A Blower Motor Wiring Diagram Manual offers an illustrative guide to the electrical connections and circuitry of a blower motor. It serves as a comprehensive reference for technicians and homeowners alike, providing detailed instructions on how to wire the motor correctly for various applications.

This manual is particularly relevant in the installation, repair, and maintenance of HVAC systems, as well as other industrial and automotive applications where blower motors are utilized. Its meticulous schematics and step-by-step instructions ensure the proper functioning and safety of the equipment. The development of standardized wiring diagrams has been a key historical milestone, simplifying electrical troubleshooting and enhancing system reliability.

With a Blower Motor Wiring Diagram Manual at hand, electricians and technicians gain access to the information necessary to diagnose and rectify electrical issues, optimize motor performance, and ensure the longevity of the equipment. This article will delve into the fundamentals of blower motor wiring, providing a comprehensive understanding of its principles and practical applications.

The essential aspects of a Blower Motor Wiring Diagram Manual are crucial for understanding the intricacies of blower motor wiring. These aspects provide a comprehensive framework for working with blower motors, ensuring safety and optimizing performance.

- Circuitry: The manual outlines the electrical pathways and connections within the motor.

- Components: It identifies the individual components of the motor and their roles.

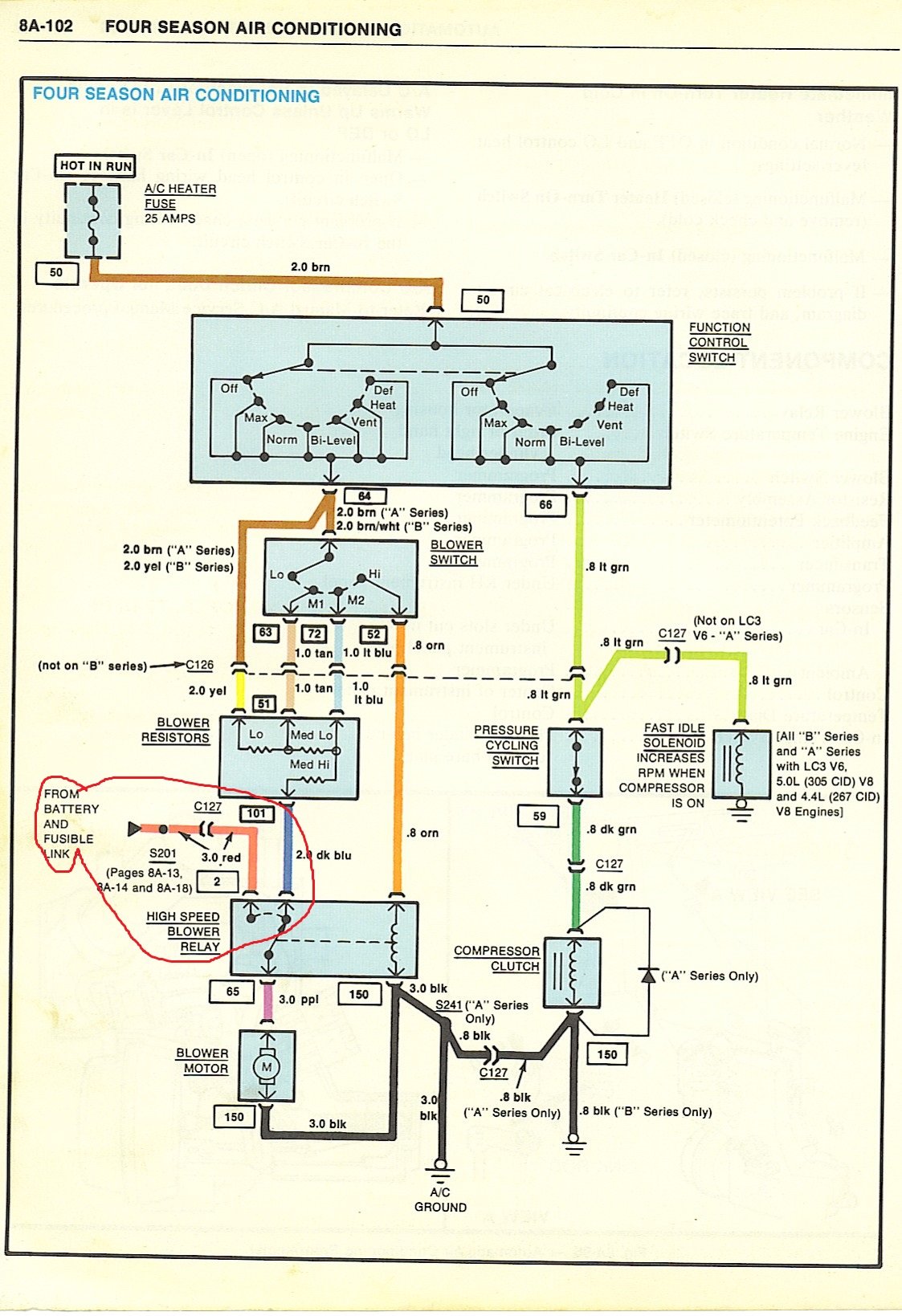

- Diagrams: Schematic representations illustrate the motor’s wiring configurations.

