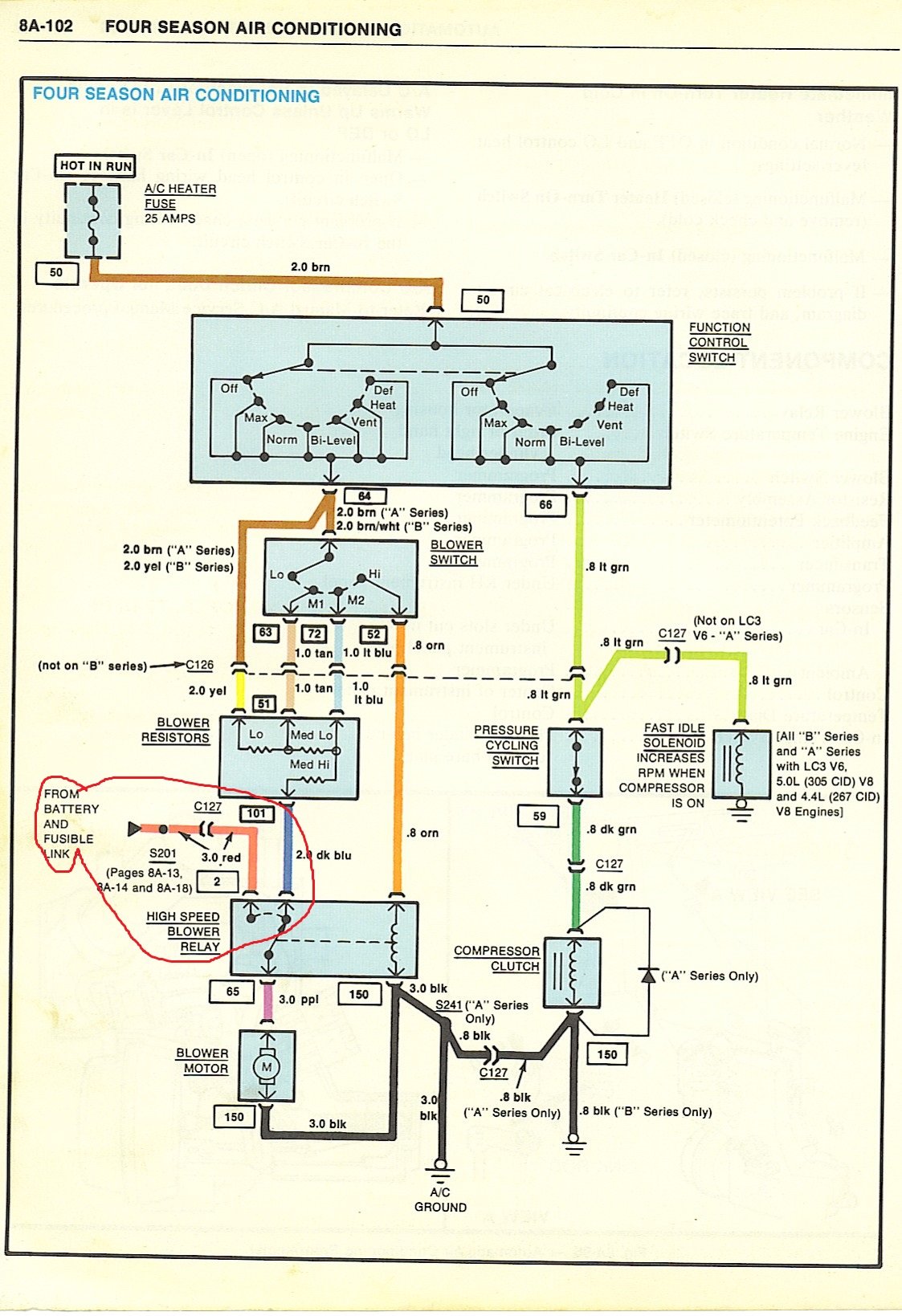

A Blower Motor Wiring Diagram is a technical schematic that outlines the electrical connections, pathways, and components pertaining to the blower motor within a given system or device. It visually represents how the motor is wired, providing a comprehensive overview of its electrical configuration. For instance, HVAC systems commonly employ blower motors, and their wiring diagrams aid technicians in troubleshooting, maintenance, and repair processes, ensuring efficient and safe operation.

