240V Power Plug Wiring refers to the electrical wiring configuration used to connect appliances and devices to a 240-volt power supply. It typically involves connecting three wires: a live wire, a neutral wire, and a ground wire, which provide power, complete the circuit, and ensure safety, respectively.

The use of 240V power is common in many countries around the world, particularly for high-power appliances such as electric stoves, ovens, water heaters, and air conditioners. It allows for efficient power transmission and reduced energy loss over shorter distances, making it suitable for homes and industrial settings.

One significant historical development in 240V power plug wiring was the standardization of plug and socket designs. This standardization ensures compatibility and safety across different devices and electrical systems, reducing the risk of accidents and ensuring reliable power distribution. As we explore further in this article, we will delve into the technical details, safety considerations, and various applications of 240V power plug wiring.

Understanding the essential aspects of 240V power plug wiring is crucial for ensuring safety, efficiency, and compatibility in electrical systems. These aspects encompass various dimensions, from technical specifications to practical applications. Let’s explore nine key elements:

- Voltage: 240 volts, providing higher power transmission.

- Current: Typically used with high-power appliances, requiring higher current capacity.

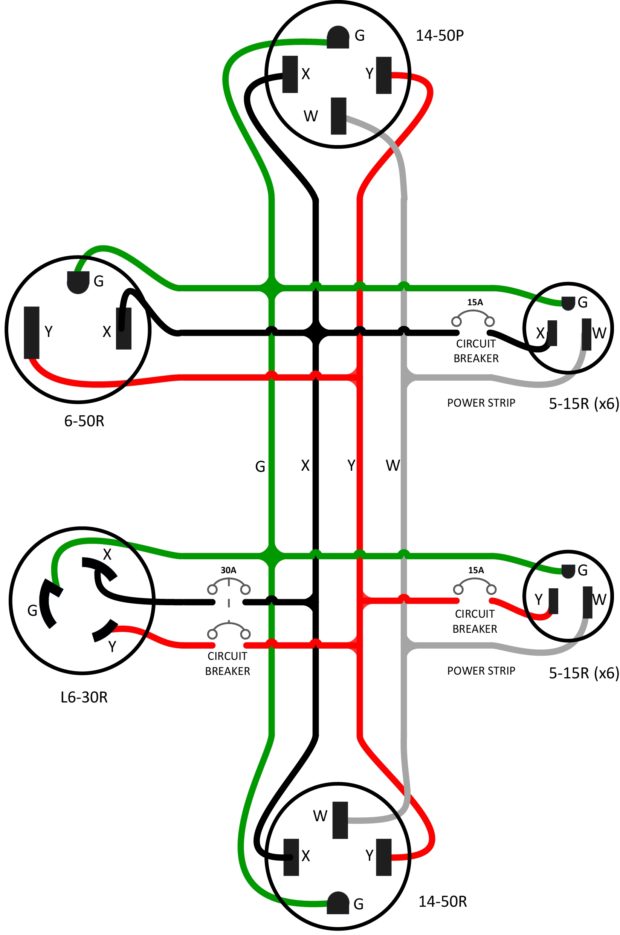

- Wiring Configuration: Involves three wires – live, neutral, and ground – for power, circuit completion, and safety.

- Plug and Socket Design: Standardized designs ensure compatibility and safety across devices.

- Safety Features: Grounding and insulation measures protect against electrical hazards.

- Efficiency: Reduces energy loss over shorter distances, making it suitable for homes and industries.

- Applications: Commonly used for high-power appliances like stoves, ovens, and air conditioners.

- Codes and Standards: Adherence to electrical codes ensures safe installation and operation.

- Historical Development: Standardization of plug and socket designs has enhanced safety and compatibility.

These aspects are interconnected, forming a comprehensive framework for 240V power plug wiring. Understanding these elements is essential for electricians, engineers, and anyone working with electrical systems. Proper installation and maintenance of 240V wiring ensure safety, prevent electrical hazards, and support efficient power distribution.

Voltage

The voltage of an electrical system directly influences its power transmission capabilities. In the context of 240V power plug wiring, the 240-volt supply provides significantly higher power transmission compared to lower voltage systems. This higher voltage allows for the efficient operation of high-power appliances and devices, such as electric stoves, ovens, water heaters, and air conditioners.

