A Flat Four Wiring Diagram schematically depicts the electrical connections within a specific type of four-cylinder engine. Each of the four cylinders is arranged in a horizontally opposed configuration, also known as a “boxer” or “flat” engine design.

The diagram serves as a comprehensive reference for technicians and engineers, detailing the correct wiring and components for the ignition, fuel injection, and other electrical systems of the engine. It helps ensure proper functioning, troubleshooting, and maintenance of the engine.

The Flat Four Wiring Diagram is particularly relevant for vehicles like the Subaru Boxer engine, which frequently employs this design for its compact size, low center of gravity, and balanced power delivery. Understanding this diagram is crucial during engine diagnostics, repairs, and modifications.

Understanding the essential aspects of a Flat Four Wiring Diagram is crucial for comprehending the electrical intricacies of this unique engine design. These aspects govern the functionality, reliability, and performance of the engine.

- Circuit Layout: Depicts the arrangement and connections of electrical components, including ignition coils, fuel injectors, sensors, and wiring harnesses.

- Grounding Points: Indicates the locations where electrical circuits are connected to the vehicle’s chassis, ensuring proper grounding and preventing electrical faults.

- Fuse and Relay Locations: Identifies the positions of fuses and relays, which protect electrical circuits from overcurrent and provide switching functionality.

- Sensor Interfaces: Details the connections between sensors and the engine’s electronic control unit (ECU), allowing the ECU to monitor engine parameters.

- ECU Pinouts: Specifies the pin assignments on the ECU, enabling technicians to correctly connect external devices and diagnostic tools.

- Wire Color Coding: Establishes a standardized color scheme for wires, facilitating circuit identification and troubleshooting.

- Splice Points: Indicates locations where wires are joined together, providing flexibility for repairs or modifications.

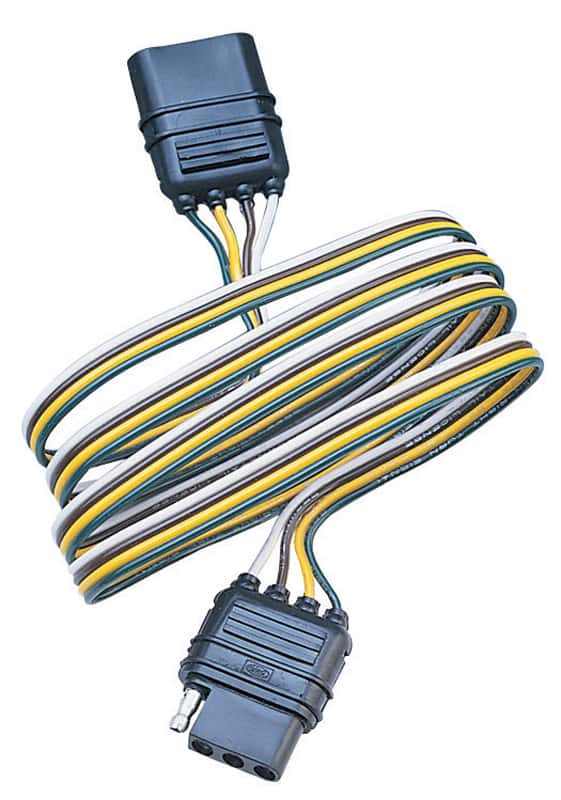

- Connector Types: Outlines the types of electrical connectors used, ensuring proper mating and secure connections.

- Signal Paths: Traces the flow of electrical signals throughout the wiring system, aiding in diagnosing electrical issues.

- Troubleshooting Guide: Provides a structured approach to identifying and resolving electrical problems, minimizing downtime.

These aspects collectively provide a comprehensive understanding of the Flat Four Wiring Diagram, enabling technicians to diagnose, repair, and maintain engines with precision and efficiency.

Circuit Layout

The circuit layout is a fundamental component of a Flat Four Wiring Diagram, serving as the blueprint for the electrical connections within the engine. It provides a detailed map of how various electrical components, such as ignition coils, fuel injectors, sensors, and wiring harnesses, are interconnected to ensure proper engine operation.

Understanding the circuit layout is crucial for troubleshooting electrical issues, performing repairs, and modifying the engine’s electrical system. By tracing the flow of electricity through the diagram, technicians can identify open circuits, shorts, or faulty components, enabling them to diagnose and resolve problems efficiently.