- Instructions: Step-by-step guidance ensures proper wiring and installation.

- Safety: The manual emphasizes electrical safety measures and precautions.

- Troubleshooting: It provides diagnostic procedures for identifying and resolving electrical issues.

- Applications: The manual covers various applications where blower motors are used.

- Codes: It incorporates relevant electrical codes and regulations.

- Maintenance: The manual includes guidelines for maintaining the motor’s performance.

These key aspects are interconnected and essential for comprehending the operation and wiring of blower motors. For instance, understanding the circuitry and components allows technicians to identify potential faults and perform repairs. The diagrams provide a visual representation of the connections, facilitating troubleshooting and ensuring proper installation. Furthermore, adhering to safety guidelines and electrical codes promotes workplace safety and prevents electrical hazards.

Circuitry

The circuitry section of a Blower Motor Wiring Diagram Manual is a critical component that provides a comprehensive understanding of the electrical pathways and connections within the motor. It is a detailed roadmap of how electrical current flows through the motor, allowing technicians to troubleshoot and repair electrical issues efficiently.

Real-life examples of circuitry in a Blower Motor Wiring Diagram Manual include schematics that illustrate the connections between the motor’s terminals, windings, and other electrical components. These schematics are essential for understanding how the motor operates and for diagnosing problems. Without a clear understanding of the circuitry, it would be challenging to identify and resolve electrical faults, potentially leading to motor failure or safety hazards.

The practical significance of understanding circuitry in a Blower Motor Wiring Diagram Manual extends to various applications, including HVAC systems, industrial machinery, and automotive vehicles. By comprehending the electrical pathways and connections, technicians can ensure the proper functioning and safety of these systems. Additionally, they can optimize motor performance, reduce downtime, and extend the lifespan of the equipment.

In summary, the circuitry section of a Blower Motor Wiring Diagram Manual is a crucial element that provides a thorough understanding of the electrical connections and pathways within the motor. It enables technicians to troubleshoot, repair, and maintain blower motors effectively, ensuring optimal performance and safety in diverse applications.

Components

Within the comprehensive framework of a Blower Motor Wiring Diagram Manual, the identification of individual components and their roles plays a pivotal role in understanding the intricacies of blower motor wiring. This aspect provides a thorough breakdown of the motor’s constituent parts, their functions, and their interconnections, forming the foundation for effective troubleshooting, repair, and maintenance.

- Motor Housing: The sturdy exterior casing that encloses and protects the motor’s internal components.

- Stator: The stationary part of the motor that generates a magnetic field, inducing rotation in the rotor.

- Rotor: The rotating component of the motor that interacts with the stator’s magnetic field, producing torque and motion.

- Bearings: Critical components that support the rotor, allowing smooth rotation while minimizing friction and wear.

Comprehending the individual components and their roles empowers technicians to diagnose issues accurately, pinpoint faulty parts, and perform repairs efficiently. By recognizing the function of each component, they can trace electrical pathways, identify potential points of failure, and devise effective maintenance strategies. Ultimately, a thorough understanding of the motor’s components and their interrelationships ensures optimal performance, extends the lifespan of the equipment, and enhances overall system reliability.

Diagrams

In the realm of Blower Motor Wiring Diagram Manuals, diagrams hold immense significance. They provide a visual representation of the motor’s intricate wiring configurations, enabling technicians to comprehend the electrical connections and pathways effortlessly. These visual aids simplify complex concepts, facilitating troubleshooting, repair, and maintenance procedures.

- Circuit Layout: Diagrams depict the arrangement of electrical components, including terminals, windings, and capacitors, offering a comprehensive view of the circuit.

- Wiring Paths: Schematic representations trace the paths of individual wires, indicating their connections to various components, ensuring accurate wiring and minimizing electrical hazards.

- Component Identification: Diagrams label each component clearly, assisting technicians in identifying and locating specific parts for repair or replacement, reducing downtime and enhancing efficiency.

