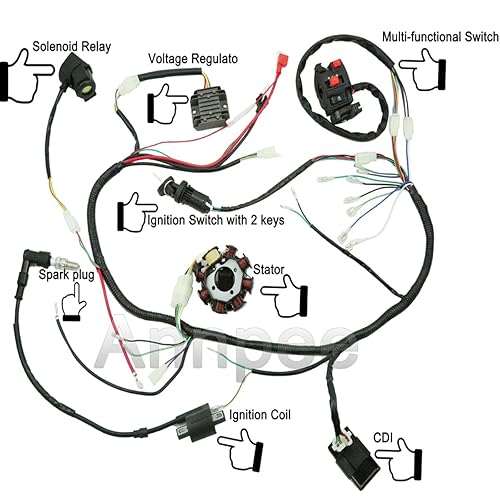

A Pit Bike Kick Start Only Wiring Diagram is a simplified schematic outlining the electrical connections necessary for a motorized bicycle to operate exclusively through a kick start mechanism. It typically incorporates components such as the ignition coil, battery, starter solenoid, and kill switch.

Eliminating the electric start system reduces complexity, enhances reliability, and lowers the overall weight of the pit bike. These advantages make kick start wiring diagrams particularly relevant for competitive racing scenarios or off-road applications where durability and agility are paramount.

Historically, kick start mechanisms were prevalent in early motorcycles and remained popular until the introduction of electric starters. However, their simplicity and adaptability have ensured their continued use in specialized applications like pit bikes.

Understanding the essential aspects of a Pit Bike Kick Start Only Wiring Diagram is crucial for those seeking to delve into electrical circuit design, motorsports, or small engine repair. These aspects encompass multiple domains, including electrical engineering, mechanical principles, and practical application.

- Components: Ignition coil, battery, starter solenoid, kill switch.

- Circuit Design: Arrangement of components to facilitate electrical flow.

- Electrical Connections: Wires and connectors used to establish current pathways.

- Kick Start Mechanism: Lever or pedal used to initiate engine rotation.

- Ignition Timing: Precise moment when spark is generated in the engine.

- Power Distribution: Delivery of electrical energy to various components.

- Troubleshooting: Techniques for identifying and resolving electrical faults.

- Safety Features: Kill switch to prevent uncontrolled engine operation.

- Customization: Modifications to enhance performance or adapt to specific requirements.

These aspects are interconnected and play vital roles in ensuring the proper functioning of a pit bike’s kick start system. A thorough understanding of these elements empowers individuals to diagnose and rectify electrical issues, optimize performance, and customize their pit bikes for optimal riding experiences.

Components

Within the context of a Pit Bike Kick Start Only Wiring Diagram, specific components play crucial roles in enabling the kick start mechanism to function effectively. These components include the ignition coil, battery, starter solenoid, and kill switch, each serving a distinct purpose within the electrical circuit.

- Ignition Coil: Responsible for generating the high-voltage spark necessary for ignition, converting low-voltage electrical energy from the battery into a high-voltage pulse.

- Battery: Provides the electrical energy required to power the ignition coil and other electrical components, storing chemical energy and releasing it as electrical current when needed.

- Starter Solenoid: Acts as a switch, engaging the starter motor when current flows through it, initiating the engine’s rotation.

- Kill Switch: A safety device that allows the rider to quickly cut off the engine’s ignition, typically mounted on the handlebars for easy access in emergency situations.

These components work in conjunction to facilitate the kick start process. When the rider actuates the kick start lever, the starter solenoid engages the starter motor, which in turn rotates the engine. This motion generates an electrical signal in the ignition coil, which is then converted into a high-voltage spark and delivered to the spark plug. The spark ignites the air-fuel mixture in the engine’s combustion chamber, initiating the combustion process and starting the engine.

Circuit Design

In the context of a Pit Bike Kick Start Only Wiring Diagram, circuit design plays a pivotal role in ensuring the efficient and reliable operation of the kick start mechanism. The arrangement of electrical components within the circuit is meticulously planned to facilitate the proper flow of electrical current, enabling the various components to function in harmony and initiate the engine’s starting process.

