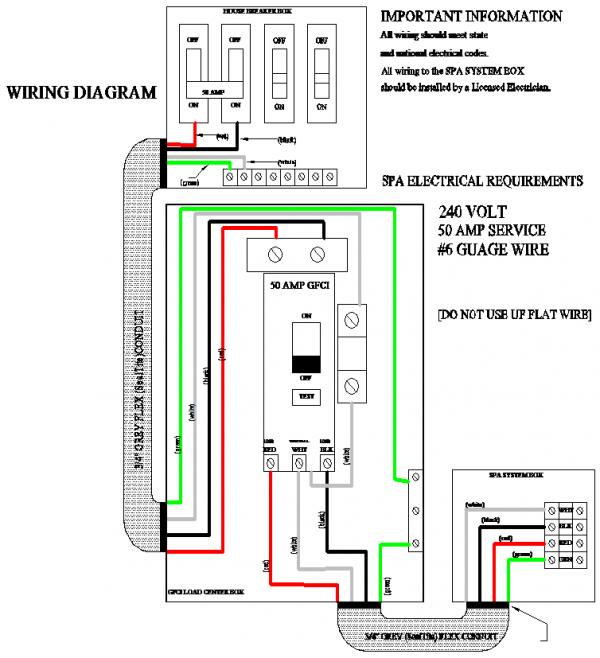

A “240v 3 Wire Hot Tub Wiring Diagram” illustrates the electrical connections necessary to safely power a hot tub using a 240-volt, three-wire electrical system. For instance, it specifies the wiring of the hot tub’s heater, pump, and other components to a circuit breaker panel and ground rod.

This diagram is crucial for ensuring the hot tub’s safe and efficient operation. It prevents electrical hazards, facilitates troubleshooting, and ensures compliance with electrical codes. Historically, the advent of three-wire systems marked a significant advancement in electrical safety, providing a separate ground wire to minimize the risk of electrical shock.

The following sections will delve into the components, considerations, and safety protocols associated with 240v 3 Wire Hot Tub Wiring Diagrams, serving as a comprehensive resource for homeowners, electricians, and those seeking to understand the electrical systems of hot tubs.

Understanding the key aspects of a “240v 3 Wire Hot Tub Wiring Diagram” is essential for ensuring the safe and efficient installation and operation of a hot tub. These aspects encompass various dimensions related to the diagram, encompassing its components, considerations, and safety protocols.

- Components: Heater, pump, circuit breaker, ground rod

- Considerations: Wire gauge, conduit size, electrical code compliance

- Safety protocols: Grounding, bonding, GFCI protection

- Electrical principles: Voltage, amperage, resistance

- Troubleshooting: Identifying and resolving electrical issues

- Maintenance: Regular inspections, cleaning, and repairs

- Codes and standards: NEC, local building codes

- Tools and materials: Wire strippers, electrical tape, conduit

These aspects are interconnected and play vital roles in the overall functionality and safety of the hot tub wiring system. For instance, proper component selection ensures efficient operation, while adherence to safety protocols minimizes electrical hazards. Understanding these aspects empowers homeowners, electricians, and professionals to make informed decisions regarding hot tub wiring, ensuring a safe and enjoyable hot tub experience.

Components

In the context of a “240v 3 Wire Hot Tub Wiring Diagram,” the componentsheater, pump, circuit breaker, and ground rodplay pivotal roles in ensuring the safe and efficient operation of the hot tub.

- Heater: The heater is responsible for raising and maintaining the water temperature to the desired level. It is typically an electric resistance heater that converts electrical energy into heat.

- Pump: The pump circulates the water throughout the hot tub, ensuring even distribution of heat and chemicals. It is usually a centrifugal pump that uses impellers to move the water.

- Circuit breaker: The circuit breaker is a safety device that protects the electrical system from overcurrent. It trips and breaks the circuit if the current exceeds a predetermined threshold, preventing damage to the equipment and potential electrical fires.

- Ground rod: The ground rod is a metal rod driven into the earth, providing a low-resistance path for electrical current to flow in the event of a fault. It helps ensure the safety of users by preventing electrical shocks.

These components are interconnected and work together to provide a safe and enjoyable hot tub experience. Proper selection, installation, and maintenance of these components are crucial for the overall functionality and safety of the hot tub wiring system.

Considerations

In the context of a “240v 3 Wire Hot Tub Wiring Diagram,” considerations such as wire gauge, conduit size, and electrical code compliance play a crucial role in ensuring the safety and efficiency of the electrical system. These factors directly impact the diagram’s design and implementation.

Wire gauge, which refers to the thickness of the electrical wire, is a critical determinant of current-carrying capacity. Proper wire gauge selection is essential to prevent overheating, voltage drop, and potential fire hazards. Conduit size, on the other hand, affects the protection of the electrical wires from physical damage and environmental factors. It also influences the overall aesthetics of the installation.

Electrical code compliance is paramount for ensuring adherence to safety standards and regulations. Wiring diagrams must comply with the National Electrical Code (NEC) or local building codes to maintain safety and minimize the risk of electrical accidents. By adhering to these codes, electricians can ensure proper grounding, bonding, and circuit protection, reducing the likelihood of electrical shock or fire.

