Two Wire Thermostat Wiring refers to a simplified electrical connection between a thermostat and an HVAC system, typically comprised of only two wires. An example is seen in older homes, where a single wire controls heating and another controls cooling.

Its significance lies in its simplicity and cost-effectiveness, making it a common choice for basic temperature control. Key historical development includes the advent of electronic thermostats, which replaced mercury-based models and enabled more precise temperature regulation.

This article delves further into the principles of two-wire thermostat wiring, its applications, and the factors determining wire gauge and voltage requirements.

Two-wire thermostat wiring, a fundamental aspect of basic HVAC systems, involves understanding various essential elements that influence its functionality and effectiveness. These key aspects encompass:

- Compatibility: Matching thermostat type to system requirements

- Polarity: Correct wire connections for proper operation

- Voltage: Compatibility between thermostat and HVAC system

- Wire Gauge: Appropriate wire thickness for optimal current flow

- Splicing: Proper wire connections to ensure reliable operation

- Routing: Safe and efficient wire placement

- Testing: Verifying proper installation and functionality

- Troubleshooting: Identifying and resolving common issues

- Safety: Adhering to electrical codes and guidelines

These aspects are interconnected and play vital roles in ensuring the efficient and reliable operation of two-wire thermostat wiring systems. Understanding and considering these elements during installation, maintenance, and troubleshooting is essential for optimal temperature control and system longevity.

Compatibility

In the realm of two-wire thermostat wiring, compatibility between the thermostat and the HVAC system is paramount. A compatible thermostat ensures seamless communication and proper control over heating and cooling functions. Conversely, a mismatch can lead to system malfunctions, energy inefficiencies, and potential hazards.

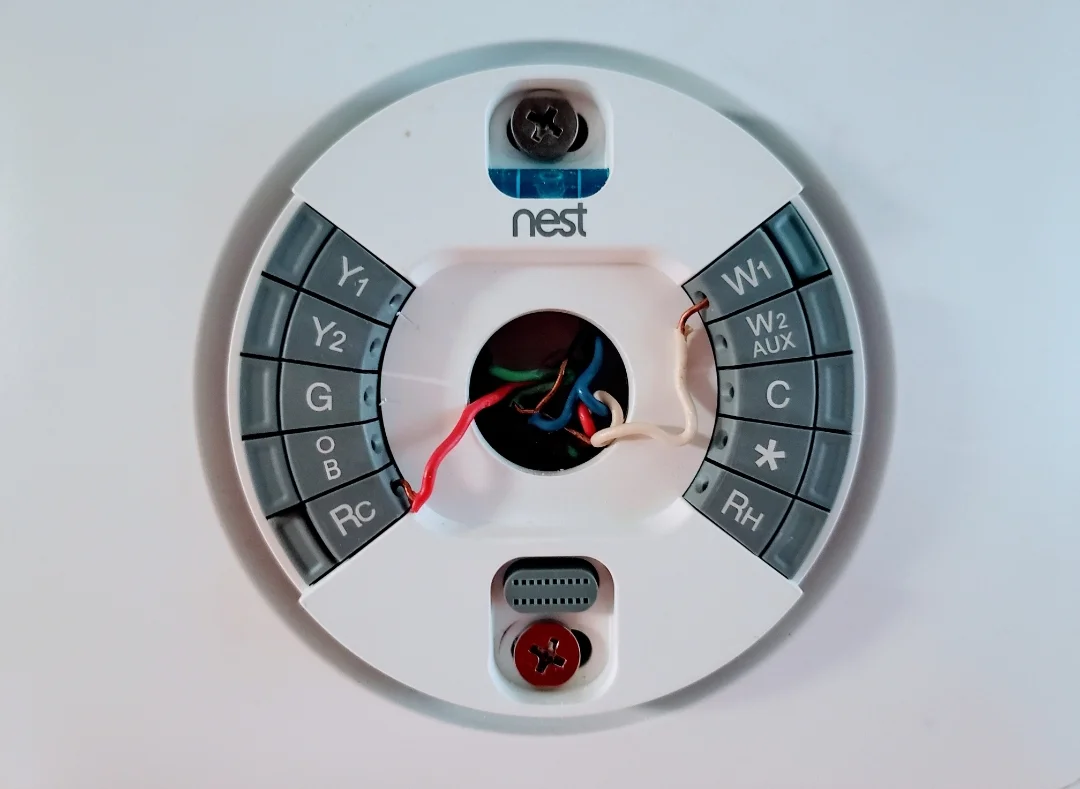

Two-wire thermostats come in various types, each designed for specific HVAC system configurations. For instance, a basic two-wire thermostat may be suitable for simple heating or cooling systems, while a more advanced model with additional terminals might be required for systems with fans, humidifiers, or other auxiliary components. Matching the thermostat’s capabilities to the system’s needs is crucial for optimal performance and longevity.

