Definite Purpose Contactor Wiring Diagram: A detailed plan illustrating the electrical connections required for contactor-based control systems designed to perform specific tasks. It outlines the wiring configuration for controlling electrical loads, such as motors, solenoids, and lighting.

Importance, Benefits, and Historical Context:

- Ensures safe and reliable operation of contactor-controlled systems.

- Simplifies troubleshooting and maintenance tasks.

- Improves efficiency and performance by optimizing the electrical connections.

Historically, definite purpose contactor wiring diagrams emerged as essential tools in industrial automation, providing a standardized framework for electrical contractors and engineers.

Transition: This article delves deeper into the intricacies of definite purpose contactor wiring diagrams, exploring their components, applications, and the latest advancements in the field. Readers will gain valuable insights into electrical control systems design and implementation.

Essential Aspects of Definite Purpose Contactor Wiring Diagrams: Understanding the core aspects of definite purpose contactor wiring diagrams is crucial for designing, installing, and maintaining electrical control systems effectively. These diagrams provide a comprehensive blueprint for the electrical connections required to control loads such as motors, solenoids, and lighting. Here are eight key aspects to consider:

- Components: Contactors, overload relays, timers, and other electrical devices used in the diagram.

- Circuit Protection: Fuses, circuit breakers, and other protective devices to safeguard the system from electrical faults.

- Control Logic: The logic behind the contactor’s operation, including start/stop sequences and interlocks.

- Power Distribution: The flow of electricity through the diagram, from the power source to the loads.

- Grounding: The proper grounding of the system to ensure electrical safety and prevent shock hazards.

- Wire Selection: The type and size of wires used in the diagram, based on current carrying capacity and voltage requirements.

- Documentation: Clear and accurate documentation of the diagram, including wire numbers, terminal connections, and any special instructions.

- Compliance: Adherence to electrical codes and standards to ensure safety and reliability.

These aspects are interconnected and essential for creating functional and reliable contactor wiring diagrams. By understanding and considering each aspect carefully, electrical professionals can ensure the safe and efficient operation of electrical control systems.

