An 8 Pin CDI Box Wiring Diagram is a schematic representation of the electrical connections between an 8-pin Capacitive Discharge Ignition (CDI) box and its associated components. It provides a visual guide for installing and troubleshooting the ignition system.

The CDI box is a crucial component of an engine’s ignition system, responsible for generating the high-voltage spark that ignites the air-fuel mixture in the combustion chamber. The 8 Pin CDI Box Wiring Diagram ensures the proper connection of the CDI box to the ignition coil, flywheel, and other components, enabling the ignition system to function effectively.

Understanding and utilizing the 8 Pin CDI Box Wiring Diagram is essential for maintaining optimal engine performance and ensuring reliable ignition. Historically, the introduction of CDI technology marked a significant advancement in ignition systems, providing improved spark energy and combustion efficiency, leading to enhanced engine performance.

Understanding the essential aspects of an 8 Pin CDI Box Wiring Diagram is crucial for ensuring the optimal performance and reliability of an engine’s ignition system. These aspects encompass various dimensions related to the wiring diagram, including its components, functionality, installation, troubleshooting, and historical significance.

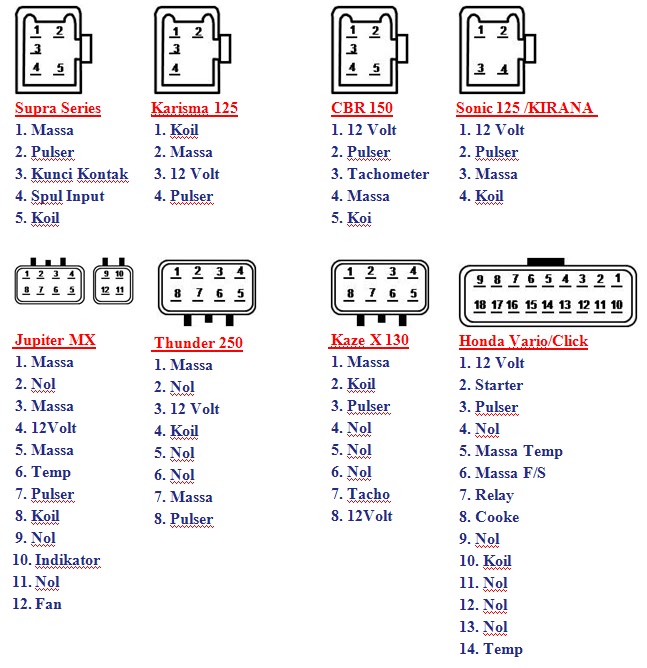

- Components: The 8 Pin CDI Box Wiring Diagram outlines the electrical connections between the CDI box, ignition coil, flywheel, and other associated components.

- Functionality: The wiring diagram provides a visual guide for understanding how the CDI box generates the high-voltage spark that ignites the air-fuel mixture in the combustion chamber.

- Installation: The diagram serves as a reference during the installation process, ensuring the proper connection of all components for optimal ignition system performance.

- Troubleshooting: The wiring diagram aids in identifying and resolving any issues or malfunctions within the ignition system.

- Historical Significance: The development of the 8 Pin CDI Box Wiring Diagram marked an advancement in ignition systems, leading to improved spark energy, combustion efficiency, and engine performance.

- Accuracy: Precise and accurate wiring diagrams are essential for ensuring the correct operation of the ignition system.

- Compatibility: The wiring diagram must be compatible with the specific CDI box and engine model being used.

- Safety: Proper wiring, as per the diagram, is crucial for maintaining electrical safety and preventing potential hazards.

These aspects, when considered collectively, provide a comprehensive understanding of the 8 Pin CDI Box Wiring Diagram, enabling technicians, enthusiasts, and researchers to effectively work with and troubleshoot ignition systems. They highlight the importance of accuracy, compatibility, and safety in the design, installation, and maintenance of these systems.

Components

The 8 Pin CDI Box Wiring Diagram plays a critical role in ensuring the proper operation of the ignition system. It provides a detailed visual representation of the electrical connections between the CDI box, ignition coil, flywheel, and other associated components, such as sensors and switches. This allows technicians to accurately install, troubleshoot, and maintain the ignition system.

Understanding the relationship between the components of the 8 Pin CDI Box Wiring Diagram is essential for diagnosing and resolving ignition system issues. For example, if the engine is not starting or is experiencing misfires, the wiring diagram can be used to check for loose connections, damaged wires, or faulty components. By following the diagram, technicians can quickly identify the source of the problem and implement the necessary repairs.

In summary, the 8 Pin CDI Box Wiring Diagram serves as a valuable tool for understanding, maintaining, and troubleshooting ignition systems. Its accurate and comprehensive representation of the electrical connections between the CDI box and its associated components enables technicians to efficiently diagnose and resolve issues, ensuring optimal engine performance and reliability.

Functionality

The 8 Pin CDI Box Wiring Diagram serves as a critical component in understanding the functionality of the ignition system. It provides a detailed visual representation of the electrical connections between the CDI box and its associated components, including the ignition coil, flywheel, and sensors. This allows technicians and enthusiasts to comprehend how the CDI box generates the high-voltage spark that ignites the air-fuel mixture in the combustion chamber.

