the most suitable option for a given “Barrel Connector Wiring” application. By considering factors such as voltage requirements, environmental conditions, and flexibility needs, electrical professionals can ensure safe, reliable, and long-lasting electrical connections.

Voltage and current ratings

In the realm of “Barrel Connector Wiring”, understanding the relationship between voltage and current ratings and their impact on power handling capability is crucial for ensuring safe and efficient electrical connections. Voltage and current ratings are interdependent factors that determine the amount of power that a barrel connector can safely handle.

Voltage, measured in volts, represents the electrical potential difference between two points in a circuit. Current, measured in amperes, represents the flow of electrical charge through a circuit. The power handling capability, measured in watts, is calculated by multiplying voltage and current. Therefore, higher voltage and current ratings result in higher power handling capability.

Selecting a barrel connector with appropriate voltage and current ratings is critical to prevent overheating, damage to the connector, and potential fire hazards. For instance, in an application requiring a power handling capability of 100 watts at 12 volts, a barrel connector with a voltage rating of 12 volts and a current rating of at least 8.33 amperes (100 watts / 12 volts) would be necessary.

Understanding the connection between voltage and current ratings and power handling capability empowers electrical professionals to make informed decisions when selecting barrel connectors for specific applications. By adhering to the recommended ratings, they can ensure reliable and safe electrical connections that meet the power requirements of the system.

Environmental protection

Within the realm of “Barrel Connector Wiring”, environmental protection plays a critical role in ensuring the reliability, longevity, and safety of electrical connections. Environmental factors such as moisture, dust, and extreme temperatures can pose significant challenges to the integrity of barrel connectors and the overall wiring system.

Exposure to moisture can lead to corrosion of metal components, short circuits, and insulation breakdown. Dust and other contaminants can accumulate on the connector surfaces, hindering proper contact and increasing the risk of arcing. Extreme temperatures can cause insulation materials to deteriorate, reducing their protective capabilities.

To address these challenges, barrel connectors are often equipped with environmental protection features such as:

- Waterproof: Designed to withstand immersion in water or exposure to high humidity, preventing moisture penetration and ensuring reliable operation in wet environments.

- Dustproof: Protected against the ingress of dust and other small particles, maintaining proper contact and preventing insulation damage.

- Corrosion-resistant: Constructed from materials that resist corrosion, ensuring long-lasting performance in harsh environments.

In real-life applications, environmental protection is paramount for barrel connectors used in outdoor lighting fixtures, industrial machinery, marine electrical systems, and other applications exposed to demanding conditions. By choosing barrel connectors with appropriate environmental protection features, electrical professionals can ensure reliable and safe operation in challenging environments.

Understanding the connection between environmental protection and barrel connector wiring empowers engineers and technicians to make informed decisions when selecting and installing connectors for specific applications. It underscores the importance of considering the environmental factors that may impact the wiring system, ensuring the long-term integrity and performance of electrical connections.