The circuit design of a Pit Bike Kick Start Only Wiring Diagram typically involves the following key considerations:

- Component placement: Positioning the ignition coil, battery, starter solenoid, and kill switch in optimal locations to minimize electrical resistance and maximize signal strength.

- Wire selection: Choosing wires with appropriate gauge and insulation to handle the electrical current required by the components without excessive voltage drop or overheating.

- Connection type: Utilizing secure and reliable electrical connectors to ensure proper contact between components and prevent intermittent connections.

- Grounding: Establishing a solid electrical ground to provide a reference point for the electrical circuit and prevent electrical noise.

Understanding the principles of circuit design is essential for troubleshooting and repairing electrical faults in Pit Bike Kick Start Only Wiring Diagrams. By analyzing the circuit layout and identifying potential points of failure, individuals can effectively diagnose and resolve electrical issues, restoring the proper functioning of the kick start mechanism.

In summary, circuit design plays a critical role in Pit Bike Kick Start Only Wiring Diagrams, governing the arrangement of components and facilitating the flow of electrical current. A well-designed circuit ensures efficient and reliable engine starting, while also enabling easy maintenance and troubleshooting.

Electrical Connections

In the context of a Pit Bike Kick Start Only Wiring Diagram, electrical connections play a critical role in ensuring the proper functioning of the kick start mechanism. Wires and connectors serve as the pathways for electrical current to flow between the various components, enabling the transfer of energy and signals necessary for starting the engine.

Without secure and reliable electrical connections, the components within the wiring diagram would be unable to communicate and operate effectively. The wires provide a conductive path for the flow of electrical current, while the connectors ensure a stable and low-resistance connection between the wires and components.

In a Pit Bike Kick Start Only Wiring Diagram, the electrical connections are typically configured in a specific manner to facilitate the kick start process. When the rider actuates the kick start lever, the starter solenoid receives an electrical signal, which engages the starter motor. The starter motor then rotates the engine, generating an electrical signal in the ignition coil. This signal is then converted into a high-voltage spark and delivered to the spark plug, igniting the air-fuel mixture in the combustion chamber and starting the engine.

Understanding the importance of electrical connections in a Pit Bike Kick Start Only Wiring Diagram is crucial for troubleshooting and repairing electrical faults. By inspecting the wires and connectors for damage or loose connections, individuals can identify potential issues and restore the proper functioning of the kick start mechanism.

In summary, electrical connections serve as the vital links between components in a Pit Bike Kick Start Only Wiring Diagram, enabling the flow of electrical current and the proper operation of the kick start mechanism. Secure and reliable electrical connections are essential for ensuring the efficient and trouble-free starting of the engine.

Kick Start Mechanism

In the context of a Pit Bike Kick Start Only Wiring Diagram, the kick start mechanism plays a central role in initiating the engine’s rotation, enabling the rider to start the pit bike without relying on an electric starter motor. The kick start mechanism typically consists of a lever or pedal connected to a series of gears and a ratchet mechanism.

When the rider actuates the kick start lever or pedal, the gears engage and transmit mechanical energy to the engine’s crankshaft, causing it to rotate. This rotation generates an electrical signal in the ignition coil, which is then converted into a high-voltage spark and delivered to the spark plug, igniting the air-fuel mixture in the combustion chamber and starting the engine.

The kick start mechanism is a critical component of a Pit Bike Kick Start Only Wiring Diagram, as it provides the initial force required to rotate the engine and initiate the combustion process. Without a functional kick start mechanism, the rider would be unable to start the pit bike, rendering it inoperable.

Real-life examples of kick start mechanisms can be found in various types of pit bikes, including those used for racing, off-road riding, and recreational purposes. These mechanisms are designed to be durable and reliable, capable of withstanding the rigors of riding conditions and providing a consistent starting experience.

