Wiring batteries in parallel connects the positive terminals together and the negative terminals together, while wiring them in series connects the positive terminal of one battery to the negative terminal of the next. A real-world example is a flashlight that uses two batteries in series to power its bulb.

Wiring batteries in parallel increases their total voltage while keeping their combined amperage the same. Wiring batteries in series increases their total amperage while keeping their combined voltage the same. A key historical development in battery technology was the invention of the lead-acid battery in 1859.

This article will explore the benefits, drawbacks, and applications of wiring batteries in parallel and series, providing insights into the practical implications of these techniques in various electronic systems.

Understanding the essential aspects of wiring batteries in parallel and series is crucial for designing and maintaining electrical systems. These aspects encompass the fundamental characteristics and applications of these wiring methods.

- Voltage: Combining batteries in series increases voltage.

- Current: Connecting batteries in parallel increases current.

- Capacity: Wiring batteries in parallel increases capacity.

- Efficiency: Series wiring provides higher efficiency in high-voltage applications.

- Cost: Parallel wiring can be more cost-effective for low-voltage systems.

- Safety: Series wiring allows for individual battery monitoring and protection.

- Applications: Parallel wiring is suitable for high-current devices, while series wiring is ideal for high-voltage applications.

- Limitations: Parallel wiring can lead to overcurrent, while series wiring has voltage limitations.

- Maintenance: Series wiring requires balancing to ensure equal voltage distribution.

- Design considerations: Battery type, load requirements, and safety factors influence the choice of wiring method.

These aspects highlight the importance of carefully considering the requirements of the electrical system when wiring batteries. By understanding the implications of each aspect, engineers and technicians can optimize the performance, efficiency, and safety of their battery systems.

Voltage

In the context of wiring batteries in parallel vs series, understanding the impact of series wiring on voltage is crucial. When batteries are connected in series, their voltages add up, while their currents remain the same. This principle underpins various applications and has specific implications in electrical systems.

- Cumulative Voltage: Connecting batteries in series directly increases the total voltage available. This is particularly useful in applications that require higher voltages, such as electric vehicles or industrial machinery.

- Independent Power Sources: Each battery in a series configuration acts as an independent power source. This allows for modularity and flexibility in system design, as batteries can be added or removed to adjust the overall voltage.

- Voltage Multipliers: Series wiring is commonly used in voltage multipliers, which are circuits designed to generate higher voltages from lower voltage sources. These multipliers are essential in applications like CRT displays and particle accelerators.

- Battery Management: In series configurations, each battery experiences the full system voltage. Therefore, careful monitoring and management are necessary to prevent overcharging or damage to individual batteries.

In summary, connecting batteries in series provides a straightforward method to increase the overall voltage in an electrical system. This technique has wide-ranging applications, from powering high-voltage devices to designing voltage multipliers. However, it is important to consider the implications on battery management and system safety when implementing series wiring.

Current

In the context of “Wiring Batteries in Parallel vs Series,” understanding the relationship between current and parallel wiring is crucial. When batteries are connected in parallel, their currents add up, while their voltages remain the same. This principle has significant implications in electrical systems and opens up various applications.

Parallel wiring effectively increases the overall current capacity of the system. By connecting multiple batteries in parallel, the total current available to power devices or circuits increases proportionally. This is particularly advantageous in applications that demand high currents, such as electric motors, power tools, and audio amplifiers. In such scenarios, parallel wiring ensures that the combined current output meets the load requirements.

Real-life examples of “Current: Connecting batteries in parallel increases current.” within “Wiring Batteries in Parallel Vs Series” are prevalent in our daily lives. For instance, portable power banks often employ multiple batteries connected in parallel to provide higher current output for charging electronic devices. Similarly, electric vehicles utilize multiple battery packs wired in parallel to deliver the high currents needed to power their electric motors.

Understanding this relationship is critical for designing and maintaining electrical systems. By carefully configuring batteries in parallel, engineers and technicians can optimize the current capacity of the system to meet specific load requirements. This knowledge also aids in selecting appropriate battery configurations for various applications, ensuring efficient and reliable power delivery.

Capacity

Within the context of “Wiring Batteries In Parallel Vs Series,” understanding the aspect of “Capacity: Wiring batteries in parallel increases capacity.” is paramount. This principle plays a crucial role in various applications and has specific implications in electrical systems.

- Cumulative Capacity: Connecting batteries in parallel directly increases the total capacity available. This is particularly useful in applications that require longer runtimes, such as backup power systems or electric vehicles.

- Extended Runtime: Each battery in a parallel configuration contributes its capacity to the overall system. This allows for extended runtime and reduces the need for frequent battery replacements.

- Modular Design: Parallel wiring provides a modular approach to capacity management. Batteries can be easily added or removed to adjust the overall capacity as needed.