The wiring diagram plays a crucial role in troubleshooting and diagnosing ignition system issues. By tracing the electrical connections and understanding the functionality of each component, technicians can quickly identify and resolve problems such as misfires, starting difficulties, and performance issues. For example, if the engine is experiencing misfires, the wiring diagram can be used to check for loose connections, damaged wires, or faulty sensors that may be disrupting the proper generation and delivery of the spark.

Practical applications of understanding the functionality of the 8 Pin CDI Box Wiring Diagram extend beyond troubleshooting. It enables technicians to optimize ignition timing and adjust the ignition system to suit specific engine modifications or performance requirements. By understanding the relationship between the CDI box, ignition coil, and flywheel, tuners can fine-tune the ignition system to improve engine performance, fuel efficiency, and emissions.

In summary, the 8 Pin CDI Box Wiring Diagram provides a valuable tool for understanding, maintaining, and troubleshooting ignition systems. Its detailed representation of the electrical connections and functionality allows technicians to diagnose and resolve issues quickly, optimize ignition timing, and tailor the ignition system to meet specific performance goals.

Installation

The installation process of an 8 Pin CDI Box Wiring Diagram involves carefully connecting the CDI box to the ignition coil, flywheel, and other associated components, as outlined in the diagram. Following the diagram’s instructions ensures that all components are properly connected, providing a solid electrical connection and optimal ignition system performance.

Understanding the relationship between the diagram and installation is critical for several reasons. First, incorrect wiring can lead to ignition system malfunctions, such as misfires, starting difficulties, or reduced engine performance. The diagram serves as a guide to prevent these issues by providing a clear and accurate representation of the electrical connections.

Furthermore, the diagram is useful for troubleshooting ignition system problems. By comparing the actual wiring configuration to the diagram, technicians can quickly identify any deviations or faults that may be causing issues. This can significantly reduce troubleshooting time and effort.

In practical applications, the 8 Pin CDI Box Wiring Diagram plays a vital role in ensuring the proper installation and maintenance of ignition systems in various applications, including motorcycles, ATVs, and other small engines. It enables technicians to install, inspect, and repair ignition systems accurately, ensuring optimal engine performance and reliability.

In summary, the 8 Pin CDI Box Wiring Diagram is a critical component for properly installing and maintaining ignition systems. Its detailed representation of the electrical connections guides technicians through the installation process, aids in troubleshooting, and contributes to the overall performance and reliability of the ignition system.

Troubleshooting

Within the context of the 8 Pin CDI Box Wiring Diagram, troubleshooting plays a pivotal role in maintaining optimal ignition system performance and resolving any issues that may arise. The wiring diagram serves as a valuable tool for technicians, allowing them to identify and rectify malfunctions within the ignition system, ensuring reliable engine operation.

- Identifying Faulty Components: The wiring diagram provides a comprehensive overview of the electrical connections within the ignition system, enabling technicians to pinpoint faulty components by tracing the circuit and identifying any breaks, shorts, or loose connections.

- Real-Life Example: In a motorcycle ignition system, a misfire issue can be traced back to a faulty ignition coil. By referring to the wiring diagram, a technician can determine the specific connections and components associated with the ignition coil and conduct further tests to confirm the diagnosis.

- Understanding Circuit Behavior: The wiring diagram offers insights into the electrical behavior of the ignition system, allowing technicians to understand how each component interacts with the others. This knowledge aids in troubleshooting complex issues, such as timing problems or intermittent faults.

- Implications for Performance: Resolving ignition system issues using the wiring diagram contributes to overall engine performance and reliability. By addressing malfunctions promptly, technicians can prevent further damage to components and ensure optimal combustion, leading to improved fuel efficiency and reduced emissions.

In summary, the troubleshooting aspect of the 8 Pin CDI Box Wiring Diagram empowers technicians and enthusiasts with the knowledge and tools to identify and resolve ignition system issues effectively. It serves as a valuable resource for maintaining optimal engine performance, ensuring reliability, and understanding the intricacies of the ignition system.

Historical Significance

The evolution of the 8 Pin CDI Box Wiring Diagram holds significant historical significance within the realm of ignition systems. It marked a turning point in ignition technology, paving the way for improved spark energy, enhanced combustion efficiency, and increased engine performance.

- Standardization and Reliability: The introduction of the standardized 8 Pin CDI Box Wiring Diagram brought order to the previously fragmented ignition system designs. It established a common framework for connecting and configuring CDI boxes, ignition coils, flywheels, and other components, ensuring compatibility and reliable operation across various engines and applications.

- Optimized Ignition Timing: The 8 Pin CDI Box Wiring Diagram enabled precise control over ignition timing, allowing engineers to fine-tune the spark delivery to align with the specific combustion characteristics of different engines. This optimization resulted in improved engine efficiency, reduced emissions, and enhanced overall performance.

- Compact Design and Ease of Installation: The 8 Pin CDI Box Wiring Diagram simplified the design and installation of ignition systems. By standardizing the electrical connections, it allowed for compact and efficient packaging of components, making it easier to integrate ignition systems into various engine configurations.