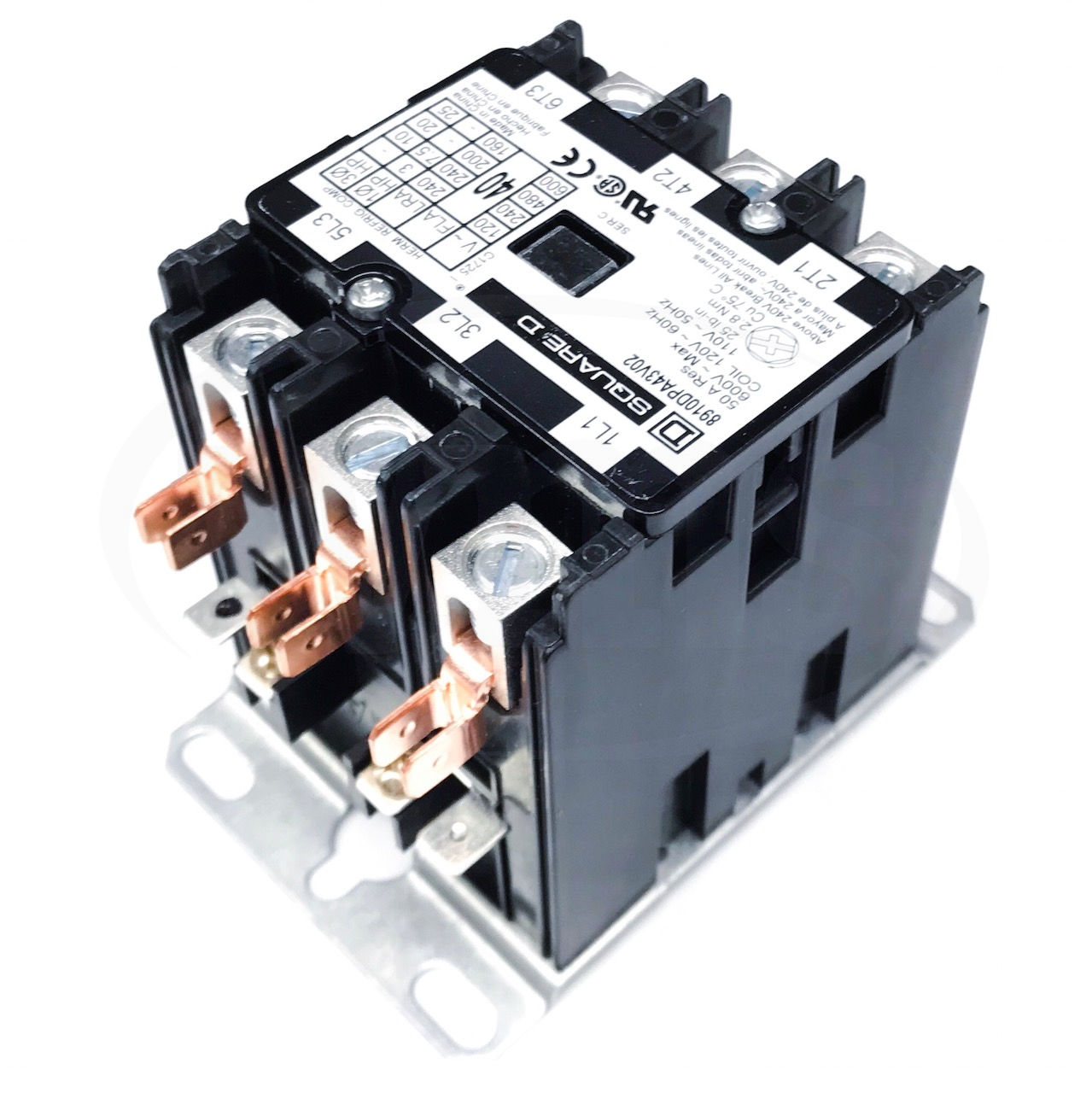

Components: Contactors, overload relays, timers, and other electrical devices used in the diagram.

In a definite purpose contactor wiring diagram, the selection and arrangement of electrical components play a critical role in achieving the desired control functionality. Contactors, overload relays, timers, and other devices work in conjunction to provide safe and reliable operation of electrical loads, such as motors, solenoids, and lighting. Here’s how these components contribute to the overall function of a definite purpose contactor wiring diagram:

- Contactors: Contactors are electromagnetic switches that control the flow of electricity to the load. They are actuated by a coil and have multiple contacts that open and close to make or break the circuit.

- Overload relays: Overload relays protect the motor from damage caused by excessive current draw. They monitor the current flowing through the motor and trip the contactor if the current exceeds a predetermined limit.

- Timers: Timers are used to control the duration of contactor operation. They can be used to delay the start of the motor, stop the motor after a set period of time, or provide timed intervals for sequential operation.

The proper selection and configuration of these components are essential for the safe and reliable operation of the electrical control system. By understanding the function and interconnections of these components, electrical professionals can design and implement effective contactor wiring diagrams for a wide range of applications.

Circuit Protection: Fuses, circuit breakers, and other protective devices to safeguard the system from electrical faults.

In definite purpose contactor wiring diagrams, circuit protection plays a critical role in ensuring the safety and reliability of electrical control systems. Fuses, circuit breakers, and other protective devices are essential components of these diagrams, as they safeguard the system from electrical faults that could lead to damage or injury.

Circuit protection devices function by interrupting the flow of electricity when an electrical fault occurs. Fuses melt and break the circuit when the current exceeds a predetermined limit, while circuit breakers trip and open the circuit. This rapid response time helps to prevent damage to electrical components and wiring, as well as reducing the risk of electrical fires.

In definite purpose contactor wiring diagrams, circuit protection devices are strategically placed throughout the system to provide protection for specific components and circuits. For example, a fuse may be placed in series with a contactor coil to protect it from damage caused by a short circuit. Circuit breakers may be used to protect motors and other loads from overcurrent conditions.

The proper selection and installation of circuit protection devices is essential for the safe operation of electrical control systems. By understanding the importance of circuit protection and the function of different protective devices, electrical professionals can design and implement definite purpose contactor wiring diagrams that meet the highest standards of safety and reliability.