The relationship between voltage and power transmission can be understood using Ohm’s law: Power (P) is directly proportional to the square of the Voltage (V) and inversely proportional to the Resistance (R) in a circuit. Therefore, increasing the voltage while maintaining a constant resistance leads to a quadratic increase in power transmission.

In practical terms, 240V power plug wiring is commonly employed in homes and industrial settings where high-power appliances are prevalent. The higher voltage allows these appliances to draw more current, enabling them to perform their tasks more effectively. For example, a 240V electric stove can deliver more heat and cook food faster compared to a 120V stove, provided that the wiring and circuit can handle the increased power draw.

Understanding the connection between voltage and power transmission is crucial for electrical engineers and technicians. It helps them design and implement electrical systems that can safely and efficiently meet the power demands of various appliances and devices. Additionally, it enables informed decision-making when selecting the appropriate voltage for a specific application, ensuring optimal performance and energy efficiency.

Current

In the context of 240V power plug wiring, the relationship between current and high-power appliances is crucial. Current, measured in amperes (A), represents the flow of electrical charge through a conductor. High-power appliances, by their very nature, demand a higher flow of current to operate effectively.

The connection between current and 240V power plug wiring stems from the power equation: Power (P) is equal to Voltage (V) multiplied by Current (I). In a 240V system, a higher current capacity is necessary to deliver the required power to high-power appliances. Without sufficient current capacity, the appliances may not function correctly or may even pose safety hazards.

Real-life examples of high-power appliances that utilize 240V power plug wiring include electric stoves, ovens, water heaters, and air conditioners. These appliances typically draw significant amounts of current, ranging from 15 to 30 amps or even higher. To accommodate this demand, 240V power plug wiring employs thicker gauge wires that can handle the increased current flow without overheating or posing fire hazards.

Understanding the connection between current and 240V power plug wiring is essential for several reasons. Firstly, it ensures that electrical systems are designed and installed with the appropriate wiring capacity to meet the demands of high-power appliances. Secondly, it helps prevent electrical overloads and potential safety hazards, such as fires or electrocution.

Furthermore, this understanding allows for efficient energy usage. By matching the current capacity of the wiring to the power requirements of the appliances, energy loss is minimized, leading to lower electricity bills and a reduced environmental impact.

Wiring Configuration

The three-wire configuration live, neutral, and ground plays a critical role in 240V power plug wiring, ensuring the safe and efficient operation of high-power appliances. Each wire serves a distinct function:

– Live wire: Carries the electrical current from the power source to the appliance. It is typically colored red or black. – Neutral wire: Completes the circuit, providing a path for the current to return to the power source. It is typically colored white or gray. – Ground wire: Provides a safety path for any stray electrical current, preventing electrical shocks or fires. It is typically colored green or bare copper.

This three-wire configuration is essential for 240V power plug wiring because it ensures proper power flow, circuit completion, and safety. Without the live wire, the appliance would not receive power. Without the neutral wire, the circuit would not be complete, and the appliance would not function. Without the ground wire, there would be a risk of electrical shocks or fires in the event of a fault.

Real-life examples of 240V power plug wiring with three-wire configuration include electric stoves, ovens, water heaters, and air conditioners. These appliances require high power and thus utilize 240V supply. The three-wire configuration ensures that these appliances operate safely and efficiently.

Understanding the importance of three-wire configuration in 240V power plug wiring is crucial for electricians, engineers, and homeowners alike. It enables safe installation, maintenance, and troubleshooting of electrical systems. By adhering to the three-wire configuration, we can minimize electrical hazards, ensure reliable appliance operation, and create a safe electrical environment.

Plug and Socket Design

Within the context of 240V power plug wiring, standardized plug and socket designs play a crucial role in ensuring compatibility and safety across various devices. These standardized designs establish uniform specifications for the physical dimensions, electrical configurations, and safety features of plugs and sockets used in 240V power systems.

Standardization is critical because it eliminates the risk of mismatches and ensures that any 240V appliance can be safely and reliably connected to any compatible power outlet. Without standardized designs, there would be a multitude of incompatible plug and socket types, leading to confusion, potential safety hazards, and difficulties in device interoperability.

