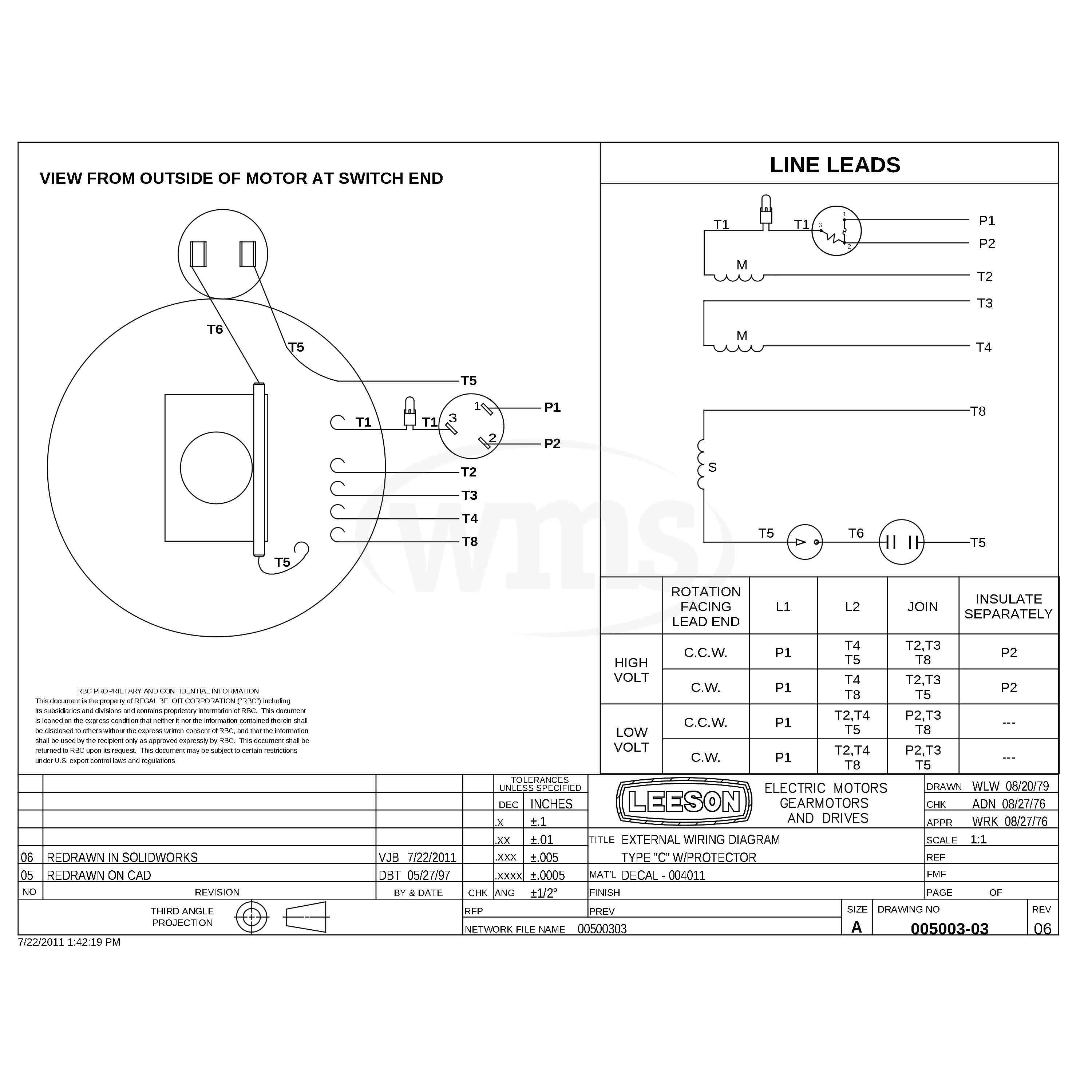

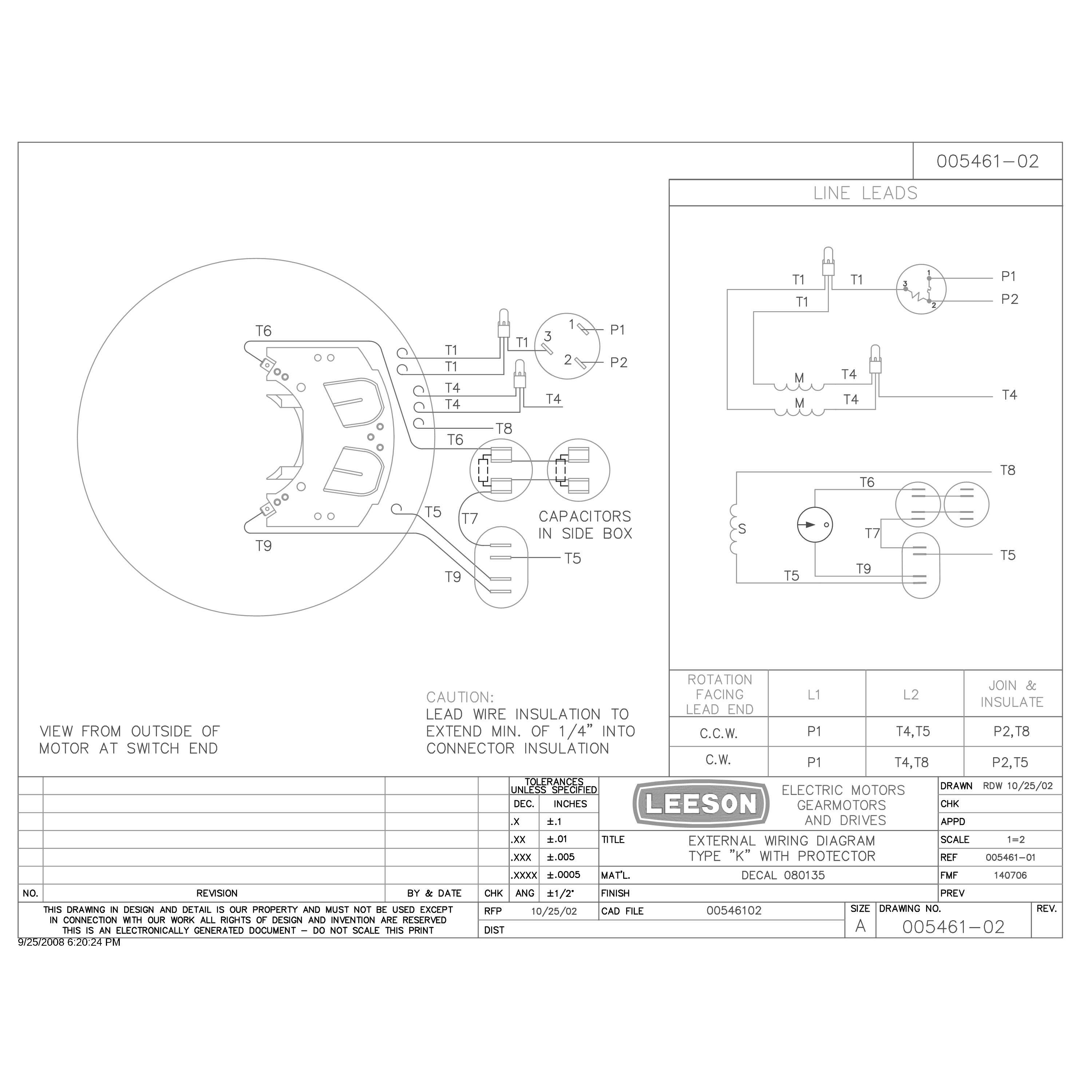

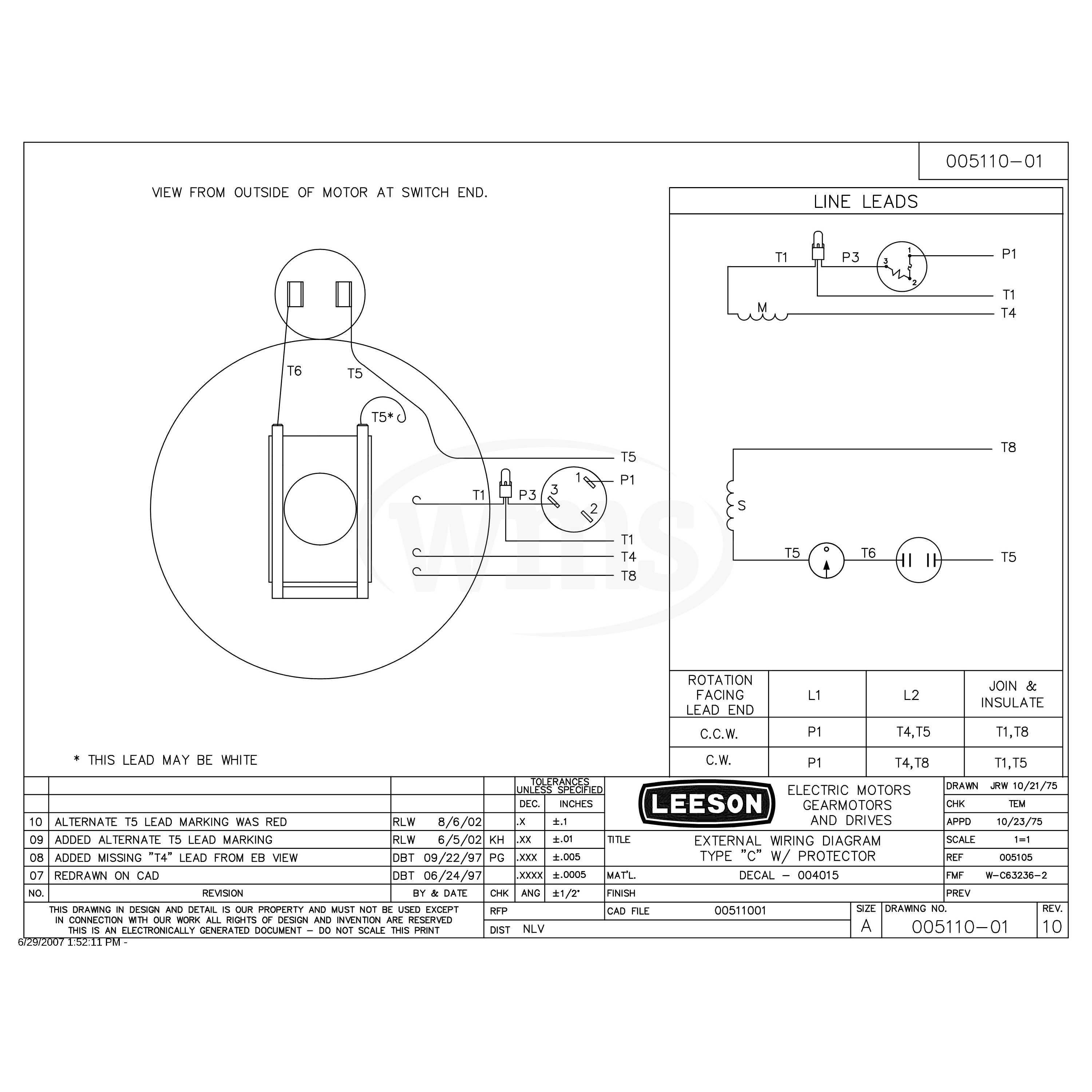

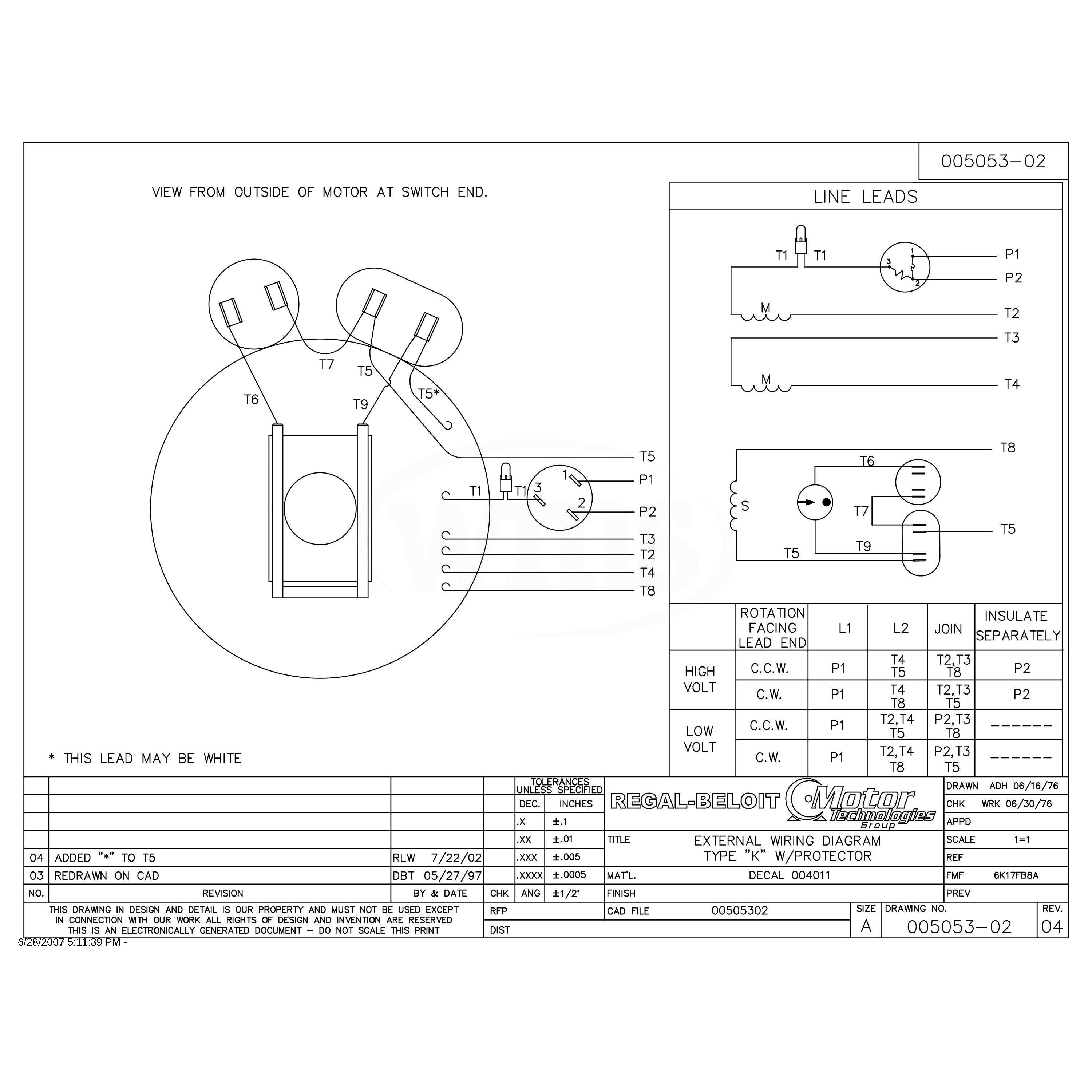

Leeson Motors Wiring Diagrams are fundamental references that provide concise instructions and guidance on the electrical connections and configurations for Leeson motors. They are essential for ensuring the correct installation, operation, and maintenance of these electrical machines.

The diagrams are highly significant as they enable technicians and engineers to understand the intricate electrical wiring of Leeson