14/2 vs. 12/2 Wiring, denoted by its gauge (thickness) and number of current-carrying conductors, refers to electrical wiring commonly used in residential and commercial buildings.

14/2 Wiring is typically used for lighting circuits, while 12/2 Wiring is used for general-purpose outlets and appliances requiring higher current. Both types offer advantages in terms of flexibility, cost-effectiveness, and safety.

Understanding the differences between 14/2 and 12/2 wiring is essential for ensuring proper electrical installation and meeting safety codes. This article delves into the technical details, applications, and considerations associated with these two common wiring configurations.

Understanding the essential aspects of 14/2 vs. 12/2 Wiring is crucial for ensuring proper electrical installation and adherence to safety codes. These aspects encompass various dimensions, including:

- Gauge

- Number of Conductors

- Current Capacity

- Voltage Rating

- Insulation Type

- Flexibility

- Cost

- Applications

Each of these aspects plays a significant role in determining the suitability of 14/2 or 12/2 wiring for a specific application. For instance, gauge and current capacity directly impact the amount of current the wire can safely carry, while insulation type influences its resistance to heat and moisture. Understanding these aspects enables informed decision-making and ensures the safe and efficient operation of electrical systems.

Gauge

In the context of “14/2 Vs 12/2 Wiring”, “Gauge” primarily refers to the thickness or diameter of the electrical wire. It is a crucial aspect that directly influences the current-carrying capacity, voltage rating, and overall performance of the wiring system.

-

Conductor Thickness

Conductor thickness, measured in American Wire Gauge (AWG), determines the amount of current the wire can safely carry. Thicker conductors, such as those in 12/2 wiring, have a lower resistance and can handle higher currents. -

Current Capacity

The current capacity of a wire is directly related to its gauge. 14/2 wiring has a current capacity of 15 amps, while 12/2 wiring can handle up to 20 amps. This difference is significant when considering the power requirements of various electrical devices. -

Voltage Rating

The voltage rating of a wire indicates the maximum voltage it can withstand without breaking down. Both 14/2 and 12/2 wiring are typically rated for 600 volts, making them suitable for most residential and commercial applications. -

Flexibility

Gauge also affects the flexibility of the wire. Thinner conductors, such as those in 14/2 wiring, are more flexible and easier to work with in tight spaces. This flexibility is particularly beneficial for DIY electrical projects or when installing wiring in confined areas.

Understanding the gauge of electrical wire is essential for selecting the appropriate wiring for a specific application. By considering factors such as current capacity, voltage rating, and flexibility, electricians and homeowners can ensure the safe and efficient operation of their electrical systems.

Number of Conductors

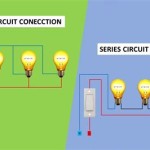

The “number of conductors” in “14/2 Vs 12/2 Wiring” refers to the quantity of current-carrying wires within the cable. This aspect is crucial because it directly influences the type of electrical circuits that can be supported and the overall functionality of the wiring system.

In the context of “14/2 Vs 12/2 Wiring”, the number of conductors is always 2. However, the difference lies in the gauge of these conductors. 14/2 wiring has two 14-gauge conductors, while 12/2 wiring has two 12-gauge conductors. This difference in gauge affects the current-carrying capacity, voltage rating, and flexibility of the wiring.

Understanding the relationship between the number of conductors and gauge is essential for selecting the appropriate wiring for a specific application. For instance, 14/2 wiring with its two 14-gauge conductors is commonly used for lighting circuits, which typically require lower current. On the other hand, 12/2 wiring with its two 12-gauge conductors is suitable for general-purpose outlets and appliances that demand higher current.

In conclusion, the number of conductors in “14/2 Vs 12/2 Wiring” is a critical component that determines the wiring’s capabilities and applications. By considering the number of conductors in conjunction with gauge, voltage rating, and flexibility, electricians and homeowners can ensure the safe and efficient operation of their electrical systems.

Current Capacity

Within the context of “14/2 Vs 12/2 Wiring”, “Current Capacity” stands as a pivotal aspect that directly influences the safety and effectiveness of electrical installations. It refers to the maximum amount of electrical current that a wire can safely carry without overheating or causing damage to the wiring system or connected devices.