- Balanced Discharge: In parallel configurations, the current is distributed evenly among the batteries, ensuring balanced discharge and prolonging the lifespan of each battery.

In summary, connecting batteries in parallel offers a straightforward method to increase the overall capacity of an electrical system. This technique has wide-ranging applications, from extending runtime in backup power systems to providing longer operating times for electric vehicles. By carefully configuring batteries in parallel, engineers and technicians can optimize the capacity of the system to meet specific requirements and ensure reliable power delivery.

Efficiency

When considering “Wiring Batteries In Parallel Vs Series,” understanding the aspect of efficiency in series wiring is crucial. In high-voltage applications, series wiring offers distinct advantages, leading to improved efficiency and optimized performance.

- Reduced Losses: In series wiring, the current flows through each battery sequentially, minimizing the internal resistance and reducing energy losses compared to parallel wiring.

- Voltage Regulation: Series wiring allows for better voltage regulation, as the combined voltage of the batteries is directly applied to the load, resulting in more stable and consistent power delivery.

- Lower Heat Dissipation: Due to reduced losses and better voltage regulation, series wiring generates less heat, improving the overall efficiency of the system and extending component life.

- Compact Design: Series wiring often requires fewer components and a more compact design compared to parallel wiring, making it suitable for space-constrained applications.

These factors collectively contribute to the higher efficiency of series wiring in high-voltage applications. By minimizing losses, regulating voltage, reducing heat dissipation, and enabling compact designs, series wiring enhances the overall performance and efficiency of electrical systems.

Cost

When considering “Wiring Batteries In Parallel Vs Series,” understanding the aspect of cost in relation to parallel wiring is crucial. In low-voltage systems, parallel wiring often presents a more cost-effective solution, offering several advantages and implications.

- Fewer Batteries: Parallel wiring requires fewer batteries to achieve the desired voltage, making it a more economical option for low-voltage applications where high currents are not necessary.

- Lower Battery Cost: In general, batteries with lower voltage ratings are more cost-effective than their higher voltage counterparts. Parallel wiring allows the use of these lower voltage batteries, reducing the overall cost of the battery system.

- Simplified Wiring: Parallel wiring is relatively straightforward and requires less complex connections compared to series wiring. This simplicity can lead to lower labor and assembly costs.

- Easier Maintenance: In a parallel configuration, batteries can be individually replaced or serviced without affecting the rest of the system. This ease of maintenance can save time and costs over the lifetime of the system.

These factors collectively contribute to the cost-effectiveness of parallel wiring in low-voltage systems. By utilizing fewer, lower-cost batteries, simplifying wiring, and easing maintenance, parallel wiring offers a more economical solution for applications where high voltages are not required.

Safety

In the context of “Wiring Batteries In Parallel Vs Series,” the aspect of safety becomes paramount when considering series wiring. Unlike parallel wiring, where batteries are connected in parallel, series wiring connects batteries in sequence, offering unique advantages in terms of safety and system protection.

Series wiring allows each battery in the system to be individually monitored and protected. This is achieved by connecting a monitoring device, such as a voltage or current sensor, to each battery. By continuously monitoring each battery’s performance, the system can quickly detect any irregularities or potential issues, such as overcharging or discharging, and take appropriate action to protect the battery and the overall system.

The ability to individually monitor and protect batteries is particularly important in applications where battery safety is critical. For instance, in electric vehicles, series wiring allows for the monitoring of each battery cell within the battery pack. This ensures that individual cells are operating within safe parameters, preventing catastrophic failures that could lead to fires or explosions.

Therefore, the safety advantage of series wiring makes it a preferred choice in applications where battery safety and reliability are of utmost importance. By enabling individual battery monitoring and protection, series wiring helps prevent system failures, ensures operational safety, and extends the lifespan of the battery system.

Applications

In the realm of “Wiring Batteries In Parallel Vs Series,” the topic of applications holds significant importance. Understanding the specific applications where parallel wiring excels for high-current devices and where series wiring reigns supreme for high-voltage applications provides valuable insights for system design and optimization.

- Electric Vehicles: Electric vehicles heavily rely on high-current batteries to power their motors. Parallel wiring allows multiple batteries to be connected in parallel, increasing the overall current capacity and meeting the high current demands of electric motors.

- Power Tools: Power tools often require high currents to operate. Parallel wiring enables the combination of multiple batteries, increasing the total current output and providing the necessary power for demanding tasks.

- Medical Equipment: Certain medical devices, such as defibrillators and surgical lasers, require high-voltage batteries. Series wiring allows multiple batteries to be connected in series, increasing the overall voltage and meeting the specific voltage requirements of these devices.

- Industrial Machinery: Heavy machinery used in industrial settings often utilizes high-voltage motors. Series wiring enables the connection of multiple batteries in series, providing the necessary voltage to power these motors and drive industrial processes.

