A Pit Boss Wiring Diagram is an electrical schematic that illustrates the complete layout and connections of the wiring system within a Pit Boss grill or smoker. It provides a detailed representation of the power supply, electrical components, and circuitry, enabling users to troubleshoot issues, perform repairs, and modify the electrical system.

Wiring diagrams are essential for maintaining and servicing Pit Boss devices. They aid in identifying faulty connections, shorts, and blown fuses, ensuring the safe and efficient operation of the grill. Moreover, they facilitate modifications and upgrades, allowing users to improve the functionality and performance of their equipment.

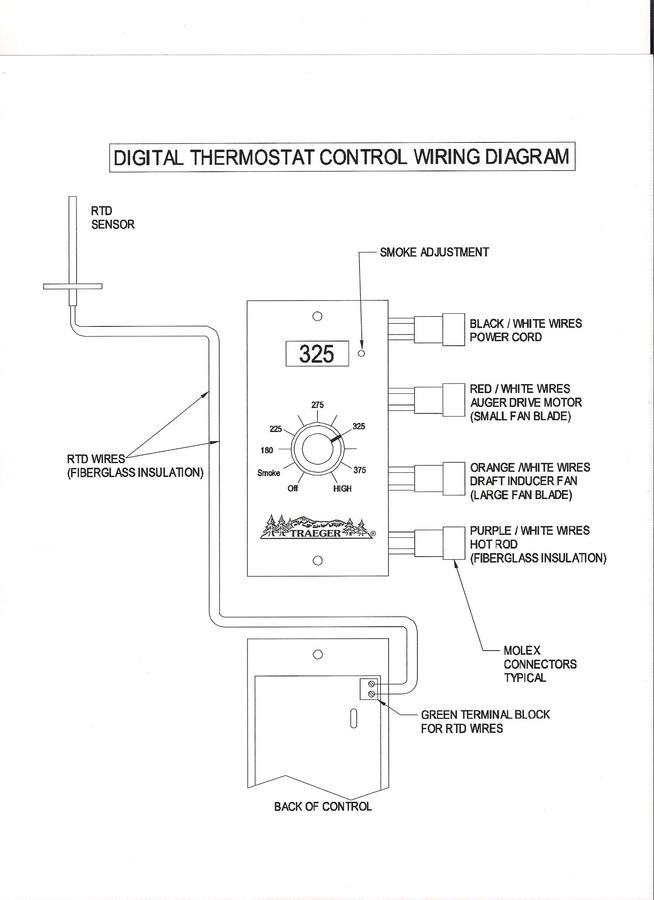

A key historical development in Pit Boss wiring diagrams was the introduction of digital control systems. These systems incorporate advanced electronics and software, providing more precise temperature control, user-friendly interfaces, and additional features. They have significantly enhanced the user experience and simplified the maintenance process.

Pit Boss Wiring Diagrams are essential components of Pit Boss grills and smokers, providing a comprehensive overview of the electrical system. Understanding the key aspects of these diagrams is crucial for maintaining and troubleshooting Pit Boss devices, as well as for modifying and upgrading the electrical system.

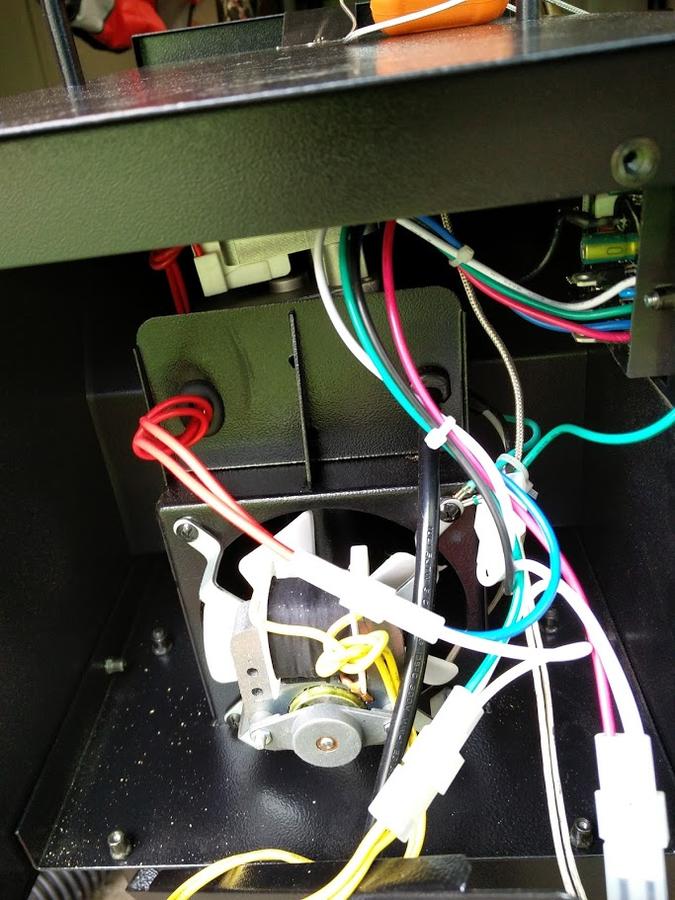

- Components: Electrical components, including power supply, control board, sensors, and wiring.