-

Conductor Material

The material used for the conductors, typically copper or aluminum, significantly impacts current capacity. Copper, with its lower resistance, allows for higher current flow compared to aluminum.

-

Wire Gauge

The gauge of the wire, measured in American Wire Gauge (AWG), is inversely related to current capacity. Thicker wires, such as 12-gauge, have lower resistance and can carry more current than thinner wires, like 14-gauge.

-

Insulation Type

The type of insulation surrounding the conductors affects current capacity. thicker insulation provides better protection against heat buildup, enabling the wire to carry higher currents.

-

Ambient Temperature

The ambient temperature surrounding the wire influences current capacity. Higher temperatures can reduce the wire’s ability to dissipate heat, necessitating the use of wires with higher current ratings in warmer environments.

Understanding the factors that affect current capacity is crucial for selecting the appropriate wiring for a specific application. By considering the conductor material, wire gauge, insulation type, and ambient temperature, electricians and homeowners can ensure that their electrical systems operate safely and efficiently, minimizing the risk of electrical hazards such as overheating and fires.

Voltage Rating

Within the context of “14/2 Vs 12/2 Wiring”, “Voltage Rating” holds significant importance as it determines the maximum voltage that a wire can withstand without experiencing damage or insulation breakdown. Understanding voltage rating is essential for ensuring the safe and efficient operation of electrical systems.

-

Conductor Insulation

The insulation surrounding the conductors plays a crucial role in determining the voltage rating. Thicker and higher-quality insulation provides greater protection against voltage spikes and surges.

-

Wire Gauge

The gauge of the wire, measured in American Wire Gauge (AWG), also influences the voltage rating. Thicker wires, such as 12-gauge, can withstand higher voltages compared to thinner wires, like 14-gauge.

-

Environmental Conditions

Environmental factors such as humidity, temperature, and exposure to chemicals can affect the voltage rating of a wire. Wires installed in harsh environments may require higher voltage ratings.

-

NEC Requirements

The National Electrical Code (NEC) sets specific voltage rating requirements for different types of electrical installations. These requirements help ensure the safety and reliability of electrical systems.

Understanding the components and implications of “Voltage Rating” is critical for selecting the appropriate wiring for a specific application. By considering conductor insulation, wire gauge, environmental conditions, and NEC requirements, electricians and homeowners can ensure that their electrical systems operate safely and efficiently, minimizing the risk of electrical hazards.

Insulation Type

Within the context of “14/2 Vs 12/2 Wiring”, “Insulation Type” holds critical importance as it directly influences the safety and reliability of electrical systems. The type of insulation used around the conductors determines their ability to withstand voltage, resist heat, and protect against environmental factors.

-

Material

Insulation materials, such as PVC, rubber, or polyethylene, vary in their electrical properties, temperature resistance, and flexibility. The choice of material depends on the specific application and environmental conditions.

-

Thickness

The thickness of the insulation affects its voltage rating and ability to withstand heat. Thicker insulation provides greater protection but may also increase the overall diameter of the wire.

-

Color

Insulation color is often used to indicate the voltage rating or application of the wire. For instance, white insulation is typically used for neutral wires, while black or red insulation indicates live wires.

-

Environmental Rating

Insulation materials are rated for their ability to withstand specific environmental conditions, such as moisture, sunlight, or chemicals. Choosing the appropriate insulation rating is crucial for ensuring the long-term integrity of the wiring system.

Understanding the components and implications of “Insulation Type” is essential for selecting the appropriate wiring for a specific application. By considering factors such as material, thickness, color, and environmental rating, electricians and homeowners can ensure that their electrical systems operate safely and efficiently, minimizing the risk of electrical hazards.

Flexibility

Within the context of “14/2 Vs 12/2 Wiring”, “Flexibility” stands as a critical component that significantly influences the ease of installation, adaptability to various spaces, and overall functionality of the wiring system.