Wiring diagrams hold immense relevance in electrical and HVAC industries, serving as vital reference materials for engineers, technicians, and homeowners. They simplify complex electrical systems, making it easier to understand and troubleshoot electrical issues. Historically, the development of standardized wiring conventions and symbols has significantly enhanced the clarity and accessibility of these diagrams, enabling broader comprehension and effective communication.

This article delves into the specifics of Blower Motor Wiring Diagrams, providing a deeper understanding of their components, interpretation, and practical applications. By exploring real-world examples, we aim to enhance your knowledge and empower you to navigate electrical systems with greater confidence.

The key aspects of Blower Motor Wiring Diagrams encompass the fundamental elements that define their purpose, application, and significance. Understanding these aspects is vital for effectively utilizing wiring diagrams in electrical and HVAC systems.

- Components: Illustrates the individual components within the blower motor circuit, such as the motor itself, resistors, capacitors, and switches.

- Connections: Outlines the electrical pathways between components, including wire colors and terminal designations, ensuring proper connectivity.

- Power Source: Indicates the voltage and current requirements of the blower motor, ensuring compatibility with the power supply.

- Control Circuit: Depicts the wiring for switches, sensors, and other control devices that regulate the operation of the blower motor.

- Safety Features: Highlights protective measures such as fuses and thermal overload protection, ensuring safe operation.

- Grounding: Shows the grounding connections for the blower motor and associated components, providing protection against electrical hazards.

- Troubleshooting: Guides technicians in identifying and resolving electrical issues by providing a visual representation of the circuit.

- Maintenance: Assists in performing routine maintenance tasks, such as cleaning and lubrication, by providing a clear understanding of component locations.

- Installation: Provides a roadmap for installing a new blower motor or replacing an existing one, ensuring proper wiring and functionality.

These aspects are interconnected, forming a comprehensive framework that enables the effective design, installation, maintenance, and troubleshooting of blower motor circuits. Understanding these aspects empowers individuals to confidently navigate electrical systems, ensuring safety and optimal performance.

Components

The intricate relationship between “Components: Illustrates the individual components within the blower motor circuit, such as the motor itself, resistors, capacitors, and switches” and “Blower Motor Wiring Diagram” lies at the heart of electrical system comprehension. Wiring diagrams serve as visual representations of circuits, detailing the connections and components that make up the system. Without a clear understanding of the individual components, deciphering the wiring diagram becomes an arduous task.

Each component plays a pivotal role in the blower motor circuit. The motor itself converts electrical energy into mechanical energy, driving the fan blades to circulate air. Resistors regulate the flow of current, protecting the motor from damage. Capacitors store electrical energy, providing a surge of power to assist the motor during startup. Switches control the operation of the motor, allowing for manual or automatic activation.

Real-life examples abound, showcasing the practical significance of understanding components within blower motor wiring diagrams. HVAC technicians rely on these diagrams to troubleshoot and repair malfunctioning blower motors, ensuring efficient and safe operation of heating and cooling systems. Electricians utilize wiring diagrams during the installation of new blower motors, guaranteeing proper connectivity and adherence to safety codes.

By grasping the connection between components and wiring diagrams, individuals gain the ability to interpret electrical schematics with greater ease and accuracy. This understanding empowers them to perform maintenance tasks, resolve electrical issues, and navigate complex blower motor circuits with confidence.

Connections

Within the realm of “Blower Motor Wiring Diagram,” the aspect of “Connections: Outlines the electrical pathways between components, including wire colors and terminal designations, ensuring proper connectivity” holds paramount importance. It establishes the roadmap for the flow of electricity within the circuit, dictating how components interact and function harmoniously.

- Wire Colors: Wiring diagrams utilize a standardized color code system to identify the function of each wire, simplifying the tracing of electrical pathways. This color-coding scheme ensures correct connections, preventing mismatches and potential hazards.

- Terminal Designations: Terminals serve as the connection points for wires within electrical components. Wiring diagrams clearly label these terminals, enabling technicians to effortlessly identify the intended wire connections. Proper terminal identification minimizes the risk of incorrect wiring, ensuring the blower motor operates as intended.