motors. They are crucial for resolving electrical issues, troubleshooting malfunctions, and performing maintenance tasks. By following the diagrams, professionals can establish reliable connections, ensuring optimal motor performance and preventing electrical hazards.

The advent of Leeson Motors Wiring Diagrams marked a significant advancement in the field of electrical engineering. They provided a standardized and simplified approach to the installation and maintenance of these motors, leading to increased safety, reliability, and efficiency in various industries. These diagrams have played a vital role in the widespread adoption and successful operation of Leeson motors across a diverse range of applications.

Leeson Motors Wiring Diagrams are vital references that ensure the proper installation, operation, troubleshooting, and maintenance of Leeson motors. Understanding the various aspects of these diagrams is crucial for effectively leveraging their benefits. Let’s explore nine key aspects that shed light on their importance:

- Accuracy: Leeson Motors Wiring Diagrams provide precise instructions that reduce errors and ensure reliable electrical connections.

- Clarity: Diagrams simplify complex wiring configurations, making them easy to understand and follow.

- Comprehensiveness: Diagrams cover a wide range of motor models and variations, providing a comprehensive reference guide.

- Safety: Diagrams promote safe electrical practices by guiding technicians on proper wiring techniques.

- Efficiency: Diagrams facilitate quick and efficient troubleshooting, minimizing downtime and maintenance costs.

- Standardization: Diagrams adhere to industry standards, ensuring consistency and reducing the risk of misinterpretations.