- Connections: Wiring schematics illustrate the connections between electrical components, ensuring proper functionality.

- Troubleshooting: Diagrams aid in identifying electrical faults, shorts, and blown fuses, facilitating repairs.

- Modifications: Diagrams enable users to modify the electrical system, adding or removing components as needed.

- Safety: Proper wiring is crucial for the safe operation of Pit Boss grills and smokers, preventing electrical hazards.

- Maintenance: Regular inspection and maintenance of wiring diagrams ensures optimal performance and longevity.

- Upgrading: Diagrams facilitate the integration of upgrades, such as digital control systems and additional features.

- Compatibility: Diagrams are specific to each Pit Boss model, ensuring compatibility and proper operation.

These key aspects are interconnected and essential for understanding and working with Pit Boss Wiring Diagrams. They provide a roadmap for troubleshooting, maintenance, and modifications, ensuring the safe and efficient operation of Pit Boss grills and smokers.

Components

Electrical components are the fundamental building blocks of Pit Boss Wiring Diagrams, forming the backbone of the electrical system and enabling the grill or smoker to function properly. Understanding the different types of components and their roles is crucial for effectively using and troubleshooting Pit Boss devices.

- Power Supply: The power supply provides electrical power to the entire system. It converts AC power from the outlet to the DC power required by the Pit Boss device.

- Control Board: The control board is the brain of the Pit Boss device. It monitors temperature, controls the heating element, and manages other functions. It receives input from sensors and sends commands to actuators.

- Sensors: Sensors monitor various aspects of the Pit Boss device, such as temperature, smoke level, and meat probe readings. They provide real-time data to the control board.

- Wiring: Wiring connects all the electrical components together, allowing electricity to flow through the system. Proper wiring is essential for the safe and efficient operation of the Pit Boss device.

These electrical components work in conjunction to provide precise temperature control, user-friendly interfaces, and advanced features in Pit Boss grills and smokers. By understanding the function and interconnections of these components through wiring diagrams, users can troubleshoot issues, perform maintenance, and make modifications to enhance the performance of their Pit Boss devices.

Connections

In the context of Pit Boss Wiring Diagrams, the connections between electrical components are of paramount importance. They provide a clear and detailed representation of how each component is wired together, ensuring the proper functionality of the entire system. Understanding these connections is critical for troubleshooting, maintenance, and modifications to Pit Boss grills and smokers.

Wiring schematics are essential for understanding the cause-and-effect relationships within Pit Boss electrical systems. By tracing the connections between components, users can identify the source of electrical faults, shorts, and blown fuses. This knowledge enables them to make informed decisions about repairs and modifications, ensuring the safe and efficient operation of their devices.

Practical applications of this understanding include:

- Troubleshooting: Wiring diagrams guide users in identifying the root cause of electrical issues, facilitating quick and effective troubleshooting.

- Maintenance: Regular inspection and maintenance of wiring connections ensure optimal performance and longevity of Pit Boss devices.

- Modifications: Wiring schematics enable users to modify the electrical system, adding or removing components as needed to enhance functionality.

In summary, the connections between electrical components in Pit Boss Wiring Diagrams are critical for understanding, troubleshooting, and modifying the electrical system. By studying these connections, users can ensure the safe and efficient operation of their Pit Boss grills and smokers, unlocking the full potential of their devices.

Troubleshooting

Within the comprehensive framework of “Pit Boss Wiring Diagrams,” the aspect of “Troubleshooting: Diagrams aid in identifying electrical faults, shorts, and blown fuses, facilitating repairs” assumes great significance. Understanding the intricacies of this troubleshooting process empowers users to pinpoint and rectify electrical issues, ensuring the smooth operation and longevity of their Pit Boss grills and smokers.

- Identifying Electrical Faults: Wiring diagrams provide a visual representation of the electrical circuitry, enabling users to trace wire connections, identify loose connections, and detect potential short circuits.