- Conductor Sizing: The diameter or gauge of the wire is crucial for handling the electrical load. Wiring diagrams specify the appropriate conductor size for each connection, ensuring that the wires can safely carry the required current without overheating or causing a fire hazard.

- Grounding: Electrical safety demands proper grounding to protect against electrical shocks and circuit malfunctions. Wiring diagrams indicate the grounding points within the blower motor circuit, guiding technicians in establishing a secure connection to the grounding system.

Understanding the significance of “Connections: Outlines the electrical pathways between components, including wire colors and terminal designations, ensuring proper connectivity” empowers individuals to confidently tackle electrical tasks related to blower motors. Whether troubleshooting a malfunction, installing a new motor, or performing routine maintenance, a thorough grasp of these connections is essential for ensuring safety, efficiency, and optimal performance.

Power Source

In the context of “Blower Motor Wiring Diagram,” “Power Source: Indicates the voltage and current requirements of the blower motor, ensuring compatibility with the power supply” plays a pivotal role. It establishes the electrical foundation upon which the blower motor operates, dictating its performance and longevity. The power source specification within the wiring diagram provides crucial information for proper installation and maintenance, ensuring that the motor receives the appropriate electrical input to function optimally and safely.

Consider the voltage requirement: If a blower motor is designed to operate on 120 volts and is mistakenly connected to a 240-volt power source, it can lead to catastrophic damage, potentially causing a fire hazard. Conversely, if a 240-volt motor is connected to a 120-volt supply, it may fail to start or operate erratically, compromising system performance.

Understanding the power source requirements also extends to the current draw of the blower motor. The wiring diagram specifies the amperage rating, which determines the appropriate wire gauge and circuit breaker size. Undersized wiring or an inadequate circuit breaker can lead to overheating, insulation damage, and potential electrical fires. Conversely, oversized wiring and circuit breakers provide unnecessary protection and may increase installation costs.

Real-life examples abound, emphasizing the practical significance of power source compatibility. HVAC technicians rely on wiring diagrams to ensure that blower motors in heating and cooling systems receive the correct voltage and current. Industrial electricians utilize these diagrams to connect blower motors in manufacturing facilities, ensuring optimal performance and adherence to safety codes.

By grasping the connection between “Power Source: Indicates the voltage and current requirements of the blower motor, ensuring compatibility with the power supply” and “Blower Motor Wiring Diagram,” individuals gain the ability to interpret electrical schematics with greater accuracy. This understanding empowers them to perform electrical tasks related to blower motors with confidence, ensuring safety, efficiency, and optimal performance.

Control Circuit

Within the realm of “Blower Motor Wiring Diagram,” the “Control Circuit: Depicts the wiring for switches, sensors, and other control devices that regulate the operation of the blower motor” plays a pivotal role in orchestrating the blower motor’s behavior. This aspect of the wiring diagram provides a roadmap for the electrical connections and components responsible for starting, stopping, and modulating the speed of the blower motor, ensuring its efficient and responsive operation.

- Switches: The wiring diagram outlines the electrical connections for various types of switches, such as on/off switches, selector switches, and variable speed controllers. These switches provide manual or automatic control over the blower motor, allowing users to activate, deactivate, or adjust its speed.

- Sensors: The wiring diagram may also include sensors, such as temperature sensors or pressure switches, that monitor operating conditions and provide feedback to the control circuit. This feedback enables the blower motor to respond to changes in the environment, such as adjusting its speed to maintain a desired temperature or airflow.

- Logic Devices: In more sophisticated systems, the control circuit may incorporate logic devices, such as relays or programmable logic controllers (PLCs), to implement complex control algorithms. These devices receive input from switches and sensors and use programmed logic to determine the appropriate control actions for the blower motor.

- Safety Features: The wiring diagram often includes safety features, such as thermal overload protection or fault detection circuits, to protect the blower motor from damage in the event of abnormal operating conditions. These features ensure the safe and reliable operation of the blower motor.

Understanding the “Control Circuit: Depicts the wiring for switches, sensors, and other control devices that regulate the operation of the blower motor” is essential for troubleshooting, maintenance, and repair of blower motor circuits. By deciphering the wiring diagram and comprehending the function of each component, technicians can effectively diagnose and resolve issues, ensuring optimal performance and extending the lifespan of the blower motor.