- Troubleshooting Guide: Diagrams serve as invaluable troubleshooting aids, providing visual cues to potential problem areas, expediting the identification and rectification of electrical issues.

In summary, the diagrams in a Blower Motor Wiring Diagram Manual are indispensable tools that visually convey the motor’s wiring configurations. They empower technicians with a comprehensive understanding of the motor’s electrical architecture, enabling effective troubleshooting, repair, and maintenance. These diagrams streamline complex electrical concepts, minimize errors, and promote system reliability, making them essential resources for professionals working with blower motors.

Instructions

Within the context of a Blower Motor Wiring Diagram Manual, instructions hold paramount importance. They provide a structured, step-by-step guide that ensures the proper wiring and installation of the blower motor, minimizing errors and maximizing system performance.

The instructions typically encompass a comprehensive sequence of actions, meticulously detailing the preparation, connection, and testing procedures. They serve as a valuable resource for technicians, guiding them through the intricacies of blower motor wiring, promoting safety, and ensuring adherence to industry standards.

Real-life examples of instructions in a Blower Motor Wiring Diagram Manual include:

- Preparing the motor for installation, including grounding and mounting.

- Connecting the motor to the power supply, following the specified wiring sequence.

- Testing the motor’s operation and verifying its performance.

Understanding and following the instructions in a Blower Motor Wiring Diagram Manual are critical for various practical applications:

- Safe and Reliable Installation: Proper wiring and installation ensure the safe and reliable operation of the blower motor, preventing electrical hazards and potential equipment damage.

- Optimized Performance: Following the recommended instructions optimizes the motor’s performance, ensuring it operates efficiently and delivers the desired airflow.

- Reduced Downtime: Clear and concise instructions minimize the risk of errors during installation and maintenance, reducing downtime and disruptions to the system.

In summary, the instructions in a Blower Motor Wiring Diagram Manual are essential for proper wiring and installation. They provide a step-by-step guide that empowers technicians to work safely and effectively, ensuring optimal motor performance and minimizing downtime. Understanding and adhering to these instructions are crucial for the successful operation and maintenance of blower motors in various industrial and residential applications.

Safety

Within the comprehensive framework of a Blower Motor Wiring Diagram Manual, safety takes paramount importance. The manual underscores essential electrical safety measures and precautions to minimize risks, prevent accidents, and ensure the well-being of personnel working with blower motors. Understanding and adhering to these safety guidelines are paramount for proper installation, maintenance, and operation of blower motors.

- Electrical Hazards: Blower motors involve high electrical currents and voltages, posing potential hazards such as electric shock, short circuits, and fires. The manual provides detailed instructions on grounding, insulation, and proper wiring techniques to mitigate these risks.

- Lockout/Tagout Procedures: The manual emphasizes the importance of lockout/tagout procedures to prevent accidental energization during maintenance or repairs. It outlines step-by-step instructions for isolating the motor from power sources, ensuring the safety of personnel.

- Protective Equipment: The manual stresses the use of appropriate personal protective equipment (PPE) when working with blower motors. This includes insulated gloves, safety glasses, and non-conductive footwear to minimize the risk of electrical shock and injuries.

- Compliance with Codes and Standards: The manual aligns with established electrical codes and safety standards, such as the National Electrical Code (NEC) and Occupational Safety and Health Administration (OSHA) regulations. Adhering to these standards ensures compliance with legal requirements and industry best practices.

By incorporating safety measures and precautions, the Blower Motor Wiring Diagram Manual empowers technicians to work confidently and minimize electrical hazards. These safety guidelines provide a structured framework for safe practices, contributing to a secure work environment and preventing accidents. Understanding and implementing these measures are essential for responsible and professional handling of blower motors in various industrial and commercial applications.

Troubleshooting

The troubleshooting aspect of a Blower Motor Wiring Diagram Manual is a critical component for maintaining optimal motor performance and ensuring system reliability. It provides comprehensive diagnostic procedures, empowering technicians to identify and resolve electrical issues efficiently, minimizing downtime and ensuring the smooth operation of blower motors in various applications.

- Electrical Testing: Troubleshooting involves performing electrical tests, such as continuity checks, voltage measurements, and insulation resistance tests, to pinpoint the source of electrical faults or malfunctions.

- Component Inspection: Visual inspection of motor components, including windings, bearings, and terminals, can reveal signs of damage or wear that may be causing electrical issues.

- Circuit Analysis: Analyzing the electrical circuit, tracing wire connections, and identifying potential loose connections or short circuits helps isolate the problem area.

- Symptom Recognition: Troubleshooting also involves recognizing specific symptoms, such as abnormal noises, excessive vibration, or overheating, which can indicate potential electrical issues and guide the diagnostic process.