- Locating Shorts: Short circuits occur when electricity flows through an unintended path, causing malfunctions and safety hazards. Wiring diagrams help identify the specific components or wires involved in a short circuit, facilitating targeted repairs.

- Diagnosing Blown Fuses: Fuses protect electrical circuits from excessive current flow. By studying wiring diagrams, users can locate blown fuses and determine the underlying cause, preventing further damage to the device.

- Facilitating Repairs: Troubleshooting diagrams guide users through the repair process, providing clear instructions on replacing faulty components, repairing damaged wires, and restoring the electrical system to optimal functionality.

In conclusion, the troubleshooting capabilities offered by Pit Boss Wiring Diagrams empower users to effectively diagnose and resolve electrical faults, shorts, and blown fuses. By understanding the electrical connections and components illustrated in these diagrams, users can maintain and repair their Pit Boss devices, ensuring safe and efficient operation while extending the lifespan of their equipment.

Modifications

Within the realm of Pit Boss Wiring Diagrams, the ability to modify the electrical system is a crucial aspect that empowers users to customize their grills and smokers to suit their specific needs and preferences. Wiring diagrams serve as the roadmap for these modifications, providing a clear understanding of the system’s circuitry and connections.

Users can leverage wiring diagrams to add or remove various components, such as digital temperature controllers, meat probes, and fans, to enhance the functionality and performance of their Pit Boss devices. These modifications may involve adding new wiring, altering connections, or integrating third-party accessories.

Real-life examples of modifications enabled by Pit Boss Wiring Diagrams include:

- Installing a digital temperature controller to achieve more precise temperature management.

- Adding a meat probe to monitor the internal temperature of the meat, ensuring optimal cooking.

- Integrating a fan to improve air circulation within the grill or smoker, promoting even cooking.

Understanding the electrical connections and components illustrated in Pit Boss Wiring Diagrams is essential for successful modifications. By studying these diagrams, users can plan their modifications effectively, identify potential compatibility issues, and avoid electrical hazards.

In summary, Pit Boss Wiring Diagrams play a critical role in empowering users to modify their electrical systems. These diagrams provide a comprehensive understanding of the circuitry and connections, enabling users to customize their devices, enhance their functionality, and tailor their grilling and smoking experiences.

Safety

In the context of “Pit Boss Wiring Diagrams,” the aspect of “Safety: Proper wiring is crucial for the safe operation of Pit Boss grills and smokers, preventing electrical hazards” takes center stage. Pit Boss Wiring Diagrams serve as essential guides for understanding the electrical connections and components within Pit Boss devices, ensuring that they operate safely and efficiently, preventing potential electrical hazards.

Proper wiring is a critical component of Pit Boss Wiring Diagrams. By following the diagrams accurately, users can ensure that all electrical connections are made correctly, minimizing the risk of electrical shorts, fires, and other hazards. These diagrams provide clear instructions on wire sizing, connection points, and grounding requirements, empowering users to maintain the integrity of the electrical system.

Real-life examples of the importance of proper wiring in Pit Boss Wiring Diagrams include:

- Correct wire sizing prevents overheating and potential fire hazards.

- Secure connections eliminate loose wires that could cause arcing and electrical faults.

- Proper grounding protects users from electrical shocks and ensures the safe operation of the device.

Understanding the safety implications of proper wiring in Pit Boss Wiring Diagrams is paramount. By studying these diagrams thoroughly and adhering to the recommended guidelines, users can mitigate electrical hazards, ensuring the safe enjoyment of their Pit Boss grills and smokers.

Maintenance

Within the realm of “Pit Boss Wiring Diagrams,” the aspect of “Maintenance: Regular inspection and maintenance of wiring diagrams ensures optimal performance and longevity” holds great significance. By understanding and adhering to regular maintenance practices, users can prolong the lifespan of their Pit Boss grills and smokers, ensuring consistent performance and reliability.

- Component Inspection: Regularly inspecting electrical components such as wires, connections, and terminals is crucial. Loose connections, frayed wires, and damaged components can lead to electrical faults and safety hazards. By visually examining these components, users can identify potential issues early on and address them promptly.

- Wiring Diagram Review: Periodically reviewing the Pit Boss Wiring Diagram allows users to verify the integrity of the electrical system. By comparing the actual wiring to the diagram, any discrepancies or deviations can be detected and corrected, ensuring proper functionality and minimizing the risk of electrical problems.

- Environmental Factors: External factors such as moisture, heat, and vibration can affect the condition of wiring diagrams. Regular maintenance should include checking for any signs of damage or deterioration caused by these factors. Taking appropriate measures to protect the wiring diagrams from harsh conditions enhances their longevity.