Safety Features

Within the context of “Blower Motor Wiring Diagram,” “Safety Features: Highlights protective measures such as fuses and thermal overload protection, ensuring safe operation” holds paramount importance. These safety features safeguard the blower motor from electrical hazards, preventing damage and ensuring reliable operation. Their inclusion in wiring diagrams is a critical aspect, providing a clear understanding of how protective measures are implemented within the circuit.

Fuses and thermal overload protection devices act as the first line of defense against electrical faults. Fuses interrupt the circuit if excessive current flows, preventing damage to the motor and preventing electrical fires. Thermal overload protectors monitor the temperature of the motor and automatically shut it off in the event of overheating, protecting against burnout and potential fire hazards.

Real-life examples abound, highlighting the practical significance of safety features in blower motor wiring diagrams. In HVAC systems, blower motors are equipped with thermal overload protection to prevent overheating due to restricted airflow or other issues. Industrial machinery often incorporates fuses to safeguard blower motors from electrical faults caused by sudden voltage spikes or overloads.

Understanding the connection between “Safety Features: Highlights protective measures such as fuses and thermal overload protection, ensuring safe operation” and “Blower Motor Wiring Diagram” empowers individuals to identify and implement appropriate protective measures when installing or maintaining blower motors. This knowledge contributes to the safe and reliable operation of electrical systems, preventing accidents and extending the lifespan of equipment.

Grounding

Within the realm of “Blower Motor Wiring Diagram,” “Grounding: Shows the grounding connections for the blower motor and associated components, providing protection against electrical hazards” plays a pivotal role in ensuring the safe and reliable operation of the blower motor. By establishing a conductive path to the ground, grounding prevents dangerous electrical currents from flowing through unintended paths, minimizing the risk of electrical shocks, fires, and equipment damage.

- Electrical Safety: Grounding provides a safe path for stray electrical currents to dissipate, preventing them from accumulating and potentially causing electrical shocks or fires.

- Equipment Protection: By diverting excess current away from sensitive electrical components, grounding safeguards the blower motor and associated circuitry from damage.

- Code Compliance: Grounding is an essential aspect of electrical installations and is required by electrical codes to ensure compliance and adherence to safety standards.

- Real-Life Example: In HVAC systems, grounding the blower motor prevents electrical currents from traveling through the ductwork, minimizing the risk of shocks to individuals coming into contact with the system.

In summary, “Grounding: Shows the grounding connections for the blower motor and associated components, providing protection against electrical hazards” is a crucial aspect of “Blower Motor Wiring Diagram,” ensuring the safe and reliable operation of blower motors by preventing electrical hazards and adhering to safety codes. Understanding the importance of grounding empowers individuals to design, install, and maintain electrical systems with confidence, prioritizing safety and preventing potential hazards.

Troubleshooting

Within the realm of “Blower Motor Wiring Diagram,” “Troubleshooting: Guides technicians in identifying and resolving electrical issues by providing a visual representation of the circuit” holds immense significance. It empowers technicians with a comprehensive roadmap to diagnose and rectify electrical faults, ensuring the efficient and reliable operation of blower motors. The wiring diagram serves as a visual aid, providing a clear understanding of the electrical connections and components involved, enabling technicians to trace current flow, identify potential issues, and implement appropriate solutions.

The cause-and-effect relationship between “Troubleshooting: Guides technicians in identifying and resolving electrical issues by providing a visual representation of the circuit” and “Blower Motor Wiring Diagram” is evident in real-life scenarios. When a blower motor malfunctions, technicians rely on the wiring diagram to systematically inspect the circuit, identify the root cause of the issue, and determine the necessary repairs. By analyzing the wiring diagram, they can pinpoint faulty components, loose connections, or incorrect wiring practices, enabling them to resolve the problem efficiently and effectively.

Practical applications of this understanding extend to various industries and settings. In HVAC systems, technicians utilize blower motor wiring diagrams to diagnose and repair blower motors that may malfunction due to clogged filters, faulty capacitors, or electrical faults. In industrial settings, electricians rely on these diagrams to troubleshoot and resolve issues with blower motors used in machinery and equipment, ensuring optimal performance and preventing costly downtime.