Understanding the connection between the kick start mechanism and the Pit Bike Kick Start Only Wiring Diagram is crucial for troubleshooting and repairing any issues that may arise with the starting system. By inspecting the kick start mechanism for damage or wear, and ensuring that it is properly adjusted, riders can maintain the optimal functioning of their pit bikes.

In summary, the kick start mechanism is an essential component of a Pit Bike Kick Start Only Wiring Diagram, providing the means to initiate engine rotation and start the pit bike. Its practical significance lies in enabling riders to start their pit bikes without relying on an electric starter motor, particularly in situations where reliability and simplicity are paramount.

Ignition Timing

Within the context of a Pit Bike Kick Start Only Wiring Diagram, ignition timing plays a crucial role in ensuring the efficient and reliable starting of the engine. It refers to the precise moment when the spark plug generates a spark to ignite the air-fuel mixture in the combustion chamber, initiating the combustion process and starting the engine.

-

Ignition Coil:

The ignition coil is a key component in the ignition system, responsible for generating the high-voltage spark required for ignition. It converts the low-voltage electrical energy from the battery into a high-voltage pulse, which is then delivered to the spark plug.

-

Spark Plug:

The spark plug is the final point in the ignition system, delivering the high-voltage spark to the combustion chamber. It consists of two electrodes separated by a gap, and when the high-voltage pulse reaches the spark plug, it jumps across the gap, creating a spark that ignites the air-fuel mixture.

-

Engine Speed Sensor:

In some Pit Bike Kick Start Only Wiring Diagrams, an engine speed sensor is incorporated to monitor the engine’s rotational speed. This information is used to adjust the ignition timing accordingly, ensuring optimal engine performance at different RPM ranges.

-

Timing Advance:

Timing advance refers to the practice of advancing the ignition timing to optimize engine performance. By triggering the spark slightly before the piston reaches the top of the compression stroke, the air-fuel mixture has more time to burn, resulting in increased power and efficiency.

Understanding the various aspects of ignition timing is crucial for troubleshooting and optimizing the performance of a Pit Bike Kick Start Only Wiring Diagram. By ensuring that the ignition timing is set correctly, riders can improve the starting reliability, power output, and overall efficiency of their pit bikes.

Power Distribution

Within the context of a Pit Bike Kick Start Only Wiring Diagram, the distribution of electrical power to various components plays a pivotal role in ensuring the proper functioning of the entire system. The electrical energy generated by the battery or other sources must be efficiently and reliably distributed to the ignition system, lighting system, and other electrical components to ensure optimal performance.

-

Battery:

The battery serves as the primary source of electrical energy for the Pit Bike Kick Start Only Wiring Diagram. It stores chemical energy and releases it as electrical current when needed, providing power to the ignition system, lighting system, and other electrical components. -

Wiring Harness:

The wiring harness is a network of wires that connect the battery to the various electrical components in the Pit Bike Kick Start Only Wiring Diagram. It ensures the proper flow of electrical current throughout the system, allowing the components to function as intended. -

Fuses:

Fuses are safety devices designed to protect the electrical system from damage caused by excessive current flow. They act as sacrificial elements, breaking the circuit when the current exceeds a predetermined threshold, preventing damage to the more expensive electrical components. -

Grounding:

Grounding is essential for providing a reference point for the electrical system. It establishes a common electrical potential throughout the system, ensuring that electrical current flows properly and preventing electrical noise and interference.

Understanding the principles of power distribution is crucial for troubleshooting and maintaining a Pit Bike Kick Start Only Wiring Diagram. By ensuring that the electrical power is distributed efficiently and reliably, riders can enhance the performance, reliability, and longevity of their pit bikes.

Troubleshooting

In the context of Pit Bike Kick Start Only Wiring Diagrams, troubleshooting electrical faults is a critical skill for ensuring the proper functioning and reliability of the pit bike. Troubleshooting involves a systematic approach to identify and resolve electrical issues, ranging from minor inconveniences to major breakdowns.