In practice, the circuit layout guides technicians in tasks such as:

- Identifying the correct wiring harness to connect a new sensor

- Locating a blown fuse or a faulty relay

- Tracing signal paths to diagnose sensor malfunctions

- Modifying the wiring for performance enhancements or custom installations

Furthermore, the circuit layout serves as a valuable reference for engineers designing and developing new Flat Four engines. By optimizing the circuit layout, engineers can improve engine performance, reliability, and fuel efficiency. This understanding also supports the integration of advanced electronic control systems, enabling features such as variable valve timing and direct fuel injection.

In summary, the circuit layout is a critical aspect of a Flat Four Wiring Diagram, providing a comprehensive overview of the electrical connections within the engine. It empowers technicians and engineers to diagnose, repair, and modify the engine’s electrical system effectively, contributing to optimal engine performance and reliability.

Grounding Points

Within the Flat Four Wiring Diagram, grounding points play a crucial role in maintaining electrical stability and ensuring the proper functioning of the engine. These points provide a low-resistance path for electrical current to return to the vehicle’s chassis, which acts as a common reference point for all electrical circuits.

The absence of proper grounding can lead to a variety of electrical faults, including:

- Voltage fluctuations and electrical noise

- Malfunctioning sensors and electronic components

- Dim or flickering lights

- Battery drain and premature failure

The Flat Four Wiring Diagram identifies the designated grounding points, which are typically located on the engine block, cylinder heads, or chassis frame. By connecting electrical circuits to these points, technicians ensure that current can flow properly and that electrical faults are minimized.

For instance, in a Subaru Impreza WRX with a Flat Four engine, the grounding point for the engine control unit (ECU) is located on the passenger side strut tower. This point provides a reliable electrical connection between the ECU and the vehicle’s chassis, ensuring that the ECU receives a stable voltage supply and can accurately control the engine’s functions.

Understanding the significance of grounding points in the Flat Four Wiring Diagram empowers technicians to diagnose and resolve electrical issues effectively. By ensuring proper grounding, they can prevent electrical faults, improve engine performance, and enhance overall vehicle reliability.

In summary, grounding points are critical components of the Flat Four Wiring Diagram, serving as the foundation for a stable and reliable electrical system. Proper grounding prevents electrical faults, optimizes engine performance, and ensures the longevity of electrical components.

Fuse and Relay Locations

Within the Flat Four Wiring Diagram, fuse and relay locations play a critical role in safeguarding the engine’s electrical system and ensuring its reliable operation. Fuses act as sacrificial devices, interrupting the flow of excessive current to protect sensitive electrical components from damage. Relays, on the other hand, serve as electrically controlled switches, allowing high-power circuits to be controlled by low-power signals.

The Flat Four Wiring Diagram provides precise information on the placement of fuses and relays within the engine’s electrical system. This knowledge empowers technicians to:

- Quickly identify and replace blown fuses, restoring power to affected circuits

- Locate and troubleshoot faulty relays, preventing intermittent electrical issues

- Modify the electrical system by adding or relocating fuses and relays for specific applications

For instance, in a Subaru Outback with a Flat Four engine, the main fuse box is situated in the engine compartment, while individual fuses for specific components, such as the fuel pump and ignition system, are located in smaller fuse boxes distributed throughout the engine bay. Understanding the fuse and relay locations in the Flat Four Wiring Diagram enables technicians to efficiently diagnose and resolve electrical problems, minimizing downtime and enhancing vehicle safety.

Moreover, the Flat Four Wiring Diagram serves as a valuable reference for engineers designing and developing advanced engine control systems. By optimizing the placement of fuses and relays, engineers can enhance the system’s reliability, durability, and overall performance.

In summary, fuse and relay locations are essential components of the Flat Four Wiring Diagram, providing a comprehensive overview of the engine’s electrical protection and switching mechanisms. This understanding empowers technicians to diagnose and repair electrical faults effectively, contributing to optimal engine performance and reliability.

Sensor Interfaces

Within the Flat Four Wiring Diagram, sensor interfaces play a critical role in providing the engine’s electronic control unit (ECU) with vital information about the engine’s operating conditions. These interfaces establish the electrical connections between various sensors, such as oxygen sensors, temperature sensors, and airflow sensors, and the ECU. The ECU relies on this data to make informed decisions regarding fuel injection, ignition timing, and other engine control parameters.

Understanding the sensor interfaces within the Flat Four Wiring Diagram empowers technicians to diagnose and resolve sensor-related issues, ensuring optimal engine performance and fuel efficiency. For instance, if a technician encounters an engine fault code related to an oxygen sensor, they can refer to the wiring diagram to identify the correct sensor and its connection to the ECU. This information guides them in testing the sensor, inspecting the wiring harness, and ultimately resolving the issue.

