2 Wire Thermostat Wiring is a straightforward method of connecting a thermostat to an HVAC unit using only two wires. This wiring configuration is commonly found in older residential and commercial buildings. An example is the connection between a simple single-stage heat-only thermostat and a gas furnace, with one wire for power and the other for signaling heating.

2 Wire Thermostat Wiring is important for its simplicity and cost-effectiveness, making it suitable for budget-conscious installations. Its historical significance lies in its widespread use before the advent of more advanced thermostats requiring additional wires for features like fan control and multi-stage heating/cooling.

This article will delve further into the technical aspects of 2 Wire Thermostat Wiring, including its limitations and compatibility with different HVAC systems. We will also explore the evolution of thermostat wiring and the advantages of modern wiring methods for enhancing energy efficiency and home comfort.

2 Wire Thermostat Wiring, as a noun, encompasses several essential aspects that define its purpose, function, and impact on HVAC systems. Understanding these aspects is crucial for effectively managing temperature control and energy efficiency in residential and commercial buildings.

- Simplicity: Only two wires are used for connection.

- Cost-effectiveness: Minimal wiring materials and labor costs.

- Compatibility: Works with single-stage heating or cooling systems.

- Limited functionality: Basic temperature control without fan or multi-stage options.

- Wiring method: Typically uses color-coded wires for power and signaling.

- Voltage: Typically operates on 24 volts AC.

- Polarity: Wires must be connected with correct polarity for proper operation.

- Troubleshooting: Simple to diagnose and repair due to the basic wiring configuration.

- Energy efficiency: Can contribute to energy savings when used with programmable thermostats.

- Historical significance: Widely used before the advent of more advanced thermostats.

These aspects collectively define the nature and application of 2 Wire Thermostat Wiring. Its simplicity and cost-effectiveness make it a viable option for basic temperature control, while its limitations highlight the need for more advanced wiring methods for increased functionality and energy efficiency. Understanding these aspects empowers HVAC professionals and homeowners to make informed decisions regarding thermostat selection and installation.

Simplicity

2 Wire Thermostat Wiring is distinguished by its straightforward wiring configuration, utilizing only two wires for connection. This simplicity stems from its fundamental design, which is tailored to control basic single-stage heating or cooling systems. The use of just two wires for both power and signaling eliminates the need for complex wiring diagrams and reduces the potential for installation errors.

The simplicity of 2 Wire Thermostat Wiring makes it an ideal solution for budget-conscious installations and straightforward temperature control applications. Its cost-effectiveness is particularly advantageous in scenarios where minimizing material and labor costs is a priority. Additionally, the reduced number of wires simplifies troubleshooting and repair procedures, ensuring efficient maintenance and system uptime.

In practical applications, 2 Wire Thermostat Wiring is commonly employed in residential and commercial buildings with basic HVAC systems. For instance, in a single-family home with a gas furnace, a 2-wire thermostat can provide sufficient control over the heating system. Similarly, in small retail stores or offices, 2 Wire Thermostat Wiring can effectively manage single-stage air conditioning units.

Understanding the connection between simplicity and 2 Wire Thermostat Wiring empowers HVAC professionals and homeowners to make informed decisions regarding thermostat selection and installation. Its straightforward wiring configuration and cost-effectiveness make it a viable option for basic temperature control, while its limitations highlight the need for more advanced wiring methods for increased functionality and energy efficiency. This understanding enables optimized HVAC system design and efficient temperature management, contributing to enhanced comfort and reduced energy consumption.

Cost-effectiveness

The cost-effectiveness of 2 Wire Thermostat Wiring is directly attributed to its minimal wiring materials and labor costs. The use of only two wires for connection significantly reduces the amount of materials required, lowering the overall installation cost. Moreover, the straightforward wiring configuration minimizes the time and effort needed for installation, resulting in lower labor expenses.

In practical terms, the cost-effectiveness of 2 Wire Thermostat Wiring makes it an attractive option for budget-conscious installations. For instance, in a residential setting, replacing an old thermostat with a new 2-wire model can be done quickly and affordably. Similarly, in commercial buildings, 2 Wire Thermostat Wiring can be employed to control multiple single-stage HVAC units without incurring excessive costs.

Understanding the connection between cost-effectiveness and 2 Wire Thermostat Wiring empowers decision-makers to optimize HVAC system design and installation. By leveraging the cost-saving benefits of 2 Wire Thermostat Wiring, building owners and contractors can allocate resources more efficiently, ensuring cost-effective temperature management without compromising comfort or energy efficiency.