Real-life examples abound where compatibility issues can manifest. An incompatible thermostat may fail to trigger heating or cooling cycles, resulting in uncomfortable indoor temperatures. It might also cause excessive energy consumption due to improper system operation. By understanding the compatibility requirements of two-wire thermostat wiring, homeowners and technicians can avoid these pitfalls, ensuring efficient and reliable temperature control.

In conclusion, compatibility between the thermostat and the HVAC system is a cornerstone of effective two-wire thermostat wiring. Matching the thermostat’s capabilities to the system’s needs is essential for proper operation, energy efficiency, and system longevity. Understanding this compatibility aspect empowers individuals to make informed decisions when selecting and installing two-wire thermostats, ultimately contributing to a comfortable and energy-conscious indoor environment.

Polarity

Polarity, the correct alignment of positive and negative electrical connections, is a critical aspect of two-wire thermostat wiring. Understanding polarity ensures the proper flow of electricity through the circuit, enabling accurate temperature control and system efficiency. Conversely, incorrect polarity can lead to malfunctions, safety hazards, and damage to the thermostat or HVAC system.

In two-wire thermostat wiring, polarity is determined by the specific terminals on the thermostat and the corresponding wires connected to them. Typically, one wire is designated as “power” and the other as “load.” Reversing these connections can disrupt the circuit, preventing the thermostat from functioning correctly. For instance, if the power wire is mistakenly connected to the load terminal, the thermostat may not receive power, rendering it inoperable.

Real-life examples underscore the importance of correct polarity in two-wire thermostat wiring. Incorrect polarity can cause the thermostat to display inaccurate temperature readings, leading to uncomfortable indoor conditions and wasted energy. Furthermore, reversed polarity can create electrical shorts, posing safety risks and potentially damaging the thermostat or HVAC system components.

Practical applications of understanding polarity in two-wire thermostat wiring extend beyond ensuring proper operation and safety. Correct polarity enables efficient energy consumption by optimizing the heating and cooling cycles. Additionally, it facilitates troubleshooting and repair, as technicians can quickly identify and resolve polarity-related issues.

In summary, polarity plays a crucial role in two-wire thermostat wiring. Correct polarity ensures proper electrical flow, accurate temperature control, system efficiency, and safety. Understanding and adhering to polarity guidelines is essential for the effective operation and longevity of two-wire thermostat wiring systems.

Voltage

Voltage compatibility is a critical aspect of two-wire thermostat wiring, directly influencing the proper functioning, safety, and longevity of the system. The voltage supplied by the HVAC system must match the voltage requirements of the thermostat for effective communication and control. Incorrect voltage can lead to a range of issues, from inaccurate temperature readings to potential damage to the thermostat or HVAC components.

Real-life examples illustrate the importance of voltage compatibility. For instance, a thermostat designed for a 24-volt system connected to a 120-volt system may malfunction or become damaged due to the excessive voltage. Conversely, a thermostat requiring 24 volts connected to a 12-volt system may not receive sufficient power to operate correctly.

Understanding voltage compatibility in two-wire thermostat wiring has practical applications in various scenarios. During installation, technicians must ensure that the thermostat’s voltage rating aligns with the HVAC system’s voltage output. Additionally, when replacing a thermostat, homeowners need to consider voltage compatibility to avoid potential issues. Proper voltage matching also minimizes energy waste and optimizes system performance.

In summary, voltage compatibility plays a crucial role in two-wire thermostat wiring. Matching the thermostat’s voltage requirements to the HVAC system’s voltage output is essential for safe, efficient, and reliable operation. Understanding voltage compatibility empowers individuals to make informed decisions during thermostat selection, installation, and troubleshooting, ultimately contributing to a comfortable and energy-conscious indoor environment.

Wire Gauge

In the context of “Two Wire Thermostat Wiring,” the appropriate wire gauge is paramount for ensuring optimal current flow and maintaining a safe and efficient system. Wire gauge, measured in American Wire Gauge (AWG), directly correlates to the thickness of the wire, impacting its current-carrying capacity and resistance.

- Conductor Material: The type of metal used in the wire, such as copper or aluminum, influences its resistance and current-carrying capabilities.