- Technical Support: Diagrams provide a valuable resource for technical support teams to assist with installation and maintenance queries.

- Compliance: Diagrams help ensure compliance with electrical codes and regulations, enhancing safety and reliability.

- Training: Diagrams serve as training materials for apprentices and practicing electricians, promoting knowledge and skill development.

In conclusion, Leeson Motors Wiring Diagrams are multifaceted resources that provide essential guidance for the safe and efficient use of Leeson motors. They encompass accuracy, clarity, comprehensiveness, safety, efficiency, standardization, technical support, compliance, and training. These diagrams play a critical role in various industries, enabling technicians and engineers to confidently install, operate, troubleshoot, and maintain Leeson motors.

Accuracy

The accuracy of Leeson Motors Wiring Diagrams is a crucial component of their effectiveness. Precise instructions within these diagrams guide technicians and engineers through the intricate electrical connections of Leeson motors, minimizing errors and ensuring reliable operation. Inaccurate diagrams, on the other hand, can lead to incorrect wiring, electrical faults, and potential hazards.

Real-life examples demonstrate the significance of accuracy in Leeson Motors Wiring Diagrams. In industrial settings, miswiring due to inaccurate diagrams can result in costly downtime, production delays, and safety risks. Conversely, accurate diagrams enable technicians to establish reliable electrical connections, ensuring optimal motor performance and preventing electrical issues.

The practical applications of understanding the connection between accuracy and Leeson Motors Wiring Diagrams extend beyond industrial settings. Accurate diagrams are essential for troubleshooting electrical faults, performing maintenance tasks, and ensuring compliance with electrical codes and regulations. By following precise instructions, technicians can identify and resolve electrical issues quickly and safely, minimizing downtime and maintaining optimal motor operation.

In conclusion, the accuracy of Leeson Motors Wiring Diagrams is paramount for reducing errors, ensuring reliable electrical connections, and facilitating efficient maintenance. Understanding this connection is critical for leveraging the full benefits of these diagrams, promoting safety, reliability, and optimal performance of Leeson motors.

Clarity

In the realm of Leeson Motors Wiring Diagrams, clarity emerges as a crucial factor that simplifies the comprehension and execution of intricate electrical configurations. By breaking down complex wiring into easily digestible visual representations, these diagrams empower technicians and engineers to navigate electrical connections with precision and confidence. Clarity within Leeson Motors Wiring Diagrams encompasses several key aspects:

- Standardized Symbols: Leeson Motors Wiring Diagrams adhere to industry-recognized symbols, ensuring consistency and ease of understanding across different models and variations.

- Logical Flow: Diagrams organize electrical connections in a logical and sequential manner, allowing technicians to trace the flow of electricity effortlessly.

- Color Coding: Color-coded wires and terminals enhance visual clarity, simplifying the identification and connection of corresponding components.

- Detailed Annotations: Diagrams include clear annotations and labels, providing additional context and guidance for specific connections and configurations.

The clarity of Leeson Motors Wiring Diagrams translates into tangible benefits in real-life applications. Accurate diagrams reduce installation time, minimize the risk of errors, and facilitate troubleshooting. They empower technicians with the confidence to handle complex wiring configurations, ensuring optimal motor performance and system reliability. Clarity also enhances communication among team members, as diagrams provide a shared visual reference point, reducing misunderstandings and promoting efficient collaboration.

Comprehensiveness

In the realm of Leeson Motors Wiring Diagrams, comprehensiveness emerges as a defining characteristic, ensuring the diagrams serve as a reliable and all-inclusive reference guide for technicians and engineers. By encompassing a wide range of motor models and variations, these diagrams empower professionals to confidently handle electrical connections across diverse applications and configurations.

Real-life examples underscore the significance of comprehensiveness in Leeson Motors Wiring Diagrams. In industrial settings, motors come in various models and variations, each with unique electrical requirements. Comprehensive diagrams ensure technicians have the necessary guidance at their fingertips, enabling them to establish reliable connections and troubleshoot issues efficiently. This reduces downtime, enhances productivity, and minimizes the risk of electrical hazards.

Furthermore, comprehensiveness facilitates knowledge transfer and training. With diagrams covering a wide range of motor models and variations, technicians can gain a thorough understanding of electrical connections across different types of motors. This promotes standardization, ensures consistency, and enables effective troubleshooting.