Compatibility

Within the context of “2 Wire Thermostat Wiring,” compatibility refers to its ability to seamlessly integrate with single-stage heating or cooling systems. This compatibility stems from the inherent design of 2 Wire Thermostat Wiring, which is tailored to control systems with a single stage of operation.

-

Stage of Operation

Single-stage systems operate at a single level of intensity, either heating or cooling at full capacity. This simplicity aligns perfectly with the limited functionality of 2 Wire Thermostat Wiring, which provides basic on/off control. -

Common Applications

2 Wire Thermostat Wiring is commonly found in residential and commercial buildings with single-stage HVAC systems, such as gas furnaces and window air conditioners. Its compatibility makes it an ideal choice for controlling these systems effectively. -

Wiring Configuration

The wiring configuration of 2 Wire Thermostat Wiring matches the requirements of single-stage systems. The two wires carry both power and control signals, enabling the thermostat to communicate with the HVAC unit and regulate its operation. -

Cost Implications

The compatibility of 2 Wire Thermostat Wiring with single-stage systems has cost implications. Since single-stage systems are generally less expensive than multi-stage systems, the use of 2 Wire Thermostat Wiring can result in overall cost savings for installation and maintenance.

In conclusion, the compatibility of “2 Wire Thermostat Wiring” with single-stage heating or cooling systems is a key aspect that defines its application and cost-effectiveness. Understanding this compatibility empowers HVAC professionals and homeowners to make informed decisions regarding thermostat selection and installation, ensuring efficient temperature management and optimized energy consumption.

Limited functionality

Within the context of “2 Wire Thermostat Wiring,” “Limited functionality: Basic temperature control without fan or multi-stage options.” succinctly encapsulates the inherent constraints of this wiring method. Its simplicity, while cost-effective and straightforward, comes with certain limitations that impact the range of features and capabilities available to users.

-

Fan control

2 Wire Thermostat Wiring does not provide dedicated control over the fan, limiting the ability to independently adjust airflow for circulation or ventilation. -

Multi-stage heating/cooling

The wiring configuration supports only single-stage systems, meaning the HVAC unit operates at full capacity without the ability to adjust intensity levels for more precise temperature control and energy efficiency. -

Programmable settings

Basic thermostats compatible with 2 Wire Thermostat Wiring typically lack advanced programmable features, limiting the ability to set automated temperature schedules for optimal comfort and energy savings. -

Remote access

Thermostats connected via 2 Wire Thermostat Wiring generally do not support remote access or integration with smart home systems, restricting convenient temperature management from anywhere.

These limitations should be carefully considered when selecting a thermostat for a specific application. While 2 Wire Thermostat Wiring remains a suitable option for basic temperature control in budget-conscious scenarios or with single-stage HVAC systems, users who desire greater functionality, energy efficiency, and advanced features may need to explore alternative wiring methods and compatible thermostats.