Control Logic: The logic behind the contactor’s operation, including start/stop sequences and interlocks.

In definite purpose contactor wiring diagrams, control logic plays a central role in defining the behavior and functionality of the electrical control system. It encompasses the logic behind the contactor’s operation, including start/stop sequences and interlocks, ensuring that the system operates safely, efficiently, and according to the desired specifications.

- Sequencing: Sequencing logic defines the order in which contactors are energized and de-energized to achieve the desired sequence of operations. This is particularly important in complex systems where multiple contactors are involved and a specific sequence of events is required.

- Interlocks: Interlocks are logic conditions that prevent certain operations from occurring unless certain conditions are met. For example, an interlock may prevent a motor from starting if a safety guard is not in place, ensuring the safety of personnel.

- Timers: Timers are used to introduce time delays into the control logic. This can be used to delay the start of a motor, stop a motor after a set period of time, or create timed intervals for sequential operation.

- Feedback: Feedback loops are used to monitor the status of the system and provide feedback to the control logic. This allows the system to respond to changes in operating conditions and adjust its behavior accordingly, improving overall performance and reliability.

Understanding and designing effective control logic is essential for the proper operation of definite purpose contactor wiring diagrams. By carefully considering the sequencing, interlocks, timers, and feedback mechanisms, electrical professionals can create control systems that are safe, efficient, and meet the specific requirements of the application.

Power Distribution: The flow of electricity through the diagram, from the power source to the loads.

In the context of definite purpose contactor wiring diagrams, power distribution plays a critical role in ensuring that electrical power is delivered safely and efficiently from the power source to the intended loads. It involves the proper sizing and routing of conductors, selection of appropriate circuit protection devices, and consideration of voltage drop and power quality.

- Components: Contactors, overload relays, fuses, circuit breakers, and wires are key components involved in power distribution within a definite purpose contactor wiring diagram.

- Real-Life Examples: Industrial machinery, HVAC systems, and lighting circuits are common examples where definite purpose contactor wiring diagrams are used to distribute power safely and efficiently.

- Implications: Proper power distribution is essential for the reliable operation of electrical systems, preventing damage to equipment and ensuring the safety of personnel.

- Voltage Drop and Power Quality: Considerations such as voltage drop and power quality are crucial in power distribution to ensure that the voltage supplied to the loads is within acceptable limits and that the power quality meets the specific requirements of the application.

Understanding the principles of power distribution is essential for electrical professionals to design and implement effective definite purpose contactor wiring diagrams. By carefully considering the components, real-life examples, and implications of power distribution, they can create electrical control systems that are safe, efficient, and meet the specific requirements of the application.

Grounding: The proper grounding of the system to ensure electrical safety and prevent shock hazards.

In the context of definite purpose contactor wiring diagrams, grounding plays a critical role in ensuring the safe and reliable operation of electrical control systems. It involves connecting the electrical system to the earth ground, providing a low-resistance path for electrical current to flow in the event of a fault or surge.

- Components: Ground rods, grounding conductors, and grounding terminals are key components involved in grounding a definite purpose contactor wiring diagram.

- Real-Life Examples: Industrial machinery, data centers, and residential buildings are common examples where proper grounding is essential to prevent electrical shock and ensure the safety of personnel and equipment.

- Implications: Grounding helps protect against electrical shock by providing a safe path for fault currents to flow, preventing them from passing through the body.

- Safety Standards: Electrical codes and regulations mandate proper grounding to ensure compliance with safety standards and minimize the risk of electrical accidents.

Understanding the importance and principles of grounding is essential for electrical professionals to design and implement effective definite purpose contactor wiring diagrams. By carefully considering the components, real-life examples, and implications of grounding, they can create electrical control systems that are safe, reliable, and meet the specific requirements of the application.

Wire Selection: The type and size of wires used in the diagram, based on current carrying capacity and voltage requirements.

In the context of definite purpose contactor wiring diagrams, wire selection plays a crucial role in ensuring the safe and reliable operation of electrical control systems. It involves choosing the appropriate type and size of wires based on their current carrying capacity and voltage requirements, ensuring that the wires can safely handle the electrical load without overheating or causing voltage drop.