- Electrical Safety: Proper maintenance of wiring diagrams is essential for electrical safety. By ensuring that all connections are secure, wires are properly sized, and the system is grounded correctly, users can prevent electrical shocks, fires, and other hazards.

Regular inspection and maintenance of wiring diagrams empower users to maintain optimal performance and longevity of their Pit Boss devices. By following these maintenance practices, users can proactively identify and address potential issues, minimize the risk of electrical hazards, and extend the lifespan of their grills and smokers.

Upgrading

Within the comprehensive framework of “Pit Boss Wiring Diagrams,” the aspect of “Upgrading: Diagrams facilitate the integration of upgrades, such as digital control systems and additional features” holds significant importance. Pit Boss Wiring Diagrams serve as the blueprints for enhancing the capabilities and functionality of Pit Boss grills and smokers, allowing users to customize their devices and elevate their grilling and smoking experiences.

By providing detailed illustrations of the electrical connections and components, Pit Boss Wiring Diagrams empower users to seamlessly integrate upgrades into their devices. These upgrades may range from installing digital control systems for precise temperature management to incorporating meat probes for monitoring internal temperatures, and even integrating fans for improved air circulation. The wiring diagrams guide users through the process of adding new components, modifying existing connections, and ensuring proper integration with the original electrical system.

Real-life examples of upgrades facilitated by Pit Boss Wiring Diagrams include:

- Upgrading to a digital control system with an intuitive interface for enhanced temperature control and monitoring capabilities.

- Integrating wireless meat probes to monitor the internal temperature of multiple cuts of meat simultaneously, ensuring optimal cooking.

- Installing a fan to improve air circulation within the grill or smoker, promoting even cooking and reducing hot spots.

Understanding the electrical connections and components illustrated in Pit Boss Wiring Diagrams is essential for successful upgrades. By studying these diagrams, users can plan their upgrades effectively, identify potential compatibility issues, and avoid electrical hazards. The diagrams provide clear instructions on wire sizing, connection points, and grounding requirements, ensuring the safe and efficient integration of upgrades.

In summary, Pit Boss Wiring Diagrams play a critical role in enabling users to upgrade their grills and smokers with advanced features and functionality. These diagrams provide a comprehensive understanding of the electrical system, allowing users to seamlessly integrate upgrades, customize their devices, and enhance their overall grilling and smoking experience.

Compatibility

Within the context of “Pit Boss Wiring Diagrams,” the aspect of “Compatibility: Diagrams are specific to each Pit Boss model, ensuring compatibility and proper operation” holds critical importance. Pit Boss Wiring Diagrams are tailored to the specific electrical configurations of different Pit Boss grill and smoker models. This specificity is essential for ensuring compatibility and proper operation, as each model may have unique wiring requirements based on its features, size, and intended use.

The direct connection between “Compatibility: Diagrams are specific to each Pit Boss model, ensuring compatibility and proper operation” and “Pit Boss Wiring Diagram” lies in the fact that the wiring diagrams are designed to match the exact electrical specifications of each Pit Boss model. This ensures that the electrical components, such as heating elements, control boards, and sensors, are properly connected and function as intended. Using a wiring diagram not specific to the user’s Pit Boss model could lead to incorrect connections, electrical faults, or even safety hazards.

Real-life examples of “Compatibility: Diagrams are specific to each Pit Boss model, ensuring compatibility and proper operation” within “Pit Boss Wiring Diagram” include:

- Installing a digital control board upgrade designed for a specific Pit Boss model, ensuring compatibility with the existing wiring harness and electrical components.

- Replacing a faulty heating element with a compatible model, based on the wiring diagram for the specific Pit Boss grill or smoker.

- Adding an additional meat probe to a Pit Boss smoker, using the wiring diagram to identify the correct connection points and wire sizing.

Practical applications of this understanding include:

- Troubleshooting electrical issues by referencing the correct wiring diagram for the specific Pit Boss model.

- Modifying the electrical system to add or remove components, ensuring compatibility with the existing wiring.

- Maintaining the electrical integrity of the Pit Boss device by using the wiring diagram as a guide for proper maintenance and repair.

In summary, “Compatibility: Diagrams are specific to each Pit Boss model, ensuring compatibility and proper operation” is a critical component of “Pit Boss Wiring Diagram.” Understanding this connection is crucial for ensuring the safe, efficient, and optimal performance of Pit Boss grills and smokers. By utilizing the correct wiring diagram specific to their Pit Boss model, users can confidently troubleshoot issues, make modifications, and maintain their devices, enhancing their overall grilling and smoking experience.

Related Posts