-

Visual Inspection:

A thorough visual inspection is the first step in troubleshooting electrical faults. This involves examining the wiring harness, connectors, and components for any visible signs of damage, loose connections, or corrosion. -

Electrical Testing:

Electrical testing involves using a multimeter or other diagnostic tools to measure voltage, resistance, and continuity in the electrical system. This helps identify open circuits, short circuits, and other electrical faults. -

Component Testing:

In some cases, it may be necessary to test individual electrical components, such as the ignition coil, stator, and voltage regulator, to determine if they are functioning properly. -

Circuit Analysis:

Circuit analysis involves tracing the electrical pathways in the wiring diagram to identify potential points of failure. This is particularly useful for complex electrical systems or when the fault is not immediately apparent.

By understanding and applying these troubleshooting techniques, individuals can effectively identify and resolve electrical faults in Pit Bike Kick Start Only Wiring Diagrams. This ensures that the pit bike operates reliably, performs optimally, and provides a safe and enjoyable riding experience.

Safety Features

In the context of Pit Bike Kick Start Only Wiring Diagrams, safety features play a critical role in ensuring the safe and controlled operation of the pit bike. Among these features, the kill switch stands out as a crucial component designed to prevent uncontrolled engine operation, enhancing rider safety and preventing potential accidents.

The kill switch is a simple yet effective device typically mounted on the handlebars of the pit bike. When activated, either intentionally by the rider or automatically in the event of a fall, the kill switch instantly cuts off the electrical power to the engine. This immediate interruption of power causes the engine to stop running, preventing uncontrolled acceleration or movement of the pit bike.

Real-life examples of kill switches in Pit Bike Kick Start Only Wiring Diagrams are prevalent across various makes and models of pit bikes. These kill switches are often designed to be easily accessible and operable, allowing riders to quickly react in emergency situations.

The practical significance of understanding the connection between safety features, particularly the kill switch, and Pit Bike Kick Start Only Wiring Diagrams cannot be overstated. Equipping pit bikes with functional kill switches not only enhances rider safety but also contributes to the overall reliability and control of the vehicle. By incorporating kill switches into the wiring diagrams, manufacturers prioritize rider safety, ensuring that riders have the means to respond swiftly to unforeseen circumstances.

In summary, safety features, such as the kill switch, are indispensable components of Pit Bike Kick Start Only Wiring Diagrams. Their presence underscores the importance of prioritizing rider safety and preventing uncontrolled engine operation. Understanding this connection empowers individuals to make informed decisions regarding pit bike safety and contributes to a more enjoyable and responsible riding experience.

Customization

Within the context of Pit Bike Kick Start Only Wiring Diagrams, customization plays a significant role in tailoring the pit bike’s performance and functionality to meet specific requirements or preferences. Modifications can range from simple adjustments to extensive overhauls, all aimed at enhancing the riding experience and achieving desired outcomes.

One common area of customization involves modifying the ignition timing to optimize engine performance. By adjusting the timing of the spark, riders can fine-tune the engine’s power output and responsiveness, particularly in racing applications where every millisecond counts.

Another popular customization is the installation of aftermarket exhaust systems. These systems can improve engine breathing, resulting in increased power and a more aggressive sound. However, it’s crucial to ensure that the exhaust system is compatible with the Pit Bike Kick Start Only Wiring Diagram to prevent any electrical conflicts or damage.

Understanding the relationship between customization and Pit Bike Kick Start Only Wiring Diagrams empowers individuals to make informed decisions about modifications. It allows them to assess the potential benefits and drawbacks, ensuring that customizations align with their intended purpose and do not compromise the safety or reliability of the pit bike.

In summary, customization plays a vital role in Pit Bike Kick Start Only Wiring Diagrams, enabling riders to modify and adapt their pit bikes to suit their individual needs and preferences. By understanding the connection between these two aspects, individuals can unlock the full potential of their pit bikes and achieve optimal performance and functionality.

Related Posts