Furthermore, the Flat Four Wiring Diagram serves as a valuable resource for engineers designing and developing advanced engine control systems. By optimizing the sensor interfaces, engineers can improve the accuracy and responsiveness of the ECU, leading to enhanced engine performance and reduced emissions.

In summary, sensor interfaces are a critical component of the Flat Four Wiring Diagram, providing a comprehensive overview of the electrical connections between sensors and the ECU. This understanding empowers technicians to diagnose and repair sensor-related issues effectively, while also supporting engineers in the development of advanced engine control systems.

ECU Pinouts

Within the Flat Four Wiring Diagram, ECU pinouts play a critical role in enabling communication between the engine’s electronic control unit (ECU) and external devices, such as diagnostic tools and performance monitors. These pinouts define the specific functions assigned to each pin on the ECU’s connector, allowing technicians to connect external devices correctly and access vital engine data.

Understanding the ECU pinouts is essential for:

- Connecting diagnostic tools to retrieve fault codes and engine performance data

- Installing aftermarket performance modules or sensors that require direct ECU integration

- Troubleshooting electrical issues related to the ECU or its connections

For example, in a Subaru WRX with a Flat Four engine, the ECU pinout diagram identifies the pin responsible for the vehicle speed sensor signal. By connecting a diagnostic tool to this specific pin, a technician can monitor the vehicle’s speed and identify any potential issues with the sensor or its wiring.

ECU pinouts are also crucial for engineers designing and developing advanced engine control systems. By optimizing the pin assignments, engineers can ensure efficient and reliable communication between the ECU and various sensors and actuators, leading to improved engine performance and fuel efficiency.

In summary, ECU pinouts are a vital component of the Flat Four Wiring Diagram, providing a comprehensive overview of the ECU’s external connectivity. This understanding empowers technicians to diagnose and resolve electrical issues effectively, while also supporting engineers in the development of advanced engine control systems.

Wire Color Coding

Within the context of the Flat Four Wiring Diagram, wire color coding plays a crucial role in simplifying circuit identification and troubleshooting. It establishes a standardized color scheme for wires, ensuring that each wire’s function and destination can be easily determined. This color coding is consistent across different Flat Four engine applications, allowing technicians to quickly trace circuits and identify potential issues.

For instance, in Subaru’s Flat Four engines, ground wires are typically black, while power wires are often red or yellow. Sensor wires may be assigned specific colors based on their function, such as blue for coolant temperature sensors or green for oxygen sensors. This standardized color coding allows technicians to quickly identify and trace circuits without the need to refer to the wiring diagram constantly.

The practical application of wire color coding extends beyond troubleshooting. It also enhances the efficiency of electrical system modifications and repairs. By following the color-coded wires, technicians can easily locate the correct wires to tap into for adding accessories or diagnosing electrical faults. This simplifies the installation process and reduces the risk of errors.

In summary, wire color coding is a critical component of the Flat Four Wiring Diagram, enabling technicians to identify and troubleshoot circuits quickly and accurately. It promotes efficient electrical system servicing and modification, contributing to the overall reliability and performance of the engine.

Splice Points

Within the context of the Flat Four Wiring Diagram, splice points play a critical role in enabling electrical system modifications and repairs. These points identify locations where wires are intentionally joined together, providing flexibility and accessibility when troubleshooting or making changes to the electrical system.

Splice points are commonly used for various purposes, including:

- Adding accessories: When installing additional electrical components, such as gauges or lighting, splice points provide a convenient way to connect new wires to the existing wiring harness without cutting or modifying the original wires.

- Repairing damaged wires: In the event of a wire break or damage, splice points allow technicians to repair the connection by joining the severed wires together.

- Modifying electrical circuits: Splice points enable technicians to alter the configuration of the electrical system, such as rerouting wires or adding additional circuits, to accommodate specific requirements or performance modifications.

Understanding the location and purpose of splice points is crucial for effective electrical system servicing. By identifying these points on the Flat Four Wiring Diagram, technicians can efficiently trace and modify circuits, ensuring proper electrical functionality and system reliability. This understanding empowers them to diagnose and resolve electrical issues, customize the electrical system for specific needs, and maintain optimal engine performance.

In summary, splice points are an essential component of the Flat Four Wiring Diagram, providing flexibility and accessibility for electrical system modifications and repairs. By understanding the location and purpose of these points, technicians can effectively troubleshoot, modify, and maintain the electrical system, contributing to the overall performance and reliability of the engine.