By providing a systematic approach to troubleshooting, the Blower Motor Wiring Diagram Manual empowers technicians to diagnose and resolve electrical issues with greater accuracy and efficiency. This ensures the reliable operation of blower motors, minimizes equipment downtime, and promotes a safe and productive work environment.

Applications

Within the comprehensive scope of a Blower Motor Wiring Diagram Manual, the section dedicated to applications holds significant importance. It provides detailed insights into the diverse range of applications where blower motors play a vital role, empowering technicians and engineers to effectively utilize these motors in various settings.

- HVAC Systems: Blower motors are extensively used in heating, ventilation, and air conditioning systems to circulate air, ensuring proper temperature control and indoor air quality.

- Industrial Machinery: Blower motors are employed in a wide range of industrial machinery, including conveyors, fans, and dust collectors, providing efficient air movement and cooling.

- Automotive Applications: Blower motors are essential components in automotive heating and cooling systems, providing airflow for climate control and defogging.

- Electronics Cooling: Blower motors are utilized in electronic devices, such as computers and servers, to dissipate heat and prevent overheating, ensuring optimal performance and longevity.

Understanding the wide range of applications covered in the Blower Motor Wiring Diagram Manual enables technicians and engineers to select the appropriate motor for each specific application, ensuring optimal performance and system reliability. By considering the specific requirements and operating conditions of each application, they can effectively design and implement blower motor systems that meet the desired outcomes.

Codes

Within the comprehensive framework of a Blower Motor Wiring Diagram Manual, the incorporation of relevant electrical codes and regulations is a critical aspect that ensures the safety, reliability, and compliance of blower motor installations. These codes and regulations establish standardized guidelines and requirements for electrical systems, ensuring adherence to industry best practices and minimizing potential hazards.

- National Electrical Code (NEC): The NEC is a widely recognized and adopted electrical code that provides comprehensive regulations for electrical installations, including those involving blower motors. By incorporating NEC requirements, the manual ensures compliance with established safety standards and minimizes electrical hazards.

- Local Building Codes: Local building codes may impose additional regulations specific to the region or municipality where the blower motor is installed. The manual incorporates these local requirements to ensure compliance with local ordinances and building safety standards.

- Manufacturer’s Specifications: Blower motor manufacturers provide specific guidelines and specifications for the installation and operation of their products. The manual incorporates these manufacturer’s recommendations to ensure optimal performance and longevity of the blower motor.

- Industry Standards: Various industry organizations and standards bodies develop guidelines and recommendations for the safe and efficient use of blower motors. The manual aligns with these industry standards to promote best practices and ensure the reliability of blower motor systems.

By incorporating relevant electrical codes and regulations, the Blower Motor Wiring Diagram Manual empowers technicians and engineers to design and implement blower motor systems that meet the highest safety and performance standards. Adherence to these codes and regulations ensures the protection of personnel, the integrity of electrical systems, and the overall reliability of blower motor applications.

Maintenance

Within the comprehensive framework of a Blower Motor Wiring Diagram Manual, the section dedicated to maintenance plays a pivotal role in ensuring the sustained performance and longevity of blower motors. This section provides detailed guidelines and recommendations for regular maintenance procedures, enabling technicians and engineers to proactively care for and maintain blower motors, minimizing downtime and optimizing their lifespan.

The importance of maintenance within a Blower Motor Wiring Diagram Manual stems from the critical role that blower motors play in various applications. Blower motors are responsible for circulating air in HVAC systems, providing cooling in electronic devices, and driving industrial machinery. Regular maintenance ensures that these motors operate at peak efficiency, delivering consistent airflow and performance over an extended period.

Real-life examples of maintenance guidelines found in a Blower Motor Wiring Diagram Manual include periodic cleaning and inspection of the motor, lubrication of bearings, and monitoring of operating temperature. These routine maintenance tasks help prevent the accumulation of dust and debris, reduce friction, and identify potential issues before they escalate into major problems. By adhering to the recommended maintenance schedule, technicians can minimize the risk of motor failure, extend its lifespan, and ensure reliable operation.

The practical significance of understanding maintenance guidelines in a Blower Motor Wiring Diagram Manual lies in the direct impact it has on the performance, efficiency, and longevity of blower motors. Regular maintenance helps maintain optimal airflow, reduces energy consumption, and minimizes the likelihood of costly repairs. By incorporating maintenance guidelines into their practices, technicians and engineers can proactively manage blower motor systems, ensuring they operate reliably and efficiently throughout their service life.

Related Posts