- Wire Length: Longer wires require a larger gauge to compensate for increased resistance, ensuring adequate current flow to the thermostat.

- Voltage Drop: A thicker wire gauge minimizes voltage drop over longer distances, maintaining accurate temperature readings and preventing system malfunctions.

- Safety: Using the correct wire gauge reduces the risk of overheating and potential fire hazards due to excessive current.

Understanding wire gauge in two-wire thermostat wiring enables informed decisions during system design and installation. Selecting the appropriate wire gauge ensures efficient operation, accurate temperature control, and long-term reliability of the HVAC system. Neglecting wire gauge considerations can lead to system inefficiencies, premature component failure, and potential safety hazards.

Splicing

In the realm of “Two Wire Thermostat Wiring,” the significance of “Splicing: Proper wire connections to ensure reliable operation” cannot be overstated. Splicing, the process of joining two or more wires to create a continuous electrical path, plays a critical role in maintaining a safe, efficient, and dependable thermostat wiring system.

The connection between splicing and two-wire thermostat wiring is inseparable. Without proper splicing techniques, the electrical flow between the thermostat and the HVAC system can be compromised, leading to a range of issues. Loose or improperly connected wires can cause intermittent operation, inaccurate temperature readings, and potential safety hazards. Conversely, well-executed splicing ensures a secure and reliable electrical connection, enabling the thermostat to effectively control the HVAC system and maintain a comfortable indoor environment.

Real-life examples abound where improper splicing has led to problems in two-wire thermostat wiring systems. Loose connections can result in flickering lights, humming noises, or even complete system failure. In severe cases, faulty splicing can pose fire hazards due to overheating or arcing. Conversely, proper splicing practices, such as using appropriate connectors, insulating the spliced area, and adhering to electrical codes, minimize these risks and ensure long-term system reliability.

The practical applications of understanding splicing in two-wire thermostat wiring extend beyond troubleshooting and repair. Proper splicing techniques empower homeowners and technicians to confidently extend or modify wiring systems, adapting them to changing needs or floor plans. Additionally, understanding splicing enables individuals to identify and resolve common wiring issues, reducing the need for costly professional assistance.

In summary, “Splicing: Proper wire connections to ensure reliable operation” is an integral component of “Two Wire Thermostat Wiring.” By adhering to proper splicing practices, individuals can enhance the safety, efficiency, and longevity of their thermostat wiring systems. Understanding the connection between splicing and two-wire thermostat wiring empowers homeowners and technicians alike to maintain a comfortable indoor environment while minimizing potential hazards and maximizing system performance.

Routing

In the realm of “Two Wire Thermostat Wiring,” the aspect of “Routing: Safe and efficient wire placement” plays a crucial role in ensuring the system’s reliability, safety, and longevity. Proper wire routing involves carefully planning and executing the path of wires, considering factors such as potential hazards, accessibility for maintenance, and adherence to electrical codes.

- Concealed Wiring: Involving hiding wires within walls, ceilings, or conduits, concealed wiring enhances the aesthetics of the space while protecting wires from physical damage and environmental factors.

- Conduit Protection: Utilizing conduits or protective sleeves provides an extra layer of safety by safeguarding wires from crushing, moisture, and other external threats, ensuring continued functionality.

- Avoiding Hazards: Routing wires away from sources of heat, moisture, and sharp objects minimizes the risk of damage and potential fire hazards, promoting a safe and reliable wiring system.

- Accessibility for Maintenance: Considering future maintenance needs, wires should be routed in a way that allows for easy access to connections and components, facilitating troubleshooting and repairs when necessary.

Properly routed wires contribute to a well-functioning and long-lasting thermostat wiring system. Concealed wiring, conduit protection, hazard avoidance, and accessibility for maintenance collectively ensure the system’s efficiency, reliability, and safety. By adhering to these routing principles, individuals can create a safe and effective “Two Wire Thermostat Wiring” system that meets their specific needs and ensures a comfortable indoor environment.

Testing

In the realm of “Two Wire Thermostat Wiring,” the significance of “Testing: Verifying proper installation and functionality” cannot be overstated. Testing plays a crucial role in ensuring that the wiring system operates safely, efficiently, and in accordance with design specifications. Without proper testing, potential issues may remain undetected, leading to system malfunctions, discomfort, and even safety hazards.

The connection between testing and two-wire thermostat wiring is inseparable. During installation, testing verifies that the wires are correctly connected and that the thermostat is communicating properly with the HVAC system. This involves checking for continuity, voltage, and proper polarity to ensure accurate temperature control and system functionality. Regular testing, such as annually or after any major changes to the system, helps identify developing issues before they escalate into costly repairs or system failures.

