Goodman Furnace Wiring entails the electrical connections necessary for the operation of a Goodman furnace, a heating system commonly found in residential and commercial buildings. It involves establishing safe and efficient connections between the furnace’s components, such as the blower motor, gas valve, and thermostat. Proper wiring ensures that these components receive the appropriate electrical power and signals needed to function correctly.

The accurate wiring of Goodman furnaces is crucial for ensuring the system’s optimal performance, reliability, and safety. It allows for the precise control of temperature, ignition, and airflow, optimizing energy efficiency and maintaining comfortable indoor air temperatures. Moreover, proper wiring helps prevent electrical hazards, such as short circuits and overheating.

Historically, advances in furnace wiring have been driven by technological developments in electrical components and safety standards. The advent of electronic ignition systems, for instance, led to more efficient and reliable gas valve control. Furthermore, ongoing research in electrical engineering and materials science continues to contribute to the improvement of wiring techniques and materials used in Goodman furnaces.

Understanding the essential aspects of Goodman Furnace Wiring is paramount for ensuring the safe, efficient, and reliable operation of these heating systems. Each aspect plays a distinct role in the overall functionality of the furnace.

- Electrical Safety: Proper wiring minimizes electrical hazards and ensures compliance with building codes.

- Power Supply: Establishing a stable and adequate power supply is crucial for the furnace’s operation.

- Circuit Protection: Circuit breakers and fuses protect the wiring and components from overcurrent conditions.

- Thermostat Compatibility: Matching the furnace wiring to the thermostat ensures accurate temperature control.

- Gas Valve Control: Precise wiring is essential for safe and efficient gas flow regulation.

- Blower Motor Operation: Proper wiring ensures the blower motor operates at the correct speed and airflow.

- Diagnostic Capabilities: Wiring facilitates diagnostic procedures by providing access points for troubleshooting.

- Maintenance and Repair: Well-organized wiring simplifies maintenance tasks and expedites repairs.

These aspects are intertwined, forming a comprehensive system that governs the furnace’s performance. Each aspect contributes to the safety, reliability, efficiency, and maintainability of the heating system.

Electrical Safety

Electrical safety is paramount in Goodman Furnace Wiring as improper wiring can lead to electrical hazards, including short circuits, overheating, and electrical fires. These hazards not only pose a direct threat to the occupants of the building but can also damage the furnace and other electrical appliances. Moreover, faulty wiring can result in inefficient operation, increased energy consumption, and premature component failure.

To ensure electrical safety, Goodman Furnace Wiring must adhere to strict building codes and electrical standards. These codes specify the proper gauge and type of wiring, as well as the appropriate methods for installing and connecting electrical components. By following these codes, electricians can minimize the risk of electrical hazards and ensure that the furnace operates safely and efficiently.

Real-life examples of electrical safety measures in Goodman Furnace Wiring include the use of circuit breakers and fuses to protect against overcurrent conditions, proper grounding to prevent electrical shocks, and the use of insulated wires to prevent short circuits. Adhering to these safety measures helps prevent electrical fires, ensures the longevity of the furnace, and protects the occupants of the building.

Understanding the connection between electrical safety and Goodman Furnace Wiring is crucial for ensuring the safe and efficient operation of the heating system. By following building codes and employing proper wiring techniques, electricians can minimize electrical hazards and create a safe and comfortable indoor environment.

Power Supply

A stable and adequate power supply is a critical component of Goodman Furnace Wiring. The furnace relies on a continuous supply of electricity to power its various components, including the blower motor, gas valve, and thermostat. Without a reliable power supply, the furnace cannot operate efficiently or safely.

Proper Goodman Furnace Wiring ensures that the furnace receives the correct voltage and amperage. The wiring must be properly sized and installed to handle the electrical load of the furnace. Inadequate wiring can lead to voltage drops, which can cause the furnace to malfunction or even pose a safety hazard. Additionally, loose or damaged wiring can create electrical arcs, which can ignite nearby materials and cause a fire.

Real-life examples of the importance of power supply in Goodman Furnace Wiring include:

- Voltage drops: If the wiring is too small or the electrical load is too high, voltage drops can occur. These drops can cause the furnace to operate erratically or even shut down completely.

- Overloads: If the wiring is overloaded, it can overheat and cause a fire. This can be dangerous and can also damage the furnace.

- Electrical arcs: Loose or damaged wiring can create electrical arcs, which can ignite nearby materials and cause a fire. This is a serious safety hazard.

Understanding the connection between power supply and Goodman Furnace Wiring is crucial for ensuring the safe and efficient operation of the heating system. By providing a stable and adequate power supply, electricians can prevent electrical hazards and ensure that the furnace operates at peak performance.