In conclusion, the comprehensiveness of Leeson Motors Wiring Diagrams is a critical component that empowers technicians and engineers to handle complex electrical connections with confidence. By providing a comprehensive reference guide, these diagrams streamline installation, maintenance, and troubleshooting tasks, contributing to optimal motor performance and system reliability.

Safety

In the context of Leeson Motors Wiring Diagrams, safety emerges as a critical component, emphasizing the crucial role of diagrams in promoting safe electrical practices. These diagrams guide technicians through proper wiring techniques, minimizing the risk of electrical hazards and ensuring the safe operation of Leeson motors.

Real-life examples underscore the significance of safety within Leeson Motors Wiring Diagrams. Incorrect wiring, often caused by misinterpretation or lack of clarity in diagrams, can lead to electrical faults, fires, and other hazardous situations. Accurate and comprehensive diagrams provide clear instructions and visual representations, empowering technicians to establish reliable electrical connections, reducing the likelihood of accidents.

The practical applications of understanding the connection between safety and Leeson Motors Wiring Diagrams extend beyond immediate hazard prevention. By following proper wiring techniques, technicians can ensure optimal motor performance, minimize downtime, and contribute to a safer work environment. Moreover, well-documented diagrams facilitate knowledge transfer and training, promoting standardized and safe practices across teams.

Efficiency

Leeson Motors Wiring Diagrams contribute significantly to the efficiency of troubleshooting and maintenance processes. These diagrams provide clear and concise instructions, enabling technicians to quickly identify and resolve electrical issues, minimizing downtime and maintenance costs. The efficiency gained through the use of Leeson Motors Wiring Diagrams has a direct impact on the overall productivity and profitability of organizations that rely on Leeson motors.

Real-life examples demonstrate the practical significance of efficiency in Leeson Motors Wiring Diagrams. In industrial settings, unplanned downtime can lead to significant financial losses. By facilitating quick and accurate troubleshooting, these diagrams help minimize the duration of downtime, ensuring that motors are back in operation as soon as possible. Additionally, efficient troubleshooting reduces the need for extensive maintenance work, resulting in lower maintenance costs.

The broader connection between efficiency and Leeson Motors Wiring Diagrams lies in the concept of preventive maintenance. By enabling technicians to proactively identify and address potential electrical issues, these diagrams help prevent major breakdowns and costly repairs. This proactive approach contributes to the long-term reliability and performance of Leeson motors, further enhancing efficiency and reducing maintenance costs.

Standardization

Within the context of Leeson Motors Wiring Diagrams, standardization emerges as a critical aspect that promotes consistency and minimizes the risk of misinterpretations. By adhering to industry standards, these diagrams ensure a uniform approach to electrical connections, enabling technicians and engineers to work with Leeson motors confidently and efficiently.

- Uniform Symbolism: Leeson Motors Wiring Diagrams conform to established industry symbols for electrical components and connections. This standardized symbolism facilitates easy recognition and interpretation, reducing the likelihood of errors.

- Consistent Color Coding: Diagrams utilize consistent color coding for wires and terminals, providing a visual cue that simplifies the identification of matching components. This consistency enhances clarity and reduces the risk of misinterpretations.

- Logical Flow: Diagrams are structured according to logical conventions, ensuring a sequential flow of information. This logical flow makes it easier for technicians to trace electrical connections and identify potential issues.

- Clear Annotations: Diagrams include clear annotations and labels that provide additional context and guidance. These annotations minimize ambiguity and ensure accurate interpretation.

The standardization of Leeson Motors Wiring Diagrams has far-reaching implications. It enables seamless collaboration among technicians, reduces training time for new personnel, and minimizes the risk of electrical hazards. By promoting consistency and clarity, standardization contributes to the safe and efficient operation of Leeson motors across various industries.

Technical Support

Within the realm of Leeson Motors Wiring Diagrams, technical support emerges as a crucial aspect, empowering support teams to provide effective assistance with installation and maintenance queries. These diagrams serve as a valuable resource, enabling technicians to access clear and concise instructions, troubleshooting guidance, and component identification information.

- Component Identification: Leeson Motors Wiring Diagrams provide detailed illustrations of motor components, enabling technical support teams to accurately identify and locate specific parts. This facilitates efficient troubleshooting and ensures that replacement parts are correctly selected.