Polarity

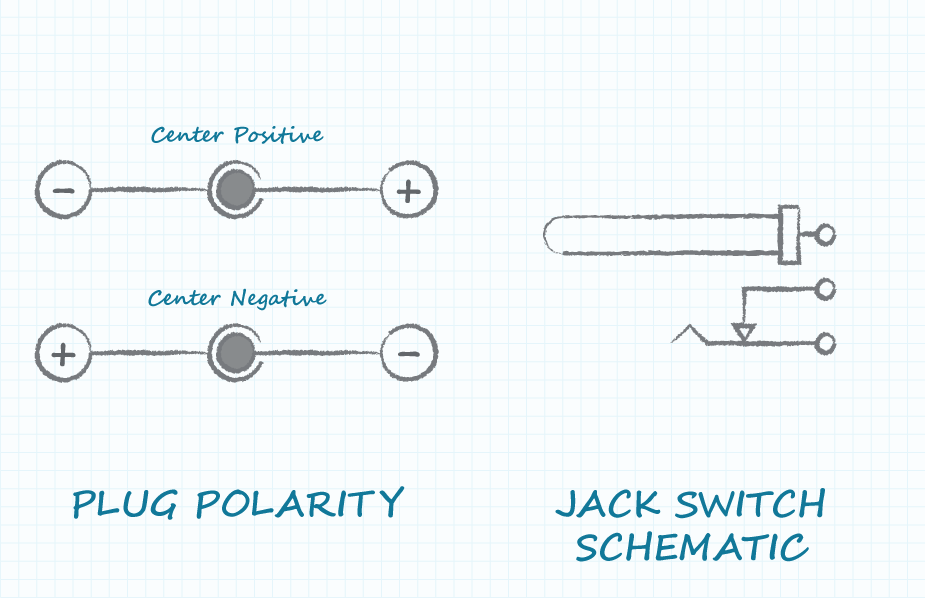

In the realm of “Barrel Connector Wiring”, understanding the significance of polarity is crucial when working with DC (direct current) connections. Polarity refers to the distinction between the positive and negative terminals of a DC electrical circuit. Ensuring proper polarity is essential for the safe and effective operation of DC circuits, including those utilizing barrel connectors.

- Components of Polarized Barrel Connectors:Barrel connectors designed for DC applications typically incorporate physical or color-coded markings to indicate polarity. These markings help identify the positive and negative terminals, ensuring proper orientation during connection.

- Real-Life Examples:Polarity is particularly important in applications such as battery-powered devices, where incorrect polarity can damage sensitive electronic components. Reversing the polarity when connecting a battery to a circuit can lead to malfunctions or even permanent damage to the device.

- Implications for Circuit Operation:In DC circuits, electrons flow from the positive terminal to the negative terminal. Maintaining proper polarity ensures that current flows in the intended direction, enabling proper operation of circuit components such as diodes, transistors, and motors.

- Safety Considerations:Incorrect polarity can also pose safety hazards. For instance, in DC power supplies, reversing polarity can create a short circuit, potentially leading to overheating, insulation damage, or even electrical fires.

Understanding and adhering to proper polarity in “Barrel Connector Wiring” is paramount for ensuring reliable circuit operation, preventing damage to equipment, and maintaining electrical safety. By observing the polarity markings and connecting terminals correctly, electrical professionals can ensure the integrity and functionality of DC circuits utilizing barrel connectors.

Durability

In the realm of “Barrel Connector Wiring”, durability encompasses the ability of connectors to withstand various environmental and mechanical challenges, ensuring reliable performance over an extended lifespan. Three key aspects of durability are resistance to vibration, corrosion, and mechanical stress.

-

Vibration Resistance:

Barrel connectors are often subjected to vibrations in applications such as industrial machinery or portable devices. Continuous exposure to vibrations can loosen connections, leading to intermittent or complete loss of electrical contact. Durable connectors employ vibration-dampening materials or locking mechanisms to maintain secure connections despite vibrations.

-

Corrosion Resistance:

In humid or corrosive environments, moisture and chemical agents can attack the metal components of barrel connectors, causing rust or corrosion. Durable connectors utilize corrosion-resistant materials such as stainless steel or plated finishes to prevent degradation and maintain electrical integrity.

-

Mechanical Stress Resistance:

Barrel connectors may experience mechanical stress during installation or operation, such as bending, pulling, or twisting. Durable connectors are designed to withstand these stresses without compromising their electrical performance. They employ robust construction, strain reliefs, or reinforced terminals to protect against mechanical damage.

Ensuring durability in “Barrel Connector Wiring” is crucial for applications where reliability and longevity are paramount. By selecting connectors with appropriate resistance to vibration, corrosion, and mechanical stress, electrical professionals can minimize downtime, improve safety, and extend the lifespan of their electrical systems.