Real-life examples abound where thorough testing has prevented or resolved problems in two-wire thermostat wiring systems. For instance, testing can identify loose connections that could lead to intermittent heating or cooling, or detect potential shorts that pose fire hazards. By proactively identifying and addressing these issues, testing helps maintain a safe and reliable indoor environment while extending the lifespan of the thermostat wiring system.

The practical applications of understanding testing in two-wire thermostat wiring extend beyond troubleshooting and repair. Regular testing empowers homeowners and technicians to monitor the health of their wiring systems, ensuring continued optimal performance. Additionally, testing enables individuals to identify potential issues early on, allowing for timely repairs or upgrades, thus minimizing the risk of system breakdowns and costly replacements.

In summary, “Testing: Verifying proper installation and functionality” is an integral component of “Two Wire Thermostat Wiring.” By adhering to proper testing practices, individuals can enhance the safety, efficiency, and longevity of their thermostat wiring systems. Understanding the connection between testing and two-wire thermostat wiring empowers homeowners and technicians alike to maintain a comfortable indoor environment while minimizing potential hazards and maximizing system performance.

Troubleshooting

Within the realm of “Two Wire Thermostat Wiring,” the significance of “Troubleshooting: Identifying and resolving common issues” cannot be overstated. Troubleshooting plays a pivotal role in maintaining a safe, efficient, and reliable wiring system. Without proper troubleshooting techniques, minor issues can escalate into costly repairs or even hazardous situations, compromising the comfort and safety of the indoor environment.

Troubleshooting is an indispensable component of “Two Wire Thermostat Wiring” due to the potential complexities and challenges that may arise during installation, operation, and maintenance. By identifying and resolving common issues proactively, individuals can minimize downtime, prevent system failures, and ensure the longevity of their thermostat wiring systems. Real-life examples abound where effective troubleshooting has prevented or resolved a wide range of issues in two-wire thermostat wiring systems. For instance, troubleshooting can identify loose connections that could lead to intermittent heating or cooling, or detect potential shorts that pose fire hazards. By addressing these issues promptly, homeowners and technicians can maintain a safe and reliable indoor environment while extending the lifespan of the thermostat wiring system.

The practical applications of understanding troubleshooting in two-wire thermostat wiring extend beyond resolving immediate problems. Regular troubleshooting empowers homeowners and technicians to monitor the health of their wiring systems, ensuring continued optimal performance. Additionally, troubleshooting enables individuals to identify potential issues early on, allowing for timely repairs or upgrades, thus minimizing the risk of system breakdowns and costly replacements. By understanding common issues and their resolutions, individuals gain the confidence to maintain their thermostat wiring systems effectively, contributing to a comfortable and energy-efficient indoor environment.

In summary, “Troubleshooting: Identifying and resolving common issues” is inextricably linked to “Two Wire Thermostat Wiring.” Proactive troubleshooting practices enhance the safety, efficiency, and longevity of thermostat wiring systems. By understanding the connection between troubleshooting and two-wire thermostat wiring, homeowners and technicians alike can maintain a comfortable indoor environment while minimizing potential hazards and maximizing system performance.

Safety

Within the realm of “Two Wire Thermostat Wiring,” the aspect of “Safety: Adhering to electrical codes and guidelines” holds paramount importance. By adhering to established electrical standards and regulations, individuals can ensure the safe, efficient, and reliable operation of their thermostat wiring systems. Neglecting safety guidelines can lead to a range of hazards, including electrical shocks, fires, and damage to equipment or property.

- Proper Grounding: Ensuring a proper electrical ground provides a safe path for excess current to flow, protecting against electrical shocks and fires.

- Circuit Protection: Utilizing appropriate circuit breakers or fuses prevents excessive current flow, safeguarding wires and components from overheating and potential damage.

- Polarity Compliance: Adhering to correct polarity ensures the proper flow of electricity through the circuit, preventing malfunctions and potential hazards.

- Wire Insulation and Protection: Ensuring wires are properly insulated and protected from physical damage minimizes the risk of electrical shorts and fires.

By understanding and implementing these safety guidelines, individuals can create and maintain a safe and reliable “Two Wire Thermostat Wiring” system. Adherence to electrical codes and regulations not only safeguards against potential hazards but also contributes to the longevity and efficiency of the wiring system, ensuring a comfortable and energy-efficient indoor environment.

Related Posts