Circuit Protection

Circuit protection is a crucial aspect of Goodman Furnace Wiring, safeguarding the system and the building from electrical hazards. It involves the strategic placement of circuit breakers and fuses, which are designed to interrupt the flow of electricity when it exceeds a safe level, preventing damage to the wiring, components, and the furnace itself.

- Circuit Breakers: Circuit breakers are reusable devices that automatically trip when an overcurrent condition occurs. They are commonly used in Goodman Furnace Wiring to protect the furnace from electrical faults and overloads. When a circuit breaker trips, it can be manually reset, restoring power to the furnace once the fault has been resolved.

- Fuses: Fuses are single-use devices that sacrifice themselves to protect the circuit. They contain a thin wire that melts and breaks the circuit when an overcurrent condition occurs. Fuses are often used in Goodman Furnace Wiring to protect specific components, such as the blower motor or the gas valve.

- Overcurrent Protection: Circuit breakers and fuses work together to provide overcurrent protection for Goodman Furnace Wiring. They prevent excessive current flow, which can lead to overheating, electrical fires, and damage to the furnace and its components.

- Real-Life Example: A common example of circuit protection in Goodman Furnace Wiring is the use of a circuit breaker to protect the blower motor. If the blower motor draws too much current, the circuit breaker will trip, preventing damage to the motor and the furnace.

Understanding the importance of circuit protection in Goodman Furnace Wiring is essential for ensuring the safe and reliable operation of the heating system. By incorporating circuit breakers and fuses, electricians can minimize the risk of electrical hazards, protect the furnace from damage, and create a safe and comfortable indoor environment.

Thermostat Compatibility

In the realm of Goodman Furnace Wiring, thermostat compatibility plays a pivotal role in ensuring precise temperature regulation. Matching the furnace wiring to the thermostat establishes a seamless communication channel, allowing for accurate and efficient temperature control within the building.

- Compatibility with Furnace Control Board: The furnace control board acts as the brain of the furnace, coordinating the operation of various components. Thermostat compatibility ensures that the wiring aligns with the specific signals and protocols required by the control board for effective communication.

- Type of Thermostat: Goodman furnaces are compatible with various types of thermostats, including traditional manual thermostats, programmable thermostats, and smart thermostats. The wiring must be adapted to match the specific input/output requirements of the chosen thermostat.

- Number of Wires: The number of wires used in the thermostat wiring harness can vary depending on the thermostat type and the features it offers. Proper matching ensures that all necessary connections are established, enabling full functionality of the thermostat.

- Wiring Color Codes: Different types of wires are designated for specific purposes in Goodman Furnace Wiring. Adhering to the designated color codes ensures that the wires are connected to the correct terminals on both the furnace and the thermostat.

Understanding the importance of thermostat compatibility in Goodman Furnace Wiring allows for precise temperature control, maximizing comfort levels and energy efficiency. By matching the wiring to the specific requirements of the thermostat, homeowners can ensure optimal performance and create a comfortable and energy-conscious indoor environment.

Gas Valve Control

Within the intricate network of Goodman Furnace Wiring, gas valve control stands as a critical component, ensuring the safe and efficient flow of gas to the furnace’s burners. Precise wiring is paramount to achieving this delicate balance, directly impacting the furnace’s overall performance and safety.

The gas valve, acting as the gatekeeper of the fuel supply, relies on precise wiring to receive the correct electrical signals from the furnace control board. These signals dictate the opening and closing of the valve, regulating the amount of gas flowing into the burners. Improper wiring can lead to insufficient gas flow, resulting in poor combustion and reduced heating efficiency. Conversely, excessive gas flow due to faulty wiring can pose safety hazards, potentially leading to gas leaks and even explosions.

Real-life examples within Goodman Furnace Wiring showcase the practical significance of gas valve control. For instance, incorrect wiring can cause the gas valve to remain partially open, leading to a continuous flow of gas even when the furnace is not operating. This poses a significant safety risk, as the accumulated gas can ignite unexpectedly, causing a fire or explosion. Conversely, proper wiring ensures that the gas valve opens and closes precisely, preventing gas leaks and maintaining efficient combustion.

Understanding the connection between gas valve control and Goodman Furnace Wiring empowers homeowners and technicians alike to prioritize safety and optimize furnace performance. By employing accurate wiring techniques, they can ensure that the gas valve operates as intended, providing a reliable and energy-efficient source of heat while minimizing potential hazards.