- Troubleshooting Guidance: Diagrams often include troubleshooting tables or flowcharts that guide technicians through a step-by-step process to diagnose and resolve common electrical issues. This structured approach minimizes downtime and helps ensure that motors are restored to optimal operation quickly.

- Installation Assistance: Diagrams provide clear instructions on how to properly install Leeson motors, including wiring configurations, mounting procedures, and grounding requirements. This information is essential for ensuring safe and reliable motor operation.

- Remote Support: In situations where on-site support is not feasible, Leeson Motors Wiring Diagrams enable technical support teams to provide remote assistance. By referring to the diagrams, technicians can guide users through troubleshooting steps or provide advice on specific wiring configurations.

In conclusion, the technical support aspect of Leeson Motors Wiring Diagrams plays a significant role in ensuring the efficient installation, maintenance, and troubleshooting of Leeson motors. These diagrams provide a comprehensive resource for technical support teams, enabling them to quickly and accurately assist customers, minimize downtime, and promote optimal motor performance.

Compliance

In the realm of Leeson Motors Wiring Diagrams, compliance with electrical codes and regulations emerges as a critical aspect, contributing to the safe and reliable operation of these motors. These diagrams play a vital role in ensuring that electrical installations adhere to established standards, minimizing the risk of electrical hazards and ensuring optimal performance.

- Adherence to Safety Standards: Leeson Motors Wiring Diagrams align with recognized safety standards, such as the National Electrical Code (NEC) and the International Electrotechnical Commission (IEC) standards. By following these guidelines, diagrams help ensure that electrical connections meet the required safety criteria, reducing the risk of electrical fires, shocks, and other hazards.

- Compliance with Building Codes: Many regions and municipalities have specific building codes that govern electrical installations. Leeson Motors Wiring Diagrams assist in meeting these requirements by providing guidance on proper wiring methods, grounding techniques, and the use of appropriate materials. This compliance ensures that motors are installed according to local regulations, minimizing the risk of code violations and potential fines.

- Insurance and Liability: Accurate and up-to-date Leeson Motors Wiring Diagrams serve as valuable documentation for insurance purposes. In the event of an electrical incident, these diagrams can provide evidence of proper installation and maintenance, potentially reducing liability and insurance costs.

- Professionalism and Reputation: By adhering to industry standards and regulations, Leeson Motors Wiring Diagrams demonstrate a commitment to professionalism and quality workmanship. This attention to detail enhances the reputation of businesses and individuals involved in the installation and maintenance of electrical systems.

In conclusion, the compliance aspect of Leeson Motors Wiring Diagrams is inextricably linked to the safety, reliability, and overall effectiveness of electrical installations. These diagrams serve as essential tools for ensuring adherence to electrical codes and regulations, promoting safe and efficient operation of Leeson motors, and safeguarding against potential hazards and liabilities.

Training

Within the comprehensive landscape of Leeson Motors Wiring Diagrams, the aspect of training emerges as a crucial element, fostering the development of skilled professionals in the electrical field. These diagrams serve as invaluable training materials for apprentices and practicing electricians, providing a solid foundation for electrical knowledge and practical skills.

- Visual Learning: Leeson Motors Wiring Diagrams offer a visual representation of complex electrical connections, making it easier for apprentices to grasp abstract concepts and understand the practical implementation of electrical principles.

- Step-by-Step Guidance: Diagrams provide apprentices with detailed, step-by-step instructions on how to wire and connect Leeson motors, bridging the gap between theoretical knowledge and hands-on experience.

- Troubleshooting Exercises: Some diagrams include troubleshooting exercises that challenge apprentices to identify and resolve common electrical issues, enhancing their problem-solving abilities and preparing them for real-world scenarios.

- Skill Assessment: Leeson Motors Wiring Diagrams can be used as assessment tools to evaluate the progress and skill level of apprentices and practicing electricians, ensuring they meet the required standards of proficiency.

In conclusion, the role of diagrams in training is integral to the development of competent electricians. Leeson Motors Wiring Diagrams not only provide a valuable resource for apprentices but also serve as a continuous learning tool for practicing professionals, enabling them to stay abreast of the latest industry practices and ensure the safe and efficient operation of Leeson motors.

Related Posts