Practical applications of this understanding include the following:

- Selecting the appropriate wire gauge based on the current draw of the hot tub components, such as the heater and pump, to prevent overheating and voltage drop.

- Choosing the right conduit size to accommodate the number and size of wires, ensuring adequate protection and ease of maintenance.

- Following electrical codes to ensure proper grounding, bonding, and circuit protection, minimizing the risk of electrical hazards.

In summary, “Considerations: Wire gauge, conduit size, electrical code compliance” are critical components of a “240v 3 Wire Hot Tub Wiring Diagram” as they directly impact the safety, efficiency, and reliability of the electrical system. Adhering to these considerations is essential for the proper design, installation, and maintenance of hot tub wiring systems.

Safety protocols

In the context of a “240v 3 Wire Hot Tub Wiring Diagram,” safety protocols such as grounding, bonding, and GFCI protection are paramount to ensuring the safe operation of the electrical system. These protocols work together to minimize the risk of electrical shock, fire, and other hazards.

Grounding provides a low-resistance path for electrical current to flow in the event of a fault. This helps prevent voltage buildup on the metal components of the hot tub, which could otherwise pose a shock hazard. Bonding connects all metal components of the hot tub together, ensuring that they are at the same electrical potential. This further reduces the risk of shock and helps to ensure the proper functioning of the electrical system.

GFCI (Ground Fault Circuit Interrupter) protection is a type of circuit breaker that trips when it detects a difference in current between the hot and neutral wires. This can indicate a fault, such as a short circuit or a ground fault, and the GFCI will quickly shut off power to prevent shock or fire. GFCI protection is required by code in many areas for hot tub installations.

Real-life examples of “Safety protocols: Grounding, bonding, GFCI protection” within “240v 3 Wire Hot Tub Wiring Diagram” include:

- The green wire in the electrical cable is used for grounding.

- Metal components of the hot tub, such as the frame and heater, are bonded together using bonding straps.

- A GFCI outlet is used to power the hot tub.

The practical applications of this understanding include:

- Preventing electrical shock and electrocution.

- Reducing the risk of electrical fires.

- Ensuring the safe and reliable operation of the hot tub electrical system.

In conclusion, “Safety protocols: Grounding, bonding, GFCI protection” are critical components of a “240v 3 Wire Hot Tub Wiring Diagram.” These protocols work together to minimize the risk of electrical hazards and ensure the safe and enjoyable use of hot tubs.

Electrical principles

Understanding electrical principles, particularly voltage, amperage, and resistance, is crucial in the context of “240v 3 Wire Hot Tub Wiring Diagram.” These principles govern the flow of electricity within the system, ensuring safe and efficient operation.

- Voltage: Voltage is the electrical potential difference between two points in a circuit. In a 240v 3 Wire Hot Tub Wiring Diagram, the voltage is 240 volts, which is the potential difference between the hot wires and the neutral wire.

- Amperage: Amperage is the rate of flow of electrical current. In a 240v 3 Wire Hot Tub Wiring Diagram, the amperage is determined by the load connected to the circuit. The heater and pump are the primary load in a hot tub, and the amperage must be sufficient to meet their power requirements.

- Resistance: Resistance is the opposition to the flow of electrical current. In a 240v 3 Wire Hot Tub Wiring Diagram, resistance exists in the wires, components, and the water itself. Proper wire gauge selection and minimizing resistance in connections are important for efficient operation.

- Power: Power is the rate at which electrical energy is transferred or consumed. In a 240v 3 Wire Hot Tub Wiring Diagram, power is measured in watts and is determined by the voltage and amperage. The higher the voltage or amperage, the greater the power.

These electrical principles are interconnected and must be carefully considered in the design and implementation of a 240v 3 Wire Hot Tub Wiring Diagram. Proper understanding and adherence to these principles ensure the safe and efficient operation of the hot tub electrical system.

Troubleshooting

In the context of a “240v 3 Wire Hot Tub Wiring Diagram,” troubleshooting plays a pivotal role in maintaining the safety and functionality of the electrical system. Troubleshooting involves identifying and resolving electrical issues to ensure the proper operation of the hot tub. A “240v 3 Wire Hot Tub Wiring Diagram” provides a roadmap for troubleshooting, as it outlines the electrical connections and components of the system.

Electrical issues in a hot tub wiring system can manifest in various ways, such as tripped circuit breakers, flickering lights, or malfunctioning components. Troubleshooting involves a systematic approach to identify the root cause of the issue. This may include checking for loose connections, faulty wires, or damaged components. The wiring diagram serves as a valuable guide during troubleshooting, as it provides a visual representation of the electrical system, making it easier to trace connections and identify potential problem areas.

For instance, if a circuit breaker trips repeatedly, the wiring diagram can help identify the circuit that is causing the issue. This allows the electrician or homeowner to focus their troubleshooting efforts on that specific circuit, saving time and effort. Additionally, the diagram can provide insights into the electrical load on each circuit, helping to identify potential overloading issues that could lead to electrical hazards.