Blower Motor Operation

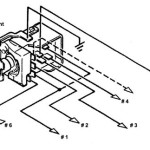

Within the intricate network of Goodman Furnace Wiring, the proper operation of the blower motor is a critical component, directly affecting the furnace’s ability to distribute heated air effectively throughout the building. Precise wiring is essential to ensure that the blower motor receives the correct electrical signals from the furnace control board, enabling it to operate at the correct speed and airflow.

Insufficient or excessive airflow due to improper wiring can lead to a range of issues. Inadequate airflow can result in poor heat distribution, leaving some areas of the building cold and uncomfortable. Conversely, excessive airflow can waste energy and increase noise levels. In extreme cases, improper wiring can even cause the blower motor to overheat or fail, leading to costly repairs or replacements.

Real-life examples within Goodman Furnace Wiring demonstrate the practical significance of blower motor operation. For instance, if the blower motor is wired incorrectly, it may not receive the necessary power to operate at the correct speed. This could lead to insufficient airflow, resulting in uneven heating and discomfort for the occupants of the building. On the other hand, proper wiring ensures that the blower motor runs at the optimal speed, effectively circulating warm air throughout the building and maintaining a comfortable indoor environment.

Understanding the connection between blower motor operation and Goodman Furnace Wiring empowers homeowners and technicians alike to prioritize efficient and reliable heating. By employing accurate wiring techniques, they can ensure that the blower motor operates as intended, providing optimal heat distribution, energy efficiency, and long-term performance of the furnace.

Diagnostic Capabilities

Within the intricate network of Goodman Furnace Wiring, diagnostic capabilities play a critical role in ensuring the efficient and reliable operation of the heating system. By providing designated access points for troubleshooting, the wiring facilitates the identification and resolution of issues, minimizing downtime and maximizing comfort for the building’s occupants.

The connection between diagnostic capabilities and Goodman Furnace Wiring is two-fold. Firstly, the wiring provides a direct pathway for diagnostic tools and equipment to connect to the furnace’s control board and other components. This allows technicians to access vital data, such as error codes and system parameters, which can help pinpoint the source of a problem.

Secondly, the strategic placement of test points and jumper connections within the wiring harness enables technicians to isolate specific components and circuits for further testing. This allows them to determine if a particular component or circuit is faulty, without the need for extensive disassembly or replacement of the entire furnace.

Real-life examples of diagnostic capabilities within Goodman Furnace Wiring abound. For instance, if the furnace is experiencing intermittent ignition failures, a technician can use a voltmeter to check the voltage at the ignition module. If the voltage is too low, it could indicate a faulty wiring connection or a problem with the power supply. Similarly, if the blower motor is not operating correctly, a technician can use an ammeter to measure the current draw. If the current draw is too high, it could indicate a wiring issue or a problem with the blower motor itself.

Understanding the connection between diagnostic capabilities and Goodman Furnace Wiring empowers homeowners and technicians alike to proactively maintain their heating systems. By utilizing the designated access points and following proper diagnostic procedures, they can quickly identify and resolve issues, ensuring optimal performance, energy efficiency, and long-term reliability of the furnace.

Maintenance and Repair

In the context of Goodman Furnace Wiring, the organization of wiring plays a pivotal role in ensuring efficient maintenance and timely repairs. Well-organized wiring facilitates easy access to components, reduces troubleshooting time, and minimizes the risk of further issues during servicing.

The connection between maintenance and repair and Goodman Furnace Wiring is two-fold. Firstly, organized wiring allows technicians to quickly locate and identify specific components, reducing the time spent on troubleshooting and disassembly. Color-coded wires, labeled terminals, and accessible wire bundles simplify the process of tracing circuits and diagnosing problems.

Secondly, well-organized wiring minimizes the risk of accidental damage during maintenance or repair. By keeping wires neatly routed and secured, technicians can avoid inadvertently pulling or cutting wires, which could lead to additional issues. This organized approach ensures that the furnace remains in optimal condition, extending its lifespan and reducing the likelihood of costly repairs.

Real-life examples of the benefits of organized wiring in Goodman Furnace Wiring are numerous. For instance, if a blower motor needs to be replaced, well-organized wiring allows the technician to quickly locate the motor’s electrical connections and remove it without disturbing other components. Similarly, if a faulty thermostat needs to be replaced, organized wiring enables the technician to easily identify and disconnect the thermostat wires, minimizing the risk of short circuits or other problems.

Understanding the connection between maintenance and repair and Goodman Furnace Wiring empowers homeowners and technicians alike to maintain and service their heating systems with greater efficiency and accuracy. By adhering to best practices for wire organization, they can minimize downtime, reduce repair costs, and extend the lifespan of the furnace.

Related Posts