In summary, “Troubleshooting: Guides technicians in identifying and resolving electrical issues by providing a visual representation of the circuit” is a critical component of “Blower Motor Wiring Diagram.” It empowers technicians with the knowledge and tools to diagnose and rectify electrical faults, ensuring the safe, efficient, and reliable operation of blower motors across diverse applications. Understanding this connection provides a solid foundation for electrical troubleshooting, enabling individuals to confidently maintain and repair electrical systems.

Maintenance

Within the context of “Blower Motor Wiring Diagram,” “Maintenance: Assists in performing routine maintenance tasks, such as cleaning and lubrication, by providing a clear understanding of component locations” holds significant importance. It empowers individuals with the knowledge necessary to maintain blower motors efficiently and effectively, ensuring their optimal performance and longevity. The wiring diagram serves as a visual guide, providing a comprehensive overview of the blower motor’s components and their interconnections. This enables technicians to easily locate specific components, such as bearings, brushes, and capacitors, for inspection, cleaning, and lubrication.

The connection between “Maintenance: Assists in performing routine maintenance tasks, such as cleaning and lubrication, by providing a clear understanding of component locations” and “Blower Motor Wiring Diagram” is evident in real-world applications. Regular maintenance of blower motors is crucial to prevent premature failure and extend their lifespan. By referring to the wiring diagram, technicians can identify the lubrication points, access panels, and other maintenance-related features, ensuring that all necessary maintenance tasks are performed correctly and efficiently.

Practical examples abound, showcasing the significance of “Maintenance: Assists in performing routine maintenance tasks, such as cleaning and lubrication, by providing a clear understanding of component locations” within “Blower Motor Wiring Diagram.” In HVAC systems, technicians rely on wiring diagrams to locate and clean blower motors, ensuring optimal airflow and preventing overheating. In industrial settings, electricians utilize wiring diagrams to perform regular maintenance on blower motors used in machinery and equipment, minimizing downtime and maintaining productivity.

In summary, “Maintenance: Assists in performing routine maintenance tasks, such as cleaning and lubrication, by providing a clear understanding of component locations” is an integral part of “Blower Motor Wiring Diagram.” It provides technicians with the knowledge and tools necessary to maintain blower motors effectively, ensuring their reliable operation and extending their lifespan. Understanding this connection empowers individuals to confidently perform maintenance tasks, preventing costly repairs and maximizing the efficiency of blower motor systems.

Installation

Within the realm of “Blower Motor Wiring Diagram,” “Installation: Provides a roadmap for installing a new blower motor or replacing an existing one, ensuring proper wiring and functionality” holds paramount importance. It provides a comprehensive guide for technicians and DIY enthusiasts to navigate the process of installing or replacing blower motors, ensuring the proper electrical connections and optimal performance of the system. The wiring diagram serves as a visual roadmap, outlining the step-by-step instructions, component locations, and wire connections necessary for successful installation.

The cause-and-effect relationship between “Installation: Provides a roadmap for installing a new blower motor or replacing an existing one, ensuring proper wiring and functionality” and “Blower Motor Wiring Diagram” is evident in real-world applications. Incorrect installation or faulty wiring can lead to improper operation, safety hazards, or damage to the blower motor and connected equipment. Conversely, by adhering to the wiring diagram, installers can ensure that the blower motor is wired correctly, minimizing the risk of electrical issues and maximizing system efficiency.

Practical examples of “Installation: Provides a roadmap for installing a new blower motor or replacing an existing one, ensuring proper wiring and functionality” within “Blower Motor Wiring Diagram” abound in various industries. In HVAC systems, technicians rely on wiring diagrams to guide the installation of new blower motors or replace faulty ones, ensuring proper airflow and maintaining optimal indoor air quality. In industrial settings, electricians utilize wiring diagrams to install blower motors in machinery and equipment, ensuring efficient operation and preventing costly downtime.

In summary, “Installation: Provides a roadmap for installing a new blower motor or replacing an existing one, ensuring proper wiring and functionality” is a critical component of “Blower Motor Wiring Diagram.” It provides a clear and systematic approach to installing or replacing blower motors, ensuring electrical safety, optimal performance, and longevity of the system. Understanding this connection empowers individuals to confidently undertake blower motor installation tasks, minimizing the risk of errors and maximizing the efficiency of the installed system.

Related Posts