Safety certifications

In the realm of “Barrel Connector Wiring”, safety certifications play a crucial role in ensuring the reliability, performance, and overall safety of electrical connections. These certifications, issued by independent testing organizations, attest to a product’s compliance with specific safety standards and requirements.

-

UL Certification:

Underwriters Laboratories (UL) is a global safety science company that tests and certifies products to meet specific safety standards. UL certification for barrel connectors ensures that they meet stringent requirements for electrical safety, fire resistance, and mechanical integrity.

-

CE Marking:

The CE marking is a mandatory conformity mark required for products sold in the European Economic Area (EEA). It signifies that a product meets the essential health and safety requirements set forth by European directives.

-

RoHS Compliance:

RoHS (Restriction of Hazardous Substances) is a directive that restricts the use of certain hazardous substances in electrical and electronic equipment. RoHS compliance ensures that barrel connectors do not contain harmful substances such as lead, mercury, and cadmium, making them environmentally friendly.

Obtaining safety certifications for “Barrel Connector Wiring” demonstrates a commitment toand safety. These certifications provide assurance to users that connectors have undergone rigorous testing and meet recognized standards. By incorporating certified barrel connectors into their electrical systems, engineers and technicians can mitigate risks, enhance reliability, and ensure the safe operation of their equipment.

Cost-effectiveness

In the realm of “Barrel Connector Wiring”, cost-effectiveness plays a pivotal role in achieving a balance between quality and affordability. It involves selecting barrel connectors that meet the required performance and safety standards while optimizing costs without compromising reliability.

Cost-effective barrel connectors are crucial for large-scale projects or applications where budget constraints are a factor. By carefully considering the trade-offs between quality and cost, electrical professionals can make informed decisions that align with project requirements and financial limitations.

Real-life examples of cost-effective “Barrel Connector Wiring” include:

- Utilizing barrel connectors with plastic insulators instead of more expensive ceramic insulators in low-voltage applications.

- Opting for non-locking barrel connectors in situations where secure connections are not critical.

- Purchasing barrel connectors in bulk quantities to take advantage of volume discounts.

Understanding the principles of cost-effectiveness in “Barrel Connector Wiring” enables electrical professionals to make practical decisions that optimize project outcomes. By carefully assessing quality requirements, considering alternative materials, and exploring cost-saving opportunities, they can achieve reliable and cost-efficient electrical connections.

In summary, cost-effectiveness is a critical component of “Barrel Connector Wiring”, driving informed decision-making and ensuring a balance between quality and affordability. By embracing cost-effective practices, electrical professionals can optimize project costs without sacrificing reliability or safety.

Ease of installation

In the realm of “Barrel Connector Wiring”, the aspect of “Ease of installation: Time and effort required for assembly and maintenance” holds significant importance, impacting project timelines, labor costs, and overall efficiency. Understanding the factors that contribute to ease of installation is crucial for optimizing the wiring process.

-

Connector design:

The design of the barrel connector itself plays a vital role in ease of installation. Connectors with features such as color-coded terminals, intuitive locking mechanisms, and ergonomic grips can significantly reduce assembly time and effort.

-

Tool requirements:

Some barrel connectors require specialized tools for installation, while others can be installed by hand. Choosing connectors that require minimal or no tooling can save time and simplify the assembly process.

-

Wire preparation:

The preparation of wires before connecting them to barrel connectors can impact installation time. Connectors designed for specific wire gauges and insulation types can simplify wire stripping and insertion, reducing the overall effort.

-

Accessibility:

The accessibility of the connection points can influence the ease of installation. Barrel connectors that can be easily accessed in tight spaces or awkward angles can save time and effort during assembly and maintenance.

Taking into account the factors related to “Ease of installation: Time and effort required for assembly and maintenance” allows electrical professionals to make informed decisions when selecting barrel connectors. By prioritizing ease of installation, they can optimize project timelines, reduce labor costs, and ensure efficient and reliable electrical connections.

Related Posts