Wiring method

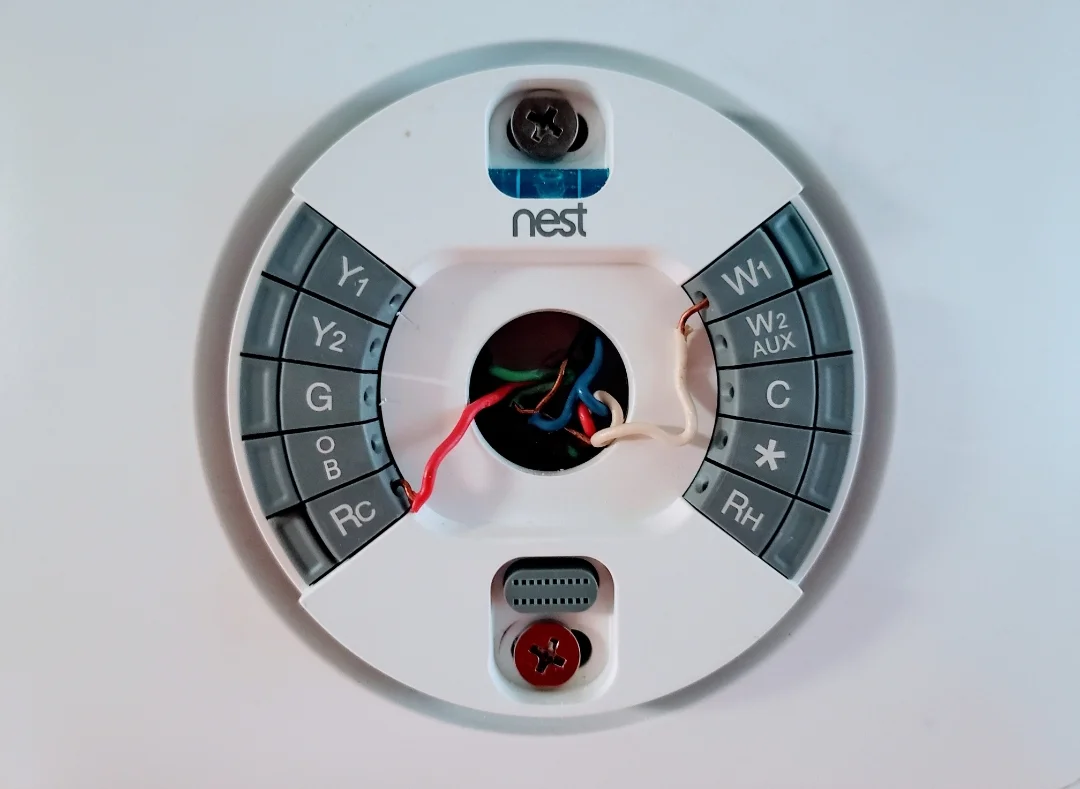

In the context of “2 Wire Thermostat Wiring,” the “Wiring method: Typically uses color-coded wires for power and signaling” is a crucial aspect that defines the installation and functionality of the system. The use of color-coded wires simplifies the wiring process and ensures correct connections between the thermostat and the HVAC unit.

In practice, the color-coding of wires adheres to industry standards, making it easier for technicians to identify the purpose of each wire. For instance, in a typical 2-wire thermostat wiring configuration, the red wire is designated for power, while the white wire carries the control signal. This color-coding ensures that the thermostat can receive power and communicate with the HVAC unit to regulate temperature.

The use of color-coded wires in “2 Wire Thermostat Wiring” offers several benefits. First, it streamlines the installation process, reducing the risk of errors and ensuring proper connections. Second, it facilitates troubleshooting and maintenance by allowing technicians to quickly identify and address any issues with the wiring.

Understanding the connection between “Wiring method: Typically uses color-coded wires for power and signaling” and “2 Wire Thermostat Wiring” is essential for effective installation, maintenance, and troubleshooting of HVAC systems. By adhering to color-coding standards and following best practices, technicians can ensure the reliable and efficient operation of 2-wire thermostats and the HVAC systems they control.

Voltage

The voltage requirement of “2 Wire Thermostat Wiring” is a crucial aspect that defines its functionality and safety considerations. The use of 24 volts AC as the operating voltage for thermostats connected via 2-wire wiring is a well-established industry standard, ensuring compatibility with a wide range of HVAC systems and ensuring the safety of installers and users.

The low voltage of 24 volts AC used in “2 Wire Thermostat Wiring” offers several key advantages. First, it enhances safety by reducing the risk of electrical shocks or fires. Second, it simplifies the installation process, as 24-volt wiring does not require special licensing or training to handle, making it accessible to a broader range of technicians.

In practice, “2 Wire Thermostat Wiring” is commonly used in residential and commercial buildings with single-stage HVAC systems. The 24-volt AC power is typically supplied by a transformer located within the HVAC unit itself, ensuring compatibility with the thermostat’s voltage requirements. Once connected, the thermostat can effectively communicate with the HVAC system to regulate temperature, utilizing the two wires for both power and signaling.

Understanding the connection between “Voltage: Typically operates on 24 volts AC.” and “2 Wire Thermostat Wiring” is essential for the safe and efficient installation and maintenance of HVAC systems. By adhering to industry standards and using appropriate wiring materials, technicians can ensure the reliable operation of thermostats and the HVAC systems they control.

Polarity

In the context of “2 Wire Thermostat Wiring,” polarity plays a crucial role in ensuring the proper operation of the system. Polarity refers to the correct alignment of the positive and negative terminals of the thermostat and the HVAC unit. Reversing the polarity can lead to incorrect operation, damage to components, or even electrical hazards.

-

Power Supply

The power supply to the thermostat must be connected with the correct polarity. If the positive and negative terminals are reversed, the thermostat will not receive the necessary power to operate.

-

Control Signal

The wires carrying the control signal between the thermostat and the HVAC unit must also be connected with the correct polarity. Reversing the polarity can cause the HVAC unit to operate incorrectly or not at all.

-

Color Coding

Most 2-wire thermostat wiring systems use color-coded wires to indicate polarity. Typically, the red wire is positive, and the white wire is negative. Connecting the wires according to the color code ensures correct polarity.

-

Consequences of Incorrect Polarity

Connecting the wires with incorrect polarity can lead to various problems, including: improper temperature control, damage to the thermostat or HVAC unit, electrical shorts, and even fire.