These applications exemplify the practical implications of “Applications: Parallel wiring is suitable for high-current devices, while series wiring is ideal for high-voltage applications.” By carefully considering the current and voltage requirements of specific devices and systems, engineers can determine the most appropriate wiring configuration, ensuring optimal performance, efficiency, and safety.

Limitations

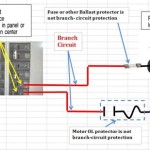

Understanding the limitations associated with wiring batteries in parallel and series is crucial for the safe and efficient design of electrical systems. In parallel wiring, connecting batteries in parallel increases the overall current capacity. However, this configuration can lead to overcurrent conditions if the load draws more current than the individual batteries can safely handle. Overcurrent can result in excessive heat generation, damage to the batteries, and potential fire hazards.

Conversely, series wiring increases the overall voltage while maintaining the same current capacity. However, this configuration has voltage limitations. Connecting too many batteries in series can result in a voltage that exceeds the safe operating range of the load or the insulation materials used in the system. High voltage can lead to electrical arcing, insulation breakdown, and potential safety hazards.

Real-life examples of these limitations can be seen in various applications. For instance, in automotive electrical systems, batteries are typically connected in parallel to provide sufficient current for starting the engine and powering electrical components. However, if an excessive load is placed on the system, such as operating multiple high-power accessories simultaneously, it can lead to overcurrent and potential damage to the batteries.

In contrast, in high-voltage applications, such as industrial machinery or power transmission systems, batteries are often connected in series to achieve the necessary voltage levels. However, careful consideration must be given to the voltage limitations of the system components and insulation materials to prevent electrical hazards.

Understanding these limitations is essential for designing reliable and safe electrical systems. Engineers and technicians must carefully calculate the current and voltage requirements of the load and select the appropriate wiring configuration to ensure that the batteries operate within their safe operating limits. By addressing these limitations, system designers can prevent potential hazards, extend battery life, and ensure the optimal performance of electrical systems.

Maintenance

In the context of “Wiring Batteries In Parallel Vs Series,” maintenance plays a critical role in ensuring the longevity and reliability of the battery system. Series wiring, in particular, requires careful balancing to maintain equal voltage distribution across the individual batteries, presenting unique maintenance considerations.

- Battery Aging: Over time, batteries naturally age, leading to variations in their internal resistance and capacity. These differences can cause imbalances in voltage distribution, affecting the overall performance and lifespan of the battery system.

- Load Variations: The load connected to the battery system can also impact voltage distribution. Uneven load distribution can lead to overcharging or undercharging of certain batteries, reducing their life and increasing the risk of premature failure.

- Temperature Effects: Temperature variations can affect the voltage output of batteries. Batteries operating at different temperatures may experience voltage imbalances, requiring adjustments to maintain equal voltage distribution.

- Monitoring and Maintenance: Regular monitoring of individual battery voltages and timely maintenance are crucial to ensure equal voltage distribution. This may involve periodic rebalancing of the batteries using chargers or balancing circuits to compensate for variations and maintain optimal performance.

Understanding these maintenance considerations is essential for maintaining a reliable and efficient series-wired battery system. By addressing potential imbalances through proper monitoring, maintenance, and balancing techniques, the longevity and performance of the battery system can be significantly enhanced.

Design considerations

When considering “Wiring Batteries In Parallel Vs Series,” understanding the design considerations that influence the choice of wiring method is crucial. These factors encompass a range of aspects, including battery type, load requirements, and safety factors, which must be carefully evaluated to ensure optimal performance, efficiency, and safety in the intended application.

- Battery Type: Different battery types, such as lead-acid, lithium-ion, and nickel-cadmium, possess unique characteristics that influence their suitability for parallel or series wiring. Factors like voltage, capacity, and internal resistance must be considered to ensure compatibility and optimal performance.

- Load Requirements: The load to be powered by the battery system plays a significant role in determining the wiring method. High-current loads require parallel wiring to increase current capacity, while high-voltage loads may necessitate series wiring to achieve the desired voltage levels.

- Safety Factors: Safety considerations, such as overcurrent and overvoltage protection, must be taken into account when choosing the wiring method. Series wiring allows for individual battery monitoring and protection, while parallel wiring may require additional safety measures to prevent overcurrent conditions.

- Cost and Space Constraints: Cost and space limitations can also influence the choice of wiring method. Parallel wiring typically requires more batteries and wiring, increasing the cost and space requirements, while series wiring may offer a more compact and cost-effective solution in certain applications.

By carefully considering these design considerations, engineers and technicians can make informed decisions about the choice of wiring method for their specific application, ensuring a reliable, efficient, and safe battery system.

Related Posts