The flexibility of electrical wiring is primarily determined by the number and gauge of the conductors. 14/2 wiring, with its two 14-gauge conductors, offers greater flexibility compared to 12/2 wiring, which has two 12-gauge conductors. Thinner conductors, like those in 14/2 wiring, are more pliable and can be easily bent and maneuvered around corners or through tight spaces.

The practical applications of “Flexibility” in “14/2 Vs 12/2 Wiring” are numerous. For instance, in residential settings, 14/2 wiring is commonly used for lighting circuits due to its flexibility and ability to fit within the limited space of electrical boxes and fixtures. On the other hand, 12/2 wiring, with its reduced flexibility, is better suited for general-purpose outlets and appliances that require higher current and are typically installed in more open areas.

Understanding the relationship between “Flexibility” and “14/2 Vs 12/2 Wiring” empowers electricians and homeowners to make informed decisions when selecting the appropriate wiring for specific applications. By considering factors such as installation space, accessibility, and intended use, they can ensure that the wiring system is not only safe and efficient but also adaptable to the unique requirements of their electrical projects.

Cost

The aspect of “Cost” plays a significant role in the practical considerations of “14/2 Vs 12/2 Wiring”. Understanding the different cost components associated with each wiring type is essential for informed decision-making, project planning, and budget allocation.

-

Materials

The cost of materials, including the wire itself, insulation, and any necessary accessories like connectors and junction boxes, is a primary factor to consider. 14/2 wiring is generally more cost-effective than 12/2 wiring due to its smaller conductor size and lower material requirements.

-

Labor

The labor costs associated with electrical wiring can vary depending on the complexity of the project, local labor rates, and the experience of the electrician. However, the increased flexibility and ease of installation of 14/2 wiring can potentially reduce labor costs compared to 12/2 wiring, especially in complex or confined spaces.

-

Permits and Inspections

In many areas, electrical work requires permits and inspections to ensure compliance with safety codes and regulations. The cost of these permits and inspections can vary depending on local requirements and the scope of the project. It is important to factor in these costs when budgeting for electrical wiring.

-

Long-Term Savings

While 14/2 wiring may have a lower initial cost, it is important to consider the potential long-term savings offered by 12/2 wiring. 12/2 wiring’s higher current capacity can support future electrical upgrades or the addition of appliances without requiring costly rewiring. This can lead to savings in the long run.

Ultimately, the cost considerations of “14/2 Vs 12/2 Wiring” extend beyond the initial purchase price and encompass various factors such as materials, labor, permits, and long-term implications. Carefully weighing these factors against the specific requirements of the project allows for informed decision-making and cost-effective electrical wiring solutions.

Applications

The aspect of “Applications” holds significant importance within the context of “14/2 Vs 12/2 Wiring”. Understanding the different applications where each wiring type is suitable is crucial for ensuring electrical safety, efficiency, and compliance with building codes.

-

Lighting Circuits

14/2 wiring is commonly used in lighting circuits due to its flexibility and ability to handle the lower current requirements of lighting fixtures. It is suitable for residential and commercial applications where lighting is the primary electrical load.

-

General-Purpose Outlets

12/2 wiring is often used for general-purpose outlets, which power a wide range of appliances and electronic devices. Its higher current capacity ensures safe operation of these devices and prevents overloading.

-

Appliances

12/2 wiring is also suitable for powering larger appliances, such as refrigerators, stoves, and air conditioners. These appliances typically require higher current than lighting or general-purpose outlets.

-

Outdoor Wiring

Both 14/2 and 12/2 wiring can be used for outdoor applications, provided they are properly protected from moisture and UV radiation. However, 12/2 wiring is preferred for outdoor circuits that may experience higher current demands, such as those powering outdoor lighting or appliances.

In summary, the applications for 14/2 and 12/2 wiring vary based on the electrical load requirements of the circuit. 14/2 wiring is ideal for lighting circuits, while 12/2 wiring is better suited for general-purpose outlets, appliances, and outdoor applications. Understanding these applications is essential for selecting the appropriate wiring for each electrical circuit, ensuring safety, efficiency, and code compliance.

Related Posts