Understanding the importance of polarity and connecting the wires with the correct polarity is essential for the safe and reliable operation of a 2-wire thermostat system. By adhering to the correct polarity, technicians can ensure that the thermostat and HVAC unit communicate effectively, providing accurate temperature control and maintaining a comfortable indoor environment.

Troubleshooting

The simplicity of “2 Wire Thermostat Wiring” is not only reflected in its installation but also extends to its troubleshooting and repair process. The straightforward wiring configuration makes it easier to identify and address any issues that may arise, minimizing downtime and ensuring efficient temperature control.

One of the key advantages of the basic wiring configuration is that it reduces the number of potential failure points. With only two wires connecting the thermostat to the HVAC unit, there are fewer components that can malfunction or cause interruptions in operation. This makes it easier to isolate the source of a problem, whether it’s a loose connection, a faulty wire, or a malfunctioning thermostat.

For example, if the thermostat is not responding or displaying an error message, a simple visual inspection of the wires and connections can often reveal the cause. Loose connections can be tightened, and damaged wires can be replaced relatively easily. In many cases, these minor repairs can be completed by homeowners or building maintenance staff, eliminating the need for costly service calls.

The ease of troubleshooting and repair associated with “2 Wire Thermostat Wiring” is a valuable advantage for both residential and commercial applications. It ensures that temperature control systems can be restored to functionality quickly and efficiently, minimizing discomfort and disruption to occupants and maximizing energy efficiency.

Energy efficiency

Within the context of “2 Wire Thermostat Wiring,” energy efficiency emerges as a significant aspect, particularly when paired with programmable thermostats. This combination enables optimized temperature control, leading to reduced energy consumption and cost savings. To delve deeper into this topic, we explore four key facets that contribute to the energy-saving potential of “2 Wire Thermostat Wiring” with programmable thermostats.

-

Automated temperature adjustments

Programmable thermostats allow for automated temperature adjustments based on user-defined schedules. By setting different temperatures for different times of the day, such as lower temperatures during sleep or when away from home, energy is conserved without compromising comfort.

-

Reduced heating/cooling cycles

By maintaining a consistent temperature, programmable thermostats reduce the frequency of heating or cooling cycles. This reduces wear and tear on the HVAC system, prolonging its lifespan and improving overall efficiency.

-

Improved temperature management

Programmable thermostats provide precise temperature control, eliminating temperature fluctuations that can lead to energy waste. This consistent temperature management ensures optimal comfort while minimizing unnecessary energy consumption.

-

Energy-saving modes

Some programmable thermostats offer energy-saving modes, such as vacation mode, which automatically adjusts temperatures when the home is unoccupied for an extended period. This feature further reduces energy usage and lowers utility bills.

In conclusion, “2 Wire Thermostat Wiring” paired with programmable thermostats offers significant energy-saving benefits through automated temperature adjustments, reduced heating/cooling cycles, improved temperature management, and energy-saving modes. By leveraging these capabilities, homeowners and businesses can optimize their HVAC systems for greater efficiency and reduced energy consumption, contributing to a more sustainable and cost-effective indoor environment.

Historical significance

Within the realm of “2 Wire Thermostat Wiring,” its historical significance lies in its widespread use before the introduction of more advanced thermostats. This section delves into specific facets and implications of this historical significance, providing a comprehensive understanding of its role in shaping the evolution of temperature control systems.

-

Prevalence in Older Buildings

2 Wire Thermostat Wiring was the predominant method of connecting thermostats to HVAC systems in older residential and commercial buildings. Its simplicity and cost-effectiveness made it a practical choice for widespread adoption.

-

Compatibility with Basic Systems

The wiring configuration of 2 Wire Thermostat Wiring aligns well with the requirements of single-stage heating or cooling systems, which were commonly used in the past. It provides basic on/off control, making it suitable for these systems.

-

Limited Functionality

As technology advanced, the limitations of 2 Wire Thermostat Wiring became more apparent. It lacks support for features such as fan control, multi-stage heating/cooling, and remote access, which became increasingly desirable in modern HVAC systems.

-

Transition to Advanced Wiring

With the advent of more sophisticated thermostats and HVAC systems, the use of 2 Wire Thermostat Wiring gradually declined. Advanced wiring methods, such as 5-wire and 7-wire systems, emerged to meet the demands of modern temperature control, offering greater functionality and energy efficiency.

Understanding the historical significance of “2 Wire Thermostat Wiring” provides insights into the evolution of temperature control systems. It highlights the role of this wiring method as a foundation for basic temperature control and its eventual limitations as technology progressed. By examining these facets, we gain a deeper appreciation for the advancements in HVAC systems and the increasing focus on energy efficiency and user convenience.

Related Posts