- Foundation for Advanced Ignition Systems: The 8 Pin CDI Box Wiring Diagram laid the groundwork for the development of more advanced ignition systems. Its standardized approach provided a stable platform for incorporating additional features and technologies, such as electronic ignition timing control, knock sensors, and engine management systems, further enhancing engine performance and efficiency.

In summary, the historical significance of the 8 Pin CDI Box Wiring Diagram lies in its role as a catalyst for standardization, optimization, and innovation in ignition systems. It facilitated the development of more efficient, reliable, and powerful engines, leaving a lasting impact on the automotive and powersports industries.

Accuracy

The accuracy of an 8 Pin CDI Box Wiring Diagram is of paramount importance for the proper functioning of the ignition system. A precise and accurate diagram ensures that all electrical connections between the CDI box, ignition coil, flywheel, and other components are established correctly. Any deviation from the correct wiring can lead to malfunctions, misfires, reduced engine performance, or even damage to the ignition system.

For instance, consider a situation where the wiring diagram is inaccurate, resulting in a reversed connection between the ignition coil and the CDI box. This error could lead to the ignition coil receiving an incorrect firing signal, causing misfires or preventing the engine from starting altogether. By contrast, an accurate wiring diagram provides clear instructions for connecting the ignition coil in the correct polarity, ensuring proper spark generation and optimal engine performance.

The practical applications of accurate wiring diagrams extend beyond troubleshooting and repair. In the design and development of new ignition systems, precise wiring diagrams are essential for ensuring reliability and efficiency. Engineers rely on accurate diagrams to optimize the layout of components, minimize electrical interference, and ensure proper signal transmission. This attention to detail contributes to the overall performance and longevity of the ignition system.

In summary, the accuracy of an 8 Pin CDI Box Wiring Diagram plays a critical role in ensuring the correct operation of the ignition system. Precise and accurate diagrams are essential for proper installation, troubleshooting, and design. By adhering to the specified wiring connections, technicians and engineers can ensure optimal ignition system performance, prevent malfunctions, and extend the lifespan of the system.

Compatibility

Within the context of 8 Pin CDI Box Wiring Diagrams, compatibility plays a crucial role in ensuring the proper functioning and performance of the ignition system. The wiring diagram must be compatible with the specific CDI box and engine model being used to establish the correct electrical connections and ensure optimal ignition timing.

- CDI Box Type: CDI boxes come in various types, such as AC-CDI and DC-CDI. The wiring diagram must match the type of CDI box used to ensure proper signal transmission and ignition timing.

- Engine Configuration: Different engine configurations, such as single-cylinder or multi-cylinder engines, require specific wiring configurations. The wiring diagram must be compatible with the engine configuration to ensure the correct firing order and spark delivery.

- Flywheel Specifications: The flywheel is a critical component in the ignition system, and its specifications, such as the number of magnets and the trigger pattern, must match the wiring diagram. An incompatible flywheel can disrupt the ignition timing and cause malfunctions.

- Electrical System Voltage: The wiring diagram must be compatible with the electrical system voltage of the vehicle or equipment. Using a wiring diagram designed for a different voltage can lead to electrical damage or incorrect ignition timing.

Ensuring compatibility between the wiring diagram, CDI box, engine model, and other components is essential for reliable ignition system operation. By adhering to the specified wiring diagram, technicians and enthusiasts can avoid potential issues, such as misfires, reduced engine performance, or damage to ignition system components. Compatibility plays a pivotal role in the overall performance, efficiency, and longevity of the ignition system in various applications.

Safety

In the context of 8 Pin CDI Box Wiring Diagrams, safety plays a paramount role. Proper wiring, in accordance with the diagram’s specifications, is essential for ensuring the electrical safety of the ignition system and preventing potential hazards that could arise from improper installation or handling.

- Electrical Short Circuit Prevention: Accurate wiring as per the diagram helps prevent electrical short circuits by ensuring that wires are properly connected and insulated, minimizing the risk of accidental contact between wires of different polarities. This reduces the chances of electrical fires or damage to the ignition system’s components.

- Grounding for Safety: The wiring diagram specifies the proper grounding points for the CDI box and other ignition system components. Proper grounding provides a safe path for electrical current to flow, preventing voltage spikes and protecting against electrical shock hazards.

- Protection from Overheating: Proper wiring ensures that the ignition system components, such as the CDI box and ignition coil, receive the correct amount of current. This prevents overheating, which can damage the components and potentially cause fires.

- Compliance with Electrical Codes: Following the wiring diagram for proper installation helps ensure compliance with electrical codes and standards. This is especially important in applications where safety regulations are strictly enforced, such as in the automotive or marine industries.

By adhering to the safety guidelines outlined in the 8 Pin CDI Box Wiring Diagram, technicians, enthusiasts, and professionals can minimize electrical hazards, protect the ignition system from damage, and ensure the safe and reliable operation of engines and equipment. Proper wiring not only optimizes ignition system performance but also contributes to the overall safety and longevity of the electrical system.

Related Posts