- Current Carrying Capacity: The current carrying capacity of a wire refers to the maximum amount of electrical current that can safely flow through it without overheating. Factors to consider include the wire’s material, cross-sectional area, and ambient temperature.

- Voltage Requirements: The voltage requirements of a wire refer to its ability to withstand the voltage applied to it without breaking down. Factors to consider include the wire’s insulation type and thickness.

- Real-Life Examples: In industrial settings, motor control panels often use large gauge wires to handle high current loads. In residential buildings, smaller gauge wires are used for lighting and power outlets.

- Implications: Improper wire selection can lead to overheating, voltage drop, and electrical fires. By carefully considering the current carrying capacity and voltage requirements, electrical professionals can ensure the safe and efficient operation of electrical control systems.

Understanding the principles and implications of wire selection is essential for electrical professionals to design and implement effective definite purpose contactor wiring diagrams. By carefully considering the factors discussed above, they can choose the appropriate wires that meet the specific requirements of the application, ensuring the safety and reliability of the electrical control system.

Documentation: Clear and accurate documentation of the diagram, including wire numbers, terminal connections, and any special instructions.

In the context of definite purpose contactor wiring diagrams, clear and accurate documentation is a critical component that ensures the proper installation, maintenance, and troubleshooting of electrical control systems.

Proper documentation includes:

- Wire numbers: Identifying each wire by its unique number allows for easy tracing and troubleshooting.

- Terminal connections: Documenting the specific terminals where each wire is connected provides a clear understanding of the circuit’s layout.

- Special instructions: Any specific instructions or notes regarding the installation or operation of the system should be clearly documented.

Without clear documentation, it becomes challenging to make changes or troubleshoot issues within the electrical control system. Accurate documentation serves as a valuable resource for electricians and maintenance personnel, enabling them to quickly identify and resolve any problems that may arise.

Real-life examples of the importance of documentation in definite purpose contactor wiring diagrams can be found in various industrial and commercial settings.

For instance, in a manufacturing plant, a definite purpose contactor wiring diagram may control a complex system of machinery. Proper documentation ensures that maintenance technicians can quickly identify the specific wires and terminals involved in the event of a malfunction. This allows for efficient troubleshooting and minimizes downtime.

In conclusion, clear and accurate documentation is an integral part of definite purpose contactor wiring diagrams. It provides a roadmap for installation, maintenance, and troubleshooting, ensuring the safe and reliable operation of electrical control systems.

Compliance: Adherence to electrical codes and standards to ensure safety and reliability.

Within the realm of definite purpose contactor wiring diagrams, compliance with electrical codes and standards is paramount for ensuring the safety and reliability of electrical control systems. By adhering to established guidelines, electrical professionals can minimize risks, prevent accidents, and guarantee the proper functioning of these systems.

- Code Requirements: Electrical codes, such as the National Electrical Code (NEC) or IEC standards, provide detailed regulations governing the design, installation, and maintenance of electrical systems. These codes specify requirements for wire sizes, circuit protection, grounding, and other aspects, ensuring compliance with safety standards.

- Safety Precautions: Compliance with electrical codes helps prevent electrical hazards such as shocks, fires, and explosions. Proper grounding, circuit protection devices, and adherence to safe wiring practices minimize the risk of electrical accidents and protect personnel and equipment.

- Reliability and Performance: Wiring diagrams that comply with electrical codes and standards promote the reliable operation of electrical control systems. By following prescribed guidelines, electrical professionals can ensure that systems meet performance expectations, minimize downtime, and extend the lifespan of equipment.

- Legal and Insurance Implications: Compliance with electrical codes and standards has legal and insurance implications. Failure to adhere to these regulations may result in legal liabilities, insurance claim denials, or fines. By maintaining compliance, electrical professionals can protect their businesses and clients.

In conclusion, adherence to electrical codes and standards is a critical aspect of definite purpose contactor wiring diagrams. By following established guidelines, electrical professionals can ensure the safety, reliability, and legal compliance of electrical control systems, protecting personnel, equipment, and the integrity of the electrical infrastructure.

Related Posts