Connector Types

Within the context of the Flat Four Wiring Diagram, connector types play a critical role in establishing reliable and secure electrical connections throughout the engine’s electrical system. These connectors ensure proper mating between components, preventing intermittent connections, voltage drops, and potential electrical faults.

The Flat Four Wiring Diagram details the specific types of connectors used for each electrical connection, including:

- Multi-pin connectors: Used for connecting multiple wires to a single component, such as the engine control unit (ECU) or sensor modules.

- Bullet connectors: Simple and reliable connectors used for low-current applications, such as connecting wires to switches or sensors.

- Weatherpack connectors: Waterproof connectors designed to withstand harsh environmental conditions, often used for connections exposed to moisture or dirt.

Understanding the types of connectors used is crucial for proper electrical system servicing and maintenance. By identifying the correct connector type, technicians can ensure that connections are made securely and in accordance with the manufacturer’s specifications. This understanding also enables them to diagnose and resolve electrical issues related to faulty or damaged connectors.

For instance, if a technician encounters an intermittent electrical fault in a Subaru Impreza WRX with a Flat Four engine, they can refer to the wiring diagram to identify the type of connector used for the affected circuit. By inspecting the connector for damage or loose connections, the technician can quickly identify and resolve the issue, restoring proper electrical functionality.

In summary, connector types are a vital component of the Flat Four Wiring Diagram, providing essential information for ensuring proper mating and secure electrical connections. Understanding the types of connectors used empowers technicians to diagnose and repair electrical faults effectively, maintain optimal engine performance, and ensure the reliability of the electrical system.

Signal Paths

Within the context of the Flat Four Wiring Diagram, signal paths play a critical role in troubleshooting and diagnosing electrical issues within the engine’s electrical system. These paths trace the flow of electrical signals through the wiring harness, allowing technicians to identify the source of electrical faults and ensure proper signal transmission.

Signal paths are represented in the wiring diagram as lines connecting various electrical components, such as sensors, actuators, and the engine control unit (ECU). By following these paths, technicians can identify:

- Open circuits: Breaks in the wiring harness that prevent electrical signals from passing through.

- Short circuits: Unintended connections between wires that can disrupt signal transmission and cause electrical damage.

- Ground faults: Connections between wires and the vehicle’s chassis that can interfere with signal integrity.

Understanding signal paths is crucial for effective electrical system diagnostics. For instance, if a technician encounters an issue with a faulty sensor, they can trace the signal path from the sensor to the ECU using the wiring diagram. By measuring the signal voltage at various points along the path, they can pinpoint the location of the fault, whether it’s a wiring issue, a sensor malfunction, or a problem with the ECU.

In summary, signal paths are a critical component of the Flat Four Wiring Diagram, providing a roadmap for troubleshooting and diagnosing electrical issues. By understanding the flow of electrical signals through the wiring system, technicians can efficiently identify and resolve electrical faults, ensuring optimal engine performance and reliability.

Troubleshooting Guide

Within the context of the Flat Four Wiring Diagram, the troubleshooting guide plays a critical role in empowering technicians to diagnose and resolve electrical issues efficiently, minimizing downtime and ensuring optimal engine performance.

The troubleshooting guide provides a structured approach that guides technicians through a series of logical steps to identify and isolate electrical faults. It includes:

- Symptom identification: A list of common electrical symptoms and their potential causes.

- Diagnostic procedures: Step-by-step instructions for testing electrical components and circuits using multimeters and other diagnostic tools.

- Repair recommendations: Guidance on repairing or replacing faulty components, including wiring repairs and connector replacements.

For instance, if a technician encounters an electrical issue with a Subaru Impreza WRX with a Flat Four engine, they can refer to the troubleshooting guide in the wiring diagram. By following the guide, they can systematically test the electrical components and circuits related to the issue, such as fuses, relays, sensors, and wiring harnesses. This structured approach enables them to pinpoint the root cause of the problem and implement the appropriate repairs.

Moreover, the troubleshooting guide serves as a valuable resource for engineers designing and developing advanced engine control systems. By incorporating effective troubleshooting mechanisms into the system, engineers can reduce diagnostic time and improve overall system reliability.

In summary, the troubleshooting guide is an indispensable component of the Flat Four Wiring Diagram, providing a structured approach to diagnosing and resolving electrical issues. This understanding empowers technicians to minimize downtime, ensure optimal engine performance, and contribute to the overall reliability of the vehicle.

Related Posts