Real-life examples of standardized plug and socket designs for 240V power systems include the NEMA 6-15 and NEMA 6-20 configurations commonly found in North America, as well as the IEC 60309 standard used in many countries worldwide. These standardized designs ensure that plugs and sockets fit together securely, providing a reliable electrical connection while preventing accidental disconnections or improper insertions.

Furthermore, standardized plug and socket designs incorporate essential safety features, such as grounding mechanisms, which provide a low-resistance path for fault currents to flow, minimizing the risk of electrical shocks. Standardized designs also often include features like polarized plugs and recessed contacts to prevent incorrect connections and enhance safety.

Understanding the importance of standardized plug and socket designs in 240V power plug wiring is crucial for several reasons. Firstly, it enables the safe and efficient operation of electrical devices by ensuring proper connections and preventing mismatches. Secondly, standardization simplifies the installation and maintenance of electrical systems, allowing for easy replacement and interchangeability of devices.

In summary, standardized plug and socket designs are an integral part of 240V power plug wiring, ensuring compatibility, safety, and ease of use. They provide a foundation for reliable electrical connections, reduce the risk of accidents, and facilitate the seamless integration of various devices into 240V power systems.

Safety Features

Within the context of 240V power plug wiring, safety features play a crucial role in preventing electrical hazards and ensuring the safe operation of electrical appliances. Among these safety features, grounding and insulation measures stand out as essential components in protecting users from electrical shocks and fires.

- Grounding: Grounding provides a low-resistance path for fault currents to flow, preventing them from passing through the user’s body. This is achieved by connecting the appliance’s metal frame or chassis to the grounding terminal in the power outlet, which is connected to the earth ground.

- Insulation: Insulation materials, such as rubber or plastic, are used to cover electrical wires and components, preventing direct contact with live parts. This prevents current leakage and reduces the risk of electrical shocks.

- Polarized Plugs: Polarized plugs have one blade wider than the other, ensuring that the plug can only be inserted into the socket in one orientation. This prevents incorrect connections and reduces the risk of shocks or short circuits.

- Double Insulation: Double insulation involves using two layers of insulation instead of one. This provides an extra layer of protection against electrical shocks, even if one layer is damaged.

In conclusion, grounding and insulation measures are vital safety features in 240V power plug wiring, working together to protect users from electrical hazards. By providing a safe path for fault currents and preventing direct contact with live parts, these measures enhance the safety and reliability of electrical systems.

Efficiency

In the context of 240V power plug wiring, the efficiency of reduced energy loss over shorter distances plays a significant role in its suitability for homes and industries. This efficiency stems from the reduced resistance encountered by electrical current flowing through shorter conductors, resulting in less energy dissipation as heat.

The relationship between efficiency and 240V power plug wiring is critical because it enables the effective and economical transmission of electrical power within buildings and industrial facilities. By minimizing energy loss over shorter distances, 240V power plug wiring ensures that a higher proportion of the generated power reaches the intended appliances and devices.

Real-life examples of this efficiency can be observed in various applications within homes and industries. For instance, in residential settings, 240V power plug wiring is commonly used for high-power appliances such as electric stoves, ovens, and air conditioners. These appliances typically require significant amounts of power, and the reduced energy loss associated with 240V wiring ensures that they operate efficiently, minimizing energy waste and reducing electricity bills.

In industrial settings, 240V power plug wiring finds applications in powering machinery, lighting systems, and other equipment. The reduced energy loss over shorter distances contributes to overall energy savings, leading to increased operational efficiency and reduced production costs.

Understanding the efficiency benefits of 240V power plug wiring is crucial for several reasons. Firstly, it enables informed decision-making when selecting the appropriate voltage for electrical systems, ensuring optimal energy usage and cost savings. Secondly, it helps design and implement electrical systems that minimize energy loss and promote sustainability.

In summary, the efficiency of 240V power plug wiring in reducing energy loss over shorter distances is a critical factor contributing to its suitability for homes and industries. By minimizing energy dissipation, this efficiency enhances the performance of high-power appliances, contributes to energy conservation, and supports sustainable electrical practices.

Applications

The use of 240V power plug wiring is closely tied to its applications, particularly in powering high-power appliances like stoves, ovens, and air conditioners. This connection arises from the need to safely and efficiently supply the substantial amount of power required by these appliances.