In summary, “Troubleshooting: Identifying and resolving electrical issues” is a critical component of “240v 3 Wire Hot Tub Wiring Diagram.” The wiring diagram provides a visual representation of the electrical system, making it easier to identify and resolve electrical issues, ensuring the safe and efficient operation of the hot tub.

Maintenance

In the context of a “240v 3 Wire Hot Tub Wiring Diagram,” maintenance practices such as regular inspections, cleaning, and repairs are essential to ensure the safety, longevity, and optimal performance of the electrical system. This comprehensive approach involves proactive measures to prevent issues, identify potential hazards, and address any necessary repairs promptly.

- Electrical Component Inspections: Regularly inspecting electrical components such as wires, connections, circuit breakers, and the GFCI outlet is crucial to identify any signs of damage, corrosion, or loose connections. Prompt attention to these issues can prevent electrical hazards and ensure the safe operation of the hot tub.

- Circuit Testing: Periodically testing circuits using a voltage tester helps verify proper voltage levels and circuit functionality. This proactive measure can identify potential issues, such as overloaded circuits or faulty wiring, before they lead to more severe problems.

- Cleaning and Debris Removal: Accumulation of dirt, dust, and debris on electrical components can impair their performance and pose safety risks. Regular cleaning, including vacuuming and wiping down components, helps maintain optimal conditions for electrical connections and prevents potential hazards.

- Timely Repairs: Addressing electrical issues promptly is essential to prevent further damage and ensure the safe operation of the hot tub. Whether it’s a loose connection, a faulty component, or a more complex electrical problem, timely repairs by a qualified electrician are crucial to maintain the integrity of the electrical system.

By adhering to a regular maintenance schedule that includes inspections, cleaning, and repairs, homeowners can proactively safeguard their hot tub’s electrical system, ensuring a safe and enjoyable hot tub experience. Regular maintenance not only extends the lifespan of the electrical components but also minimizes the likelihood of electrical hazards, providing peace of mind and protecting the investment in the hot tub.

Codes and standards

Within the context of “240v 3 Wire Hot Tub Wiring Diagram,” adherence to codes and standards, including the National Electrical Code (NEC) and local building codes, is paramount for ensuring the safety and compliance of the electrical installation. These codes and standards provide a comprehensive framework for the design, installation, and maintenance of electrical systems, including those related to hot tubs.

- Wire gauge and circuit ampacity: NEC and local building codes specify the minimum wire gauge and circuit ampacity requirements based on the load and type of equipment being used. This ensures that the wires can safely carry the electrical current without overheating or causing a fire.

- Grounding and bonding: Proper grounding and bonding are essential for protecting against electrical shock and ensuring the safe operation of the hot tub. NEC and local building codes provide detailed requirements for grounding and bonding, including the use of grounding rods, bonding straps, and equipment grounding conductors.

- GFCI protection: GFCI (Ground Fault Circuit Interrupter) protection is required by NEC and local building codes for hot tub circuits. GFCIs are designed to quickly trip and interrupt the circuit in the event of a ground fault, preventing electrical shock.

- Circuit breakers and fuses: Circuit breakers and fuses are essential for protecting the electrical system from overcurrent conditions. NEC and local building codes specify the type and rating of circuit breakers and fuses to be used based on the load and circuit characteristics.

Compliance with codes and standards is not only a legal requirement but also a crucial aspect of ensuring the safety and reliability of the hot tub electrical system. By adhering to these guidelines, homeowners, electricians, and inspectors can work together to create and maintain a safe and enjoyable hot tub experience.

Tools and materials

Within the context of “240v 3 Wire Hot Tub Wiring Diagram,” the selection and proper use of tools and materials are crucial for ensuring the safety, efficiency, and longevity of the electrical system. Among the essential tools and materials required for hot tub wiring are wire strippers, electrical tape, and conduit, each playing a specific role in the installation and maintenance process.

- Wire strippers: Wire strippers are essential for removing the insulation from electrical wires to create proper connections. Using the appropriate gauge of wire strippers helps ensure clean, precise cuts without damaging the conductors.

- Electrical tape: Electrical tape is used to insulate and protect electrical connections. It creates a waterproof seal that prevents short circuits and electrical shock. Choosing high-quality electrical tape rated for outdoor use is important for durability and longevity.

- Conduit: Conduit is a protective casing that houses and protects electrical wires from physical damage, moisture, and environmental hazards. Selecting the right type and size of conduit is crucial for proper wire management and maintaining electrical safety.

- Other tools: Additional tools commonly used in hot tub wiring include screwdrivers, pliers, voltage testers, and a multimeter. These tools are necessary for making electrical connections, testing circuits, and troubleshooting any issues.

Properly utilizing these tools and materials is essential for ensuring the integrity of the electrical system. By following manufacturer’s instructions, adhering to electrical codes, and seeking professional assistance when needed, homeowners and electricians can work together to create a safe and reliable hot tub wiring system.

Related Posts