High-power appliances demand a higher voltage and current capacity to operate effectively. 240V power plug wiring provides this increased voltage, allowing these appliances to draw the necessary power without overloading the circuit or causing voltage drops. This ensures that the appliances can deliver their intended performance, such as generating sufficient heat for cooking or cooling a large space.

Real-life examples of 240V power plug wiring in action can be found in residential and commercial kitchens, where electric stoves and ovens are commonly used. These appliances utilize 240V power to provide rapid heating and precise temperature control, essential for efficient cooking. Additionally, in many regions, central air conditioning systems rely on 240V power to operate their compressors and fans, effectively cooling large areas.

Understanding the connection between 240V power plug wiring and its applications in powering high-power appliances is crucial for several reasons. Firstly, it enables informed decision-making when designing and installing electrical systems, ensuring that the appropriate voltage and wiring capacity are provided to meet the demands of these appliances. Secondly, it helps prevent electrical hazards by avoiding overloading circuits or using inadequate wiring, which could lead to fires or electrical shocks.

In summary, the connection between 240V power plug wiring and its applications in powering high-power appliances like stoves, ovens, and air conditioners is driven by the need to safely and efficiently supply the substantial power required by these appliances. Understanding this connection is essential for ensuring proper electrical system design, preventing hazards, and maximizing the performance of these appliances.

Codes and Standards

Within the realm of 240V power plug wiring, adherence to electrical codes and standards is a critical component, ensuring the safe installation and operation of electrical systems. These codes and standards establish comprehensive guidelines and requirements for the design, installation, and maintenance of electrical systems, including 240V power plug wiring.

The connection between codes and standards and 240V power plug wiring is driven by the inherent risks associated with high-voltage electrical systems. Improper installation or maintenance of 240V wiring can lead to electrical hazards, such as fires, shocks, and electrocution. Codes and standards provide a framework to mitigate these risks by specifying safe practices and materials for electrical installations.

Real-life examples of codes and standards being applied to 240V power plug wiring include the National Electrical Code (NEC) in the United States and the Canadian Electrical Code (CEC) in Canada. These codes specify requirements for wire size, insulation, grounding, and overcurrent protection, ensuring that 240V wiring is installed and maintained to minimize electrical hazards.

Understanding the practical applications of codes and standards in 240V power plug wiring is essential for several reasons. Firstly, it ensures that electrical systems are designed and installed in a manner that meets safety regulations, reducing the risk of accidents and harm to individuals. Secondly, adherence to codes and standards helps prevent property damage and financial losses that can result from electrical fires or accidents.

In summary, codes and standards play a crucial role in ensuring the safe installation and operation of 240V power plug wiring. By providing a framework for safe electrical practices, these codes and standards help prevent electrical hazards, protect individuals and property, and contribute to the overall safety and reliability of electrical systems.

Historical Development

In the realm of “240v Power Plug Wiring,” the historical development of standardized plug and socket designs has played a pivotal role in enhancing safety and compatibility. This standardization has brought forth a cohesive framework for electrical connections, ensuring seamless interoperability and minimizing the risks associated with high-voltage electrical systems.

- Universal Compatibility: Standardized plug and socket designs have eliminated the confusion and hazards of multiple incompatible formats. By establishing uniform dimensions and configurations, these standards have enabled the interchangeability of plugs and sockets, regardless of the manufacturer or region.

- Improved Safety: Standardization has incorporated essential safety features into plug and socket designs. Grounding mechanisms provide a safe path for fault currents, preventing electrical shocks. Polarized plugs and recessed contacts ensure proper insertion and reduce the risk of accidental contact with live parts.

- Reduced Electrical Hazards: Standardized designs have minimized the likelihood of loose connections, arcing, and overheating. Precision-engineered plugs and sockets fit securely, ensuring good electrical contact and preventing power loss or potential fire hazards.

- Simplified Installation and Maintenance: Standardized plug and socket designs have simplified the installation and maintenance of electrical systems. Electricians can easily identify and connect compatible components, reducing the risk of errors and ensuring reliable operation.

In conclusion, the standardization of plug and socket designs for “240v Power Plug Wiring” has revolutionized electrical safety and compatibility. This historical development has established a universal language for electrical connections, enabling the safe and efficient use of high-power appliances, promoting interoperability, and minimizing the risks associated with electrical hazards.

Related Posts